Академический Документы

Профессиональный Документы

Культура Документы

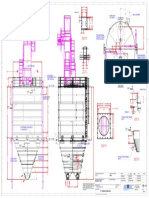

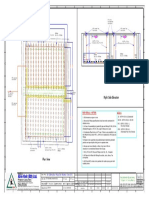

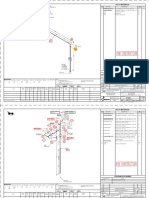

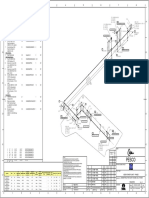

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Загружено:

Valesh MonisОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1

Загружено:

Valesh MonisАвторское право:

Доступные форматы

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 100 PAAZZBOZZABAABSAAZZUS 81.5 M B01

A106-B, Seamless, S-40

2 Sockolet® Size on Size, 100X25 MEUAWBVZZAEYABQZZUS 1 B01

A CL3000, Beveled end, A

ASME-B36.10M, A105

3 90 degree elbow, long radius, 100 MCMZZBOZZAAEADCZZUSA 6 B01

, Beveled end, ASME-B16.9, S4

A234-WPB, S-40 11END02BQ013 152 3

PIPE SUPPORTS

4 Design Pipe Assembly 100 DesignPipeH_5 14 B01 2618

ERECTION MATERIALS S4 152

11END02BQ014 6000

5 Pipe, PE, ASME-B36.10M, 25 PAAZZBPZZABAABSAAZZUS 0.3 M

A106-B, Seamless, S-40

6 90 degree elbow, CL3000, 25 MCKAWBVZZAAGABQZZUS 1 B01

S4

Socket welded end, 00

903

11END02BQ016 60 5996

599

ASME-B16.11, A105

<7> 1

7 Plug, CL3000, Male threaded 25 MFIAWBNZZAAGABQZZUS 1 B01 <6> 1

00

end, ASME-B16.11, A105 60

8 Ball valve, full port, CL600, 25 VAIAPBUZZAAFABQZZBFUS 1 B01

B Threaded end, ASME-B16.10, 00 B

60 S4

A105 11END02BQ015

152 152

00 S4

0 60

07 11END02BQ017

68 3

S4 100DN EL -693

00 11END02BQ018 SEE ISO

60 11END02BR001 SHT 04

S4 E 393770

00 11END02BQ019 N 257324

60 EL -693

S4

00 11END02BQ020

60

S4

2152 00 11END02BQ021

60 S4

C 152 C

11END02BQ022

00

30 S4

152 11END02BQ023

S4

1353

11END02BQ024

SEE SHT 152 3

11END02BR001 SHT 02 1049 EL +210

E 314248 152

N 257172 2

EL +210 100X25DN <5> 1

5 0 3

9 33 3 53 24

2 0

1 48 323 <4> 1

152 100DN

31 S4

52

79 11END02BQ050

D 152 D

8 E 315170 S4

1049 77

0 61

11END02BQ051

183

80

152

<2> 5

1353

<1> 1 24

152 35

6

EL -1326 15 8

24 3

3

EL -1143

181

8

<3> 5 STEM UP

25DN 11END02AA402

7

E TO NEAREST DRAIN PIT E

7 599 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

6 67766 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS OWNER

5 1049 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

4 10996 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS DISTRIBUTION W/C

3 153 25 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS MATRIX

2 80 25 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS

1 1049 100 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

11END02BR001 03 of 05

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P4

FILE NAME 11END02BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Вам также может понравиться

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- 10END30BR001Документ1 страница10END30BR001Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- 10ENA01BR003 Sheet3-ModelДокумент1 страница10ENA01BR003 Sheet3-ModelValesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Документ1 страницаPE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Stlop: (L.M.U Stlop) Skid Pumps Base Oil A520090 B001Документ1 страницаStlop: (L.M.U Stlop) Skid Pumps Base Oil A520090 B001Shelton S S SheltonОценок пока нет

- Piping Isometric - 4Документ1 страницаPiping Isometric - 4CosminMarianОценок пока нет

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOДокумент1 страницаD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodОценок пока нет

- Piping Isometric - 3Документ1 страницаPiping Isometric - 3CosminMarianОценок пока нет

- C11 Pillar: Schedule of R.C. Columns & FootingsДокумент1 страницаC11 Pillar: Schedule of R.C. Columns & FootingsHusen GhoriОценок пока нет

- 4139M06017 Default 000Документ1 страница4139M06017 Default 000gopi krishnaОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Документ1 страница10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanОценок пока нет

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Документ1 страница0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadОценок пока нет

- Client P.O. No.: Client Dwg. No.:: Krupp Industrial Solutions (USA), IncДокумент10 страницClient P.O. No.: Client Dwg. No.:: Krupp Industrial Solutions (USA), Incjosseph fabianОценок пока нет

- J3BGDF02BR005 01 01Документ1 страницаJ3BGDF02BR005 01 01saleem naheedОценок пока нет

- Piping Isometric - 10Документ1 страницаPiping Isometric - 10CosminMarianОценок пока нет

