Академический Документы

Профессиональный Документы

Культура Документы

Mettech AXIAL III Thermal Spray Gun Description

Загружено:

chipulinoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mettech AXIAL III Thermal Spray Gun Description

Загружено:

chipulinoАвторское право:

Доступные форматы

Axial III™ Spray System - Advanced Coating Solutions

Axial III Saves You Money

Typical Analysis Axial III Radial

System System

Deposition Efficiency 80% 50%

Feed Rate (g/min) 120 35

Powder costs / kg $75 $75

Powder on part 10 kg 10kg

Powder sprayed 13 kg 20 kg

Powder wasted 3 kg 10 kg

Deposition time 120 min 600 min

The Axial III torch design gives the user a highly Total Operating Cost $ 177 $ 850

flexible, robust, field proven tool that can apply Total Powder costs $ 500 $ 1150

almost any coating. Axially fed powders or Total Costs $ 1115 $ 2350

suspensions ensure consistent heat treatment of

all particles which leads to superior coatings

possible at the most economic results for:

Total Savings 50%

Total Time Reduction 80%

• Wear (abrasion, adhesion, fretting, erosion)

• Thermal Barriers

• Clearance Control (abradables)

• Corrosion / Oxidation

• Electrical (resistance and conductivity)

Benefits

Efficiency and Productivity

• High deposition efficiencies, less powder waste

• High flow rates, reducing job time

• Can spray Ceramics, Cermets and Metals

• Can spray superfine powders

• Savings on powders and operating cost

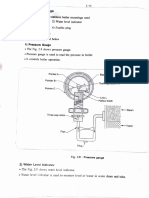

Enhanced Coating Quality Axial III Operation

• No separation of mixed powders in the flame

• No flame deflection from torch axis The Axial III is a 3-anode/3-cathode DC plasma

• Increased process stability torch with powder injection along the central axis.

• Highly stable plasma The plasma streams converge at the point where

the powder or suspension is injected. At this point,

• Denser coatings

the plasma/powder flow is accelerated through a

specially designed nozzle. Particle velocities are

Capabilities

significantly higher than those of other plasma

• Low angle (>15° ) spraying torches and approach those attained with HVOF

• Focused gas and supersonic nozzle designs systems. The resultant coatings are very

• Suspension or solution feed possible consistent, reproducible and of superior quality.

• Reactive materials

• Nano materials

Three-Gas Chemistry Control Equipment

The Axial III Plasma Spray Torch utilizes three Touch screen control panel, with full display

gases: Argon (Ar), Nitrogen (N2), and Hydrogen of process variables, data trending and

(H2). Helium (He) can be substituted for H2. recording, run parameter database, self-

diagnostic tools, all bundled in an industrial

The Axial IIITM can operate using either Argon or grade computer.

Nitrogen as the primary gas. Factory set

maximum flow rates for the gases are:

Control cabinets with segregation between

Ar: 400 l/min water/gas MFC’s and electrical PCL’s, CE marked,

N2: 200 l/min process feedback control, gas pressure

H2: 100 l/min or; He: 140 l/min transducers, water flow and temperature

measurement for system heat balance.

Power Supplies: Proven Industrial design, built-

in high voltage pulse, input voltage protection and

“forced” air-cooled

Axial III Specifications

• Powder Feeding: Axial, carbide-reinforced

injector

• Electrical Power: 50 – 150 kW

• Number of Cathodes: three cathodes

arranged at 120° angles

• Number of Anodes: three

• Plasma Nozzles: 8mm – 25mm

• Maximum Pressure Limit in Arc: 4 bars

• Mixture of Plasma Gas:

− argon

− argon/hydrogen

− argon/nitrogen

Contact Information

− argon/nitrogen/hydrogen

− nitrogen/hydrogen

Northwest Mettech Corp.

