Академический Документы

Профессиональный Документы

Культура Документы

Tps Sensor

Загружено:

mutasim0 оценок0% нашли этот документ полезным (0 голосов)

64 просмотров15 страницEngine

Оригинальное название

Tps Sensor(2)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документEngine

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

64 просмотров15 страницTps Sensor

Загружено:

mutasimEngine

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 15

Yes.

How do you know if a throttle position

sensor (TPS) is bad? Of course, some

symptoms can tell you when a TPS may

be bad. But these symptoms may come

from other bad sensors, parts or

components. So you need to conduct

some tests.

The TPS connects to the throttle plate on

the throttle body. The position sensor has

a variable resistance potentiometer (or

contact points, depending on model) that

sends a varying voltage signal to the

Power Control Module (PCM, your car's

engine computer) according to the

position of the throttle plate.

This plate rotates when you depress the

gas pedal to allow more air to enter the

intake manifold. With the engine running,

the position of the throttle plate (along

with other sensors) tells the computer

how much fuel the engine needs at any

given moment.

So, without the correct signal coming from

the TPS, you begin to notice drivability

problems. Fortunately, it's not that hard to

test the sensor. You can use the position

sensor operating characteristics to test it

using a digital multimeter (DMM).

If you haven't used a multimeter before,

just take a look at the next video. In a

couple of minutes you'll be ready to test

the throttle position sensor in your car.

And if you're looking for an inexpensive

but good DMM for your toolbox—you need

to use one for many DIY car projects—you

can find one at your local auto parts store

or online.

The most typical failure you'll find on a

TPS is wear, a short or an open on the

circuit of the contacts or variable resistor.

This guide will help you test the throttle

position sensor in a few minutes and

know whether you need to replace it.

Bad TPS Symptoms

Lean and Rich fuel condition problems

Bad computer signals to other actuators

Ignition timing problems

Triggering of trouble codes (depending on

car model)

Rough idle

Hesitation

Stumble

Surging

Stalling

Crank-No start condition

I. How to Test a Throttle Position Sensor

The most common TPS test is to measure

for resistance (ohms) or voltage at the

various positions, including throttle plate

closed, half open and fully open. We'll use

voltage to test the TPS here.

1. Open the hood and remove the air

cleaner assembly where it connects with

the throttle body.

2. Inspect the throttle plate and the walls

of the throttle body surrounding the

throttle plate.

* If you see carbon buildup around the

walls and under the throttle plate, spray

some carburetor cleaner on a clean shop

rag and wipe the buildup with it until the

surface is completely clean. Carbon

buildup can prevent the throttle plate from

closing properly and moving freely.

3. Locate the TPS mounted on the side of

the throttle body. The TPS is a small

plastic block with a three wire connector.

A. Is Your TPS Connected to Ground?

1. Carefully unplug the electrical

connector from the TPS.

2. Examine the electrical connector wires

and terminals for dirt, contamination and

damage.

3. Now, set your DMM to a suitable

setting, like 20 Volts, on the DC voltage

scale.

4. Turn the ignition key to the ON position,

but don't start the engine.

5. Connect the red test lead from your

DMM to the battery positive post, the one

marked with a "+" sign.

6. And touch the black test lead from your

DMM to each of the three electrical

terminals of the TPS electrical connector.

* The one terminal that reads 12 Volts on

your DMM is the ground terminal. Make a

note of the color of this wire.

* If none of the terminals reads 12 Volts,

there's a problem in that part of the wiring

leading to the TPS you need to fix because

the TPS has no ground.

7. Turn the ignition key OFF.

B. Is Your TPS Connected to Reference

Voltage?

1. Now connect the black test lead from

your DMM to the ground terminal on the

TPS connector you just identified.

2. Turn the ignition key to the ON position,

but don't start the engine.

3. Connect the red test lead to each of the

other two terminals.

