Академический Документы

Профессиональный Документы

Культура Документы

Instruction Manual For POC Bushings: Caution

Загружено:

SSDОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Instruction Manual For POC Bushings: Caution

Загружено:

SSDАвторское право:

Доступные форматы

Instruction Manual for POC® Bushings

1. Scope

This instruction contains general procedures to be followed Broken porcelain is

during receiving, installation, storage and maintenance of all EXTREMELY sharp. Gloves

!

PCORE® POC® bushings. This instruction does not cover all must be used when handling

contingencies that may arise during installation, operation, or broken porcelain.

maintenance of such equipment. If you require additional CAUTION

information regarding a particular installation and the

operation or maintenance of your bushing, contact PCORE. 3.2 Conductors

PCORE does not assume any liability or responsibility for Lower current bushings have aluminum conductors and high

any damage or failure that would result from improper current bushings have copper conductors.

transportation, application, installation, storage, or

maintenance. 3.3 Insulation Materials

Standard POC bushings use electrical grade Kraft paper.

2. Safety High temperature bushings use Nomex©, high temperature

These tasks may cause safety hazards if they are not gaskets and o-rings.

performed properly. Those who are responsible for or

3.4 Oil Expansion Tanks

involved in the installation, maintenance, storage and

Three types of oil expansion tanks are used on PCORE

operation of the bushings must read this instruction and

POC bushings: cylindrical sight glass, metal tank with

understand the details before they perform the tasks.

“eyeball” sight glass, metal tank with oil level gage.

Required procedures and instructions must be followed

when installing bushings on apparatus or building (hereafter, 3.5 Oil Level Indicators

any equipment or buildings on which bushings are to be The following are the recommended oil levels at 25°C with

installed will be called apparatus). the bushing in a vertical position. A bushing with either sight

glass should show half full. A magnetic oil level pointer

All applicable safety procedures such as OSHA should indicate 250C.

requirements, regional and local safety requirements, safe

working practices and good judgment must also be used by Slight variation in levels due to ambient conditions can be

personnel when installing, operating and maintaining such expected and are not an indication of oil loss or over filling.

equipment.

3.6 Flanges and Flange Adapter

Some of the hazards associated with these tasks are: Flanges and flange adapters are made of aluminum. For

replacing older bushings or other manufacturers’ bushings,

Lethal electric shock Heavy equipment PCORE offers custom-made flange adapters.

Fire or burning due to high current High pressure

3.7 Terminals

Lifting hazards Hot oil Terminals are copper or brass. Some are silver or tin plated.

Hazards will be identified by the three following categories: 4. Cable Connections

4.1 Bottom Connections

Immediate hazard, which PCORE POC bushings have one of the following bottom

WILL result in SEVERE terminals: Flat spade or threaded stud. The bushings with a

! personal injury, death, or flat spade can be directly connected to the apparatus. The

property damage. bushings with a threaded stud MAY need adapters to

connect to the apparatus.

DANGER

4.2 Draw Lead Connections

Hazard or unsafe practice, Some bushings are designed with a hollow conductor

which MAY result in SEVERE through which a flexible cable or a rod can be pulled. The

cable is a part of the apparatus on which the bushing is

! personal injury, death, or mounted and is not supplied with the bushing. Most draw-

property damage. lead terminals have a flat spade for brazing, crimp type, or

WARNING tubular brazing terminals are available.

4.3 Transformer and Oil Circuit Breaker

Hazard or unsafe practice, Interchangeability

which MAY result in MINOR The 800 ampere draw-lead bushings in the 115 kV through

! 230 kV class can be bottom connected for 1200 ampere

personal injury or property

damage. transformer rating and can also be 1600 ampere bottom

CAUTION connected for oil circuit breaker application.

PCORE POC bushings can provide maximum

interchangeability between transformer and oil circuit

3. Bushing Components breaker applications with the same basic bushing by just

changing some hardware. The current rating for transformer

3.1 Housings application is based on the maximum oil temperature of 95o

The top and bottom insulating housings are made of C while that for the oil circuit breaker application is on the

electrical grade porcelain. The porcelain is completely maximum oil temperature of 800C.

vitrified and is NOT POROUS. Chips or small broken

petticoats WILL NOT affect performance. BROKEN

PORCELAIN DOES NOT NEED TO BE SEALED FROM

MOISTURE.

B-53744 Page 1 of 6 Rev. Date 1-14-16

5. Crates 8. Handling and Installation

Three types of crates are used. Small bushings are shipped

in wire-bound crates. Large bushings are shipped in crates 8.1 Removing Bushings from Crates

with top covers held in place with reusable fasteners. The

88xxx Series 25 kV ~ 69 kV Bushings

top covers of export bushings are nailed. POC bushings in

(Vertical or Horizontal Mounting)

the 15 kV through 69 kV class are shipped in the horizontal

position in crates. The top end of bushings in the115 kV PCORE POC bushings in the 25 kV through 69 kV class can

through 230 kV class are shipped at a 5° to 7° angle to keep be removed from the crate using a nylon choker around the

the paper insulation immersed totally in oil. EHV bushings upper porcelain. Position the bushing vertically, and check

(greater than 230 kV) are shipped in the horizontal position the oil level of the bushing before installation.

in crates because they are too large to keep on an angle.

