Академический Документы

Профессиональный Документы

Культура Документы

1 Introduction, Gas Turbines, Applications, Types

Загружено:

MostafaEslamiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 Introduction, Gas Turbines, Applications, Types

Загружено:

MostafaEslamiАвторское право:

Доступные форматы

1 Introduction, Gas Turbines, Applications, Types

Gas turbines are engines within which the chemical energy of the fuel is converted

either into mechanical energy in terms of shaft power or into kinetic energy. Gas

turbines that produce shaft power are power generation gas turbines. Gas turbines

that convert the fuel energy into kinetic energy are used for generation of thrust to

propel an aircraft. The conversion of fuel energy into shaft power or propulsive force,

requires interaction of several components of the engine, within each of them a chain

of energy conversion takes place.

Figure 1.1: Alstom heavy duty power generation gas turbine GT13E2 with gross

output of 202.7 MW and a combined cycle efficiency of 53.5%.

1.1 Power Generation Gas Turbines

Consider a power generation gas turbine shown in Figure 1.1. Air from the

environment enters the inlet nozzle, where its total pressure is partially converted into

kinetic energy. After passing through the inlet, air enters a multi-stage compressor,

where its total pressure continuously increases to reach the design pressure ratio at

the exit of the compressor. The increase of total pressure is accomplished by

supplying mechanical energy through the turbine. In this case, one is dealing with a

partial conversion of mechanical energy into potential energy. Based on the

compression pressure ratio, the working medium air leaves the compressor exit at a

relatively high total temperature and total pressure. It enters the combustion chamber,

where fuel is added. Within the combustion chamber an intensive combustion process

takes place, where the chemical energy of the fuel is converted into thermal energy.

The resulting combustion gas enters a multi-stage turbine, where its total energy is,

© Springer International Publishing AG 2018 1

M.T. Schobeiri, Gas Turbine Design, Components and System

Design Integration, DOI 10.1007/978-3-319-58378-5_1

2 1 Introduction, Gas Turbines, Applications, Types

to a great extent, converted into mechanical energy. The process of energy conversion

continues within the exit diffuser (not visible in Figure.1.1), where the kinetic energy

of the exiting gas is partially converted into potential energy. The energy conversion

process that takes place in individual components is always associated with certain

total pressure losses causing entropy increase that leads to efficiency decrease. The

energy conversion process discussed above is inherent to all power generation gas

turbine irrespective of their power size, types and configurations. Similar components

are found in Figure 1.2 and all power generation gas turbines .

Figure 1.2: A General Electric heavy duty gas turbine with its major

components.

The gas turbine configurations shown in Figure 1.1 and 1.2 are characterized by

having one multi-stage compressor, one multi-stage turbine and one shaft that caries

both compressor and turbine blades. The pressure increase inside the compressor is

established by several stages, each of which comprises a stator and a rotor blade row.

Total pressure increase is established by compressor rotor row only, while the stator

row increases static pressure thus reducing velocity. The stator also provides the

necessary flow deflection for the rotor row which receives mechanical energy input

from the turbine. Figure 1.3 shows a Siemens SGT5-4000F gas turbine with the

compressor and turbine stages. Its annular type combustion chamber has several fuel

injectors that are distributed equidistantly in circumferential direction. The annular

configuration of the combustion chamber serves a more uniform temperature

Вам также может понравиться

- Gas Turbine Power Plant PresentationДокумент126 страницGas Turbine Power Plant Presentationjehadyam100% (1)

- Gas Turbine MaintenanceДокумент146 страницGas Turbine MaintenanceMamoun1969100% (9)

- JET ENGINE FundamentalsДокумент18 страницJET ENGINE FundamentalsHareesha N GОценок пока нет

- Pump System CurveДокумент133 страницыPump System Curvemohamed abd eldayem0% (1)

- Gas Turbine Performance by Rainer KurzДокумент16 страницGas Turbine Performance by Rainer KurzSulzerRuudОценок пока нет