4. One of the terminals should read 5

volts, or pretty close to it. That terminal is

providing the reference voltage to the TPS

to produce the voltage signal. Make a note

of the color of the wire connected to this

terminal. The third wire corresponds to the

signal voltage or signal wire.

* If you don't get 5 volts from any of the

two terminals, there's a problem in the

circuit you need to fix because there's no

reference voltage going to the TPS. Check

the circuit for bad terminals, loose, dirty or

damage wires.

5. Turn the ignition key OFF.

6. Plug back in the electrical connector to

the TPS.

C. Is Your TPS Producing the Correct

Signal Voltage?

1. Now backprobe the signal and ground

terminals on the TPS electrical connector.

If necessary, use a couple of pins to

backprobe the wires.

2. Connect the positive (red) test lead from

your DMM to the signal wire and the black

negative (black) test lead from your DMM

to the ground wire.

3. Turn the ignition key ON but don't start

the engine.

4. Make sure the throttle plate is fully

closed.

5. Your DMM should read around 0.2 up to

1.5 Volts or close to it, depending on your

particular model. If the readout on your

meters shows only a zero, make sure

you're at a low setting—usually at the 10

or 20 Volts setting. If your meter still reads

zero, continue with this test anyway.

6. While watching the readout on your

DMM, gradually open the throttle plate

until is fully opened (or have an assistant

gradually depress the gas pedal to the

floor).

* Your DMM should read 5 volts or close

to it when the throttle plate is fully opened.

* Also, make sure that the voltage

increases smoothly as you gradually open

the throttle plate.

* If you notice the voltage skipping or

stuck at a certain voltage value, as you

gradually open the throttle plate, your TPS

is not working properly and you need to

replace it.

* Also, if your TPS doesn't reach 5 volts, or

close to it (up to 3.5V on some models),

when the throttle plate is fully opened,

replace the TPS.

7. Repeat step 21, only this time use the

handle of a screwdriver to lightly tap on

the position sensor as you open and close

the throttle plate. If the voltage skips as

you tap the sensor, replace it.

8. Turn OFF the ignition key and remove

the pins.

If your have an adjustable throttle position

sensor (old vehicle model), and your

readings are out of specification, try to

adjust the sensor first before replacing it.

Your sensor is adjustable if you can

loosen the sensor mounting bolts and

rotate the sensor left or right. If necessary,

head over to the next

II. Throttle Position Sensor Adjustment

This is an example of an adjustment on an

externally mounted TPS. Other models

with different configurations require a

variation of the following steps. But this

will give you a general idea of the

adjustment procedure.

1. Loosen the sensor mounting bolts just

enough so that you can rotate it by lightly

tapping on it with a screwdriver handle.

2. Backprobe the position sensor to

monitor the voltage signal with your DMM.

3. Turn the ignition key to the ON position

but don't start the engine.

4. Keep the throttle plate at the close

position (or at the position specified in

your repair or service manual).

5. Verify that the voltage corresponds to

the specified in your manual. If not, rotate

the sensor left or right until you obtain the

specified voltage.

6. Then, hold the TPS in that position and

tighten up the mounting screws.

If the TPS is unable to reach the specified

voltage, replace it.

NOTE: On some models, you need a feeler

gauge to adjust the position sensor. Also,

you may need to adjust a stop screw in

the throttle body and, still in some other

models, adjust a dash pot that prevents

the throttle plates from suddenly closing.