6. Receiving and Incoming

Inspections

You should perform a visual inspection on the crate and the

bushing before unloading. When unloading crates, you must

take extreme care not to damage the crates or the bushings.

Do not drop the bushings. The bushings should be

unpacked in a flat, dry area

To open the wire bound crate, the twisted wires should be

straightened with pliers. The clips (on crates with reusable

clips) can be removed using a claw hammer. Remove any

nailed covers carefully to avoid damage.

Generator Step-Up (GSU) Bushings

Some crates contain separate boxes containing special PCORE GSU bushings must be removed from the crate

terminal adapters, bottom shields, oil reservoir tanks for while in the horizontal position. The center of gravity is not

horizontally mounted bushings, draw-lead extensions or at the flange so a double sling must be placed between the

other special parts. These special parts should also be porcelain at the air end of the bushing and the porcelain on

checked for damage from shipment. the oil end of the bushing. Once the bushing is removed

from the crate and placed horizontally on a pad, eyebolt may

Examine the porcelain for cracks or chips. Check all seals be attached to the top terminal to lift the bushing from

for oil leakage. Although surface oil is removed from the horizontal to vertical and into the apparatus.

bushing after electrical testing, occasionally a gasket seal

may weep an oil film when received. To check for gasket

seal leakage, wipe the suspected joints clean and observe

for a period of 48 hours. If oil leakage is detected, contact

the factory at Le Roy. Any special parts should be checked

for damage.

If shipping damage is evident, you must file a claim with the

transportation carrier and notify PCORE of the claim

immediately.

7. Storage

The preferred way of storing bushing is to keep them vertical

in a proper stand, which cannot be tipped over. The

preferred location is indoors, however bushings may be

stored outdoors. The crates are not made for extended

outdoor storage; inspect the crates periodically for weather

damage. It is important that the paper core be completely

submerged in oil. Eyebolts must be placed in

the vertical terminals only,

Small bushings, shipped in wire-bound crates may be stored

! lifting from the horizontal

vertically in the crates, as long as they are kept indoors. terminal may cause damaged

CAUTION to the terminal alignment.

Bushings shipped in crates at an angle can be stored on a

flat surface in the shipping crate. Do not attempt to lift bushing

from the shipping crate by the

The top end of larger bushings (greater than 230kV) and top terminal alone. The angle

low-voltage, high current bushings (25 kV through 69 kV) of the flange in the shipping

should be raised about 7 degrees. The bottoms of crates for crate may cause binding and

EHV bushings must be supported in several places to

extreme cantilever loading on

prevent crate damage. ! the terminal, which may cause

For long term outside storage, moisture or water may gather damaged to the bushing.

inside the protective plastic bag that covers the upper and

DANGER

lower porcelain. Suitable protection, such as water-repellent Do not use a single sling

grease should be provided for top and bottom terminals, and around the top porcelain shed

mounting hardware to protect the contact area from as a means of lifting. This

corrosion. Under these conditions, the voltage tap housing unbalance may cause severe

should be filled with clean, dry transformer oil. This will

pressure against the porcelain

prevent condensation and corrosion of the threads.

shed.

B-53744 Page 2 of 6 Rev. Date 1-14-16

115 kV ~ 800 kV Bushings

These PCORE POC bushings are provided with lifting eyes

in the flange. Because of the size and weight of the

bushings, they may require special handling. Before lifting a

bushing, remove any mounting flange bolts holding the

bushing in the crate and any other method of support which

may be used to secure the bushing.

The main lifting tackle should always be attached to the

flange lifting eyes. A second crane hook must be attached to

a double sling with a choker rope tied around the bottom of

the top porcelain.

115 kV through 230 kV class bushings

Tie two choker ropes around the top porcelain under the top

petticoat. Attach two slings to one crane hook. Pass the

other end of the sling through the eyes of each choker rope.

Attach a shackle to each of these ends. Connect the

shackles to the lifting eyes of the mounting flange 180

degrees apart.

Pass a sling through eyes of mounting flange and attach

both ends to the second crane hook. If it is not easy to pass

the sling through the eyes of the flange, you may tie a

choker rope with a sufficient strength under a petticoat

close to the bottom petticoat. Attach a sling to the second

crane hook. Attach the end of choke rope to the hook.

Lift the bushing by raising both crane hooks simultaneously

maintaining the air end of the bushing slightly above the oil

end until ready to lower the oil end of the bushing.

Under certain conditions it may be advantageous to remove

the bushing from the crate first to accommodate placement

of the choker sling or placement of shackles on the flange.

Under these conditions a sling or choker around the

porcelain is acceptable and a sling through the flange lifting

eyes would be adequate to raise the bushing and maintain a

slight angle. The bushing can be removed and placed on

adequate support, which will keep the air end raised while

adjusting the slings and cables.

When ready to lift the bushing for mounting, raise both crane

hooks simultaneously while maintaining the air end at a

slightly higher angle by lowering the crane hook attached

solely to the flange. The entire weight of the bushing will be

held by the two slings through the choker and attached to

the flange lifting eyes. The angle of orientation can be

adjusted by the raising and lowing of each crane.

