Академический Документы

Профессиональный Документы

Культура Документы

Automelt b20 Plus PDF

Загружено:

Sadhasivam VeluИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Automelt b20 Plus PDF

Загружено:

Sadhasivam VeluАвторское право:

Доступные форматы

SAW Fluxes

Automelt B20 Plus

GENERAL DESCRIPTION:

• Agglomerated Flux • For Carbon & Low Alloy Steels

• Fluoride-Basic Type Flux • Suitable for Narrow Gap Welding

• High Basic Flux having Basicity Index of 3.1 • Suitable for Single & Multi Wire Tandem System

• Mildly Active Flux with moderate Si and Mn • Suitable for Welding Speeds of 0.40 – 0.60 m/min

pick-up with Low Mn Wires and Mn burnout • Grain Size – 0.25-1.60mm

with high Mn wires • Type of Current – DCEP / AC

• Multi-pass Butt and Fillet Welding • Wall Neutrality Number with EM12K is 23

CLASSIFICATION :

With Wire AWS 5.17/5.23 Single / Multi-pass

AUTOMELT EM12K F7A8-EM12K Multi-pass

AUTOMELT EH10K F7A8/P8-EH10K Multi-pass

AUTOMELT EH12K F7A8/P10-EH12K Multi-pass

AUTOMELT EH14 F7A6/P6-EH14 Multi-pass

AUTOMELT EB2R F8P2-EB2R-B2R Multi-pass

AUTOMELT EB3R F8P0-EB3R-B3R Multi-pass

AUTOMELT EB91 F9PZ-EB91-B91 Multi-pass

AUTOMELT ENi1 F7A6-ENi1-Ni1 Multi-pass

AUTOMELT ENi2 F7A8-ENi2-Ni2 Multi-pass

AUTOMELT ENi3 F7A10-ENi3-Ni3 Multi-pass

AUTOMELT EF1 F8A6-EF1-F1 Multi-pass

AUTOMELT EF2 F8A6-EF2-F2 Multi-pass

AUTOMELT EF3 F9A8-EF3-F3 Multi-pass

AUTOMELT EF4 F8A6-EF4-F4 Multi-pass

AUTOMELT EF5 F9A10-EF5-F5 Multi-pass

AUTOMELT EG1 F11A8-EG-G Multi-pass

TYPICAL APPLICATIONS :

• Fabrication of Reactors, steam generators • Fabrication of Pressure Vessel and Boiler

• Long Seam and Cir Seam Welding of Pipes • Heavy Equipment Fabrication

Narrow

Fillet Single V Double V Single U Cir Seam Long Seam Single Wire Tandem

Gap

APPROVALS:

RDSO, ABS, IBR

(continue...)

WELDERS TO THE NATION SINCE 1951 247 www.adorwelding.com

SAW Fluxes

Automelt B20 Plus

(continue...)

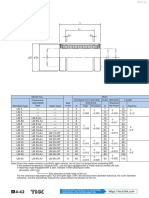

ACTIVITY OF THE FLUX:

% Mn Pick-up from the flux % Si Pick-up from the flux

0.4 0.8

0.2 0.4

0 0.2

-0.2 0

1 1.8 0.03 0.25

% Mn in Wire % Si in Wire

CHEMICAL COMPOSITION OF FLUX:

SiO2 + TiO2 CaO + MgO Al2O3 + MnO CaF2

20 15 30 30

Chemical Composition of Undiluted Weld Metal (wt%), Typical:

With wire C Mn Si Ni Cr Mo Other Elements

AUTOMELT EM12K 0.06 1.25 0.40 -- -- --

AUTOMELT EH10K 0.07 1.45 0.40 -- -- --

AUTOMELT EH12K 0.08 1.50 0.40 -- -- --

AUTOMELT EH14 0.08 1.60 0.30 -- -- --

AUTOMELT EB2R 0.06 0.90 0.30 1.10 0.50 S-0.007; P-0.009;

Cu-0.05; As-0.003;

Sn-0.003; Sb-0.003

AUTOMELT EB3R 0.07 0.90 0.30 -- 2.10 1.0 S-0.007; P-0.009;

