Академический Документы

Профессиональный Документы

Культура Документы

Design Analysis Fabrication and Testing of Composite Leaf Seminar Report

Загружено:

Manjesh ThilakИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Analysis Fabrication and Testing of Composite Leaf Seminar Report

Загружено:

Manjesh ThilakАвторское право:

Доступные форматы

1

INTRODUCTION

In order to conserve natural resources and economize energy, weight

reduction has been the main focus of automobile manufacturers in the present

scenario. Weight reduction can be achieved primarily by the introduction of better

material, design optimization and better manufacturing processes. The suspension

leaf spring is one of the potential items for weight reduction in automobiles as it

accounts for 10% - 20% of the unsprung weight. This achieves the vehicle with

more fuel efficiency and improved riding qualities. The introduction of composite

materials was made it possible to reduce the weight of leaf spring without any

reduction on load carrying capacity and stiffness. Since, the composite materials

have more elastic strain energy storage capacity and high strength to weight ratio as

compared with those of steel, multi-leaf steel springs are being replaced by mono-

leaf composite springs. The composite material offer opportunities for substantial

weight saving but not always be cost-effective over their steel counterparts.

Dept. of Mechanical Engg. MESCE Kuttippuram

2

LITERATURE REVIEW

Investigation of composite leaf spring in the early 60’s failed to yield the

production facility because of inconsistent fatigue performance and absence of

strong need for mass reduction. Researches in the area of automobile components

have been receiving considerable attention now. Particularly the automobile

manufacturers and parts makers have been attempting to reduce the weight of the

vehicles in recent years. Emphasis of vehicles weight reduction in 1978 justified

taking a new look at composite springs. Studies are made to demonstrate viability

and potential of FRP in automotive structural application. The development of a

liteflex suspension leaf spring is first achieved. Based on consideration of chipping

resistance base part resistance and fatigue resistance, a carbon glass fiber hybrid

laminated spring is constructed. A general discussion on analysis and design of

constant width, variable thickness, composite leaf spring is presented. The

fundamental characteristics of the double tapered FRP beam are evaluated for leaf

spring application. Recent developments have been achieved in the field of

materials improvement and quality assured for composite leaf springs based on

microstructure mechanism. All these literature report that the cost of composite; leaf

spring is higher than that of steel leaf spring. Hence an attempt has been made to

fabricate the composite leaf spring with the same cost as that of steel leaf spring.

Material properties and design of composite structures are reported in

many literatures. Very little information are available in connection with finite

element analysis of leaf spring in the literature, than too in 2D analysis of leaf

spring. At the same time, the literature available regarding experimental stress

analysis more. The experimental procedures are described in national and

international standards. Recent emphasis on mass reduction and developments in

materials synthesis and processing technology has led to proven production –worthy

vehicle equipment.

Dept. of Mechanical Engg. MESCE Kuttippuram

3

MATERIALS SELECTION

Materials constitute nearly 60%-70% of the vehicle cost and contribute

to the quality and the performance of the vehicle. Even a small amount in weight

reduction of the vehicle, may have a wider economic impact. Composite materials

are proved as suitable substitutes for steel in connection with weight reduction of

the vehicle. Hence, the composite material have been selected for leaf spring design.

FIBRES SELECTION

The commonly used fibers are carbon, glass, keviar, etc.. Among these, the

glass fiber has been selected based on the cost factor and strength. The types of

glass fibers are C-glass,S-glass and E-glass. The C-glass fiber is designed to give

improved surface finish.S-glass fiber is design to give very high modular, which is

used particularly in aeronautic industries. The E-glass fiber is a high quality glass,

which is used as standard reinforcement fiber for all the present systems well

complying with mechanical property requirements. Thus, E-glass fiber was found

appropriate for this application.

RESINS SELECTION

In a FRP leaf spring , the inter laminar shear strengths is controlled by the

matrix system used . since these are reinforcement fibers in the thickness direction ,

fiber do not influence inter laminar shear strength. Therefore, the matrix system

should have good inter laminar shear strength characteristics compatibility to the

selected reinforcement fiber. Many thermo set resins such as polyester, vinyl ester,

azpoxy resin are being used for fiber reinforcement plastics(FRP) fabrication .

Among these resin systems, epoxies show better inter laminar shear strength and

good mechanical properties. Hence, epoxide is found to be the best resins that

would suit this application. different grades of epoxy resins and hardener

combinations are classifieds , based on the mechanical properties.

Dept. of Mechanical Engg. MESCE Kuttippuram

4

Among these grades , the grade of epoxy resin selected is Dobeckot 520 F

and the grade of hardener used for this application is 758. Dobeckot 520 F is a

solvent less epoxy resin.

Which in combination with hardener 758 cures into hard resin . Hardener

758 is a low viscosity polyamine . Dobeckot 520 F , hardener 758 combination is

characterized by

Good mechanical and electrical properties.

Faster curing at room temperature.

Good chemical resistance properties .