Do not place a choker sling or rope

above the top shed between the

! porcelain and the metal cover. The

metal dome on PCORE bushings

DANGER consists of a spinning and may be

damaged from sling pressure.

345 kV through 765 kV class Do not attempt to lift the

From one crane hook, use two slings or a double sling

! bushing by a sling on the

passed through a spreader bar and attach the lower end of porcelain alone.

the slings to the mounting flange lifting eyes. The spreader

bar is not provided but such a bar must be used. The slings WARNING

should be long enough so when the bushing is vertical the

bushing will pass through and under the spreader bar.

After the bushing is upright, check to ensure the internal

From the second crane hook attach a sling to the choker bushing oil is at the correct height in the sight glass or that

the magnetic oil level indicator is showing the proper oil level.

around the bottom of the top porcelain 90 ° degrees from the

flange lifting eyes. This crane will be used to pivot the

bushing only while the flange crane by way of the spreader

bar will support the main weight of the bushing.

B-53744 Page 3 of 6 Rev. Date 1-14-16

8.2 Cleaning

Bushings should be kept vertically in a secure stand and you After the testing has been completed, reassemble the tap

must remove all dust, grease, oil or particles of packaging cover after coating the “0-ring” lightly with silicone grease

from the bushing with clean dry cloth. Especially the lower and tighten the cap.

porcelain and flange should be wiped clean of dust or dirt to

prevent contamination of transformer oil. Before mounting 8.4 Mounting Bushings

bushings to the apparatus cover, inspect and clean the If the bushings are stored horizontally, it is important to

mounting surfaces of both the bushing and apparatus. remove all entrapped air from the core. Place the bushing in

the vertical position and shake the oil end to force any air

Check the inside wall of draw-lead tube especially when the bubbles out of the core area before Installation. Do not

bushing has been stored outdoors a long time. If it is dirty, apply voltage for at least 24 hours after installation for

remove all the dirt, dust and other foreign materials from the the bushings rated below 230 kV and at least 48 hours

wall. for the bushings in the 230 kV class and above

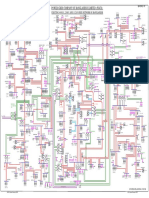

8.3 Electrical Tests 8.4.1 Mounting Angle

PCORE recommends that power factor and capacitance PCORE bushings with oil level sight glasses are designed

measurements be performed on all bushings before for safe operation in vertical position or at angles up to 70

installation. The measured values should be compared with degrees from vertical. Bushings with metal domes using

those on the nameplate. The nameplate values are of magnetic oil level gauges should not be used at angles

special importance in asking PCORE questions about exceeding 30 degrees from the vertical and should be

bushings. The bushing must be kept vertically in a secure mounted with the magnetic oil level gage facing downwards.

stand for the electrical tests. Bushings with metal domes using sight glasses should be

mounted with the sight glass facing sideways (see figure

The methods of measuring power factor and capacitance below). PCORE bushings should not be mounted

are in the user manual of your power factor measuring horizontally unless the bushing is furnished with a

device or consult IEEE Standard C57.152 IEEE Guide for supplementary oil reservoir.

Diagnostic Field Testing of Fluid-Filled Power Transformers,

Regulators, and Reactors. Only C1 power factor and

capacitance have meanings for the 25 kV through 69 kV

class bushings. PCORE recommends against measuring C2

power factor and capacitance of this voltage class bushings

for any purpose.

Do not operate the bushing

without the test tap or voltage

! tap cover in place.

CAUTION

PCORE recommends measuring C1 and C2 power factors

and capacitances of the bushings rated 92 kV and above

prior to the installation. PCORE POC Bushings rated 92 kV

and above use a voltage tap located just above the flange

which is normally grounded in operation by means of a

ground clip in the tap cover. Unless a potential device is

used, this cover must always be installed during operation of

the bushing.

These measurements should agree with the nameplate

values within equipment tolerances and should be kept as 8.4.2 Vertical Mounting

reference readings. When power factor and capacitance Lift the bushings in the same way as removing bushings

readings are in disagreement with nameplate data beyond from the crates. If a flange adapter is required, install it

reasonable tolerances, you should contact the factory at Le before moving the bushing to the mounting hole. Put the

Roy. gaskets and/or o-rings on the apparatus mounting surface

per the apparatus instruction. Move the bushing to the

Never test the bushing while mounting hole of apparatus. Tighten the bolts to the torque

in the shipping crate. specified from the apparatus manufacturer.