Cu-0.05; As-0.003;

Sn-0.003; Sb-0.003

AUTOMELT EB91 0.07 0.50 0.30 0.55 8.70 8.70 V-0.20; Nb-0.04;

N-0.04;

Mn+Ni<1.20

AUTOMELT ENi1 0.07 1.40 0.30 0.90 -- --

AUTOMELT ENi2 0.08 1.40 0.30 2.20 -- --

AUTOMELT ENi3 0.08 1.40 0.30 3.00 -- --

AUTOMELT EF1 0.08 1.20 0.40 1.00 -- 0.45

AUTOMELT EF2 0.08 1.50 0.40 0.60 -- 0.50

AUTOMELT EF3 0.08 1.50 0.40 0.90 -- 0.50

AUTOMELT EF4 0.08 1.40 0.40 0.50 0.30 0.20

AUTOMELT EF5 0.08 1.50 0.40 2.20 0.30 0.40

AUTOMELT EG1 0.07 1.60 0.45 2.40 -- 0.60

(continue...)

WELDERS TO THE NATION SINCE 1951 248 www.adorwelding.com

SAW Fluxes

Automelt B20 Plus

(continue...)

Mechanical properties of All Weld Metal, Typical:

With wire Condition UTS, YS, %E CVN Impact (J) 0°C

MPa MPa -30°C -40°C -50°C -60°C -70°C

Automelt EM12K AW 510 430 28 80 50 30

Automelt EH10K AW 520 440 27 60 40

Automelt EH10K PW1 540 420 27 70 50

Automelt EH12K AW 530 450 27 80 50

Automelt EH12K PW1 530 430 28 90 70 50

Automelt EH14 AW 530 440 27 50

Automelt EH14 PW1 520 430 28 60

Automelt EB2R PW2 600 490 24 40

Automelt EB3R PW2 630 500 24 30

Automelt EB91 PW3 660 570 19

Automelt ENi1 AW 520 430 29 50

Automelt ENi2 AW 530 430 28 90 40

Automelt ENi3 AW 540 440 27 70 60 40

Automelt EF1 AW 580 470 25 50

Automelt EF2 AW 600 480 25 40

Automelt EF3 AW 650 570 22 60 40

Automelt EF4 AW 600 490 24 40

Automelt EF5 AW 650 570 22 60 40

Automelt EG1 AW 790 700 17 60 40

AW – As Welded; PW1 – After Post weld heat treatment of 620°C for 1 hour

PW2 – After Post Weld Heat treatment of 690°C for 1 hour

PW2 – After Post Weld Heat treatment of 760°C for 2 hour

The chemistry and mechanical properties will depend on actual wire chemistry and arc voltage

CREEP TEST DATA (Automelt B20 Plus+Automelt EB2R):

Condition Temperature, °C Stress, MPa Duration, Hrs Strain% after 1000 Hrs

PWHT: 500 254 1000 2.40

690°C for 2 Hrs 550 160 1000 4.09

WELDERS TO THE NATION SINCE 1951 249 www.adorwelding.com

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesОт EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Automelt b41Документ3 страницыAutomelt b41Sushil BhansaliОценок пока нет

- Wires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresДокумент6 страницWires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDeepak BhatiОценок пока нет

- Saw ProcessДокумент55 страницSaw ProcessSatheesh KumarОценок пока нет

- Specification SummaryДокумент25 страницSpecification SummaryDeepak KumarОценок пока нет

- BM Full CatalogueДокумент109 страницBM Full CatalogueMiguelОценок пока нет

- Uv 421 TT (Sa FB 1 65 DC h5)Документ4 страницыUv 421 TT (Sa FB 1 65 DC h5)brunizzaОценок пока нет

- Automelt S33Документ2 страницыAutomelt S33gopuvinu4uОценок пока нет

- Hailiang Copper Pipe CatalogДокумент2 страницыHailiang Copper Pipe CatalogWali Ahmed KhanОценок пока нет