PROPERTIES OF E-GLASS / EPOXY COMPOSITE

By considering the property variation in the tapered system improper

bonding and improper curing, etc. some constant of property value are reduced from

calculated values using equations. The material properties for E-glass / Epoxy

composite for 60% of fiber volume is given below: -

PROPERTIES VALUES

Tensile modulus along X direction (Ex),MPa 14000

Tensile modulus along Y direction (Ey),MPa 6030

Tensile modulus along Z direction (Ez),MPa 1530

Tensile strength of the material,MPa 800

Compressive strength of the material,MPa 450

Shear modulus along XY direction(Gxy),MPa 2433

Shear modulus along YZ direction(Gyz),MPa 1600

Shear modulus along ZX direction(Gzx),MPa 2433

Flexural modulus of the material,MPa 40000

Dept. of Mechanical Engg. MESCE Kuttippuram

5

Flexural strength of the material,MPa 1000

Poisson ratio along XY direction(NUxy) 0.217

Poisson ratio along YZ direction(NUyz) 0.366

Poisson ratio along ZX direction(NUzx) 0.217

Mass density of the material (ρ),Kg/mm³ 2 * 10

Dept. of Mechanical Engg. MESCE Kuttippuram

6

DESIGN SELECTION

The leaf spring behaves like a simply supported beam and the flexural

analysis is done considering it as a simply supported beam. The simply supported

beam is subjected to both bending stress and transverse shear stress. Flexural

rigidity is an important parameter in the leaf spring design and test out to increase

from two ends to the center.

CONSTANT THICKNESS, VARYING WIDTH DESIGN

In this design the thickness is kept constant over the entire length of the

leaf spring while the width varies from a minimum at the two ends to a maximum at

the center.

CONSTANT WIDTH, VARYING THICKNESS DESIGN

In this design the width is kept constant over the entire length of the leaf

spring while the thickness varies from a minimum at the two ends to a maximum at

the center.

CONSTANT CROSS-SELECTION DESIGN

In this design both thickness and width are varied through out the leaf

spring such that the cross-section area remains constant along the length of the leaf

spring.

Out of the above mentioned design concepts, the constant cross-section

design method is selected due to the following reasons:-

♦ Due to its capability for mass production and accommodation of continuous

reinforcement of fibers.

♦ Since the cross-section area is constant through out the leaf spring, same

quantity of reinforcement fibre and resin can be fed continuously during manufacture.

♦ Also this is quite suitable for filament winding process.

Dept. of Mechanical Engg. MESCE Kuttippuram

7

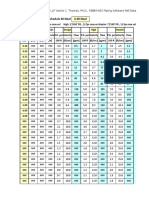

COMPUTER ALGORITHM

A computer algorithm using C language has been developed for the design

of constant cross-section leaf spring. The design requirements of composite leaf

spring are given below.

Parameter Values

1. Static load acting on the spring, (W),N 2500

2. Static deflection of the spring, mm 100

3. Distance between eyes (2L), mm 1153

4. Camber, mm 160

5. Spring rate of the leaf spring(K),N/mm 25

In constant cross-section on design both the thickness and width are varied

through to the leaf spring such that the cross-section area remains constants.

Considering the bearing strength of the steel plate, the calculated thickness of the

leaf at the bolted ends(tc)is 7.5 mm.Based on the leaf interchangeability in mounting

the rear axel, the width at the center (bm)is chosen as 30 mm and corresponding

thickness (tm) 31 mm .Stress and deflections are calculated from the theory of

bending. The output of computer algorithm is the dimensions(breath and thickness)

of leaf spring at various distances from the center. The dimensional details can be

utilized in developing models for finite element analysis and mould making process.

Dept. of Mechanical Engg. MESCE Kuttippuram

8

THREE DIMENSIONALFINITE ELEMENT ANALYSIS

The composite leaf spring is analyzed for static strength and deflection

using 3D finite element analysis. The general purpose finite element analysis

software ANSYS versin5.5 is used for the present study. Using the advantage of

symmetry in geometry and loading, only one-half of the leaf spring is modeled

analyzed. The three dimensional structure of the leaf spring is divided into a number

eight-nodded 3D brick elements. in order to get accurate results, more number of

elements are to be created.Hence,an aspect ratio of three is maintained in the finite

elementmodel.The variation of bending stress and displacement values are

predicted. The composite leaf spring from undeformed shape ,it is observed from

the results that the composite leaf spring functions equally as the conventional leaf

spring under similar loading conditions.

Dept. of Mechanical Engg. MESCE Kuttippuram

9

SELECTION OF MANUFACTURING PROCESS

Apart from the selection of material and design procedure, the selection of

manufacturing process also determines the quality and cost of the product. Hence,

the composite leaf spring manufacturing process should fulfill the following criteria.

• The process should be amenable to mass production.

• The process should be capable of producing continuous reinforcement

fiber.

Based on above requirements, filament-winding techniques is selected. In

filament winding process, continious fibre under controlled tension are drawn from

spools mounted on creel stands wetted with the resin by passing the fibers through a

resin bath and wound onto the rotating mould. After achieving the desired thickness,

the process is stopped and the mould is removed from the machine and kept for

curing. This process doesn’t involve huge investment.