8.4.3 Draw-Lead Connection

When possible, place the Bushings designed for draw-lead applications have the

bushing in a grounded test draw lead terminal, nut and pin in place. Before installation,

stand. It is important to isolate you must remove the top terminal, the draw lead nut, the

the flange from the grounded retaining pin and the draw lead terminal. Braze the

stand using a good insulating apparatus cable to the draw lead terminal. Pass a wire or

material. Wood can contain pull cord through the bushing center conductor from the top

significant moisture and and attach it to the hole in the top end of the draw lead

! terminal on the flexible cable. While lowering the bushing

should never be used.

into the opening in the cover, simultaneously pull the cable

CAUTION up through the center conductor. Secure the draw lead

The readings may be taken terminal into the top of the bushing by replacing the retaining

with the bushing installed in pin through the conductor and then replace the draw lead

the equipment provided the nut. A light coating of silicone should be applied to the 0-ring

top terminal connections are of the top terminal before replacing. Refer to the section

not made or the terminal is Bolting and Terminal Torque Settings for terminal tightness.

isolated from the main bus via

a PCORE Test terminal.

B-53744 Page 4 of 6 Rev. Date 1-14-16

Do not operate a bushing with

the bushing oil level not visible

8.4.4 Horizontal Mounting

(88xxx Series: 25 kV ~ 69 kV Bushings) in the sight glass under

The bushings are shipped with the oil reservoir-mounting normal ambient conditions.

hole plugged and with oil at the standard level for vertical This could result in serious

mounting. The oil volume in all bushings fluctuates damage to the bushing and/or

significantly with temperature. PCORE Series 88 bushings apparatus on which the

are designed to operate with air ambient from -500C to

!

bushing is being mounted.

+400C. An oil reservoir tank mounted on the flange of an 88

series horizontally mounted bushing accommodates the oil WARNING Under these conditions,

volume change.

operation may result in severe

It is important to fill and install the bushing properly to personal injury, death or

guarantee long life expectancy. Two things are extremely property damage. It is normal

important. First, all air must be out of the bushing, and for the oil level to drop below

secondly, the oil level must be adjusted properly according

the sight glass in some

to the bushing oil temperature. Failure to follow these

instructions can cause bushing failure. bushings in extremely cold

conditions. Contact PCORE

Before installing the bushing into the equipment (or wall), Electric Company if you have

perform the following steps while the bushing is held any questions.

horizontally

A. Remove the oil filler plug in the stainless steel cover at 8.4.5 Torque Specifications for Bolts

the top of the bushing. Before mounting bushings to the apparatus cover, inspect

B. Add oil through the fill hole in the top cover until the and clean the mounting surfaces of both the bushing and

bushing is completely full. Tip the bushing slightly so the air apparatus. Install the gasket or 0-ring supplied by the

bubble is at the fill hole in the top cover. Fill with oil until apparatus manufacturer. Secure the bushing on the

some oil comes out of the fill hole in the top cover. Use the apparatus cover by tightening all the bolts uniformly in

extra oil supplied with the bushing, or any NON-PCB type I several steps. Do not attempt to pull the bolts down to the

or type II transformer oil. The oil must meet the minimum final setting on the first tightening. It is good practice to

requirements for new transformer oil per IEEE C57.106 allow time between the several tightening steps for the

(latest revision). gasket to set. Care in tightening avoids possible damage or

C. Replace the fill plug in the top cover and tighten slightly distortion of the mounting flange. Normally, the torque

by hand. Rock the bushing back and forth to release all values as listed will provide adequate compression for

entrapped air inside the bushing into the sight glass area. sealing.

Watch the sight glass for air bubbles. Continue rocking until

no the air is being released into the sight glass. More oil may Use the torque recommendations and mounting

have to be added to the bushing. specification of the apparatus manufacturer. Reduce

D. Loosen the oil filler plug in the top bushing cover to torque if gasketed per manufacturing recommendations for

bleed off the entrapped air (air bubble). material being used. Adjust torque for other metals for bolts

E. Add oil to the bushing until oil comes out of the fill hole in flange. Values below are for SAE Grade 1 or 2.

in the top cover. Be sure the fill hole in the top cover is

slightly higher than the bottom of the bushing. BUSHING FLANGE

F. Repeat steps B through E as necessary until the air

Bolt Diameter Torque

bubble that remains inside the sight glass is less than 1/4

(inch) (ft-lb)

inch in diameter. DO NOT STORE THE BUSHING

¾ 105

COMPLETELY FILLED. Any oil expansion could cause the

bushing to leak. 1 200

11/8 250

Install the bushing in the apparatus and perform the

following steps immediately. It is important to keep the DRAW LEADS

bushing in a horizontal position during installation. Current Thread Size Torque

G. Remove the oil reservoir plug from the flange and (ampere) (inch) (ft-lb)

install the oil reservoir. Be sure the O-ring is properly 400 ¾ 20

installed on the reservoir. 800 11/4 40

H. Remove the oil filler plug from the oil reservoir top. IT IS

IMPORTANT TO DETERMINE THE TEMPERATURE OF REMOVABLE TOP TERMINAL

THE OIL IN THE BUSHING BEFORE ADJUSTING THE Torque

LEVEL. THIS MAY BE DIFFERENT THAN THE AMBIENT (ft-lb)

AIR. The best method is to use a dial thermometer or a 80

thermocouple inserted as far into the reservoir as possible.