- CSP 07 Ventilation Study Questions Rev004Документ4 страницыCSP 07 Ventilation Study Questions Rev004Shakeb RahmanОценок пока нет

- Gas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine EngineДокумент22 страницыGas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine Engineام البنين الرياني100% (1)

- Gas Turbine Performance: by Rainer KurzДокумент16 страницGas Turbine Performance: by Rainer Kurzthryee100% (1)

- Gas Turbine Power PlantДокумент7 страницGas Turbine Power PlantYuvraj GogoiОценок пока нет

- Gas Turbines Definition Applications Working Components Types Design Advantages PDFДокумент13 страницGas Turbines Definition Applications Working Components Types Design Advantages PDFSaadi DzОценок пока нет

- Gas Turbine Fuel ConsiderationsДокумент21 страницаGas Turbine Fuel Considerationsioan1946100% (3)

- The Art of Reading PFD and P&IDДокумент60 страницThe Art of Reading PFD and P&IDBolarinwa90% (10)

- Performance of Industrial GasturbinesДокумент28 страницPerformance of Industrial Gasturbinessomporn duangbuntaoОценок пока нет

- Gas Engine FundamentalsДокумент13 страницGas Engine Fundamentalsherdin56Оценок пока нет

- V005t15a001 88 GT 150Документ13 страницV005t15a001 88 GT 150Antonio CilindroОценок пока нет

- Introduction To Gas Turbine: 1. Operating PrincipleДокумент6 страницIntroduction To Gas Turbine: 1. Operating PrincipleMuhammad Ridhwan100% (2)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Документ4 страницыCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezОценок пока нет

- TurbineДокумент9 страницTurbineKabir Bashir ShariffОценок пока нет

- Gas TurbineДокумент53 страницыGas TurbinedipakbagОценок пока нет

- Combined Cycle, Combined Cycle With Heat Recovery..Документ4 страницыCombined Cycle, Combined Cycle With Heat Recovery..abdul100% (1)

- Steering System: Learning ObjectivesДокумент14 страницSteering System: Learning ObjectivesKJDNKJZEFОценок пока нет

- How Gas Turbine Power Plants WorkДокумент6 страницHow Gas Turbine Power Plants Workchella2705100% (1)

- Air and Fuel Induction - FiveДокумент35 страницAir and Fuel Induction - FiveasfsaedgarОценок пока нет

- 2.3.1 GT FundamentalsДокумент30 страниц2.3.1 GT FundamentalsSarah CohenОценок пока нет

- Gas Power CyclesДокумент9 страницGas Power CyclesWaqar YusufОценок пока нет

- Gas Turbine DescriptionДокумент8 страницGas Turbine DescriptionSIVAPATHASEKARANОценок пока нет

- Steam Power PlantДокумент10 страницSteam Power PlantJoel DaleОценок пока нет

- Energy Systems: Gas Turbine System IДокумент14 страницEnergy Systems: Gas Turbine System IAbhiОценок пока нет

- Class Test and EvaluationДокумент9 страницClass Test and EvaluationJared AngОценок пока нет

- 18 Gas Turbine Engines, Design and Dynamic PerformanceДокумент2 страницы18 Gas Turbine Engines, Design and Dynamic PerformanceEmerovsky ReyesОценок пока нет

- Lesson 1 CorrectionДокумент5 страницLesson 1 CorrectionAlyanna AngelesОценок пока нет

- Thermodynamic Evaluation of The Performance of A Combined Cycle Power PlantДокумент11 страницThermodynamic Evaluation of The Performance of A Combined Cycle Power PlanthansleyОценок пока нет

- 2013 02 Working of Gas TurbineДокумент3 страницы2013 02 Working of Gas TurbinetpplantОценок пока нет

- Gas TurbinesДокумент22 страницыGas Turbineswayzodeneeraj100% (1)