- Metal Coated HSLA Steels, EN10346:2015Документ3 страницыMetal Coated HSLA Steels, EN10346:2015ronakguptaОценок пока нет

- Tubes Sicam PDFДокумент28 страницTubes Sicam PDFDobrica PetrovicОценок пока нет

- Lorunser - Product CatalogДокумент325 страницLorunser - Product Catalogjerrash4598100% (1)

- Model LM: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SiteДокумент62 страницыModel LM: To Download A Desired Data, Search For The Corresponding Model Number in The Technical SitezahraОценок пока нет

- Common Mode Line Chokes: Electrical Specifications at 25 C - Operating Temperature Range - 40 CTO+85 CДокумент5 страницCommon Mode Line Chokes: Electrical Specifications at 25 C - Operating Temperature Range - 40 CTO+85 CWilsonMolloОценок пока нет

- International Standard: Cu-ETP - CW004AДокумент2 страницыInternational Standard: Cu-ETP - CW004AgnanasekarОценок пока нет

- Spectrocheck SpectrometerДокумент5 страницSpectrocheck SpectrometerChandra SekarОценок пока нет

- Pressure Vessel ITP Rev 0Документ3 страницыPressure Vessel ITP Rev 0Enaam AtaallahОценок пока нет

- E9018 M Specifications PDFДокумент2 страницыE9018 M Specifications PDFMohamed MostafaОценок пока нет

- C-MN STEEL WIRES FOR SAW WELDINGДокумент1 страницаC-MN STEEL WIRES FOR SAW WELDINGMechanical EngineeringОценок пока нет

- Dive Cps + MONOPHASE DUAL-capa (400microF:300V Start&60microF:450V Run) Elec-Motor ' Alu Housing'model ML100L-2 (2poles, 220V:50Hz, S1, 3Kw, 2800rpm, Form B3 ' Feet'IMB3) 23KgДокумент1 страницаDive Cps + MONOPHASE DUAL-capa (400microF:300V Start&60microF:450V Run) Elec-Motor ' Alu Housing'model ML100L-2 (2poles, 220V:50Hz, S1, 3Kw, 2800rpm, Form B3 ' Feet'IMB3) 23KgmanonpomОценок пока нет

- Electrical SystemДокумент42 страницыElectrical SystemTaufik RahimОценок пока нет

- Solid Bronze Bearing: Technical DataДокумент6 страницSolid Bronze Bearing: Technical DatadangminhОценок пока нет

- Woltman Flange DN50-300-KATALOG CALIBRATEДокумент4 страницыWoltman Flange DN50-300-KATALOG CALIBRATENurdin FahimОценок пока нет

- Renew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiДокумент4 страницыRenew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiIrwan PangaribuanОценок пока нет

- Assessment of Welding ConsumablesДокумент17 страницAssessment of Welding Consumablesmahmoud_allam3Оценок пока нет

- SAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiДокумент3 страницыSAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiSungJun ParkОценок пока нет

- Engine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitДокумент86 страницEngine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitWSMengine WSMengine100% (1)

- Uv 420 TTR / Uv 420 TTR-W Uv 420 TTR / Uv 420 TTR-W: Classifications EN 760Документ1 страницаUv 420 TTR / Uv 420 TTR-W Uv 420 TTR / Uv 420 TTR-W: Classifications EN 760Bala BiniОценок пока нет

- Pipeliner 7P+: Conformances Key FeaturesДокумент2 страницыPipeliner 7P+: Conformances Key FeaturesAnand GОценок пока нет

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Документ2 страницыProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoОценок пока нет

- OKFlux 1062Документ1 страницаOKFlux 1062jpvtvОценок пока нет

- Bill of Material: Total: 200.982Документ1 страницаBill of Material: Total: 200.982Tridi PrintingОценок пока нет

- Op 1250a (Sa Cs 3 97 Ccrmo Ac)Документ1 страницаOp 1250a (Sa Cs 3 97 Ccrmo Ac)brunizzaОценок пока нет

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDДокумент12 страницS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehОценок пока нет

- Weld Consumable SelectionДокумент25 страницWeld Consumable SelectionNisarg PandyaОценок пока нет