Try to get into the flange thorough the neck of the reservoir. 8.4.6 Bottom Terminal and Shields

DO NOT USE A GLASS THERMOMETER. Wait a few

If a bottom terminal and or shield is to be installed, use 40 ft-

minutes for the reading to stabilize.

lb for the ½-13 SST. bolts and 20ft-lb torque for the 3/8-16

I. Add oil to the reservoir until the oil level in the reservoir SST. bolts. Pass the cable through the hole in the shield and

is at the proper level. FOR PROPER OIL LEVEL

mount the bottom terminal. Then push the shield to the

INDICATION, THE OIL THAT YOU ADD TO THE

bushing and mount the shield on the bushing.

RESERVOIR SHOULD BE THE SAME TEMPERATURE AS

THE OIL IN THE BUSHING. Use the dip stick to measure 8.4.7 Top Terminals

the oil level. The top mark is for 55°C, the second is 40°C, After power factor and capacitance tests are completed for

the middle for 25°C, the fourth for 10°C, and the bottom for - the apparatus, connect the top terminal for energization.

5°C oil temperature. Interpolation between marks is not

critical. If in doubt, use slightly less oil.

J. Tighten the oil fill plug in the bushing cover and install

the oil fill plug in the oil reservoir top. Make sure the 0-rings

are properly installed and seated on the plugs.

B-53744 Page 5 of 6 Rev. Date 1-14-16

9. Partial Discharge Tests 12. Re-shipping or Returning

PCORE does NOT add a pressurized gas blanket over the Bushings

top of the oil in the bushings. It is possible to encounter

To ship the bushing to another site, you may re-use the

some partial discharges in the sight glass during overvoltage

original crate. Inspect the crate for damage and repair

tests. The partial discharges are a result of a partial vacuum

before using.

formed in the gas space above the oil. The condition occurs

most often after transformer heat-run tests. It can be Bushings with damaged porcelain or sight glasses pose

eliminated by venting the gas space to atmospheric pressure. a significant danger. The entire assembly is under

compressive load, releasing that load suddenly may

cause the bushing to explode. Wrap broken porcelain or

When the bushing is hot, do glasses with duct tape and blankets (Burlap works well).

! NOT remove oil fill plug.

It is recommended that bushings be returned to the factory

for all significant repairs. Inquiries concerning repairs should

be addressed to the factory at Le Roy. You MUST obtain a

CAUTION Return Authorization (RO) number before shipping bushings

or bushing attachments to PCORE. The handling of all

10. Energization requests will be expedited if the factory is furnished the

catalog number and the serial number which are on the

During initial energization, you should monitor oil level

nameplate. The catalog number identifies the bushing rating.

changes. If oil level changes excessively, contact the factory

The first two digits of the serial number are the last two digits

in Le Roy.

of the manufacturing year.

11. Maintenance

Little maintenance is required other than periodically

checking the oil level as indicated in the sight glass or the Do not attempt field repairs.

magnetic oil level gage. Unless a bushing is damaged, the

oil level should remain within the sight glass or indicate A bushing experiencing a core

normal with the oil level gage, fluctuating slightly with problem may have a high

thermal and ambient conditions. pressure and/or hot oil inside.

Do not remove oil fill plug.

Although we discourage the breaking of the seal of the oil-fill !

plug in the bushing reservoir; if the oil level over an observed

period of time remains low and ambient conditions are Bushings are assembled

normal, oil may be added. However, contact the factory in Le WARNING using heavy clamping

Roy first. pressures. A bushing with a

shattered oil sight glass must

Removal of oil filler plug should be done only in a dry

be wrapped with burlap and

atmosphere. Provide oil that meets the IEEE C57. 106

standard for new transformer oil. If there is mechanical duct tape before the bushing

damage to the bushing which results in loss of oil, or the oil is removed from installation.

level in the bushing is still indicating low after the addition of

oil the bushing should be taken out of service.

Never operate or test a

bushing with a low internal oil

! level. Under these conditions,

operation may result in severe

WARNING personal injury, death or

property damage

Bushings exposed to salt spray, cements dust, and other

abnormal contamination deposits are subject to a special

hazard and must be cleaned regularly to prevent flashover

and corrosion of metal parts. The sight glass should also be

cleaned regularly. We endorse and recommend the

measurement of power factor and capacitance at the time of

installation and repeating the measurement regularly. These

values should be used as a base to compare the TRENDS

of future measurements. Field measurements of power

factor and capacitance may differ from measurements made

under the controlled conditions in the factory. Contact the

factory if you encounter any of the following:

A. Measurement of power factor increases to 1.5 times the

original installation value.

B. Measurement of capacitance increases by 10 percent

over the original installation value.