For this, read the instructions in the repair

manual for your specific vehicle make and

model.

tps wire

tps idle and wot reading

reference to / axeladdict.com

by

Eng:mutasim altayeb ahmed

Вам также может понравиться

- Disassembly and Reassembly of A Bosch Warm-Up Regulator by Steven HauerДокумент12 страницDisassembly and Reassembly of A Bosch Warm-Up Regulator by Steven HauerFred Valintine100% (1)

- Prison Camp LatheДокумент6 страницPrison Camp LathejaesonkayОценок пока нет

- A Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialОт EverandA Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialОценок пока нет

- 107 Catalog PDFДокумент20 страниц107 Catalog PDFtri praptomoaji100% (1)

- HairspringДокумент31 страницаHairspringGabriel IacovitaОценок пока нет

- The Bell Curve Review: IQ Best Indicates PovertyДокумент22 страницыThe Bell Curve Review: IQ Best Indicates PovertyDelta ExraeОценок пока нет

- Chemistry International: The News Magazine of the International Union of Pure and Applied Chemistry (IUPAC)От EverandChemistry International: The News Magazine of the International Union of Pure and Applied Chemistry (IUPAC)Roger FennellОценок пока нет

- A Hot Air Driven Thermoacoustic-Stirling EngineДокумент5 страницA Hot Air Driven Thermoacoustic-Stirling EngineThiago Leite Dos Santos100% (1)

- BF3 Proportional Counter General InfoДокумент5 страницBF3 Proportional Counter General InfoAsih RahmatОценок пока нет

- 196 Bessemer Conversion EngineДокумент8 страниц196 Bessemer Conversion EngineAlfredoОценок пока нет

- How To Make Sodium PerchlorateДокумент17 страницHow To Make Sodium PerchlorateKing90Оценок пока нет

- Pharmaceutical DrugsДокумент92 страницыPharmaceutical DrugsFranco RazonОценок пока нет

- This Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1Документ7 страницThis Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1HERBERT SITORUS100% (1)

- Throttle Body Instruction Sheet: Tech NoteДокумент6 страницThrottle Body Instruction Sheet: Tech NoteGabriel ChiavettoОценок пока нет

- BMW - K1200 - Throttle-Position-Sensor TPS (Version 1-2)Документ7 страницBMW - K1200 - Throttle-Position-Sensor TPS (Version 1-2)steveОценок пока нет

- ECM PCM Computer Sensor Diagnosis and Testing - AxleAddi234128Документ31 страницаECM PCM Computer Sensor Diagnosis and Testing - AxleAddi234128Nitin PatilОценок пока нет

- BMW Motronic Fault CodesДокумент4 страницыBMW Motronic Fault CodesChris Palmer100% (1)

- DIY Standalone Mega Squirt Installation InstructionsДокумент14 страницDIY Standalone Mega Squirt Installation InstructionsJohn LauОценок пока нет

- The Mass Airflow Sensor On Your Mitsubishi VehicleДокумент8 страницThe Mass Airflow Sensor On Your Mitsubishi VehicleAndrey AndrienkoОценок пока нет

- Exact Voltages For A Four Wire TPSДокумент1 страницаExact Voltages For A Four Wire TPSDavid KabwamaОценок пока нет

- SensorsДокумент3 страницыSensorsCourei-FxAlcazarОценок пока нет

- How To Test The GM MAF SensorДокумент37 страницHow To Test The GM MAF SensorEngine Tuning UP100% (1)

- Readout AbsДокумент3 страницыReadout Absasamu10Оценок пока нет

- Megasquirt Instruction 1.6 MiataДокумент16 страницMegasquirt Instruction 1.6 MiataRyan KorbianОценок пока нет

- Crank and Cam Angle SensorsДокумент21 страницаCrank and Cam Angle SensorsalooookiОценок пока нет

- 4L60E Common ProblemsДокумент4 страницы4L60E Common ProblemsTransmisiones Automáticas Chepe100% (2)

- The Basics of Testing A Mass Air Flow (MAF) SensorДокумент5 страницThe Basics of Testing A Mass Air Flow (MAF) SensorbroОценок пока нет

- HHO PWM55 v1.8 +EFIEv1.3+LCD1.1Документ10 страницHHO PWM55 v1.8 +EFIEv1.3+LCD1.1هيثم خماش0% (1)