- TMP - 20393 Barmex Ruland Oldham 07101550358290Документ8 страницTMP - 20393 Barmex Ruland Oldham 07101550358290Ramsay BoltОценок пока нет

- Transformadores SumidaДокумент226 страницTransformadores SumidaMiguel MacpОценок пока нет

- ESAB Catalogue - Overview of ESAB Stainless Steel Welding ConsumablesДокумент12 страницESAB Catalogue - Overview of ESAB Stainless Steel Welding Consumablestoxicity23Оценок пока нет

- Consumbles List Section Wise.Документ9 страницConsumbles List Section Wise.engineeringОценок пока нет

- Specifications For Plates: Specification GradeДокумент15 страницSpecifications For Plates: Specification Gradeppd9890Оценок пока нет

- Free Cutting Mild Steel: Chemical Composition in Volume PercentageДокумент1 страницаFree Cutting Mild Steel: Chemical Composition in Volume PercentageGANESH KUMARОценок пока нет

- HCC4560B HCF4560B: NBCD AdderДокумент6 страницHCC4560B HCF4560B: NBCD AdderGoodLookingPirateОценок пока нет

- NiAll-HX-M290-400W Material Data Sheet 10-15 enДокумент5 страницNiAll-HX-M290-400W Material Data Sheet 10-15 enAmit PowarОценок пока нет

- Electrical System: Service Data AlternatorДокумент22 страницыElectrical System: Service Data Alternatoreko sunaryoОценок пока нет

- Metal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesДокумент3 страницыMetal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesSrikanth SrikantiОценок пока нет

- Bavaria Flux BF 5.1Документ3 страницыBavaria Flux BF 5.1Filipe CordeiroОценок пока нет

- B - Boehler EMK 6 - de - en - 5 PDFДокумент1 страницаB - Boehler EMK 6 - de - en - 5 PDFburakОценок пока нет

- Model LM: Download Data by Searching For The Corresponding Model Number On The Technical Support SiteДокумент70 страницModel LM: Download Data by Searching For The Corresponding Model Number On The Technical Support SiteSait TellezОценок пока нет

- Nickel Strip For BatteriesДокумент12 страницNickel Strip For BatteriesSidОценок пока нет

- Hobart Hachene-590Документ1 страницаHobart Hachene-590Felipe montanaОценок пока нет

- Catalog EДокумент315 страницCatalog EUsman HamidОценок пока нет

- TZB Turbine MotorsДокумент8 страницTZB Turbine MotorssrheittorОценок пока нет

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Документ1 страницаPOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelОценок пока нет

- Welding ProcessesДокумент28 страницWelding ProcessesAnaswarpsОценок пока нет

- Techalloy 625: Conformances Key FeaturesДокумент2 страницыTechalloy 625: Conformances Key FeaturesJulian AdaraqueОценок пока нет

- Anodos Galvotec Iii Esp.Документ1 страницаAnodos Galvotec Iii Esp.Alex SánchezОценок пока нет

- As1548 Pt46onrlo l20 August2010bДокумент3 страницыAs1548 Pt46onrlo l20 August2010bchoopoОценок пока нет

- Bonded Seals BrochureДокумент8 страницBonded Seals BrochureembasianОценок пока нет

- Fiche Technique CompteurДокумент6 страницFiche Technique CompteurMirriah SarlauОценок пока нет

- Process Piping MaterialsДокумент92 страницыProcess Piping MaterialsSatria 'igin' Girindra Nugraha100% (1)

- Preheating and Postheating.: The Perfect Treatment For High-Strength MaterialsДокумент5 страницPreheating and Postheating.: The Perfect Treatment For High-Strength MaterialsSadhasivam VeluОценок пока нет

- Control of Cracks in 9Cr-1Mov (P91) Material: Jacob Mathew and Sanu NakulanДокумент8 страницControl of Cracks in 9Cr-1Mov (P91) Material: Jacob Mathew and Sanu NakulanSadhasivam VeluОценок пока нет

- Hot Rolled Plate PDFДокумент2 страницыHot Rolled Plate PDFKelvin TyhОценок пока нет