- E32 P R340 2136Документ5 страницE32 P R340 2136Ranish P. KurianОценок пока нет

- M00: Lubrication Group'S Connection Box/ Caja Electrica Grupo LubricacionДокумент1 страницаM00: Lubrication Group'S Connection Box/ Caja Electrica Grupo LubricacionomarОценок пока нет

- FL3B-474-P-2603 As BuiltДокумент1 страницаFL3B-474-P-2603 As BuiltAlbet MulyonoОценок пока нет

- Sump Discharge Piping - ISOMETRIC DrawingДокумент9 страницSump Discharge Piping - ISOMETRIC DrawingIlham KelanaОценок пока нет

- JFN01 05 033 AДокумент1 страницаJFN01 05 033 Aluca.laniОценок пока нет

- f18p01 m00 000 General ArrangementДокумент1 страницаf18p01 m00 000 General ArrangementAngga Purnama PutraОценок пока нет

- Remote Reading1Документ2 страницыRemote Reading1joseph chungОценок пока нет

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Документ1 страницаR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriОценок пока нет

- Piping Isometric - 7Документ1 страницаPiping Isometric - 7CosminMarianОценок пока нет

- Aerodrome Chart: Resa 240 X 150 ALSF-1Документ2 страницыAerodrome Chart: Resa 240 X 150 ALSF-1cubanojuzaicubanoОценок пока нет

- Ele Schematic With Links PDFДокумент25 страницEle Schematic With Links PDFPeter JohnОценок пока нет

- Alim Knit (BD) LTD.: Plan ViewДокумент1 страницаAlim Knit (BD) LTD.: Plan ViewKamrul HasanОценок пока нет

- Specifications:: Section DDДокумент1 страницаSpecifications:: Section DDBharani Madamanchi100% (1)

- Bus ShelterДокумент1 страницаBus ShelterCHVN NH173Оценок пока нет

- 2300 52 AAA BD 280 282181 01 - RevS1Документ1 страница2300 52 AAA BD 280 282181 01 - RevS1CosminMarianОценок пока нет

- PipelineДокумент9 страницPipelineRhoteram VikkuОценок пока нет

- PS Mec Gen 001Документ1 страницаPS Mec Gen 001Anderson RodriguezОценок пока нет

- Tal Wsa PNG Iso 1PGW063407 - 00 - A01 - 00Документ1 страницаTal Wsa PNG Iso 1PGW063407 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoОценок пока нет

- BBS BorpileДокумент1 страницаBBS BorpileSurya Bintang RamadhanaОценок пока нет

- Eep 000097 0102148005 3 ST Det 0682 R02Документ1 страницаEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalОценок пока нет

- Bill of Materials: See Iso 10-P-1202 SHT 02Документ2 страницыBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanОценок пока нет

- Vendor:: Column Cell No.1 Column Cell Feed DistributorДокумент1 страницаVendor:: Column Cell No.1 Column Cell Feed DistributorJoseph Junior Jahuira TaparaОценок пока нет

- H31 SW F34 2475Документ4 страницыH31 SW F34 2475Bini RanishОценок пока нет

- No Requiere Aprobación Del Cliente: IG N E DДокумент1 страницаNo Requiere Aprobación Del Cliente: IG N E Dnestor159357Оценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Petrol Chemical Onshore Structure ModuleДокумент18 страницPetrol Chemical Onshore Structure ModulehavutaОценок пока нет

- HK 0FH 1027Документ1 страницаHK 0FH 1027PaoloОценок пока нет

- Isometric: 2395 Vacuum SystemДокумент1 страницаIsometric: 2395 Vacuum SystemZander MctrevorОценок пока нет

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardДокумент1 страницаB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniОценок пока нет

- Specifications:: Section DDДокумент1 страницаSpecifications:: Section DDBharani MadamanchiОценок пока нет

- J Detail J SCALE 1: 10Документ1 страницаJ Detail J SCALE 1: 10Jeisson RozoОценок пока нет

- CEGP OC053.2023 DW M 001.rev2Документ1 страницаCEGP OC053.2023 DW M 001.rev2Milagros MuedasОценок пока нет

- Expro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)Документ1 страницаExpro Production Structural Fabrication and Ga Drawing For Gdu Plant (Mol Seive Adsorber Platform A-B)vasantha kumarОценок пока нет

- Avec Chape Avant Csh2mp5 125-90-1000a3x F11cfemztcwww Emm MB 1Документ1 страницаAvec Chape Avant Csh2mp5 125-90-1000a3x F11cfemztcwww Emm MB 1Bilal BakkaliОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaДокумент1 страницаPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

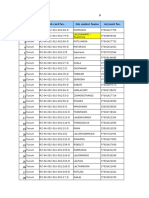

- Raw Water & Service Water Distribution System: Isometric Drawing ListДокумент1 страницаRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

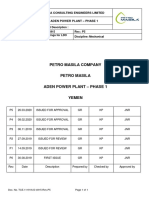

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Документ1 страницаPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- 10ENA01BR004 Sheet5-ModelДокумент1 страница10ENA01BR004 Sheet5-ModelValesh MonisОценок пока нет

