Академический Документы

Профессиональный Документы

Культура Документы

DRP001-OUF-PRO-L-000-003 Rev O1 Construction Quality Plan PDF

Загружено:

Daniel MartinezИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DRP001-OUF-PRO-L-000-003 Rev O1 Construction Quality Plan PDF

Загружено:

Daniel MartinezАвторское право:

Доступные форматы

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

Revision History

Amendment Revision Amender

Amendment

Date Number Initials

Related Documents

Document Number Document Name Description of Content

Refer section 4.0

Holds

Section Number Short Description of Hold

Definitions and Abbreviations

Term Comment

Refer section 3.0

DRP001-OUF-PRO-L-000-003 Page 2 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

CONTENTS

1. PURPOSE ....................................................................................................................... 4

2. SCOPE ............................................................................................................................ 4

3. DEFINITIONS .................................................................................................................. 4

4. REFERENCE DOCUMENTS ........................................................................................... 4

5. GUIDELINES ................................................................................................................... 5

5.1 Site Organisation identifying responsibilities for quality .................................................... 5

5.2 Pre-Start of Work Operations ........................................................................................... 5

5.3 Quality Control of the work ............................................................................................... 6

5.4 Good Documentation Practice ......................................................................................... 7

5.5 Inspection Responsibilities ............................................................................................... 7

5.6 Inspection Stamps ........................................................................................................... 8

5.7 Concessions and Field Engineering Queries ................................................................... 8

5.8 Inspection Reports and resolution of Problems ................................................................ 8

5.9 Problem Severity ............................................................................................................. 8

5.10 Problem Urgency ............................................................................................................. 9

5.11 Communications .............................................................................................................. 9

5.12 Quality Assurance Audits ............................................................................................... 10

5.13 Quality Records ............................................................................................................. 10

ATTACHMENTS-

ATTACHMENT 1 - SITE ORGANISATION CHART

ATTACHMENT 2 - TYPICAL CONTRACTOR INSPECTION AND TEST PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN

ATTACHMENT 5 - EPC INSPECTION RESPONSIBILITIES

DRP001-OUF-PRO-L-000-003 Page 3 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

1. PURPOSE

The purpose of this document is to set out the requirements for the EPC

Contractor for achieving specific standards and appropriate documentation for site

construction activities that satisfy Company’s requirements, meet specified quality

requirements and are in accordance with contractual and legislative commitments.

2. SCOPE

The Site Quality Plan shall include the quality control requirements aimed at both

monitoring and ensuring satisfactory performance at relevant stages of

construction whether by EPC Contractor, Sub-Contractors or Vendors. The

sample inspection and test certificates and other typical forms included within the

Attachments are for guidance and are not an exhaustive list of documents to be

produced by EPC Contractor. The sample documents include the attributes which

shall be inspected, measured and documented to demonstrate compliance with

specifications, standards and drawings.

3. DEFINITIONS

EPC Contractor(s) - Joint Venture (JV) of Petrofac International LTD &

Samsung Engineering Co. Ltd.

Company - Duqm Refinery & Petrochemical Industries Company

LLC ( DRIPC)

QMS – Quality Management Systems

EMS – Environmental Management Systems

PMC – Project Management Consultant.

PQP – Project Quality Plan

FEED Engineer – Amec Foster Wheeler Energy Ltd.

Vendor - Vendor, subcontractor, manufacturer or supplier of

Goods and services.

Inspection Authority - EPC Contractor, PMC/Company and/or their agent.

ITP – Inspection Test Plan.

OE – Originating Engineer.

ACI – Authorised Code Inspection/Inspector.

4. REFERENCE DOCUMENTS

ISO 9001: 2008 Quality Management Systems – Requirements

Project Quality Plan - DRP001-FED OUF-PRO GMD-

Q-000-001 500

Company Quality Management Plan - PLN-1500-1000-001

DRP001-OUF-PRO-L-000-003 Page 4 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

Company Quality Specification - SPC-1500-1000-001

QAQC Implementation during Construction - DRP001-OUF-SPE-

Q-000-507

5. GUIDELINES

5.1 Site Organisation identifying responsibilities for quality

EPC Contractor Job Descriptions and Organisation Chart shall define

responsibilities for individual job positions within the site organisation. Reporting

lines shall be included in the Job Descriptions and shall be shown in EPC Contractor

Site Organisation Chart.

The EPC Contractor shall be responsible for the quality of the erection / installation

of the plant and shall accordingly maintain a formal Quality system throughout the

performance of the contract, encompassing all the monitoring, inspection and tests

required by their contract documents.

EPC Contractor shall prepare and submit for Company, approval detailed ITP’s

(typical sample is provided in Attachment 2) and inspection procedures covering all

operations in the work scope including temporary works and demolition where

applicable.

The EPC Contractor site Chief Field Engineer, Site Quality Manager or his nominee

shall be responsible for “approval” of Sub - Contractors ITPs. EPC Contractor

construction supervision and inspectors are responsible for reviewing the Sub-

contractors ITPs and establishing inspection points in accordance with EPC

Contractors Site Quality Plan.

EPC Contractor shall monitor and witness the QA/QC activities of Sub - Contractors

and document surveillance of their work and the approved ITPs. EPC Contractor

shall audit Sub - Contractor’s activities against the approved ITPs.

Company involvement shall be as set out in Company Quality Specification SPC-

1500-1000-001.

5.2 Pre-Start of Work Operations

All standards, specifications and drawings applicable to the EPC Contractors’

construction contract are listed in the contract.

EPC Contractors ITPs shall list all operations of fabrication, erection and testing

included in their scope of work. The plans shall include controlling procedures,

acceptance criteria, verifying documents and the inspection involvement of

themselves, Sub-contractors, Company PMT and Third Party Inspection.

EPC Contractor shall review the Sub-contractor’s ITPs in conjunction with all parties

involved e.g. field supervision, inspectors, originating engineers and consolidate

comments for incorporation by Sub - Contractors.

The review shall ensure that all activities are included and that the verifying

documents proposed meet all project requirements. Inspection and test certificates

similar to those indexed in Attachment 3 shall be used to provide consistency across

the whole project. These certificates include the stages of work which shall be

inspected, measured and documented to demonstrate compliance with

specifications, standards and drawings. Sub - contractors shall be encouraged to

use these inspection forms except where they can demonstrate that they cannot be

used in which case an agreed alternative shall be used. EPC Contractor may

DRP001-OUF-PRO-L-000-003 Page 5 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

modify the sample forms if required and this is preferable to accepting a Sub-

Contractors’ format, Company shall review and approve such changes. For

turnover activities a form similar to that defined as a pinnacle document (Attachment

4) shall always be used in the turnover dossier.

Additional Sub-Contractor forms for intermediate stages may be used and shall be

compiled by the EPC Contractor or Sub- contractor into the final records dossiers.