- TpsДокумент2 страницыTpsValBMSОценок пока нет

- Defrost TimerДокумент5 страницDefrost TimerZemetu Gimjaw AlemuОценок пока нет

- Lesson - Check and Test Starting SystemДокумент138 страницLesson - Check and Test Starting SystemMarcel Baring ImperialОценок пока нет

- Transistor Tester Instructions E1821 User's ManualДокумент3 страницыTransistor Tester Instructions E1821 User's ManualKepa VidaurreОценок пока нет

- Vehicle Sensors WiringДокумент8 страницVehicle Sensors WiringAudrick RussellОценок пока нет

- Actron Probador SensoresДокумент88 страницActron Probador SensoresAli Castillo100% (1)

- Maf Map EnhancerДокумент4 страницыMaf Map Enhancerlucian_vОценок пока нет

- BMW 4HP24Документ5 страницBMW 4HP24googleheadОценок пока нет

- 4L60E Transmission Info. RepairДокумент3 страницы4L60E Transmission Info. RepairMike L.Оценок пока нет

- MAF Sensor TestДокумент11 страницMAF Sensor TestagungkiworejoОценок пока нет

- EFI ModДокумент1 страницаEFI Modbluebelle2Оценок пока нет

- H 33Документ8 страницH 33Matei AlexandruОценок пока нет

- 6t70 ATRAДокумент6 страниц6t70 ATRAfulltransmission100% (1)

- GM328A User ManualДокумент3 страницыGM328A User ManualRosu Eugen100% (1)

- Typical Mercury Ignition SystemsДокумент11 страницTypical Mercury Ignition SystemswguenonОценок пока нет

- AQ12FANДокумент9 страницAQ12FANhdave32Оценок пока нет

- ZF Transmission Repair ZF 6HP26 Pulling and Troubleshooting The Mechatronics Unit E Shift Unit by Wilson009Документ21 страницаZF Transmission Repair ZF 6HP26 Pulling and Troubleshooting The Mechatronics Unit E Shift Unit by Wilson009Eduardo Yagüe Gomez75% (4)

- 05-244 Common Rail Diag Kit Instructions 091205Документ14 страниц05-244 Common Rail Diag Kit Instructions 091205Luis Segovia Cortes100% (1)

- G - Tests W/Codes - 1.6L & 2.0L Article TextДокумент25 страницG - Tests W/Codes - 1.6L & 2.0L Article TextKoeswara SofyanОценок пока нет

- P0115 - Engine Coolant Temperature Circuit MalfunctionДокумент2 страницыP0115 - Engine Coolant Temperature Circuit Malfunctionokwirian6971Оценок пока нет

- TesterДокумент18 страницTesterantoninoxxxОценок пока нет

- Centurion D5 Gate Motor ProgrammingДокумент2 страницыCenturion D5 Gate Motor ProgrammingDebraJonesОценок пока нет

- BMW - K1200 - Throttle-Valve-Actuator TVA (Version 1-2) - 1Документ5 страницBMW - K1200 - Throttle-Valve-Actuator TVA (Version 1-2) - 1steveОценок пока нет

- FYI 4L60E Common Problems FailuresДокумент3 страницыFYI 4L60E Common Problems Failurescyber_nauticaОценок пока нет

- Warning & Alarming Instrument 5 & 6Документ28 страницWarning & Alarming Instrument 5 & 6VivekDhameliyaОценок пока нет

- Throttle Position Sensor Adjustment PDFДокумент4 страницыThrottle Position Sensor Adjustment PDFDoDuyBacОценок пока нет

- Instrument Panel Analog - Nissan Sentra 1993Документ8 страницInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaОценок пока нет

- Tenet User Manual - enДокумент16 страницTenet User Manual - enEmilien VertuОценок пока нет

- All ATS TroubleshootingДокумент3 страницыAll ATS Troubleshootingandri pristaОценок пока нет

- Diesel Trouble PDFДокумент5 страницDiesel Trouble PDFzona amrullohОценок пока нет