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- 10ENA01BR003 Sheet1-ModelДокумент1 страница10ENA01BR003 Sheet1-ModelValesh MonisОценок пока нет

- 10ENA01BR003 Sheet3-ModelДокумент1 страница10ENA01BR003 Sheet3-ModelValesh MonisОценок пока нет

- 10ENA01BR003 Sheet2-ModelДокумент1 страница10ENA01BR003 Sheet2-ModelValesh MonisОценок пока нет

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Документ1 страницаPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Документ2 страницыTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisОценок пока нет

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Документ1 страницаPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisОценок пока нет

- YUI 2.7 Cheat Sheets ConcatenatedДокумент41 страницаYUI 2.7 Cheat Sheets Concatenatedcron112Оценок пока нет

- Project DocumentДокумент50 страницProject DocumentVijay B VijayОценок пока нет

- Silica Analyzer, Series 5000, Model 6000-Intrument Manual PDFДокумент136 страницSilica Analyzer, Series 5000, Model 6000-Intrument Manual PDFAdhy Priyo Pambudi100% (1)

- WWW - Manaresults.Co - In: Set No. 1Документ1 страницаWWW - Manaresults.Co - In: Set No. 1My Technical videosОценок пока нет

- Electrical and Mechanical PlanДокумент14 страницElectrical and Mechanical PlanMarielle Bias MercadoОценок пока нет

- A Seminar Report On Virtualization Techniques in Cloud - ComputingДокумент33 страницыA Seminar Report On Virtualization Techniques in Cloud - ComputingParth AgarwalОценок пока нет

- Tuirum Adhaar Update Tur ListДокумент4 страницыTuirum Adhaar Update Tur ListLalthlamuana MuanaОценок пока нет

- Sharp BP30C25 - Installation ManualДокумент58 страницSharp BP30C25 - Installation ManualSathish SukumaranОценок пока нет

- Dispersant Manual WebДокумент108 страницDispersant Manual Webcamilinrodriguezzzz100% (1)

- SJ 9 PDFДокумент52 страницыSJ 9 PDFNicolas X FloresОценок пока нет

- Jurnal Limbah MakananДокумент6 страницJurnal Limbah MakananArdi jombangОценок пока нет

- Portugal Espacial PT Space Catalog 2011 Screen VersionДокумент86 страницPortugal Espacial PT Space Catalog 2011 Screen Versionpmjafonso100% (1)

- Oil Checks On Linde Reach Stacker Heavy TrucksДокумент2 страницыOil Checks On Linde Reach Stacker Heavy TrucksmliugongОценок пока нет

- Laserfiche Import Agent 9 Quick StartДокумент11 страницLaserfiche Import Agent 9 Quick StartFernando Munive ZacatzontleОценок пока нет

- Assignment (Module 1) IntroductionДокумент3 страницыAssignment (Module 1) Introductionkunal kumar100% (1)

- 0003-MI20-00S1-0031 Topside Paint Color Scheme PDFДокумент11 страниц0003-MI20-00S1-0031 Topside Paint Color Scheme PDFSobariandi AndiОценок пока нет

- Creating Your Online CSSD Student Profile - MA Acting ProgrammesДокумент7 страницCreating Your Online CSSD Student Profile - MA Acting ProgrammesEleanor ShawОценок пока нет

- Multi Class Coding SystemДокумент20 страницMulti Class Coding SystemDaniel LoretoОценок пока нет

- 03-Instruction Set ArchitectureДокумент40 страниц03-Instruction Set ArchitectureccoccoheadОценок пока нет

- Massey Ferguson 8570 COMBINE Parts Catalogue ManualДокумент22 страницыMassey Ferguson 8570 COMBINE Parts Catalogue ManualdidkskmdmdmОценок пока нет

- FL Studio TutorialsДокумент8 страницFL Studio TutorialsRoberto DFОценок пока нет

- Catia MaualДокумент44 страницыCatia MaualSai Venkatesh.0% (1)

- Potential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsДокумент8 страницPotential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsAugusto MeloОценок пока нет

- Topray Tpsm5u 185w-200wДокумент2 страницыTopray Tpsm5u 185w-200wThanh Thai LeОценок пока нет

- HR AuditДокумент5 страницHR AuditshanumanuranuОценок пока нет

- COVID-19 Vaccination Appointment Details: CenterДокумент1 страницаCOVID-19 Vaccination Appointment Details: CenterMohit MittalОценок пока нет

- PTC ThermistorsДокумент9 страницPTC ThermistorsbuspersОценок пока нет

- Ea295 PDFДокумент3 страницыEa295 PDFjhiilОценок пока нет

- Install OpenERP On UbuntuДокумент9 страницInstall OpenERP On UbuntuQuynh NguyenОценок пока нет

- Intro To Computing SyllabusДокумент7 страницIntro To Computing SyllabusAireen Rose Rabino ManguiranОценок пока нет