EPC Contractor in conjunction with field supervision and inspectors shall mark up

the ITPs with EPC Contractor and Company PMC involvement as per the Site

Quality Control Plan in Attachment 4. EPC Contractor shall also obtain and ensure

incorporation of Company PMC comments and inspection mark up.

The final approved ITP shall be distributed to all involved parties and shall be

incorporated in the final project construction records.

5.3 Quality Control of the work

5.3.1 ITP intervention points

ITPs shall be marked up with inspection involvement at the pre-start of work review

and approval stage. The “Action” column on the ITP defines the responsibilities

and input required from the Supervisors/Inspectors.

a) H = Hold Point – this is an inspection or test which is considered vital to the

quality, integrity and safe functioning of the equipment or material. Hold point is

a mandatory inspection. It defines a point beyond which work shall not proceed

without inspection or test being verified by the party for whom “hold point” as

marked unless waived in writing.

To minimize interruptions to the manufacturing programs, but without

jeopardizing the quality of the product, every effort shall be made to minimize the

imposition of hold points for the Company.

b) W = Witness Point - this is an inspection or test which may be performed on a

100% or sample basis and which may or may not be equally important as a Hold

Point. Witness points provide the party with the opportunity to verify the

inspection / test at their option.

Both Witness and Hold points require adequate advance written notification to

the Company of the activity. For witness point, the manufacturer,/vendor may

proceed to the next stage even if the Company representative did not attend the

inspection.

c) S = Surveillance - this consists of inspection or observation during manufacture

and testing without a formal notification from either side. It may be undertaken

whilst the inspector is attending for hold or witness points or during separately

arranged surveillance visits. The need for such surveillance visits shall be

established in the quality program and arrangements shall be made at the pre-

inspection meeting. It will only be necessary to mark activities for surveillance on

quality plans when visits are arranged solely for this purpose, but surveillance

shall nevertheless be a constituent part of all inspection visits.

d) R/A = Review/Approval - This shall be marked-up only for documents subject to

review/approval. This is used in two cases:-

DRP001-OUF-PRO-L-000-003 Page 6 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

i) Review / Approval of documents by the Inspectors at the work locations.

In such cases it shall be indicated as R/A (L).

ii) Review / Approval of documents by company offices in such cases this

shall be indicated as R/A.

5.4 Good Documentation Practice

EPC Contractor must agree the project requirements for good documentation

practice, develop a set of example forms, and provide formal training for EPC

Contractors Field personnel, and Sub-Contractors / Third party inspectors. It is not

intended that every form is countersigned by Company PMT. The extent of

signatures required shall be in accordance with the approved ITP, the specified

standards and the requirements of the EPC Contractors Site Manager. Unsigned

boxes shall be deleted with a single diagonal ruled line, marked NA and initialled by

the EPC Contractors authorised signatory.

Signatures on forms indicate actual involvement in a review, check or an

inspection as required by the ITP. If necessary a comment should be added

to indicate a clear reason for the signature.

Signatures shall not be a rubber stamping exercise long after the event.

Signing of forms must be contemporary to the actual event. The signature

should be dated to indicate the date of the signature.

Official Stamps using red ink must be used in conjunction with any signature.

The use of ‘ditto’ marks in any format shall not be acceptable.

Blue ball-point / Ink shall be used on forms.

All boxes on a form shall be completed.

Annotation of 'Not applicable' (NA) must be justified by reference to drawing,

standard or specification.

Dates shall be in a format DD MM YY.

Deletions / alterations shall be made with a single ruled line and initialled.

No tippex (Correction Fluid) or other form of liquid paper or whitener shall be

used.

Erasers shall not be used.

5.5 Inspection Responsibilities

EPC Contractors shall maintain a schedule of Inspection Responsibilities. This

schedule shall list persons responsible for the individual activities and the

inspection level required. Actual inspectors’ names shall be used to ensure no

ambiguities occur and allow auditing of operation and records. Specialists shall

be identified where required in lieu of the EPC Contractor Supervisor/Inspector,

e.g. setting of spring supports to be inspected and verified by the piping engineer.

A sample schedule is in Attachment 5.

Where intervention by independent inspection authority is required a separate

procedure shall be written to specify the requirements. The procedure will define

the Material Traceability requirements and any increased levels of surveillance

needed. To ensure the requirements are identified and communicated to the Sub

-Contractors a typical procedure for the Preparation of Piping Inspection Packs for

External inspectors shall be developed by EPC Contractor.

DRP001-OUF-PRO-L-000-003 Page 7 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

5.6 Inspection Stamps

EPC Contractor personnel who carry out inspection duties on site shall be issued

with a stamp to be used to verify their activities when signing off test/inspection

forms or completing reviews.

EPC Contractor shall co-ordinate the supply and issue of stamps and maintain a

log containing stamp number, issue date, inspector’s name and signature.

Stamps shall only be issued to personnel who have received adequate

documentation training and have been briefed on their inspection responsibilities

for the project. The stamp shall be used with a red ink pad thereby identifying the

signed off document as an original. Inspectors shall sign across the stamp imprint

in the space provided.

5.7 Concessions and Field Engineering Queries

Concessions and Field Engineering Queries procedures shall be developed by

EPC Contractor and submitted to Company PMC for review / approval.

EPC Contractor shall maintain accurate and updated logs for all Concession

requests and Field Engineering Queries.

5.8 Inspection Reports and resolution of Problems

If defects are found during construction the EPC Contractor/Inspector shall require

the Sub-Contractors to correct said defects and shall increase his percentage

inspection surveillance until the Sub-Contractor performs within the quality

requirements. Increased frequency of Inspections shall be recorded and reported

in regular Weekly QC Meetings with Company PMC. Company may issue

observation reports requiring that EPC Contractor shall raise a Non-conformance

report, the logging and close out of these reports shall be recorded during weekly

Meetings.

EPC Contractor shall ensure that Reports of quality problems shall be

documented and communicated as described in this section. Adherence to this

plan will ensure that quality problems are resolved in a structured and progressive

manner and so avoid major rework at final inspection stages. The descriptions of

severity and urgency as used within this section are as follows:-

5.9 Problem Severity

Minor Not per specification, referenced standard or Contractor’s

procedures. Extent of problem can be verified. Corrections can

be made and quality requirements can be verified with little or no

difficulty.

Serious Involves critical and primary components. Extent of problem is

difficult to identify. Damage is correctable, quality requirements

can be verified with moderate difficulty.

Very Serious Involves critical and primary components. Possible permanent

damage and material replacement may be required. Extremely

difficult to determine extent of damage and verify required quality.

DRP001-OUF-PRO-L-000-003 Page 8 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

5.10 Problem Urgency

Urgent Completion of fabrication soon, satisfaction of required quality

will be difficult to verify after completion.

Very Urgent Completion pending, satisfaction of required quality will be

difficult to verify after completion.