• Current Load: 3x30 to 250 amps

#103 – 19335 96 Ave

• Electrode Potential 60 – 200 volts

Surrey, B.C. Canada, V4N 4C4

• Cooling: Water, 50 l/min, 14 bars Tel: 1.604.987.1668

• Adaptor: straight 180°, right angled 90° Fax: 1.604.987.1669

• Special Gun: Axial III internal spraying gun email: info@mettech.com

to 325 mm at 135 kW Website: www.mettech.com

Вам также может понравиться

- MovinCool Spot Cooling CatalogueДокумент16 страницMovinCool Spot Cooling CatalogueKhizerОценок пока нет

- Peace CorpsДокумент218 страницPeace CorpsSomdev Pal100% (1)

- Geotextiles and Geomembranes HandbookОт EverandGeotextiles and Geomembranes HandbookT.S. IngoldРейтинг: 5 из 5 звезд5/5 (1)

- Wind Turbines Need Protecting Against The Effects of HumidityДокумент13 страницWind Turbines Need Protecting Against The Effects of HumiditychipulinoОценок пока нет

- Fundamentals of Vacuum - Short CourseДокумент37 страницFundamentals of Vacuum - Short CoursechipulinoОценок пока нет

- Sni 3554-2015Документ5 страницSni 3554-2015Dewi WulandhariОценок пока нет

- LARE Section 2 Study Guide 2.0Документ4 страницыLARE Section 2 Study Guide 2.0chrisОценок пока нет

- High Temperature Physicochemical Properties of High Alumina Blast Furnace SlagДокумент200 страницHigh Temperature Physicochemical Properties of High Alumina Blast Furnace SlagBernardo Loureiro PattoОценок пока нет

- Tetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsДокумент2 страницыTetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsThinura SamarawickramaОценок пока нет

- Fuel Cell PricesДокумент11 страницFuel Cell PricesengshimaaОценок пока нет

- Component List Efficent InsulationДокумент5 страницComponent List Efficent Insulationnikesh moreОценок пока нет

- Tetra Pak Homogenizer 500: Homogenizer or High Pressure Pump For Liquid Food ApplicationsДокумент4 страницыTetra Pak Homogenizer 500: Homogenizer or High Pressure Pump For Liquid Food ApplicationsKhánh HồОценок пока нет

- Technical Data Sheet - Logiclave™ LAB: DesignДокумент8 страницTechnical Data Sheet - Logiclave™ LAB: DesignharishupretiОценок пока нет

- MovinCool Climate Pro K60 CatalogДокумент4 страницыMovinCool Climate Pro K60 CatalogMiguel VieiraОценок пока нет

- Specs Perkin Elmer 5100Документ3 страницыSpecs Perkin Elmer 5100HamidОценок пока нет

- HPK03Документ4 страницыHPK03Tan CkОценок пока нет

- Benefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksДокумент17 страницBenefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksFebri AndriyudaОценок пока нет

- Ispe Nordic Cop Clean UtilitiesДокумент28 страницIspe Nordic Cop Clean UtilitiesBulent InanОценок пока нет

- Alfa Laval LKH Ultrapure Centrifugal Pump - Product LeafletДокумент8 страницAlfa Laval LKH Ultrapure Centrifugal Pump - Product LeafletHaris Fadillah AlhudaОценок пока нет

- Polycold Edwards Data Sheet Maxcool 4000HДокумент2 страницыPolycold Edwards Data Sheet Maxcool 4000HadrianioantomaОценок пока нет

- Kompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Документ2 страницыKompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Muhammad Sidik BBMОценок пока нет

- H 07 Specsheet v3.1 2015 01 07Документ2 страницыH 07 Specsheet v3.1 2015 01 07murtada gubaОценок пока нет

- May Nen IntermechДокумент2 страницыMay Nen IntermechUchiha SaitamaОценок пока нет

- HRS AF 200 Series Datasheet 2018Документ1 страницаHRS AF 200 Series Datasheet 2018Muneeb AkhtarОценок пока нет

- Hmk03 Duramax Spin-On Filters: Max Flow: 25 GPM (95 LPM)Документ4 страницыHmk03 Duramax Spin-On Filters: Max Flow: 25 GPM (95 LPM)Wilson VelásquezОценок пока нет

- AFT Trolley 50-02Документ2 страницыAFT Trolley 50-02Forum PompieriiОценок пока нет

- AltaBlue Touch Large MeltersДокумент2 страницыAltaBlue Touch Large MeltersPah AraújoОценок пока нет

- AltaBlue Touch Large MeltersДокумент2 страницыAltaBlue Touch Large MeltersPah AraújoОценок пока нет

- Altablue Touch Series Large Format Adhesive MeltersДокумент2 страницыAltablue Touch Series Large Format Adhesive MeltersPah AraújoОценок пока нет

- PSP Uppwd La Mep Hvac 31Документ81 страницаPSP Uppwd La Mep Hvac 31Arise UP ProjectsОценок пока нет