Dept. of Mechanical Engg. MESCE Kuttippuram

10

FABRICATION

In this section the details of mould fabrication, filement winding machine,

winding setup, resin preparation, winding process and metallic eye are discussed.

MOULD FABRICATION

The mould used for the fabrication of FRP leaf spring should satisfy the

following requirements.

• The cavity of the mould should resemble the actual leaf

spring shape and dimension.

• It should have a continuous positive surface of resolution .

• It should be designed such that it can be rotated about an axis

of revolution.

The mould is designed as per the design of the constant cross-section leaf

spring and above the requirements. After deciding the dimensions of the mould, it is

manufactured using wood as the pattern material. Adding small wooden pieces

along its boundaries create the composite leaf spring.

FILEMENT WINDING MACHIME

The mould that is used for the manufacture of composite leaf spring has an

outer dia. of one meter. The mould after mounting on the machine has to be rotated

as the fibre is wound on it. Hence a machine, which has the swing over dia. of one

meter has to be used.

This led to the selection of the horizontal-boring machine which has an

adjustable swing over die. An attachment is also fabricated for mounting the mould

on to the spindle head of the boring machine.

WINDING SETUP

Dept. of Mechanical Engg. MESCE Kuttippuram

11

The actual winding of the leaf spring involves the operation of the winding

machine, after attaching the resin bath and mould. Before the process is started, the

epoxy resin and hardener combination has to be placed in the resin bath. The resin

bath is an important unit of the winding setup. It provides the necessary matrix

impregnation to fibres before they are wound over the mould surface. The resin bath

should accomplish the following requirements.

1. It should wet the fibre roving uniformly with a controlled amount of resin.

2. The capacity of the resin bath should be sure that all the resin poured should

be utilized completely.

3. The resin must be poured at constant temperature to maintain a constant

viscosity.

4. It should avoid fibre breakage during impregnation.

The resin bath consists of a number of rollers, which are placed to guide

the fibres. The fibres from the creel stand are allowed to pass through the rollers that

are placed well inside the resin bath. This enables the fibres to get completely

soaked in the resin. The soaked fibre is then allowed to pass through two rollers,

which are rotating in p\opposite directions. By this method the amount of resin in

the fiber is found. The filament winding setup is shown here. The mould is first

mounted on the filament winding using the fabricated attachment and then it is

rotated at a speed of 15 rpm.

RESIN PREPRATION

The selected epoxy resin is Dobeckot 520 F with hardener 758.For every

100 parts by weight of Dobeckot 520 F ,10-12 parts by weight of hardener 758 is

mixed well at a temperature of 20°C- 40°C and used within 30-40 min, since the gel

time of epoxy resin is 30-40 min.

Dept. of Mechanical Engg. MESCE Kuttippuram

12

WINDING PROCESS

After the preparation of the resin, the resin is poured into the resin bath and

the fiber placed in the creel stand is allowed to pass through rollers in the resin bath.

The soaked fibre is then allowed to pass over the mould. The process is continued

till the desired thickness is achieved.

METALLIC EYE

Since it is difficult to fabricate a leaf spring with the eye portion by

filament winding process, a separate metallic eye is fabricated and then fixed to the

leaf spring.

Dept. of Mechanical Engg. MESCE Kuttippuram

13

Dept. of Mechanical Engg. MESCE Kuttippuram

14

EXPERIMENTATION

In this section the machine details and testing details of composite leaf

spring are discussed. The static and fatigue tests are also covered.

TESTING MACHINE

The main problem faced in using a standard material testing machine for

testing a leaf spring is the displacement. The standard machines are designed for a

displacement in the order of microns. But the leaf spring testing machine must

permit displacements in the order of centimeters. The machine must be capable of

exerting heavy loads in the range of a few tones. The machine must be equipped

with a suitable fixture, which will simulate the actual mounting of the leaf spring in

the automobile. This lead to the need of a servo-hydraulic testing machine for the

testing of leaf springs. Hence, a hydraulic-testing machine for testing of leaf springs

has been designed and fabricate. The special fixture arrangement for leaf spring

testing is shown bellow.

COMPOSIT LEAF SPRING TESTING

The leaf springs are tested following standard procedures recommended by

SAE. The spring to be tested is examined for any defects like cracks, surface

abnormality, etc.. and the surface where the strain gauges are to be fixed is cleaned

free from dust, rust and any greases. Then, strain gauges are fixed to the prepared

surface by using a cyano-acrylate adhesive.

Dept. of Mechanical Engg. MESCE Kuttippuram

15

Dept. of Mechanical Engg. MESCE Kuttippuram

16

Dept. of Mechanical Engg. MESCE Kuttippuram

17

STATIC TEST

The spring is loaded from zero to the prescribed maximum deflection and back

to zero. The applied load is measured near the center clamp location. The vertical

deflection of the spring center is also measured. The test readings are recorded at

four locations where the strain gauges are fixed in actual experimental conditions.