- Diesel Trouble PDFДокумент5 страницDiesel Trouble PDFzona amrullohОценок пока нет

- Siemens Technical Education Program Part 2Документ45 страницSiemens Technical Education Program Part 2QM_2010Оценок пока нет

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulДокумент26 страницPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Marking Sheet For Student'S WorkДокумент1 страницаMarking Sheet For Student'S WorkmutasimОценок пока нет

- Robert Louis Stevenson'S "Treasure Island" As An Adventure NovelДокумент9 страницRobert Louis Stevenson'S "Treasure Island" As An Adventure NovelmutasimОценок пока нет

- New Lanos Engine3controlДокумент49 страницNew Lanos Engine3controljose sebastian alvarado realzaОценок пока нет

- Siemens Technical Education Program Part 2Документ45 страницSiemens Technical Education Program Part 2QM_2010Оценок пока нет

- Vickers General Hydraulic BookДокумент29 страницVickers General Hydraulic BookKarthik Sarang100% (15)

- Partial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulДокумент26 страницPartial Engine Assy (1Nz Fe/2Nz Fe) : OverhaulNelson Caño Basalo100% (3)

- Confirmation of Course Enrollment: Date: 4th May 2020 Course Start Date: 2nd May 2020Документ1 страницаConfirmation of Course Enrollment: Date: 4th May 2020 Course Start Date: 2nd May 2020mutasimОценок пока нет

- MIT Preventive MaintenanceДокумент20 страницMIT Preventive MaintenanceDexron3Оценок пока нет

- Metal Casting Processes - 1 PDFДокумент136 страницMetal Casting Processes - 1 PDFRamkrishna SonavaneОценок пока нет

- Service Manual Common Rail System (CRS) - DensoДокумент134 страницыService Manual Common Rail System (CRS) - DensoThang Tong86% (7)

- Tuesday, February 21, 2012 1:43 PM: Unfiled Notes Page 1Документ47 страницTuesday, February 21, 2012 1:43 PM: Unfiled Notes Page 1mutasimОценок пока нет

- DAEWOO DTCДокумент8 страницDAEWOO DTCMinh HangОценок пока нет

- FOREWORDДокумент1 страницаFOREWORDwei fooОценок пока нет

- Updata Instructions For MS509 PDFДокумент1 страницаUpdata Instructions For MS509 PDFJorge Coke GuzmanОценок пока нет

- Automatic Gear TransmissionДокумент11 страницAutomatic Gear TransmissionIntruder 47100% (1)

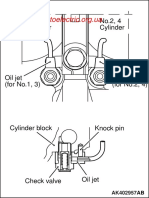

- AK402957AB00ENGДокумент1 страницаAK402957AB00ENGmutasimОценок пока нет

- Fuel Trim PDFДокумент7 страницFuel Trim PDFmutasimОценок пока нет

- Fuel Trim PDFДокумент7 страницFuel Trim PDFmutasimОценок пока нет

- DAEWOO DTCДокумент8 страницDAEWOO DTCMinh HangОценок пока нет

- AL4 TransmissionДокумент59 страницAL4 Transmissionericsolver97% (62)

- Vickers General Hydraulic BookДокумент29 страницVickers General Hydraulic BookKarthik Sarang100% (15)

- MIT Preventive MaintenanceДокумент20 страницMIT Preventive MaintenanceDexron3Оценок пока нет

- Daihatsu Sirion m100 Workshop ManualДокумент21 страницаDaihatsu Sirion m100 Workshop ManualmutasimОценок пока нет

- E IndexДокумент7 страницE Indexwei fooОценок пока нет

- Automatic Gear TransmissionДокумент11 страницAutomatic Gear TransmissionIntruder 47100% (1)

- Index PDFДокумент1 страницаIndex PDFwei fooОценок пока нет

- Manhattan Associates Technical Placement Paper Level1Документ7 страницManhattan Associates Technical Placement Paper Level1placementpapersampleОценок пока нет