- GALGALLA - Working Assignment 3 - Gas TurbineДокумент5 страницGALGALLA - Working Assignment 3 - Gas TurbineGodfrey Jr Jr.Оценок пока нет

- The Gas Turbine Cycle: Hello Read ItДокумент4 страницыThe Gas Turbine Cycle: Hello Read ItSanooj N J KurupОценок пока нет

- 18me42 Atd Module 2Документ23 страницы18me42 Atd Module 2Shaik SulemanОценок пока нет

- Energy Savings Through Electric-Assist Turbocharger For Marine Diesel EnginesДокумент6 страницEnergy Savings Through Electric-Assist Turbocharger For Marine Diesel EnginesmasoudОценок пока нет

- Steam EffДокумент4 страницыSteam EffViola ZakariaОценок пока нет

- Gas Power CycleДокумент49 страницGas Power CycleNafisa AnikaОценок пока нет

- Gas Turbine System & PropulsionДокумент35 страницGas Turbine System & PropulsionnaveedsidhuОценок пока нет

- Introduction To CCPP by BABДокумент27 страницIntroduction To CCPP by BABBilawal AhmedОценок пока нет

- Gas Turbine Power PlantДокумент14 страницGas Turbine Power PlantBouhadОценок пока нет

- Chapter 1 - Introduction - Pages 1 To 45Документ45 страницChapter 1 - Introduction - Pages 1 To 45Carlos AraujoОценок пока нет

- Principles of Jet and Fan Engine Operation - 20141012 - SДокумент9 страницPrinciples of Jet and Fan Engine Operation - 20141012 - SGurunath AeroОценок пока нет

- Literature Review: 2-1 Basic Gas Turbine OperationДокумент21 страницаLiterature Review: 2-1 Basic Gas Turbine Operationsundas Shafiq100% (1)

- SantoshДокумент6 страницSantoshSANTOSH DELADIОценок пока нет

- EEC 122 CompleteДокумент34 страницыEEC 122 CompleteAdeniji OlusegunОценок пока нет

- Stirling Cycle and The Ericsson Cycle. They Differ From The Carnot Cycle in That The TwoДокумент2 страницыStirling Cycle and The Ericsson Cycle. They Differ From The Carnot Cycle in That The TwoannukiitОценок пока нет

- TheoryДокумент3 страницыTheoryimmacoolcatОценок пока нет

- Expt. 02 Stusy of A Gas Turbine Power PlantДокумент5 страницExpt. 02 Stusy of A Gas Turbine Power PlantSajeeb SarkerОценок пока нет

- Power Plants Lab: Assignment 1Документ3 страницыPower Plants Lab: Assignment 1Faseeh GhaziОценок пока нет

- Generating Electricity With Combustion TurbinesДокумент3 страницыGenerating Electricity With Combustion TurbinesManuel HenriquezОценок пока нет

- Sala FormatДокумент82 страницыSala FormatLemuel ReñaОценок пока нет

- Site Visit Report - Se HauДокумент8 страницSite Visit Report - Se HauLiew Yu LoengОценок пока нет

- Power Plant: Lec. (7) Dr. Omar M. AliДокумент10 страницPower Plant: Lec. (7) Dr. Omar M. AliBalen KarimОценок пока нет

- Conventional Type Combustion: 3.2.1.1-1 IntroductionДокумент9 страницConventional Type Combustion: 3.2.1.1-1 IntroductionDƯƠNG CẨM TOÀNОценок пока нет

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- 12D Series Pump: Three-Screw Pumps Standard Product SpecificationsДокумент2 страницы12D Series Pump: Three-Screw Pumps Standard Product SpecificationsCapacitacion TodocatОценок пока нет

- Chapter 16Документ43 страницыChapter 16Kashan KhanОценок пока нет

- Calculations 2Документ3 страницыCalculations 2LeoОценок пока нет

- Boiler Water Dosing Station 16bar 767922Документ1 страницаBoiler Water Dosing Station 16bar 767922Luigi Angelo Machay ChavezОценок пока нет