Most Urgent Immediate solution required; completion imminent; satisfaction

of required quality cannot be verified after completion

5.11 Communications

The flow of communications, report format and the progressive manner of

handling problems is defined by the EPC Contractor.

5.11.1 Verbal Communication

Purpose Used to identify potential problems as they are detected by

Supervisors/Inspectors.

Application First offence items or problems that if not addressed could result

in more serious non-conformities.

Originator Supervisor/Inspectors

Approval Not required

Record Notation in Supervisor/Inspectors log book

Copies Field Superintendent, the EPC Contractor Chief Field Engineer

and QA/QC Engineer informed verbally.

5.11.2 Inspection Report

Purpose Written communication between Superintendent and

Contractor’s Inspection and/or Construction Supervision.

Application Used to report multiple offences, minor problems and first

offence serious problems or urgent problems not resolved

verbally.

Originator Supervisor/Inspectors

Approval Field Superintendent/QC Engineer

Record Inspection Report / Non Conformance Report

Copies Field Superintendent, Supervisor/Inspectors, Site Chief Field,

Engineer, QA/QC Engineer, EPC Contractor Site Manager.

DRP001-OUF-PRO-L-000-003 Page 9 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

5.12 Quality Assurance Audits

EPC Contractor shall conduct Construction Discipline Audits to ensure that their

Site Quality Plan is fully implemented. In addition, EPC Contractor site shall audit

the implementation of the Sub-Contractors ITPs and monitor the effectiveness of

the Sub-Contractors audits for his own activities. EPC Contractor shall plan and

maintain a log of site audits and shall ensure through personal review and audit

that material and document control procedures are fully implemented. Material

preservation requirements shall be audited on a monthly basis by the EPC

Contractor.

5.13 Quality Records

EPC Contractor shall certify all the inspections and tests carried out by them to

verify compliance with the specified requirements.

EPC Contractor shall ensure that all Sub-contractors shall compile dossiers of the

documents, certificates and reports covering their scope of work. Quality record

requirements are specified within the subcontract requisition and their referenced

attachments. These specified requirements shall be reflected in the EPC

Contractor and Sub-Contractor Quality Plans.

EPC Contractor shall have overall responsibility for ensuring that Sub-Contractors

documentation is maintained and handed over progressively in line with activity

completion and in accordance with the approved Quality Plans and ITPs. Review

and acceptance of the final documentation shall be by the Turnover Engineer

supported by the relevant supervisor/Inspectors.

DRP001-OUF-PRO-L-000-003 Page 10 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 1 - SITE ORGANISATION CHART

(To be detailed by EPC Contractor on a project specific basis and will show responsibilities for

quality once the Construction phase has commenced)

For Site Quality organization chart ; refer chart 3 of Roles and Responsibility document

No. DRP001-OUF-PRO-U-000-068

DRP001-OUF-PRO-L-000-003 Page 11 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

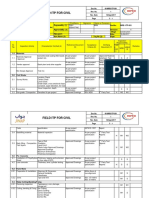

ATTACHMENT 2 - TYPICAL CONTRACTOR INSPECTION AND TEST PLAN

Typical requirements for contractor ITPs including intervention points for Verification, Inspection,

Hold, Surveillance (including surveillance levels), Review.

Below are sample ITP procedures .

Preparation of Inspection and Test Plans for Civil Works, Fireproofing and Undergrounds

Preparation of Inspection and Test Plans for Industrial Building Systems and HVAC

Preparation of Inspection and Test Plans for Pharmaceutical Building Systems and HVAC

Preparation of Inspection and Test Plans for Steelwork Fabrication and Erection

Preparation of Inspection and Test Plans for Jetties and Marine Works

Preparation of Inspection and Test Plans for Mechanical Equipment Installation

Preparation of Inspection and Test Plans for Fired Heaters - Civils

Preparation of Inspection and Test Plans for Fired Heaters - Steelwork

Preparation of Inspection and Test Plans for Fired Heaters - Welding

Preparation of Inspection and Test Plans for Fired Heaters - Refractory and Lining

Preparation of Inspection and Test Plans for Fired Heaters - Mechanical

Preparation of Inspection and Test Plans for Fired Heaters - Piping

Preparation of Inspection and Test Plans for Fired Heaters - Electrical

Preparation of Inspection and Test Plans for Fired Heaters - Instrumentation

Preparation of Inspection and Test Plans for Fired Heaters - Painting and Insulation

Preparation of Inspection and Test Plans for Piping Fabrication, Erection and Testing

Preparation of Inspection and Test Plans for Electrical Installation and Testing Work

Preparation of Inspection and Test Plans for Instrumentation Installation and Testing Work

Preparation of Inspection and Test Plans for Storage Tanks Fabrication and Erection

Preparation of Inspection and Test Plans for Welding Fabrication and Testing

Preparation of Inspection and Test Plans for Painting and Insulation Work

Preparation of Inspection and Test Plans for Refractory and Lining

DRP001-OUF-PRO-L-000-003 Page 12 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES

Index of Construction Forms

Section Description(01) Miscellaneous

Form Description

Document Index

Non-conformity Report

Request to witness inspection

Contractors Concession Request Form

Contractors Authorised QC Signatories List (Sht 1)

Contractors Authorised QC Signatories List (Sht 2)

Drawing Index

Inspection Certificate Index

Field Technical Query

Engineering Query

Section Description(02) Welding

Form Description

MT / PT Report for steelwork

Pipework Dimensional Check Certificate

Thickness Gauging Report

Orifice Flanges weld grinding Certificate

Catalyst Lines Root Weld grinding Certificate

Weld inspection Summary Sheet

Request for NDE Inspection

Welders Weekly performance Record

Daily Welder Performance Record

RT Report

MT / PT Report

UT Report

PWHT Report

Summary of approved welders

PMI Report (Valve)

PMI Report - Weld

Hardness test Report

Welder Approval Test Certificate

Ferrite Test Report

Record of Repairs

Visual Examination Report

PMI Report (Bulks) Same Heat No.