- Storage ElectrodesДокумент2 страницыStorage ElectrodesvtbkОценок пока нет

- G.O (MS) No.152 Infection Prevention and Control Regulations For COVID-19 23.03.2020 12 Pages 150 KB PDFДокумент12 страницG.O (MS) No.152 Infection Prevention and Control Regulations For COVID-19 23.03.2020 12 Pages 150 KB PDFVadivel BalasubramaniamОценок пока нет

- Thick SS316 Materials TIG Welding Development Activities Towards Advanced Fusion Reactor Vacuum Vessel ApplicationsДокумент7 страницThick SS316 Materials TIG Welding Development Activities Towards Advanced Fusion Reactor Vacuum Vessel ApplicationsSadhasivam VeluОценок пока нет

- LHF Welding WireДокумент1 страницаLHF Welding WireSadhasivam VeluОценок пока нет

- Manufact Engg FДокумент31 страницаManufact Engg FtskcbeОценок пока нет

- Experimental Studies On Effect of Heat Input On The Mechanical Properties of V Butt Joints Produced by Gtaw To Weld Aisi 202 Ss IJERTV6IS020036 PDFДокумент7 страницExperimental Studies On Effect of Heat Input On The Mechanical Properties of V Butt Joints Produced by Gtaw To Weld Aisi 202 Ss IJERTV6IS020036 PDFSadhasivam VeluОценок пока нет

- High-Strength Low-Alloy (Hsla) Steels PDFДокумент7 страницHigh-Strength Low-Alloy (Hsla) Steels PDFHumberto Garcia CedilloОценок пока нет

- Acoustic Emission Testing Method: Questions AnswersДокумент22 страницыAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- High-Strength Low-Alloy (HSLA) SteelsДокумент2 страницыHigh-Strength Low-Alloy (HSLA) SteelsSadhasivam VeluОценок пока нет

- Microstructural Parameter Controlling Weld Metal Cold CrackingДокумент4 страницыMicrostructural Parameter Controlling Weld Metal Cold CrackingSadhasivam VeluОценок пока нет

- Faxed or Emailed Applications Are NOT Accepted: Recertification Application Cwi 9 YearДокумент5 страницFaxed or Emailed Applications Are NOT Accepted: Recertification Application Cwi 9 YearSadhasivam VeluОценок пока нет

- 7 Solid State Welding 2015Документ31 страница7 Solid State Welding 2015WagnerCamposОценок пока нет

- Death Certificate FormДокумент2 страницыDeath Certificate FormcapziaОценок пока нет

- Me 2Документ8 страницMe 2johnОценок пока нет

- Gtawbook PDFДокумент24 страницыGtawbook PDFSadhasivam VeluОценок пока нет

- Form-E (PPF Nomination)Документ1 страницаForm-E (PPF Nomination)Sadhasivam VeluОценок пока нет

- WEES208 Seminar L T P 0 2 0 Course ObjectivesДокумент1 страницаWEES208 Seminar L T P 0 2 0 Course ObjectivesSadhasivam VeluОценок пока нет

- Industrial Training Report: ST THДокумент11 страницIndustrial Training Report: ST THeeit_nizamОценок пока нет

- CH4 2 Welding Joint PreparationДокумент46 страницCH4 2 Welding Joint PreparationMatija BušićОценок пока нет

- Adhhar Application FarmДокумент2 страницыAdhhar Application FarmjaigodaraОценок пока нет

- Equivalent ASTM MaterialДокумент34 страницыEquivalent ASTM Materialgolf0910251891% (45)

- Form-A - (PPF Opening)Документ2 страницыForm-A - (PPF Opening)Sadhasivam VeluОценок пока нет

- Work Procedure For Ducting Assembly & ErectionДокумент23 страницыWork Procedure For Ducting Assembly & ErectionSadhasivam VeluОценок пока нет

- OsidationДокумент49 страницOsidationSadhasivam VeluОценок пока нет

- Group 4Документ43 страницыGroup 4NaveenaAnithaОценок пока нет

- Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesДокумент4 страницыWelded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesLakesh AtwalОценок пока нет