- ESA IB BNDD Technical InformationДокумент2 страницыESA IB BNDD Technical InformationdiogosaborОценок пока нет

- Environmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationДокумент3 страницыEnvironmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationGokulSubramanianОценок пока нет

- AirSep As-Q DatasheetДокумент2 страницыAirSep As-Q Datasheetdj22500Оценок пока нет

- WT 14 - Indirect HeaterДокумент2 страницыWT 14 - Indirect Heatershakouri1370_8902064Оценок пока нет

- Hot Water Heating DevicesДокумент6 страницHot Water Heating Devicesgaga0407Оценок пока нет

- Brochure PAS VAR Dewatering Pumps English v06Документ20 страницBrochure PAS VAR Dewatering Pumps English v06Maximo MartinezОценок пока нет

- Polypropylene Poy Spinning Plant - Yoc 2006 88dtex (80den) POY - Production Capacity 800 Kg/dayДокумент9 страницPolypropylene Poy Spinning Plant - Yoc 2006 88dtex (80den) POY - Production Capacity 800 Kg/dayildalilОценок пока нет

- Tender Doc Vol 3 Page No 827 To 830Документ4 страницыTender Doc Vol 3 Page No 827 To 830Saurabh ChaudhariОценок пока нет

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsДокумент10 страницVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorОценок пока нет

- New: UH310 Series: Athalon High Pressure FiltersДокумент3 страницыNew: UH310 Series: Athalon High Pressure FiltersGustavo FreitasОценок пока нет

- ProcessMaster Data SheetsДокумент2 страницыProcessMaster Data SheetsGenkimanОценок пока нет

- Polymac PH 40Документ2 страницыPolymac PH 40Erick HernandezОценок пока нет

- General Specifications: Section 2Документ2 страницыGeneral Specifications: Section 2lusoegyi 1919Оценок пока нет

- AAS ICE3500 With GF TenderДокумент6 страницAAS ICE3500 With GF Tenderpranjal pandeyОценок пока нет

- MC High Pressure Stage Casing Pump E10026Документ6 страницMC High Pressure Stage Casing Pump E10026Deepak PandeyОценок пока нет

- Nil FiskДокумент12 страницNil FiskharisОценок пока нет

- Polycold Edwards Data Sheet Maxcool 4000HДокумент2 страницыPolycold Edwards Data Sheet Maxcool 4000HAndrea Veronica Hernandez AmatoОценок пока нет

- Smart Coater Technical Specification SheetДокумент4 страницыSmart Coater Technical Specification SheetAbhilash Narayanan100% (2)

- AirSep As-W DatasheetДокумент2 страницыAirSep As-W Datasheetdj22500Оценок пока нет

- Esdti Spray Dryer: The Cost Effective SolutionДокумент4 страницыEsdti Spray Dryer: The Cost Effective SolutionpressОценок пока нет

- Ag HR Seri S: High Rejection Brackish Water RO ElementsДокумент2 страницыAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarОценок пока нет

- Endress-Hauser Promag 55S ENДокумент4 страницыEndress-Hauser Promag 55S ENLwazi HanisiОценок пока нет

- Evaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberДокумент1 страницаEvaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberJorge EpbОценок пока нет

- Sher Plate 600Документ4 страницыSher Plate 6001Оценок пока нет

- Flue Gas Oxygen ProbeДокумент8 страницFlue Gas Oxygen Probepronat89Оценок пока нет

- Hot Water-High Pressure Cleaners: Operating ManualДокумент56 страницHot Water-High Pressure Cleaners: Operating ManualOwen BarnesОценок пока нет

- 785 Parallel Tube: Stirred Liquid BathsДокумент3 страницы785 Parallel Tube: Stirred Liquid BathsHenry Mendez OteroОценок пока нет

- 2-PX NPCU Manifold Data Sheet 20150318Документ2 страницы2-PX NPCU Manifold Data Sheet 20150318Joel FloresОценок пока нет

- AirSep As-R DatasheetДокумент2 страницыAirSep As-R Datasheetdj22500Оценок пока нет

- CharpyCool - Short Spec - Rev 005 - 0916Документ2 страницыCharpyCool - Short Spec - Rev 005 - 0916Sivaraman VisvanathanОценок пока нет

- Cortherm TankДокумент9 страницCortherm TankPely NdОценок пока нет

- Ceiling Cassette Chilled Water Fan Coil Unit - Koppel PDFДокумент2 страницыCeiling Cassette Chilled Water Fan Coil Unit - Koppel PDFatramanathanОценок пока нет