The variations of bending stress with load at location 1 to location 4 are shown in

the figure. The graphs are drawn when applying the load and releasing the load. The

finite element analysis results and experimental results for the load at 4200KN are

given below.

LOCATION PARAMETER FEMvalue EXPvalue

1 Bending stress, MPa 269.1 298

2 Bending stress, MPa 242.5 274

3 Bending stress, MPa 194.8 219

4 Bending stress, MPa 132.5 148

1 Vertical deflection, mm 145.0 150

FATIGUE TEST

A fatigue analysis is carried out with the help of hydraulic-fatigue testing

machine. The designed and fabricated composite leaf spring is mounted on testing

machine and the limit switches are fixed at a span of 50 mm in the vertical direction.

This is the amplitude of loading cycle, which is considerably high amplitude. The

frequency of one cycle is 66 mHz, which is considered to be very low. This leads to

high amplitude low frequency fatigue test. During the test the value of strain at

location 1 is recorded. The maximum and minimum stress values obtained at the

first cycle of the composite leaf spring are 299 MPa and 202 MPa respectively. As

the number of cycles goes on increasing, the fluctuation in the stress are continuing

Dept. of Mechanical Engg. MESCE Kuttippuram

18

to a certain level then settling takes place. Under this condition, the maximum and

minimum operating stress values are found to be 310 MPa and 208 MPa,

respectively. Since, the fatigue (tensile) strength of the composite material is

considered as 900 MPa, the stress level obtained from operating stress is 0.33,

which is very low and safe. Due to high amplitude and low frequency fatigue

analysis, the experimental analysis doesn’t provide final results in the short period.

The test is conducted for 100 to complete 25,000 cycles. The variations in stress

level are reduced to very low level after 25,000 cycles. It is observed from the

fatigue test that there is only a negligible reduction in spring rate (1.5%) and no

crack initiation in the spring after 25,000 cycles of fatigue loading. Hence there is

necessity to go for analytical model for finding the remaining number of cycles of

fatigue.

Dept. of Mechanical Engg. MESCE Kuttippuram

19

COMPARISION WITH STEEL LEAF SPRING

The objective of this study is to evaluate the applicability of a composite

leaf spring in automobiles by considering cost-effectiveness and strength. The

comparison between multi-leaf spring and mono-leaf composite spring is made for

the same requirements and loading conditions. The comparison is based on four

major aspects such as weight, riding comfort, cost and strength.

COMPARISON OF WEIGHT

The total weight of composite leaf spring is 4 Kg including the metal eye

weight of 1 Kg. The weight of a convectional steel spring assembly is around 15

Kg. So, around 70% of weight reduction is achieved. Thus the objective of reducing

the unsprung mass is achieved to a larger extent.

COMPARISION BASED ON RIGIDITY QUALITIES

The weight reduction of unsprung mass of an automobile will improve the

riding quality. The suspension leaf contributes 10% - 20% of the unsprung mass.

The weight of the composite leaf spring is 3.75 times less than steel leaf spring.

Hence the riding comfort of an automobile is increased due to the replacement of

the steel leaf spring by composite leaf spring. No one to the best of knowledge has

worked but qualitatively on how much improvement in mileage/lit of passenger

vehicle occurs and how much riding comfort improves. Only qualitative information

is available on riding comfort of vehicle with respect to its unsprung mass. Steel

spring is a multi-leaf spring and its inter-leaf fabrication reduces its riding quality.

But composite leaf spring is a mono-leaf spring and more conductive to riding

qualities.

Dept. of Mechanical Engg. MESCE Kuttippuram

20

COST COMPARISION

The cost estimation of composite leaf spring provides a clear economic

viability of the product in comparison to that of a convectional leaf spring.

MATERIAL OF MANUFACTURE

Material Quantity

1. E-glass Fibre 4.5

2. Dubeckot 520 F epoxy resin 1.5

3. Resin hardener 0.22

MOULD COST

Cost incurred in the manufacture of a mould is Rs 1400. This mould can be

used at least for 50,000 cycles of manufacturing composite leaf springs through

filament winding process and this results to manufacture of around 1,00,000 leaf

spring. Hence, the cost distribution over 1,00,000 leaf spring gives cost around Rs

0.14 per leaf spring.

Machine Hour Rate Of Filament Winding Machine

Machine hour rate of filament winding machine is around Rs 140 and time

required in the manufacturing of two leaf spring is only 30 min. therefore the cost

involved is Rs 35.

Labour And Miscellaneous Cost

The cost involved in employing skilled labour has to be incorporated in the

total cost. In this case there is no labour involvement. It is assumed that the labour

cost and miscellant cost in manufacture of two leaf spring is Rs 35.

Cost Of Metal Eye

Total Cost

Dept. of Mechanical Engg. MESCE Kuttippuram

21

Cost Of Convectional Leaf Spring

The convectional leaf spring assembly is available in the market for Rs

1000. By assuming a profit margin of 25%v of the leaf spring, the cost of the leaf

spring works out to be Rs 750. Hence it concerns that the cost of a composite leaf

spring is equal to that of a convectional leaf spring even at a development stage.