PMI Report (Bulks) Different Heats in Lot

PMI Report (Bulks) Various Heats

PMI Composition Report

PMI Report (Bulks)

PMI - ALLOY MATERIALS (BULKS)

APPROVED NDE OPERATORS REGISTER

DRP001-OUF-PRO-L-000-003 Page 13 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

DOCUMENT INDEX

PACK HANDOVER AND ACCEPTANCE CERTIFICATE

NON-METALLIC PIPING JOINING SUMMARY SHEET

REPORT A: ALLOY MATERIALS (BULKS)

NOTIFICATION OF RADIOGRAPHY

RADIOGRAPH CONTROL CHART

TANK COMPLETED READY FOR TEST

WELDER APPROVAL TEST RECORD

Section Description(03) Pressure Vessels

Form Description

PRESSURE VESSEL CHECKLIST

Dressed Vessel Acceptance Certificate (Sht 1 of 2)

Dressed Vessel Acceptance Certificate (Sht 2 of 2)

Pressure Vessel Tower Acceptance Report (Sht 1 of

Pressure Vessel Tower Acceptance Report (Sht 2 of

PRESSURE VESSELS - CLOSURE CERTIFICATE

Pressure Vessels Tower Acceptance Report

Pressure Vessel Tower Acceptance Certificate

Pressure Vessel Tower Acceptance, Shutdown Certifi

Pressure Vessels - Tray Test

Pressure Vessel - Structured Packing

Pressure Vessels - Packed Beds

Pressure Vessel Drum Acceptance Check List (Sht 1

Pressure Vessel Drum Acceptance Check List (Sht 2

Pressure Vessel Drum Acceptance, Shut Down

Vessel Acceptance Certificate

Tank Installation Check List

Vessel Closure Certificate

Collector/Chimney Tray Leak Test Report (Or

Drum/Vessel Check List (Sht 1 of 2)

Drum/Vessel Check List (Sht 2 of 2)

Tower Check List (Sht 1 of 3)

Tower Check List (Sht 2 of 3)

Tower Check List (Sht 3 of 3)

Section Description(04) Heat Exchangers

Form Description

Shell and Tube Exchanger Check List

Shell and Tube Exchanger - Shutdown

Air Cooled Heat Exchangers Check List

Air Fin Exchanger Fan Alignment

Air Fin Exchanger - Shut-down

Tube Rolling Record Sheet

Flare Tip Installation Check List

Plate Exchanger Check List - Installation

Plate Exchangers - Shut Down

DRP001-OUF-PRO-L-000-003 Page 14 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Plate Exchangers - Maintenance

Fin Fan Heat Exchanger Check List (Sht 1 of 3)

Fin Fan Heat Exchanger Check List (Sht 2 of 3)

Fin Fan Heat Exchanger Check List (Sht 3 of 3)

Cooling Tower Check List

Heat Exchanger Check List (Sht 1 of 2)

Heat Exchanger Check List (Sht 2 of 2)

Plate Exchanger Check List (Sht 1 of 2)

Plate Exchanger Check List (Sht 2 of 2)

Section Description(05) Mechanical Equipment

Form Description

Minor Equipment Check List

Package Equipment Check List

Equipment Rotation and Lubrication Log Sheet

MECHANICAL EQUIPMENT COLD ALIGNMENT TEST REPORT

Centrifugal Pump Check List

Reciprocating Pump Check List

Gear Unit Check List

Centrifugal and Axial Compressor Check List

Rotary and Screw Compressor Check List

Reciprocating Compressor Check List

Reciprocating Compressor Check List

Refrigeration Compressor Check List

BLOWERS CHECK LIST

Steam Turbine Check List

Gas Engines Check List

Mixer Check List

Inspection and Maintenance Record Card

Furnace and Boiler Check List (Sht 1 of 3)

Furnace and Boiler Check List (Sht 2 of 3)

Furnace and Boiler Check List (Sht 3 of 3)

Pump Check List (Sht 1 of 6)

Pump Check List (Sht 2 of 6)

Pump Check List (Sht 3 of 6)

Pump Check List (Sht 4 of 6)

Pump Check List (Sht 5 of 6)

Pump Check List (Sht 6 of 6)

Gear Box Check List

Section Description(06) HVAC & Building Services

Form Description

Air Conditioning Unit Check List

Air Conditioning Heater Unit Check List

Air Handling Unit Erection Check List

Air Conditioning Refrigeration Unit Check List

Air Conditioning Air Filter Check List

DRP001-OUF-PRO-L-000-003 Page 15 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Air Conditioning Humidifier Check List

Air Conditioning Ductwork Check List

HVAC Damper Check List

Fire Transit Block Check List

Air Conditioning Unit Test Report

Heater Unit Test Report

Air Handling Unit Test Report

Air Filter Test Report

Humidifier Test Report

Ductwork Air Leakage Report

System Balance Test Report

Grill and Diffuser Test Report

Smoke and Halon Test of Pressurised Form

Room Pressurisation Test (Part 1) Report

Room Pressurisation Test (Part 2) Report

HEPA Filter Test Report

Pitot Traverse Test Report (Rectangular)

Pitot Traverse Test Report (Circular)

Ductwork Pre-fabrication Inspection Release

ACMV Punch List

Ductwork Section Pre-insulation Checklist

Ductwork Insulation Checklist

Final Ductwork Checklist

Fan Coil Unit Erection Checklist

ACMV Fan Test Report

Dehumidifier Unit Test Report

Ceiling Closure Checklist (Sht 1 of 2)

Ceiling Closure Checklist (Sht 2 of 2)

Fresh Air Fan Test Report

Exhaust Air Fan Checklist

Fan Checklist

Section Description(07) Piling and Civil Works

Form Description

Civil Works Foundation Release Record

Civil Works Grout Release Record

Excavation Record

Piling Record - Per-cast or steel

Piling Record - Bored In-situ and Cast In Place

Piling Record - Bored Steel Shell and Cast In Plac

Concrete Pour Release Record

Civil Works Foundation Check List

Concrete Cube Test Record Summary

Underground Piping Metallic Check List

Drainage Test

Excavations and Preformed Trenches Check List

Chimney Inspection Check List

DRP001-OUF-PRO-L-000-003 Page 16 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Building Inspection Check List

Blockwork Wall Coating Check List

Concrete Cube Test Results Earthworks, Roadworks and Flexible Paving Inspecti

Underground Services/Drainage Inspection

Reinforced Concrete Works Check List

Building Works Inspection Record

Soil Compaction Check List

Room / Building Finishes Construction Punch List

Aggregates Moisture Content

Batching Plant Operation

Daily Piling Record

Readymix Concrete Checklist

Module Pit Release Form and Concrete Infill Checkl

Valve Chamber Acceptance

Catch Basin / Manhole Acceptance

Storm Drain Check Sheet

Concrete Coring Check List

Chamber/Pit/Manhole - Final Inspection

Bund Test Report

Room Finishes Check Sheet - Civil / Architectural

Room Finishes Check Sheet - Civil

Room Finishes Check Sheet - Engineering

Section Description(08) Structural Steelwork

Form Description

Steelwork Fabrication Checklist

Structural Steelwork (Unspliced) Inspection Certificates

Structural Steelwork (Spliced) Inspection

Structural Steelwork (Spliced) Inspection

Structural Steelwork Release Report

Structural Steelwork Steel Framed Building Checklist

Pipe Rack Acceptance Certificate

Module Release Report

Fireproofing Checklist

Structural Steelwork Torque Wrench Calibration

Section Description(09) Storage Tanks

Form Description

Radiographic Report Tank Construction

Record of Levels, Cardinal Points, Orientation and

Bottom / Annular Butt Weld Numbers

Tank Bottom Inspection Test Chart

Tank Bottom Vacuum Test Chart

Tank Shell Vertical and Radial Checks

Site Recorded Test Numbers - Shell Plates

Welder Identification Chart (Butts 1 - 8)