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Документ4 страницы3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizОценок пока нет

- Laser Land Leveller TopconДокумент4 страницыLaser Land Leveller TopconShubham_IndustriesОценок пока нет

- Spirax Trap Review GST - 33 PDFДокумент22 страницыSpirax Trap Review GST - 33 PDFFrank UrsОценок пока нет

- 2022 Iceland BrochureДокумент5 страниц2022 Iceland BrochurechipulinoОценок пока нет

- This Is Poland 1 07 2011Документ57 страницThis Is Poland 1 07 2011chipulinoОценок пока нет

- Secondary Ion Mass SpectrometryДокумент1 страницаSecondary Ion Mass SpectrometrychipulinoОценок пока нет

- RECETAS - Cinnamon RollsДокумент1 страницаRECETAS - Cinnamon RollschipulinoОценок пока нет

- Poland Profile enДокумент5 страницPoland Profile enchipulinoОценок пока нет

- Modular Transformers - Command and Signaling Devices (Modular DIN-Rail Products - ABB)Документ1 страницаModular Transformers - Command and Signaling Devices (Modular DIN-Rail Products - ABB)chipulinoОценок пока нет

- Hitachi ABB Power Grids in Brilon - Transformer Factory Celebrates Its 100th AnniversaryДокумент1 страницаHitachi ABB Power Grids in Brilon - Transformer Factory Celebrates Its 100th AnniversarychipulinoОценок пока нет

- Tidal Corrosion Monitoring of Wind Turbines Using WAND Corrosion CouponsДокумент2 страницыTidal Corrosion Monitoring of Wind Turbines Using WAND Corrosion CouponschipulinoОценок пока нет

- RC Circuits Fundamentals - 2Документ6 страницRC Circuits Fundamentals - 2chipulinoОценок пока нет

- Introduction To Wirewound ResistorsДокумент5 страницIntroduction To Wirewound ResistorschipulinoОценок пока нет

- Electrodes Hand PolishingДокумент4 страницыElectrodes Hand PolishingchipulinoОценок пока нет

- Guard II Electrostatic Shielded Transformers - ABB USДокумент1 страницаGuard II Electrostatic Shielded Transformers - ABB USchipulinoОценок пока нет

- Supercapacitors - User ManualsДокумент101 страницаSupercapacitors - User ManualschipulinoОценок пока нет

- Java Brochure - Overview: Gemalto Simplifies and Speeds The Internet of Things With JavaДокумент4 страницыJava Brochure - Overview: Gemalto Simplifies and Speeds The Internet of Things With JavachipulinoОценок пока нет

- BRO-0006.6 Atmospheric Plasma Solutions ENДокумент20 страницBRO-0006.6 Atmospheric Plasma Solutions ENchipulinoОценок пока нет

- Segmented 8% YSZ Thermal Barrier Coating Solutions Using Cascaded Arc Gun TechnologyДокумент5 страницSegmented 8% YSZ Thermal Barrier Coating Solutions Using Cascaded Arc Gun TechnologychipulinoОценок пока нет

- Metallisation 'S 28E ARCTEC Non-Slip CoatingДокумент3 страницыMetallisation 'S 28E ARCTEC Non-Slip CoatingchipulinoОценок пока нет

- Certified Core Java Developer VS-1036Документ8 страницCertified Core Java Developer VS-1036chipulinoОценок пока нет

- Bicycle Maintenance Made Ridiculously Easy PDFДокумент22 страницыBicycle Maintenance Made Ridiculously Easy PDFchipulinoОценок пока нет

- Delta e PDFДокумент4 страницыDelta e PDFchipulinoОценок пока нет

- Fuji Catalog 2017Документ27 страницFuji Catalog 2017chipulinoОценок пока нет

- Nasa Technical Note: A. R. Timmins Goddard Space Flight Center Greenbelt, MDДокумент20 страницNasa Technical Note: A. R. Timmins Goddard Space Flight Center Greenbelt, MDchipulinoОценок пока нет

- Titan 2017 CatalogueДокумент25 страницTitan 2017 CataloguechipulinoОценок пока нет

- Enhanced Degradation of Persistent Pharmaceuticals Found in Wastewater Treatment Ef Uents Using Tio2 Nanobelt PhotocatalystsДокумент14 страницEnhanced Degradation of Persistent Pharmaceuticals Found in Wastewater Treatment Ef Uents Using Tio2 Nanobelt PhotocatalystsSourav SutradharОценок пока нет