This shows that if mass production is achieved the cost can be reduced by 20% -

30% of the cost of a convectional leaf spring.

STRENGTH COMPARISION

Static test has been conducted on steel and composite leaf spring. The

characteristics of these two are given below.

Parameter Steel Composite

1.Maximum Stress, MPa 745 300

2.Safety Factor 1.3 – 2.0 3.0 – 4.0

3.Spring Rate, N/mm 25 - 28 25 – 28

Since, the composite leaf spring is able to with stand the static load as well

as the fatigue load, it is concluded that there is no objection from strength point of

view also, in the process of replacing convectional leaf spring by composite leaf

spring. To establish the consistency of test results, extensive trail on a large scale

has to carried out. This requires large time and infrastructure, which are beyond the

scope of the present study. Since, the composite spring is designed for same

stiffness as that of steel spring, both the springs are considered to be almost equal in

car stability. The major disadvantage of composite leaf springs is cost and

resistance. In this study, the cost factor has been proved to be ineffective. However

the matrix material is likely to chip off when it is subjected to poor road

environment (ie; if some stone hit the composite leaf spring then it may produce

chipping), which may sometimes break the fibres in the lower portion of the spring.

This may result in a loss of capability to share flexural stiffness. But this depends on

the condition of the road. In normal road condition, this type of problems will not

occur.

Dept. of Mechanical Engg. MESCE Kuttippuram

22

CONCLUSION

1. The composite leaf spring is designed according to constant cross-section

area method.

2. The 3-D model of the composite leaf spring is analyzed using finite element

analysis.

3. Static test has been conducted to predict the stress and displacement at

different locations for various load value.

4. The results of the FEM analysis are verified with the test results.

5. A comparative study has been made between composite and steel leaf

springs with respect to weight, riding quality, cost and strength.

From the study it is seen that the composite leaf spring are lighter and

more economical than that of conventional steel leaf springs for similar

performance. Hence, the composite leaf springs are the suitable replacements to the

convectional leaf springs.

Dept. of Mechanical Engg. MESCE Kuttippuram

23

REFERENCES

01. COMPOSITE SCIENCE AND TECHNOLOGY , C F JOHNSON

02. COMPOSITE STRUCTURES , W J YU and H C KIM

03. A STUDY ON COMPOSITE LEAF SPRING , SHEN

Dept. of Mechanical Engg. MESCE Kuttippuram

24

ABSTRACT

The subject gives a brief look on the suitability of composite leaf spring on

vehicles and their advantages. Efforts have been made to reduce the cost of

composite leaf spring to that of steel leaf spring. The achievement of weight

reduction with adequate improvement of mechanical properties has made composite a

very replacement material for convectional steel. Material and manufacturing process

are selected upon on the cost and strength factor. The design method is selected on

the basis of mass production.

From the comparative study, it is seen that the composite leaf spring are higher

and more economical than convectional leaf spring.

Dept. of Mechanical Engg. MESCE Kuttippuram

25

CONTENTS

01. INTRODUCTION 1

02. LITERATURE REVIEW 2

03. MATERIALS SELECTION 3

04. DESIGN SELECTION 6

05. COMPUTER ALGORITHM 7

06. THREE DIMENSIONAL FINITE ELEMENT ANALYSIS 8

07. SELECTION OF MANUFACTURING PROCESS 9

08. FABRICATION 10

09. EXPERIMENTATION 14

10. STATICTEST 16

11. COMPARISON WITH STEEL LEAF SPRING 18

12. CONCLUSION 21

Dept. of Mechanical Engg. MESCE Kuttippuram

26

ACKNOWLEDGMENT

I would like to express my deepest gratitude to Mr.Renjith B.S , my guide,

our staff in charge and tutor Prof. Jumailath Beevi for guiding and helping me in the

successful completion of this endeavor.

I would also like to thank Dr.T.N.Sathyanesan, Head Of The Department,

Mechanical Engineering, the kind help and co-operation.

I also thank, my friends for their help and guidance making this seminar a

success.

Dept. of Mechanical Engg. MESCE Kuttippuram

Вам также может понравиться

- Adhesive AnchorsДокумент5 страницAdhesive AnchorsShamim Ahsan ZuberyОценок пока нет

- Pipe Sizing Data.Документ50 страницPipe Sizing Data.haqjmiОценок пока нет

- Leaf Spring ProjДокумент27 страницLeaf Spring ProjSahad MkОценок пока нет

- Design & Analysis of Mono Composite Leaf SpringДокумент5 страницDesign & Analysis of Mono Composite Leaf Springijsret100% (1)

- Pressure Vessel BrochureДокумент18 страницPressure Vessel BrochureNikhil VermaОценок пока нет

- 01 Procedure For Structural SteelДокумент9 страниц01 Procedure For Structural Steelpunitg_2Оценок пока нет

- DEMO-ASME Filler Metals DatabaseДокумент6 страницDEMO-ASME Filler Metals DatabaseadammzjinОценок пока нет