Welder Identification Chart (Butts 9 - 16)

DRP001-OUF-PRO-L-000-003 Page 17 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Shell Welds (Visual / NDT)

Visual / Crack Detection Scar Area

Storage Tank Miscellaneous Inspections

Storage Tank Miscellaneous Inspections

Storage Tank Hydrostatic Inspections

Record of Levels During Water Test

Tank Appurtenances Orientation

Tank Bottom Plate Level Check

Tank Test Water Filling Chart

Shell Peaking and Banding Report

Shell Plumbness Report

Shell Base Roundness Report

Tank Foundation Settlement Report

Tank Installation Check List

Dimension of Shell Plate

Tank Shell Welding and NDE Summary Sheet

Tank Completed Ready for Test

Section Description(10) Refractory

Form Description

Castable Linings Inspection Check List

Refractory Applicator Qualification Test

Refractory Interim and Final Test Certificate

Section Description(11) Pipework

Form Description

Underground Piping Non-metallic Check List

Underground Piping Metallic Check List

Pipework Pre-test Checklist

Pipework Pre-test Checklist

System Flushing Report

Pipework Post Test Checklist

Piping Test Pack Completion Record

Safety Relief Valve Test Report

Safety Relief Valve - Installation Report

FLUSHING CHECK LIST

Pipework Slope Inspection Report

Piping Punch List

Piping Fit-up Report

Chemical / Mechanical Cleaning Certificate

System Spring Support Checkout Record

Cement Lining Inspection Record

Holiday Inspection Record

Pipework Internal Cleaning Report

Release of Shop Fabricated Pipework to Site or Pai

Test Pack Post Test Drying Certificate

Bolt Torque Test Report

Piping Test Pack Approval to Test

DRP001-OUF-PRO-L-000-003 Page 18 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Piping Test Pack Specification

Pipework Cleaning Inspection Record

Pipework Pre-fabrication Inspection Release

Isometric Inspection Completion Sheet

Section Description(12) Hot Taps

Form Description

Hot Tap and Stopples Check List

Hot Taps and Stopples Acceptance Certificate

Hot Taps and Stopples - Pre-operations Checklist

Hot Taps and Stopples - Pre-cutting Checklist

Hot Taps and Stopples - Machine Removal

Section Description(13) Instruments

Form Description

Pre-installation Calibration Report

Field Instrument Installation Report

Instrument Piping Inspection Report

Instrument Piping Test Report

Instrument Loop Cable Test Report

Instrument Equipment in Hazardous Area Report

Intrinsically Safe System Inspection Report

I.S. System Cable Test Report

Electrical Enclosure - Inspection Report

Fire and Gas Systems Check List

Module Release Report

Loop Acceptance Report

Multi-core Cable Test & Acceptance Report

Electrical Equipment in Safe Areas Inspection Repo

Cable Tray and Racking Installation Report

Field Loop Check Report

Instrument Full Loop Test Report

Control Device Inspection Report

Instruments (General Purpose)

Instrument Removal Sheet

Certification of Primary Calibration Standard

Certification of Secondary Calibration Standard

Control Valve Pre-Installation Calibration

Trip and Alarm Check Sheet

Instrument Installation Acceptance Form

On-Line Stream Analysers

Instrument Loop Check Sheet

Analyser Acceptance Form

Cabinet / Console* Check Sheet

Local Control Panel - Acceptance Report

Installation Acceptance of Safeguarding System and

Installation Acceptance of DCS System

Junction Box Inspection Report

DRP001-OUF-PRO-L-000-003 Page 19 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Instrument Earthing System Acceptance

Instrument Air Signal Lines - Leak Test

Instrument Air Supply Pressure Test

Impulse Line Pressure Test Report

Installation Check Sheet

Flow Orifice Inspection Report

Flow Indicator Visual Check

Flow Transmitter Calibration Report

Alarm System Inspection Report

Flow Indicator Test Report

Level Indicator Test Report

Pressure Gauge Test Report

Switch Device Test Report

Thermocouple Test Report

Thermometer Test Report

Thermoresistance Test Report

Pressure Regulator Calibration Report

Level Transmitter Caibration Report

Pressure Transmitter Calibration Report

Loop Test Report

Loop Test Report

Analyser System Performance Certificate

Section Description(14) Electrical

Form Description

Electrical Enclosure - Inspection Report

Low Voltage Cable Test Report

Cable Trench Backfilling Inspection Report

600/1000 Volt Cable Test / Acceptance Report

High Voltage Cable Test Report

Multi-core Cable Test & Acceptance Report

Earthing Test Report

Earth Loop Impedence Test Report

Electrical Equipment in Safe Areas Inspection Repo

Electrical Equipment in Hazardous Areas Report

Cable Tray and Racking Installation Report

Switchboard and Busbars Test Report

Switchboard Inspection Report

Distribution Board Inspection and Test Report

U.P.S. Test Report

Miscellaneous Items Test Schedule - Voltage Sensit

Battery Charger Test Report

Insulating Oil Test Report

Transformer Inspection and Test Report (Sht 1)

Transformer Inspection and Test Report (Sht 2)

Primary Injection Test Report

Protection Relay Test Report

DRP001-OUF-PRO-L-000-003 Page 20 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

CT and Protection Relay "MAG" Test Report

P and B Thermal Overload Report

Contactor Starter Report

Control Circuit Function Test Report

Electric Motor Test Report and Motor Running Log

Electric Motor Test Report and Motor Running Log

Area Illumination Values Test Report

Lighting Circuit Inspection Report

Trace Heating Circuit Test Report

Electrical Motor Inspection, Care and Protection R

PTFE Lined Pipe Earthing Test Report

Battery Charger Inspection Report

Neutral Earth Resistor Test Report

Variable Drive Test Report (Sht 1)

Variable Drive Test Report (Sht 2)

Metering Indicator Test Report

Cabinets - Acceptance Report

Local Control Panel - Acceptance Report

Junction Box Inspection Report

LV Switchgear Inspection Report

Differential Protection Relay Test Report

Voltage Transformers (and UV Relay) Test Report

Voltage Transformers (and UV Relay) Test Report

Alarm System Inspection Report

TEC TAG

Request For temporary Electrical Supply Modificati

Voltmeter Site Test Report

Ammeter Site Test Report

Flash and Meggar Test for Air Circuit Breakers

Millivolt Drop Test Report

Syncronisation Relay Test Report

Busbar Torque Test Report

Section Description(15) Painting

Form Description

Painting Completion Report

Paint Acceptance Report

Section Description(16) Insulation

Form Description

Insulation Completion Report

Handling of Asbestos Check Sheet

Section Description(17) Punch Listing

Form Description

Construction Punch List

Commissioning Punch List

DRP001-OUF-PRO-L-000-003 Page 21 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 3 - INSPECTION & TEST CERTIFICATES (CONT.)