- Design Construction and Testing of A Petroleum Pro PDFДокумент6 страницDesign Construction and Testing of A Petroleum Pro PDFSuit ChetriОценок пока нет

- No Title Page No: IndexДокумент2 страницыNo Title Page No: IndexANONОценок пока нет

- Unit 3 BoilerДокумент17 страницUnit 3 BoilerAnonymous R7wV0zbMОценок пока нет

- Taglus Standard MsdsДокумент8 страницTaglus Standard MsdsRushikesh GhagОценок пока нет

- Allergens Brochure09Документ8 страницAllergens Brochure09AlexSОценок пока нет

- FerrocementДокумент19 страницFerrocementayoushika abrolОценок пока нет

- Nucleophilic Acyl Substitution: The Synthesis of Esters Pre-LabДокумент3 страницыNucleophilic Acyl Substitution: The Synthesis of Esters Pre-LabThea Mae DinoОценок пока нет

- 12 Plate Type Heat ExchangerДокумент3 страницы12 Plate Type Heat ExchangerBharat ThakorОценок пока нет

- Daftar Alat, Biaya Pengujian Dan Operator: TMT 3 September 2016 Jenispengujian Biaya Per Sampel (Rupiah) Operator Ket.Документ6 страницDaftar Alat, Biaya Pengujian Dan Operator: TMT 3 September 2016 Jenispengujian Biaya Per Sampel (Rupiah) Operator Ket.Charis Achmad TajuddinОценок пока нет

- Biology Grade 11 Midterm ReviewДокумент35 страницBiology Grade 11 Midterm Review02-11TH2- Trần Ngọc Ngân AnhОценок пока нет

- Product Catalogue - Melt Flow Indexer MFI - 100Документ3 страницыProduct Catalogue - Melt Flow Indexer MFI - 100AamirMalikОценок пока нет

- Grade 8 Visto Mock Test - 2 (28.09.2022)Документ5 страницGrade 8 Visto Mock Test - 2 (28.09.2022)Anjana100% (1)

- Safe MaticДокумент4 страницыSafe Maticsulai2000Оценок пока нет

- Rousselot 160 LB 8 (Pharma)Документ2 страницыRousselot 160 LB 8 (Pharma)maha guettariОценок пока нет

- IIT JEE Advanced Syllabus 2018 For Chemistry - TopperlearningДокумент4 страницыIIT JEE Advanced Syllabus 2018 For Chemistry - Topperlearningzeeshan khanОценок пока нет

- Rafiullah Khan PHD Thesis PDFДокумент235 страницRafiullah Khan PHD Thesis PDFShehraam MalikОценок пока нет

- Polymers:: Definition: A Polymer Is A LargeДокумент19 страницPolymers:: Definition: A Polymer Is A LargeAbhisek DasОценок пока нет

- Atomic Bonding in SolidДокумент6 страницAtomic Bonding in SolidOjasviОценок пока нет

- Programme of The M.Sc. (Other Than Mathematics, Statistics & Geography) (Part I) ExaminationДокумент4 страницыProgramme of The M.Sc. (Other Than Mathematics, Statistics & Geography) (Part I) ExaminationRajkumar PomajiОценок пока нет

- KLINGERSIL C-4430plus Data SheetДокумент3 страницыKLINGERSIL C-4430plus Data SheetMichael PhamОценок пока нет

- Simulation Investment CastingДокумент19 страницSimulation Investment CastingtwanОценок пока нет

- Density Estimation For Fatty Acids and Vegetable OilsДокумент6 страницDensity Estimation For Fatty Acids and Vegetable OilscymyОценок пока нет

- Chapter 4 Chemical KineticsДокумент60 страницChapter 4 Chemical KineticsYvan Nicholas B. JasminОценок пока нет

- List of Important Metals and Their Ores With Chemical Formulas PDFДокумент2 страницыList of Important Metals and Their Ores With Chemical Formulas PDFAudibleОценок пока нет

- Past Paper Bmat 2020 Section 2Документ24 страницыPast Paper Bmat 2020 Section 2Rayyan BariОценок пока нет

- Family Tree Product Description: Apollo For Construction Chemicals Manufacturing 1 of 3Документ3 страницыFamily Tree Product Description: Apollo For Construction Chemicals Manufacturing 1 of 3Mohammad AburadiОценок пока нет