- Dyeing OverviewДокумент38 страницDyeing OverviewAmdeworkОценок пока нет

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОт EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainОценок пока нет

- Design and Analysis of Parabolic Leaf SpringДокумент5 страницDesign and Analysis of Parabolic Leaf Springvijayan m gОценок пока нет

- Proposal On Design Analysis of Composite Leaf Spring of A Light VehicleДокумент13 страницProposal On Design Analysis of Composite Leaf Spring of A Light Vehiclecobra2919Оценок пока нет

- Review of GTAW Welding ParametersДокумент14 страницReview of GTAW Welding Parameterskervyn SáenzОценок пока нет

- 20603E01, Guidelines For Material Selection in O&G Processing Facilities - Jan 2011 PDFДокумент63 страницы20603E01, Guidelines For Material Selection in O&G Processing Facilities - Jan 2011 PDFanghel_florin82Оценок пока нет

- En 1090 2 Ex3 PDFДокумент1 страницаEn 1090 2 Ex3 PDFlai nguyenОценок пока нет

- Paper Presentation Report: Anjalai Ammal Mahalingam Engineering CollegeДокумент15 страницPaper Presentation Report: Anjalai Ammal Mahalingam Engineering CollegeManjesh ThilakОценок пока нет

- ABSTRACT Leaf SpringДокумент7 страницABSTRACT Leaf SpringCuGáyLâmĐồng100% (1)

- Design Analysis Fabrication and Testing of Composite Leaf Seminar ReportДокумент26 страницDesign Analysis Fabrication and Testing of Composite Leaf Seminar Reportyash1239100% (1)

- Performance Analysis of Two Mono Leaf Spring Used For Maruti 800 VehicleДокумент3 страницыPerformance Analysis of Two Mono Leaf Spring Used For Maruti 800 VehicleVinoth KumarОценок пока нет

- Design and Analysis of Composite Built Leaf Spring Systems For Heavy and Light VehicleДокумент5 страницDesign and Analysis of Composite Built Leaf Spring Systems For Heavy and Light VehicleInternational Journal of Technology and Emerging Sciences (IJTES)Оценок пока нет

- Modeling and Expermental Analysis of Composite Leaf Spring: ArticleДокумент8 страницModeling and Expermental Analysis of Composite Leaf Spring: ArticleRadosław WałkuskiОценок пока нет

- Main ProjectДокумент67 страницMain ProjectMagesh OfficialОценок пока нет

- Design and Analysis of Leaf Spring Using Composite Materials IJERTV7IS050254Документ8 страницDesign and Analysis of Leaf Spring Using Composite Materials IJERTV7IS050254k VENKATESHWARANОценок пока нет

- Design and Analysis of Drive Shaft Using Kevlar/Epoxy and Glass/Epoxy As A Composite MaterialДокумент9 страницDesign and Analysis of Drive Shaft Using Kevlar/Epoxy and Glass/Epoxy As A Composite MaterialAnish KumarОценок пока нет

- Analysis of GFRP Leaf SpringДокумент6 страницAnalysis of GFRP Leaf SpringIJMERОценок пока нет

- 25IJMPERDAPR201925Документ6 страниц25IJMPERDAPR201925TJPRC PublicationsОценок пока нет

- Designand Fabricationof Composite ShaftsДокумент5 страницDesignand Fabricationof Composite ShaftsMario CorinziОценок пока нет

- Pneumatic Sheet Metal Cutting Machine DocumentationДокумент17 страницPneumatic Sheet Metal Cutting Machine DocumentationMs.Naidu Divya Anusha APCivilОценок пока нет

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Документ20 страницDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaОценок пока нет

- Flexural Behavior of Aluminum Honeycomb Core Sandwich StructureДокумент12 страницFlexural Behavior of Aluminum Honeycomb Core Sandwich StructureParth LalОценок пока нет

- Analysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhaДокумент6 страницAnalysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhakumarОценок пока нет

- Composite Leaf Spring 1 PDFДокумент4 страницыComposite Leaf Spring 1 PDFVijay AnandОценок пока нет

- Performance Analysis of Carbon Fiber With Epoxy Resin Based Composite Leaf SpringДокумент6 страницPerformance Analysis of Carbon Fiber With Epoxy Resin Based Composite Leaf SpringraajaahОценок пока нет

- Design Optimization & Fatigue Analysis of Composite Mono Leaf SpringДокумент8 страницDesign Optimization & Fatigue Analysis of Composite Mono Leaf SpringRahulJNairОценок пока нет

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringДокумент22 страницыDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringRahulJNairОценок пока нет

- 1 s2.0 S2214785316303856 Main - 3Документ7 страниц1 s2.0 S2214785316303856 Main - 3mesfin DemiseОценок пока нет

- AJEAT Vol.7 No.1 January June 2018pp. 66 69Документ4 страницыAJEAT Vol.7 No.1 January June 2018pp. 66 69cheran reddyОценок пока нет