Section Description(18) Acceptance and Handover

Form Description

Mechanical Completion Certificate

System Acceptance Certificate

Mechanical Completion Certificate

Turnover Dossier Contents

Turnover Dossier System Description

Turnover Dossier Electrical Certification

Mechanical Completion Certificate Hook Up

Turnover Dossier Instrument Certification

Turnover Dossier Mechanical Equipment

Mechanical Completion Certificate - Module

SCCPD Omission Report

Turnover Dossier Painting and Insulation Certifica

Turnover Dossier Piping Certification

Notification of System Walkdown - Commissioning

Precommissioning Concession Request

Turnover Dossier Relief Valve Certification

Turnover Dossier System Certification

Requirement for System Reworks (Construction)

Notification of System Walkdown (Construction)

Notification and System Walkdown (Validation)

DRP001-OUF-PRO-L-000-003 Page 22 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN

SAMPLE

SITE QUALITY CONTROL PLAN

Master

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No. : 0 DISCIPLINE :-- SITE OCCUPATION

SECTION NO :-- 0.0 SUB ACTIVITY :-- SITE OCCUPATION

ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

ACTIVITY DETAIL

NUMBER ACTION PERSON FREQUENCY DOCUMENT

1 Determine/Accept W* Chief Field On Letter

setting out baseline Engineer Occupation of

the Work Site

2 Release of Primary W* EPC On Letter/Survey report

Bench marks to Representative mobilisation

Contractors of each

contractor

3 Control of Primary R/A* Civil Engineer Weekly Surveyors record

Bench marks points initially,

Monthly or

quarterly

4 Control of H* Civil Engineer Every New

Secondary Setting Point and by

each

foundation or

group of piles.

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 23 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 1 DISCIPLINE CIVIL

SECTION NO: 1.1 SUB ACTIVITY PILING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Release of piles W Civil Engineer To be specified for Calculations

for fabrication pile type

2 Approve Pile H Civil Engineer and Each Yard before Approved Quality

prefabrication Superintendent starting, At start, and Plan and inspection

operation every 2v weeks and test plans

3 Release of Piles W Civil Superintendent Every Shipment FW Release Note

to site

4 Check Pile H* Civil Superintendent One pile per rig per Survey reports

locations and day

release for

driving

5 Pile driving R/A* Civil Superintendent All piles

records --- driven

piles

6 Pile driving R/A* Civil Superintendent All piles

records --- bored

piles

7 Pile driving R/A* Civil Superintendent All piles

records --- bored

steel shell

8 Pile integrity H Civil Superintendent All piles

tests

9 Load test W Civil Superintendent All tested piles

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 1 DISCIPLINE CIVIL

SECTION NO: 1.2 SUB ACTIVITY SOILS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Excavation S Civil Superintendent Once per work area

per week

2 Soil S Civil Superintendent Once per work area

compaction per week

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 24 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 1 DISCIPLINE CIVIL

REINFORCED

SECTION NO: 1.3 SUB ACTIVITY

CONCRETE

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Reinforced S Civil Engineer Each work piece

concrete works

check out

2 Foundation S* Civil Engineer and All major

checking before Superintendent foundations, 10%

pour release others

3 Concrete pour W Civil Superintendent All major

release foundations, 10%

others

4 Concrete cube R/A Civil Superintendent All cube results

test results

5 Concrete cube R/A Civil Superintendent All cube results

test summary

6 Foundation W* Civil & Mechanical All major

release Superintendents foundations, 10%

others

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 1 DISCIPLINE CIVIL

SECTION NO: 1.4 SUB ACTIVITY DRAINAGE

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Underground S Civil Superintendent Each system

services/drainage installed

inspection

2 Drainage testing W Civil Superintendent All tests

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 25 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 1 DISCIPLINE CIVIL

SECTION NO: 1.5 SUB ACTIVITY MISCELLANEOUS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Earthworks, S Civil Superintendent Each section

roadworks and completed

paving

2 Excavations S Civil Superintendent Each section

and preformed completed

trenches

3 Chimney S Civil Superintendent Each chimney

inspection

4 Grouting W Civil Superintendent Each item of

equipment

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 2 DISCIPLINE STEELWORK

SECTION NO: 2.0 SUB ACTIVITY STEELWORK

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Steelwork S Steelwork Each structure

fabrication Superintendent

2 Erection of S* Steelwork Each structure

unspliced Superintendent

steelwork

3 Erection of S* Steelwork Each structure

spliced Superintendent

steelwork

4 Erection of steel S* Steelwork Each building

framed building Superintendent

5 Erection of S* Steelwork Each section of rack

piperack Superintendent

6 Steelwork W* Steelwork Each structure

release Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 26 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 3 DISCIPLINE BUILDINGS

SECTION NO: 3.1 SUB ACTIVITY STRUCTURE

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Building works S Civil Superintendent Each phase of

inspection construction

2 Building W Civil Superintendent Each building

inspection

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 27 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 3 DISCIPLINE BUILDINGS

SECTION NO: 3.2 SUB ACTIVITY HVAC & SERVICES

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Air conditioning S HVAC Superintendent Each unit

unit inspection

2 Air conditioning S HVAC Superintendent Each heater

heater unit

inspection

3 Air handling unit S HVAC Superintendent Each air handling

inspection unit

4 Air conditioning S HVAC Superintendent Each refrigeration

refrigeration unit unit

inspection

5 Air conditioning S HVAC Superintendent Each air filter

filter inspection

6 Air conditioning S HVAC Superintendent Each humidifier

humidifier

inspection

7 Ductwork S HVAC Superintendent Each section of

inspection ducting

8 HVAC damper S HVAC Superintendent Each damper

inspection

9 Fire damper S HVAC Superintendent Each damper

inspection

10 Air conditioning W HVAC Superintendent Each air

unit test conditioning unit

11 Heater unit test W HVAC Superintendent Each heater unit

12 Air handling unit W HVAC Superintendent Each air handling

test unit

13 Air filter test W HVAC Superintendent Each air filter

14 Humidifier test W HVAC Superintendent Each humidifier

15 Ductwork leakage W HVAC Superintendent All ducting

test

16 System balance W HVAC Superintendent Once per

test completed system

Grille and diffuser HVAC Superintendent Once per

17 test W completed system

18 Smoke and Halon W HVAC Superintendent Each room

test of pressurised

room

19 Room W HVAC Superintendent Each room

pressurisation test

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 28 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 4 DISCIPLINE EQUIPMENT