B-53744 Page 6 of 6 Rev. Date 1-14-16

Вам также может понравиться

- The IEE Wiring Regulations Explained and IllustratedОт EverandThe IEE Wiring Regulations Explained and IllustratedРейтинг: 4 из 5 звезд4/5 (14)

- Underwater Cutting Products Operating InstructionsДокумент8 страницUnderwater Cutting Products Operating InstructionstubjackieОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- p220 en Inb43Документ10 страницp220 en Inb43Sambit MohapatraОценок пока нет

- Insulation Co-ordination in High-voltage Electric Power SystemsОт EverandInsulation Co-ordination in High-voltage Electric Power SystemsРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Broco Uw Cutting Products Operating InstructionsДокумент4 страницыBroco Uw Cutting Products Operating Instructionsyassentaha20000Оценок пока нет

- Broco Underwater Cutting Products - Operating Instructions 2019Документ4 страницыBroco Underwater Cutting Products - Operating Instructions 2019DavidОценок пока нет

- Model GB: Instruction ManualДокумент24 страницыModel GB: Instruction ManualEnrique AltuveОценок пока нет

- BMRX Series Rotary Level Control: Operating InstructionsДокумент10 страницBMRX Series Rotary Level Control: Operating Instructionstono notoОценок пока нет

- TES-P-104.04-R0 Splices and Termination of Power CablesДокумент9 страницTES-P-104.04-R0 Splices and Termination of Power CablesSalmanEjazОценок пока нет

- Crosby Manual 7Документ10 страницCrosby Manual 7Salih KaderОценок пока нет

- PDP42V18HAДокумент77 страницPDP42V18HAbobju14Оценок пока нет

- Teromatec 400 English Manual PDFДокумент24 страницыTeromatec 400 English Manual PDFex-2156100% (1)

- Broco Underwater Wet Welding Operating Instructions 2017Документ6 страницBroco Underwater Wet Welding Operating Instructions 2017Mishal SalemОценок пока нет

- Subs4 6 8 - IOM - 7 2016FINALДокумент12 страницSubs4 6 8 - IOM - 7 2016FINALFayez Al-ahmadiОценок пока нет

- Akai Lct32z4adp LCD TV - Service ManualДокумент139 страницAkai Lct32z4adp LCD TV - Service ManualAnibalОценок пока нет

- Doheny Pool PumpsДокумент12 страницDoheny Pool PumpsBenjamin DoverОценок пока нет

- Service Manual For LCT32Z5TAP - AUO - USA (07,13,07)Документ137 страницService Manual For LCT32Z5TAP - AUO - USA (07,13,07)Santiago SanchezОценок пока нет

- Power Wave455m 10942 10957Документ165 страницPower Wave455m 10942 10957Jaime ArreolaОценок пока нет

- Q4100 Igniter Installation ManualДокумент8 страницQ4100 Igniter Installation ManualDejan StevanovicОценок пока нет

- Welding, Cutting and Hot WorkДокумент6 страницWelding, Cutting and Hot WorkyahiyaОценок пока нет

- PC75 123 ManualДокумент72 страницыPC75 123 ManualAndreasОценок пока нет

- Fujifilm FinePix S9000 S9500 Service Manual PDFДокумент147 страницFujifilm FinePix S9000 S9500 Service Manual PDFadamОценок пока нет

- Invertec 200 260 400tДокумент16 страницInvertec 200 260 400tJxyz QwОценок пока нет

- Color Television: 34HF85 34HF85CДокумент51 страницаColor Television: 34HF85 34HF85CStephen HaywardОценок пока нет

- clark-public-utilities-ICEA S-94-649-AEIC CS8Документ21 страницаclark-public-utilities-ICEA S-94-649-AEIC CS8chrisОценок пока нет

- Model MCS: Instruction ManualДокумент24 страницыModel MCS: Instruction ManualDyddier Rojas100% (1)

- Color Television: 27AF46CAДокумент45 страницColor Television: 27AF46CASalvador CarreraОценок пока нет

- EHVT 69kv Class PII With FoilДокумент9 страницEHVT 69kv Class PII With FoilAntonio GresiaОценок пока нет

- Pyro Mi Specifiers GuideДокумент12 страницPyro Mi Specifiers Guideashley_moseley1918Оценок пока нет

- Guide To The Specification and Installation of Pyro Mi Wiring CablesДокумент12 страницGuide To The Specification and Installation of Pyro Mi Wiring CablesNarendra Reddy BhumaОценок пока нет

- Suggested Installation Equipment (Not Supplied With Kit) Safety InstructionsДокумент3 страницыSuggested Installation Equipment (Not Supplied With Kit) Safety InstructionsNawal SahraniОценок пока нет

- Bomba Jockey Vertical SumergibleДокумент24 страницыBomba Jockey Vertical SumergibleManuelMartinezОценок пока нет

- Lincoln IM556Документ28 страницLincoln IM556eudoОценок пока нет

- Magnum Prothru The Arm Robotic TorchДокумент29 страницMagnum Prothru The Arm Robotic TorchAnton KiryakovОценок пока нет

- Ttomahawk 1000: Operator'S ManualДокумент34 страницыTtomahawk 1000: Operator'S Manualanon_592794178Оценок пока нет

- Technical Manual: Service and PartsДокумент73 страницыTechnical Manual: Service and PartsCarlos Gabriel EstergaardОценок пока нет

- MW20FP1Документ103 страницыMW20FP1scotnelsonОценок пока нет

- Bently Housings For Prox Datasheet 141599tДокумент19 страницBently Housings For Prox Datasheet 141599tCecep AtmegaОценок пока нет

- 2ND Quarter - Slm-Week 5Документ23 страницы2ND Quarter - Slm-Week 5Ben Erick CompuestoОценок пока нет