- Licenta - Algoritmi de Rezolvare A Cubului Rubik PDFДокумент46 страницLicenta - Algoritmi de Rezolvare A Cubului Rubik PDFRazvan SavucОценок пока нет

- Veritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - SolДокумент614 страницVeritas™ Volume Manager Administrator's Guide Solaris - VXVM - Admin - 51sp1 - Solakkati123Оценок пока нет

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Документ23 страницыData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainОценок пока нет

- Activity9 PDFДокумент5 страницActivity9 PDFSmitОценок пока нет

- ESB Networks Contractor Safety RegulationsДокумент68 страницESB Networks Contractor Safety RegulationsvhlactaotaoОценок пока нет

- SEC StdsДокумент65 страницSEC Stdserson1981Оценок пока нет

- Andreki, P. (2016) - Exploring Critical Success Factors of Construction Projects.Документ12 страницAndreki, P. (2016) - Exploring Critical Success Factors of Construction Projects.beast mickeyОценок пока нет

- Am 3517Документ221 страницаAm 3517mudit9_mОценок пока нет

- Transmission and DistributionДокумент10 страницTransmission and Distributionprabhjot singh186% (21)

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongДокумент18 страницFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooОценок пока нет

- The Principles of Pulp Washing - PdfaДокумент9 страницThe Principles of Pulp Washing - Pdfashabi049Оценок пока нет

- Centrifugal PumpsДокумент6 страницCentrifugal Pumpsjerome fajardoОценок пока нет

- Komatsu PC200LC-6Документ12 страницKomatsu PC200LC-6Collin Corp100% (2)

- Developer For System Z: Quick Start GuideДокумент2 страницыDeveloper For System Z: Quick Start GuideUmesha GowdaОценок пока нет

- Using CHEMCAD For Piping Network Design and AnalysisДокумент51 страницаUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonОценок пока нет

- Databook Continental Agri 2006 PDFДокумент0 страницDatabook Continental Agri 2006 PDFdanilo3073Оценок пока нет

- Schematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Документ1 страницаSchematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Michael Camit EsoОценок пока нет

- Actividad 1 Lorena GuerreroДокумент4 страницыActividad 1 Lorena GuerreroAlfonso GutierrezОценок пока нет

- Find Serial Number of Computer in Windows 10Документ2 страницыFind Serial Number of Computer in Windows 10GabbarОценок пока нет

- Aircon Maintenance Singapore NdurwДокумент5 страницAircon Maintenance Singapore Ndurwchinfrench0Оценок пока нет

- Installation and Maintenance Information: Turbine Powered StartersДокумент28 страницInstallation and Maintenance Information: Turbine Powered StartersNajim Ahmed BulbulОценок пока нет

- Overview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Документ3 страницыOverview of Roles in Solution Manager (SAP Library - SAP Solution Manager)Sravan Kumar PendyalaОценок пока нет

- 06668967Документ10 страниц06668967PECMURUGANОценок пока нет

- Guidance On Mooring System Management Plans (MSMP)Документ39 страницGuidance On Mooring System Management Plans (MSMP)PJ Apostol Alpacas100% (4)

- GEN CHEM 2 LESSON 3 Intermolecular Forces of Solids and Their Properties1.1Документ27 страницGEN CHEM 2 LESSON 3 Intermolecular Forces of Solids and Their Properties1.1Loraine Castro0% (1)

- A Primer On Spray Drying Chemical Engineering Nov09Документ7 страницA Primer On Spray Drying Chemical Engineering Nov09Hikmah Triana HadiОценок пока нет

- 82 To 88 CompleteДокумент6 страниц82 To 88 CompleteUmer KhanОценок пока нет

- Spring Support Used in PipingДокумент7 страницSpring Support Used in Pipingashish.mathur1Оценок пока нет

- Buffer Cache AdvisoryДокумент8 страницBuffer Cache Advisorysteve_fordОценок пока нет