- What Scrap Metal Is This? A Guide To Identifying Metals: The Magnet TestДокумент3 страницыWhat Scrap Metal Is This? A Guide To Identifying Metals: The Magnet TestRakesh Ranjan MishraОценок пока нет

- INFO of Iron Nail IndustryДокумент4 страницыINFO of Iron Nail IndustrySidhant BeriyaОценок пока нет

- AISI 1035 SteelДокумент2 страницыAISI 1035 SteelCarlos Andres Garcia MuñozОценок пока нет

- Investment CastingДокумент11 страницInvestment CastingRahul LoharОценок пока нет

- Cuplaje Rigide - RoДокумент2 страницыCuplaje Rigide - Roioan cristian cotorobaiОценок пока нет

- Catalogue Section PDFДокумент49 страницCatalogue Section PDFBarreno DrillingОценок пока нет

- K2 Materials ReqДокумент71 страницаK2 Materials ReqPoetra PangestuОценок пока нет

- Durable Actuator Solutions: Centrifugal Casting Electropolishing ProcessДокумент2 страницыDurable Actuator Solutions: Centrifugal Casting Electropolishing ProcessJignesh TamkeОценок пока нет

- 0013 Bt5-Precast ConstructionДокумент27 страниц0013 Bt5-Precast ConstructionUzumakwin BatagaОценок пока нет

- WS 7 IG I Chemistry ELLECTRICITYAND CHEMICALCHДокумент4 страницыWS 7 IG I Chemistry ELLECTRICITYAND CHEMICALCHRaj MalkanОценок пока нет

- TP 1904TransIIMДокумент8 страницTP 1904TransIIMRizwan TonoyОценок пока нет

- Procedure For AluminizingДокумент4 страницыProcedure For AluminizingCorrosion FactoryОценок пока нет

- BS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireДокумент12 страницBS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireThanh Dang67% (3)

- Airframes Test QuestionsДокумент85 страницAirframes Test QuestionsRaul DeonarainОценок пока нет

- Stainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedДокумент28 страницStainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedJoao NovaisОценок пока нет

- Specifying Anodized Aluminum AACДокумент19 страницSpecifying Anodized Aluminum AACkaka**Оценок пока нет

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesДокумент42 страницыOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaОценок пока нет

- Polythionic Acid Stress Corrosion CrackingДокумент4 страницыPolythionic Acid Stress Corrosion CrackingpmkarОценок пока нет

- PVC Coated Conduit SubmittalДокумент1 страницаPVC Coated Conduit Submittaladan valdovinosОценок пока нет

- Lista de Materiales LHMATДокумент5 страницLista de Materiales LHMATfduarteОценок пока нет

- EN10083 Part 2Документ39 страницEN10083 Part 2Chandran Santhanam100% (1)

- Produktliste E PDFДокумент34 страницыProduktliste E PDFOvidiu GherendОценок пока нет

- The Feeding Systems The Feeding Systems: Topics To Discuss...Документ15 страницThe Feeding Systems The Feeding Systems: Topics To Discuss...SegОценок пока нет

- Architectural Specification DBI SALA Unirail SystemДокумент7 страницArchitectural Specification DBI SALA Unirail SystemCoordinación de Proyectos Médico ArquitectónicosОценок пока нет

- Latifi LAMY Catalog 2013 PDFДокумент76 страницLatifi LAMY Catalog 2013 PDFWang LinusОценок пока нет

- Sao Hollow Realization GuideДокумент14 страницSao Hollow Realization GuideFarsiko Risma YandiОценок пока нет

- Class Notes For Engineering Materials (MNIT Jaipur)Документ15 страницClass Notes For Engineering Materials (MNIT Jaipur)Akash JainОценок пока нет

- Cameron ChokeДокумент20 страницCameron ChokeMichael Haise0% (1)

- Lightweight Steel Framing Details: General & Axial LoadbearingДокумент7 страницLightweight Steel Framing Details: General & Axial Loadbearingrmsa17Оценок пока нет