- Electrical Level 4: Medium-Voltage Terminations/Splices 26411-14Документ60 страницElectrical Level 4: Medium-Voltage Terminations/Splices 26411-14Hendrix LevaОценок пока нет

- China pdp42v6 Chassis Pdp4210ea - EtДокумент125 страницChina pdp42v6 Chassis Pdp4210ea - EtGermán BergerОценок пока нет

- SAF Rev 3 June 2018Документ8 страницSAF Rev 3 June 2018DIOGENES HERNANDEZОценок пока нет

- Color Television/ DVD Video Player: Service ManualДокумент68 страницColor Television/ DVD Video Player: Service ManualmiltonjramirezОценок пока нет

- LG DR175, DR165, DR676XДокумент108 страницLG DR175, DR165, DR676XRICARDO ConteОценок пока нет

- Siemens Flex CableДокумент107 страницSiemens Flex CableFateh TabaichountОценок пока нет

- Toshiba-Mw20fp1c - TV+VCR+DVD Video Player SMДокумент102 страницыToshiba-Mw20fp1c - TV+VCR+DVD Video Player SMJames Larry WingОценок пока нет

- 26HF85 Parts, Service ManualДокумент68 страниц26HF85 Parts, Service ManualAnonymous HAFJjiT5VaОценок пока нет

- Toshiba TV 20AF45 - 20AF45C - SVM PDFДокумент50 страницToshiba TV 20AF45 - 20AF45C - SVM PDFcarlos avilaОценок пока нет

- Gast ROA RAA Series Oilless Vacuum PumpДокумент6 страницGast ROA RAA Series Oilless Vacuum Pumpelvisandmick0% (1)

- Operation/ Maintenance ManualДокумент24 страницыOperation/ Maintenance Manualgarden00589Оценок пока нет

- Invertec STT PDFДокумент145 страницInvertec STT PDFAltai OspanОценок пока нет

- Wiring Maintenance Practices - Including Repairing Wire and CableДокумент16 страницWiring Maintenance Practices - Including Repairing Wire and CableRodrigo ArgoteОценок пока нет

- Vantage 500 Cummins 500Документ54 страницыVantage 500 Cummins 500Bladimir Jesus Vasquez AlaveОценок пока нет

- FE 2200 Spark Resistant Fan ConstructionДокумент2 страницыFE 2200 Spark Resistant Fan ConstructionAvery OppegardОценок пока нет

- Commander 400 Svm133bДокумент197 страницCommander 400 Svm133bSebastian Rodrigo Gonzalez MuñozОценок пока нет

- 267 Welding in A Confined Space OTMLДокумент8 страниц267 Welding in A Confined Space OTMLM. KhurramОценок пока нет

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Документ14 страницEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarОценок пока нет

- Brochure Bushing 2016 English 1 PDFДокумент2 страницыBrochure Bushing 2016 English 1 PDFSSDОценок пока нет

- Bushing Replacements For Power TransformersДокумент4 страницыBushing Replacements For Power TransformersSSDОценок пока нет

- Bubble Evolution in Bushings: Bu TransformersДокумент11 страницBubble Evolution in Bushings: Bu TransformersSSDОценок пока нет

- 765 KV, 400 KV, 230 KV & 132 KV Grid Network (Existing, U/C & Planned)Документ1 страница765 KV, 400 KV, 230 KV & 132 KV Grid Network (Existing, U/C & Planned)SSDОценок пока нет

- Power Grid Company of Bangladesh Limited (PGCB)Документ1 страницаPower Grid Company of Bangladesh Limited (PGCB)SSD100% (1)

- Notice For Prebid PDFДокумент1 страницаNotice For Prebid PDFSSDОценок пока нет

- NoticeДокумент1 страницаNoticeSSDОценок пока нет

- BGD 1800 NZSS Volume 2 PDFДокумент382 страницыBGD 1800 NZSS Volume 2 PDFSSDОценок пока нет

- Volume 3 of 3Документ94 страницыVolume 3 of 3SSDОценок пока нет

- Tender NoticeДокумент1 страницаTender NoticeSSDОценок пока нет

- GP 316Документ1 страницаGP 316SSDОценок пока нет

- 3045 NegativeSequence GS 20160122-ReducedДокумент54 страницы3045 NegativeSequence GS 20160122-ReducedSSDОценок пока нет

- Trench OTAAДокумент6 страницTrench OTAASSDОценок пока нет

- 828 040 999 00001Документ1 страница828 040 999 00001SSDОценок пока нет

- KITZ Ball Valve PDFДокумент108 страницKITZ Ball Valve PDFzuhd1pОценок пока нет

- CATALOGUE Power and Heat IndustriesДокумент104 страницыCATALOGUE Power and Heat IndustriesAnonymous zq0b2Ea5Оценок пока нет

- Types of FeltДокумент6 страницTypes of FeltThanhluan NguyenОценок пока нет

- Technical Studies & Research Center Mechanical Technology Branch Mechatronics Graduate Program Machine Element, Course Fall 2008-09Документ30 страницTechnical Studies & Research Center Mechanical Technology Branch Mechatronics Graduate Program Machine Element, Course Fall 2008-09PRASAD326100% (11)