SECTION NO: 4.1 SUB ACTIVITY GENERAL

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Acceptance of W* Mech. Superintendent All items of

foundations for equipment

landing equipment

2 Acceptance of W* Mech. Superintendent All items of

steelwork for equipment

landing equipment

3 Release of W Mech. Superintendent All items of

equipment for equipment

grouting

4 Pressure vessel W Mech. Superintendent All pressure vessels

closure

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 4 DISCIPLINE EQUIPMENT

SECTION NO: 4.2 SUB ACTIVITY TOWERS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Tray test W Mech. Superintendent All towers with trays

2 Tower acceptance S Mech. Superintendent All towers

inspection

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 4 DISCIPLINE EQUIPMENT

SECTION NO: 4.3 SUB ACTIVITY DRUMS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Structured packing S Mech. Superintendent All drums with

inspection structured packing

2 Packed bed S Mech. Superintendent All drums with

inspection packed beds

3 Drum acceptance S Mech. Superintendent All drums

inspection

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 29 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 4 DISCIPLINE EQUIPMENT

SECTION NO: 4.4 SUB ACTIVITY EXCHANGERS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Shell and tube W Mech. All shell and tube

exchanger Superintendent exchangers

inspection

2 Air fin W Mech. All air fin

exchanger fan Superintendent exchangers

alignment

3 Air fin W Mech. All air fin

exchanger Superintendent exchangers

inspection

4 Plate exchanger W Mech. All plate

inspection Superintendent exchangers

5 Flare tip W Mech. Each flare tips

installation Superintendent

inspection

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 30 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 4 DISCIPLINE EQUIPMENT

SECTION NO: 4.5 SUB ACTIVITY MECH. EQUIPMENT

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Centrifugal W Mech. All centrifugal

pump installation Superintendent pumps

inspection

2 Reciprocating W Mech. All reciprocating

pump installation Superintendent pumps

inspection

3 Gear unit W Mech. All gear units

installation Superintendent

inspection

4 Centrifugal & W Mech. All compressor

axial Superintendent units

compressor

inspection

5 Rotary and W Mech. All compressor

screw Superintendent units

compressor

inspection

6 Reciprocating W Mech. All compressor

compressor Superintendent units

installation

inspection

7 Refrigeration W Mech. All compressor

compressor Superintendent units

installation

inspection

8 Blower W Mech. All blowers

installation Superintendent

inspection

9 Steam turbine W Mech. All steam turbines

installation Superintendent

inspection

10 Mixer installation W Mech. All mixers

inspection Superintendent

11 Equipment cold W Mech. All rotating

alignment test Superintendent equipment

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 31 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 5 DISCIPLINE PIPING

SECTION NO: 5.1 SUB ACTIVITY UNDERGROUND

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Non-metallic W Civil Superintendent Each system or

piping section thereof

inspection

2 Metallic piping W Civil Superintendent Each system or

inspection section thereof

3 Pre test W Piping Supervisor Each section

Inspection before testing,

wrapping and

burial

4 Pre test W Welding Engineer Each section

Welding before testing,

Inspection wrapping and

burial

5 Pipework W Piping Supervisor Each Test Pack

Testing

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 5 DISCIPLINE PIPING

SECTION NO: 5.2 SUB ACTIVITY ABOVE GROUND

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Isometric I Piping Each Iso

Acceptance Superintendent

2 Pre-test W Piping Each test pack

inspection Superintendent

3 Pipework testing W Piping Each test pack

Superintendent

4 Test pack W Piping Each test pack

reinstatement Superintendent

5 System flushing W Piping Each system

pre-inspection Superintendent flushed

6 System flushing W Piping Each system

Superintendent flushed

7 Relief valve W Piping Each relief valve

installation Superintendent

inspection

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 32 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.1 SUB ACTIVITY CABLING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 600/1000 volt W Electrical First cables @

cable testing Superintendent 50% Reducing to

10% sample

2 High voltage W Electrical Each cable

cable testing Superintendent

3 Multicore cable W Electrical First cables @

testing Superintendent 50% Reducing to

10% sample

4 Cable trench S Electrical All HV cables,

backfilling Superintendent 20% random

others

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.2 SUB ACTIVITY EARTHING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Earth testing S Electrical First Tests 100%

Superintendent then 20% random

2 Earth loop W Electrical First loops @ 50%

impedance Superintendent Reducing to 10%

testing sample

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.3 SUB ACTIVITY EQUIPMENT INSTALLATION

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Installation in W Electrical First Items 100%

safe area Superintendent Reducing to 10%

inspection

2 Installation in W Electrical First Items 100%

hazardous area Superintendent Reducing to 10%

inspection

3 Switchboard W Electrical All switchboards

inspection Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 33 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.4 SUB ACTIVITY EQUIPMENT TESTING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Switchboard W Electrical All switchboards

and busbar Superintendent

testing

2 Electrical W Electrical First Items 100%

distribution Superintendent Reducing to 10%

board testing

3 UPS testing W Electrical Each UPS system

Superintendent

4 Voltage W Electrical Each relay

sensitive relay Superintendent

testing

5 Battery charger W Electrical Each charger

testing Superintendent

6 Insulating oil R Electrical All test reports

testing Superintendent

7 Transformer W Electrical Each transformer

testing Superintendent

8 Primary W Electrical All tests

injection testing Superintendent

9 CT and W Electrical All tests

protection relay Superintendent

testing

10 CT and W Electrical All tests

protection relay Superintendent

'mag' testing

11 P&B thermal W Electrical All tests

overload Superintendent

testing

12 Contactor W Electrical All tests

starter testing Superintendent

13 Motor running W Electrical All motors

test Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 34 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.5 SUB ACTIVITY LIGHTING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Lighting circuit S Electrical First Circuits

inspection Superintendent 100% then 20%

random

2 Area W Electrical All tests

illumination Superintendent

value testing

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 35 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 6 DISCIPLINE ELECTRICAL

SECTION NO: 6.4 SUB ACTIVITY MISCELLANEOUS

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Trace heating W Electrical All tests

circuit testing Superintendent

2 Electric motor R Electrical All motors

care and Superintendent

protection

inspection

3 Cable tray and I Electrical First trays and

racking Superintendent racks 100% then

installation 20% random

inspection

4 Control circuit W Electrical All circuits tested

function testing Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 36 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 7 DISCIPLINE INSTRUMENTS

SECTION NO: 7.1 SUB ACTIVITY INSTALLATION

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Field instrument W Instrument First Installations

installation Superintendent 100% Reducing to

inspection 10%

2 Instrument piping W Instrument All field

installation Superintendent instruments

3 Installation in W Instrument First Installations

hazardous area Superintendent 100% Reducing to

inspection 10%

4 Intrinsically safe W Instrument All installations

system Superintendent

inspection

5 Enclosure W Instrument First Enclosures

inspection Superintendent 100% Reducing to

10%

6 Fire and gas W Instrument All systems

systems Superintendent

inspection

7 Tray and racking I Instrument First trays and

inspection Superintendent racks 100% then

20% random

8 On-line stream W Instrument All analysers

analyser Superintendent

installation

9 Cabinet/console W Instrument First Cabinets

inspection Superintendent 100% Reducing to

10%

10 Junction box W Instrument All junction boxes

inspection Superintendent

11 LV switchgear W Instrument All switchgear

inspection Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 37 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 7 DISCIPLINE INSTRUMENTS