- Design and Analysis of Drive ShaftДокумент13 страницDesign and Analysis of Drive ShaftCH JamshaidОценок пока нет

- Dynamic Analysis of Leaf SpringДокумент9 страницDynamic Analysis of Leaf SpringTHEBESTОценок пока нет

- Mechanical Characteristics and Analysis of Composite Leaf Spring Reinforced With AluminumДокумент4 страницыMechanical Characteristics and Analysis of Composite Leaf Spring Reinforced With AluminumabdurazakОценок пока нет

- Design & Analysis of Mono Composite Leaf Spring: Volume 2 Issue2 PP 103-107 May 2013Документ5 страницDesign & Analysis of Mono Composite Leaf Spring: Volume 2 Issue2 PP 103-107 May 2013Rajesh Kumar PОценок пока нет

- Comparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsДокумент22 страницыComparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsTJPRC PublicationsОценок пока нет

- Ijmet 08 05 002Документ14 страницIjmet 08 05 002ivs yeswanthОценок пока нет

- Ijert Ijert: Design and Experimental Analysis of Leaf Spring Using Composite MaterialsДокумент6 страницIjert Ijert: Design and Experimental Analysis of Leaf Spring Using Composite Materialssagar sutarОценок пока нет

- Design and Analysis of Composite Drive ShaftДокумент4 страницыDesign and Analysis of Composite Drive ShaftmustafaОценок пока нет

- Best 30 D&A ABSTRACTДокумент30 страницBest 30 D&A ABSTRACTRajadurai BaskaranОценок пока нет

- Design ShaftДокумент9 страницDesign ShaftCH JamshaidОценок пока нет

- Design For Fatigue and Simulation of Glass Fibre / Epoxy Composite Automobile Leaf SpringДокумент22 страницыDesign For Fatigue and Simulation of Glass Fibre / Epoxy Composite Automobile Leaf SpringRajdeep SinghОценок пока нет

- Design and Analysis of Mono Leaf Spring: August 2017Документ7 страницDesign and Analysis of Mono Leaf Spring: August 2017Matataw DeditorОценок пока нет

- ART2019695Документ10 страницART2019695Alex Pandian SОценок пока нет

- Review On Compsite Leaf Springs PDFДокумент14 страницReview On Compsite Leaf Springs PDFmadavanОценок пока нет

- Analysis of Mono Leaf Spring Using Composite MaterialsДокумент1 страницаAnalysis of Mono Leaf Spring Using Composite MaterialsDr. Mahesh GopalОценок пока нет

- Analysis of Parabolic Leaf SpringДокумент4 страницыAnalysis of Parabolic Leaf SpringretechОценок пока нет

- Fluid Mechanics: Open AccessДокумент20 страницFluid Mechanics: Open AccessWilliam Gomez ZabaletaОценок пока нет

- Ijaiem 2014 11 08 20Документ7 страницIjaiem 2014 11 08 20International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- DESIGN AND ANALYSIS OF A DRIVE SHAFT BY USING COMPOSITE MATERIALS Ijariie11158Документ20 страницDESIGN AND ANALYSIS OF A DRIVE SHAFT BY USING COMPOSITE MATERIALS Ijariie11158Vinit TyagiОценок пока нет

- Abu Talib CDSДокумент8 страницAbu Talib CDSMatthew SmithОценок пока нет

- Modelling and Analysis of Suspension System of TATA SUMO by Using Composite Material Under The Static Load Condition by Using FEAДокумент8 страницModelling and Analysis of Suspension System of TATA SUMO by Using Composite Material Under The Static Load Condition by Using FEAVaibhav KatharОценок пока нет

- DocDesign and Analysis of A Heavy Vehicle Leaf SpringДокумент6 страницDocDesign and Analysis of A Heavy Vehicle Leaf SpringIJRASETPublicationsОценок пока нет

- FinalДокумент20 страницFinalRajesh GamblerОценок пока нет

- Design and Assessment of Multi Leaf Spring: Ashish V. Amrute, Edward Nikhil Karlus, R.K.RathoreДокумент10 страницDesign and Assessment of Multi Leaf Spring: Ashish V. Amrute, Edward Nikhil Karlus, R.K.RathoreVenkatesh NanneboinaОценок пока нет

- Materials and Design: Jin Zhang, Peter Supernak, Simon Mueller-Alander, Chun H. WangДокумент7 страницMaterials and Design: Jin Zhang, Peter Supernak, Simon Mueller-Alander, Chun H. WangDiamoundDomeProgram R&DОценок пока нет

- Design and Analysis of Leaf Spring in A Heavy TruckДокумент6 страницDesign and Analysis of Leaf Spring in A Heavy Truckveerakumar B UCE-PKTОценок пока нет

- Design and Analysis Projects TITLES 2021-22Документ27 страницDesign and Analysis Projects TITLES 2021-22Karthik DmОценок пока нет