- Fans and Blowers: College of Engineering and Technology Department of Mechanical EngineeringДокумент9 страницFans and Blowers: College of Engineering and Technology Department of Mechanical EngineeringKeanu EspinaОценок пока нет

- 347 08Документ2 страницы347 08Ckaal74Оценок пока нет

- Nkgsb-Com-Pr-014-A4-C Commissioning For Fire Water Sprinkle and Spray Nozzle System-RevДокумент19 страницNkgsb-Com-Pr-014-A4-C Commissioning For Fire Water Sprinkle and Spray Nozzle System-Revahmad santosoОценок пока нет

- Safety Relief Valve: Type SRH1, SRH2, SRH3, SRH4 & Srh5Документ2 страницыSafety Relief Valve: Type SRH1, SRH2, SRH3, SRH4 & Srh5Subbarayan SaravanakumarОценок пока нет

- IMI CCI Product VSGIC DesuperheaterДокумент4 страницыIMI CCI Product VSGIC DesuperheaterangeloОценок пока нет

- Unit Iv - Jet Propulsion PDFДокумент4 страницыUnit Iv - Jet Propulsion PDFKeerthi Varman33% (3)

- Presidency University Bengaluru School of Engineering: Test - 2Документ11 страницPresidency University Bengaluru School of Engineering: Test - 2Jit MukherheeОценок пока нет

- GD6003 IO LIST Rev1.0 20211119Документ29 страницGD6003 IO LIST Rev1.0 20211119Trong HuynhОценок пока нет

- DN25F1R - 0.7 BarДокумент3 страницыDN25F1R - 0.7 Barapis21Оценок пока нет

- Scroll Compressor Operating Envelope ConsiderationsДокумент6 страницScroll Compressor Operating Envelope ConsiderationsBehnam AshouriОценок пока нет

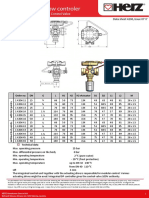

- HERZ-Motorised Flow Controler: Pressure Independant Balancing Control ValveДокумент10 страницHERZ-Motorised Flow Controler: Pressure Independant Balancing Control ValveMahmoud NmiesОценок пока нет

- Remark SN Particulars: Left TOP Front Left TOP FrontДокумент6 страницRemark SN Particulars: Left TOP Front Left TOP FrontPankaj PandeyОценок пока нет

- SES 100R (1450rpm)Документ1 страницаSES 100R (1450rpm)Jaeni GilangОценок пока нет

- Pneumatic Report Mem 665 1Документ13 страницPneumatic Report Mem 665 1Nazif NazriОценок пока нет

- Curriculum Vitae: Post Applied For: Production OperatorДокумент4 страницыCurriculum Vitae: Post Applied For: Production OperatorsureshОценок пока нет

- Sonic Velocity Mach Number PDFДокумент2 страницыSonic Velocity Mach Number PDFShreyasGadkariОценок пока нет

- TMC 49-9 Ewna F029168Документ7 страницTMC 49-9 Ewna F029168Zeevenhooven EquipmentОценок пока нет

- ARO PD01P HKS KAA A 1 4 Inch Non Metallic Diaphragm Pump ManualДокумент4 страницыARO PD01P HKS KAA A 1 4 Inch Non Metallic Diaphragm Pump ManualCarlos FiorilloОценок пока нет

- 373-0849 Winterization GuideДокумент4 страницы373-0849 Winterization GuideHASSAN FAKHOОценок пока нет

- S 6000 ASME Ratio Flanged and Dished HeadsДокумент4 страницыS 6000 ASME Ratio Flanged and Dished Headsdzat_sudrazatОценок пока нет

- Cycle of Coke DrumДокумент3 страницыCycle of Coke DrumNour M.FathyОценок пока нет