SECTION NO: 7.2 SUB ACTIVITY TESTING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Pre-installation W Instrument First Calibration

calibration Superintendent 100% Reducing to

10%

2 Instrument W Instrument All instruments

piping tests Superintendent

3 Instrument loop W Instrument First Cables 100%

cable testing Superintendent Reducing to 10%

4 Intrinsically safe W Instrument All cables

system cable Superintendent

testing

5 Loop testing W Instrument All loops

Superintendent

6 Control valve W Instrument First Control

pre-installation Superintendent Valves100%

calibration Reducing to 10%

Sample

7 Trip and alarm W Instrument All trips and

checking Superintendent alarms

8 Instrument air S Instrument First tests 100%

signal line leak Superintendent then 20% random

testing

9 Instrument air W Instrument All tests

supply pressure Superintendent

test

10 Impulse line W Instrument All tests

pressure testing Superintendent

11 Differential W Instrument All tests

protection relay Superintendent

testing

12 Voltage W Electrical All tests

transformer test Superintendent

13 Relief valve W Electrical All relief valves

setting Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 38 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 8 DISCIPLINE PAINTING

SECTION NO: 8.0 SUB ACTIVITY PAINTING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Paint S Painting First 20% then

acceptance Superintendent 20% random

2 Paint W Painting All systems

completion Superintendent

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 9 DISCIPLINE INSULATION

SECTION NO: 9.0 SUB ACTIVITY INSULATION

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Insulation W Insulation All systems

completion Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 39 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 10 DISCIPLINE WELDING

SECTION NO: 10.0 SUB ACTIVITY WELDING

ACTIVITY ACTIVITY EPC RESPONSIBLE ACTIVITY VERIFYING

NUMBER DETAIL ACTION PERSON FREQUENCY DOCUMENT

1 Weld inspection W Welding Engineer All welding

summary activities

2 NDT inspection W Welding Engineer As required by

request specifications

3 Daily welder R/A Welding Engineer Daily, all welders

performance

records

4 Radiography W Welding Engineer All reports

5 Magnetic W Welding Engineer All reports

particle or dye

penetrant

testing

6 Ultrasonic W Welding Engineer All reports

inspection

7 Post weld heat W Welding Engineer All reports

treatment

8 Approved R/A Welding Engineer All reports

welder control

9 Positive material W Welding Engineer All reports

identification

10 Hardness W Welding Engineer All reports

testing

11 Ferrite testing W Welding Engineer All reports

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 40 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 11 DISCIPLINE STORAGE TANKS

SECTION NO: 11.0 SUB ACTIVITY STORAGE TANKS

ACTIVITY ACTIVITY RESPONSIBLE ACTIVITY VERIFYING

ACTION

NUMBER DETAIL PERSON FREQUENCY DOCUMENT

1 Level, cardinal W* Tankage All tanks

point,orientation Superintendent

and dimension

inspection

2 Bottom/roof W Tankage All tanks

annular welds Superintendent

3 Tank bottom W Tankage All tanks

inspection Superintendent

4 Tank bottom W Tankage All tanks

vacuum test Superintendent

First and final

5 Tank shell S Tankage tiers, random

vertical and radial Superintendent others

checks

6 Visual/NDT of S Tankage First and final

shell welds Superintendent tiers, random

others

7 Visual/NDT of S Tankage 20% random

scar areas Superintendent

8 Miscellaneous S Tankage All tanks

inspections Superintendent

9 Hydrostatic W Tankage All tanks

inspections Superintendent

10 Level recording W* Tankage All tanks

during Superintendent

hydrotesting

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 12 DISCIPLINE REFRACTORY

SECTION NO: 12.0 SUB ACTIVITY REFRACTORY

ACTIVITY ACTIVITY RESPONSIBLE ACTIVITY VERIFYING

ACTION

NUMBER DETAIL PERSON FREQUENCY DOCUMENT

1 Castable linings H Refractory All installation

inspection Superintendent areas

2 Applicator R/A Refractory All applicators

qualification test Superintendent

3 Refractory W Refractory All installation

acceptance Superintendent areas

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 41 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 4 - SITE QUALITY CONTROL PLAN (CONT.)

PROCEDURE MASTER ATTACHMENT No. 0

SECTION No: 13 DISCIPLINE HOT TAPS

SECTION NO: 13.0 SUB ACTIVITY HOT TAPS

ACTIVITY ACTIVITY RESPONSIBLE ACTIVITY VERIFYING

ACTION

NUMBER DETAIL PERSON FREQUENCY DOCUMENT

1 Pre-operation W Piping Each hot tap

check and Superintendent

inspection

2 Hot tap W Piping Each hot tap

acceptance Superintendent

KEY TO ACTION COLUMN : -- H = HOLD - MANDATORY INSPECTING

W = WITNESS - INSPECTION AND TEST AT OWN OPTION

S = SURVEILLANCE – INSPECTION OR OBSERVATION DURING MANUFACTURE WITHOUT

FORMAL NOTIFICATION

R/A = REVIEW/APPROVAL - RESPONSIBLE FOR REVIEWING AND AUTHORISING

SUBMISSIONS

* = VERIFICATION BY INDEPENDENT PROFESSIONAL SURVEYOR REQUIRED

DRP001-OUF-PRO-L-000-003 Page 42 of 43 Rev O1

DUQM REFINERY PROJECT – EPC PACKAGE 2 CONSTRUCTION QUALITY PLAN

ATTACHMENT 5 - EPC INSPECTION RESPONSIBILITIES

ACTIVITY LEVEL RESPONSIBLE PERSON MPP NO.

Receipt of Materials

Steelwork S Steelwork Supervisor

Equipment S Mechanical Supervisor

Piping S Piping Supervisors

Electrical S Electrical Supervisors

Instrumentation S Electrical Supervisors

Paint S Painting Insulation Supervisors

Insulation S Painting Insulation Supervisor

Fireproofing S Steelwork Supervisor

Heater/refractory S Heater Supervisor

Equipment Preservation S Mechanical Supervisor

PMI Reports R Welding Engineers

Weld Consumable Control S Welding Engineers

Welder Qualification R Welding Engineers

Welder Performance S Welding Engineers

NDE Operator Qualifications R Welding Engineers

PWHT Reports R Welding Engineers

Weld Inspections R Welding Engineers

Release Test Pack for Test R Turnover Co-ordinator

Steel Erection Release for follow on trades W Steelwork Supervisor

Equipment erection and release for follow on trades W Mechanical Supervisor