- Design, Analysis and Simulation of E-Glass Fiber/Epoxy and Carbon Fiber/Epoxy Mono Leaf Composite Spring For Light Commercial VehicleДокумент6 страницDesign, Analysis and Simulation of E-Glass Fiber/Epoxy and Carbon Fiber/Epoxy Mono Leaf Composite Spring For Light Commercial VehicleNavid HoseiniОценок пока нет

- Experimental Investigation of Mono Suspension Spring: Related PapersДокумент7 страницExperimental Investigation of Mono Suspension Spring: Related PapersNINAD PANDEОценок пока нет

- Design and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410Документ8 страницDesign and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410frindgeОценок пока нет

- Leaf Spring AnalysisДокумент8 страницLeaf Spring AnalysisDaniel AlvaradoОценок пока нет

- Downloads Papers N536269d32dfa6Документ6 страницDownloads Papers N536269d32dfa6Jeevantika JОценок пока нет

- Manufacturing and Processing of Advanced MaterialsОт EverandManufacturing and Processing of Advanced MaterialsAmar PatnaikОценок пока нет

- Clamp Ring ProgramДокумент5 страницClamp Ring ProgramManjesh ThilakОценок пока нет

- Method Study Is The Systematic Recording and Critical Examination of Ways of Doing Things in Order To Make ImprovementsДокумент4 страницыMethod Study Is The Systematic Recording and Critical Examination of Ways of Doing Things in Order To Make ImprovementsManjesh ThilakОценок пока нет

- Mechciv10: Mailam Engineering College Mailam, Thindivanam (T.K), VillupuramДокумент4 страницыMechciv10: Mailam Engineering College Mailam, Thindivanam (T.K), VillupuramManjesh ThilakОценок пока нет

- Mechciv10: National Level Technical SymposiumДокумент3 страницыMechciv10: National Level Technical SymposiumManjesh ThilakОценок пока нет

- Ultrafine High Performance Polyethylene FibersДокумент11 страницUltrafine High Performance Polyethylene FibersUjjwal FinanceОценок пока нет

- Super Alloys (Ni-Base) and Dislocations, An IntroductionДокумент26 страницSuper Alloys (Ni-Base) and Dislocations, An IntroductionHassanОценок пока нет

- AquaPoly 250 TDSДокумент1 страницаAquaPoly 250 TDSAPEX SONОценок пока нет

- Ovako 280Документ2 страницыOvako 280Ejang GutОценок пока нет

- Chapter 3 - Elastic Moduli - 2019 - Engineering Materials 1Документ17 страницChapter 3 - Elastic Moduli - 2019 - Engineering Materials 1Juan Camilo AlarconОценок пока нет

- H5-311E Extracts Newsletter SMS MevacДокумент36 страницH5-311E Extracts Newsletter SMS MevacKetnipha SukwannawitОценок пока нет

- 4.B. Detection of Copper Corrosion From Petroleum Products For Diesel (ASTM D 130-04)Документ11 страниц4.B. Detection of Copper Corrosion From Petroleum Products For Diesel (ASTM D 130-04)Rafid JawadОценок пока нет

- Waller Beam Bracket Calculation SummaryДокумент2 страницыWaller Beam Bracket Calculation SummarysolidramenОценок пока нет

- Bisphenol Grade FKM DaikinДокумент5 страницBisphenol Grade FKM DaikinBudi Sapto AjiОценок пока нет

- Hydraulic Oil VG 15 - 460Документ1 страницаHydraulic Oil VG 15 - 460dnoaisapsОценок пока нет

- BRDG-2004-04-1 - StrucSteelCoatingManДокумент97 страницBRDG-2004-04-1 - StrucSteelCoatingManTony ParkОценок пока нет

- Concrete Construction Article PDF - Aluminum in Concrete PDFДокумент2 страницыConcrete Construction Article PDF - Aluminum in Concrete PDFLucasОценок пока нет

- Professional Window Mounting With Greenteq: Edition I / 2011Документ36 страницProfessional Window Mounting With Greenteq: Edition I / 2011Bejinariu ValentinОценок пока нет

- Progress in Additive Manufacturing On New Materials - A ReviewДокумент28 страницProgress in Additive Manufacturing On New Materials - A ReviewRaistlin1Оценок пока нет

- Rate CardsДокумент32 страницыRate CardsSasanka SekharОценок пока нет

- FIS Best Practice Guide Maintenance and Access Into Suspended CeilingsДокумент24 страницыFIS Best Practice Guide Maintenance and Access Into Suspended CeilingsSameer KmОценок пока нет

- Chuckeez PromopageДокумент1 страницаChuckeez PromopagemachineCanОценок пока нет

- Quality 11Smnpb37: Lucefin GroupДокумент1 страницаQuality 11Smnpb37: Lucefin GroupPaulo ZechinОценок пока нет

- Approved Vendor List - CD Live Org Awcd2Документ32 страницыApproved Vendor List - CD Live Org Awcd2Rohith KommuОценок пока нет

- JS Nek606Документ40 страницJS Nek606nokarajuОценок пока нет

- Finishing CarpentryДокумент25 страницFinishing CarpentryKevin Fernandez MendioroОценок пока нет