- Us 18-20HPRCДокумент2 страницыUs 18-20HPRCBiniyam12Оценок пока нет

- TeДокумент36 страницTeDCОценок пока нет

- AR05.00-B-5541A.fm Disassemble and Assemble The Rocker Arms Mechanism 14.08.00Документ5 страницAR05.00-B-5541A.fm Disassemble and Assemble The Rocker Arms Mechanism 14.08.00LUKASОценок пока нет

- Mechanical Seamless Tubings: 2-6-1 Marunouchi, Chiyoda-Ku, Tokyo 100-8071 Japan Tel: +81-3-6867-4111Документ14 страницMechanical Seamless Tubings: 2-6-1 Marunouchi, Chiyoda-Ku, Tokyo 100-8071 Japan Tel: +81-3-6867-4111ariОценок пока нет

- Installation and Operation Manual: PG Governor Basic ElementsДокумент32 страницыInstallation and Operation Manual: PG Governor Basic ElementsrОценок пока нет

- Steam Turbine TheoryДокумент58 страницSteam Turbine TheorySaleem QureshiОценок пока нет

- Mazda RX8 Transmission ManualДокумент49 страницMazda RX8 Transmission ManualSpyros Stasinos50% (2)

- Caterpillar: 3400 Series Reuse and Salvage Manual ContentsДокумент5 страницCaterpillar: 3400 Series Reuse and Salvage Manual ContentsRASOUL KHADIBIОценок пока нет

- BearingsДокумент4 страницыBearingsmimОценок пока нет

- Tilting Pad TroubleshootingДокумент7 страницTilting Pad Troubleshootinghamedia83Оценок пока нет

- Accord 2008-2012 EngineДокумент50 страницAccord 2008-2012 EngineAntonio GonzalezОценок пока нет

- Section 8 Cil. Boom, Linde C4230TL PDFДокумент53 страницыSection 8 Cil. Boom, Linde C4230TL PDFrodrigo belardyОценок пока нет

- Experimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialДокумент17 страницExperimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialSuren SirohiОценок пока нет

- Bomba Serie 90 100Документ98 страницBomba Serie 90 100lizbethdioses100% (3)

- Jigs and FixturesДокумент20 страницJigs and FixturesRenjith RajendraprasadОценок пока нет

- DB3, 4, 5 & 5.5 Series Sealless Centrifugal Pumps: Assembly, Installation and Operation ManualДокумент15 страницDB3, 4, 5 & 5.5 Series Sealless Centrifugal Pumps: Assembly, Installation and Operation ManualepigastiОценок пока нет

- Advanced Tribo-Materials For Gears: January 2006Документ12 страницAdvanced Tribo-Materials For Gears: January 2006Rajender KumarОценок пока нет

- Forum Aot Hercules Anchor PDFДокумент26 страницForum Aot Hercules Anchor PDFyesicaОценок пока нет

- Manual QSK19Документ634 страницыManual QSK19Drillco98% (48)

- Axod e Ax4s Ax4n 4F50NДокумент12 страницAxod e Ax4s Ax4n 4F50NHugo Sanchez67% (3)

- Mitsubishi 4DQ5Документ120 страницMitsubishi 4DQ5candongueiro100% (4)

- 8961A050WДокумент15 страниц8961A050WDenis Hernandez100% (1)

- Shell Gadus S2 OG 85Документ2 страницыShell Gadus S2 OG 85Anonymous oAbjbl4HОценок пока нет

- Ramsey Winch H 800 Winch Owner's ManualДокумент24 страницыRamsey Winch H 800 Winch Owner's ManualMartin De BruynОценок пока нет

- Wear of Hydrodynamic Journal BearingsДокумент6 страницWear of Hydrodynamic Journal Bearingskishorghatage89Оценок пока нет

- Track-Type Tractor: XL & LGPДокумент20 страницTrack-Type Tractor: XL & LGPRoussel Florez Zuloaga100% (3)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonОт EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonРейтинг: 5 из 5 звезд5/5 (2)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...От EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Оценок пока нет

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionОт EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionРейтинг: 4.5 из 5 звезд4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosОт EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosРейтинг: 5 из 5 звезд5/5 (1)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsОт EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsОценок пока нет

- Power System Control and ProtectionОт EverandPower System Control and ProtectionB. Don RussellРейтинг: 4 из 5 звезд4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersОт Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersРейтинг: 5 из 5 звезд5/5 (1)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceОт EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceОценок пока нет

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeОт EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeРейтинг: 4.5 из 5 звезд4.5/5 (10)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionОт EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionРейтинг: 4 из 5 звезд4/5 (331)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesОт EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesРейтинг: 5 из 5 звезд5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)От EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Рейтинг: 4 из 5 звезд4/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsОт EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionОт EverandTeach Yourself Electricity and Electronics, 6th EditionРейтинг: 3.5 из 5 звезд3.5/5 (15)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldОт EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldРейтинг: 4 из 5 звезд4/5 (87)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingОт EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingРейтинг: 4 из 5 звезд4/5 (1)