Академический Документы

Профессиональный Документы

Культура Документы

Loose Without Hub Type Body Flange Calculation

Загружено:

9913489806Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Loose Without Hub Type Body Flange Calculation

Загружено:

9913489806Авторское право:

Доступные форматы

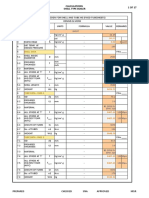

DOC NO.

DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 1 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

CHAPTER 21 PRODUCT FILTER TOP BODY THICKNESS CALCULATIONS

Remark/Code

Ref. Cha./Cla.

Ref.

* FLANGE THICKNESS CALCULATION UNDER INTERNAL PRESSURE

As per ASME Section VIII Div. 1, Edition 2017, Appendix 2

DESIGN DATA

LOOSE WITHOUT HUB

21.1.1 Flange Type

TYPE

21.1.2 Flange Design Pressure (INTERNAL) Pi 0.709 Mpa

21.1.3 Flange Design Temprature TV 150 °C

21.1.4 Flange Corrosion Allowance c 0 mm

21.1.5 Flange MOC SB-575 UNS NO. N10276

21.1.6 Bolting MOC SA-193 Gr. B8, Class 1

21.1.7 O RING O RING

21.1.8 Allowable Stress for Flange Material at Design Temp. (i.e. at 150°C ) Sfo 158.00 Mpa

21.1.9 Allowable Stress for Flange Material at Atmospheric Temp. (i.e. at 40°C ) Sfa 188.00 Mpa

21.1.10 Allowable Stress for Bolting Material at Design Temp. (i.e. at 150°C ) Sbo 103.00 Mpa

21.1.11 Allowable Stress for Bolting Material at Atmospheric Temp. (i.e. at 40°C ) Sba 130.00 Mpa

21.1.12 O RING Seating Width N 6.5 mm

21.1.13 Basic O RING Seating Width b0 = N/2 b0 3.3 mm Appendix II, Table 2.5.2

21.1.14 Effective O RING Seating Width ( b = b0 for b0 < 6mm, b = 0.5 Sqrt(b0) for b0 > 6mm b 3.3 mm Page no. 385

21.1.15 O RING Factor m 0

21.1.16 O RING Design Seating Stress y 0

21.1.17 Outsdie Daimeter of O RING Contact Face Go 278 mm

21.1.18 O RING Load Reaction Diameter G 271.5 mm

21.1.19 Outside Diamter of Flange A 300 mm

21.1.20 Inside Diameter of Flange B 250 mm

21.1.21 Provided Thickness of Flange tf 50 mm

21.1.22 Required Thickness of Flange ( Assumed ) t 45 mm

21.1.23 Thickness of Hub at small End g0 0 mm

21.1.24 Thickness of Hub at Back of End g1 0 mm

21.1.25 Hub Length h 0 mm

21.1.26 Hub Factor h0 = Sqrt( Bg0) h0 0.00 mm

21.1.27 Bolt Circle Diameter C 360 mm

21.1.28 Raidial Distance from bolt circle point of intersection R = 0.5(C - B) - g1

of hub and back of flange R = 0.5 x ( 360 - 250 ) - 0 R 55.0 mm

21.1.29 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 150°C) Efo 198000 Mpa (Table TM-1, Page no 835

21.1.30 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 40°C) Efa 205666 Mpa Group G)

21.1.31 Rigidity Factor of Integral Type Flange KL 0.2

21.2 Bolt Load Required Under Internal Pressure

21.2.1 Bolted Flange Connection to be designed in two Condition

1. At Operating Condition

2. At Gasket/O Ring Seating Condition

Of thessvalues more server shall controll the design

21.2.2 Required Bolt Load Under Operating Condition Wm1 = H + HP Secction 2-5 Eq. 1

21.2.3 Total Hydrosatic End Froce H = 0.785 x G² x Pi Section 2-3

= 0.785 x 271.5^2 x 0.709 H 41025.7 N

21.2.4 Total Joint Contact Surface Compression Load HP = 2b x (3.14Gm x Pi) Section 2-5

HP 0.00 N (c)(3)(a)

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 2 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.2.5 Hence Wm1 = H + HP =41025.65842125 + 0 Wm1 41025.66 N

21.2.6 Minimum Required initial bolt load required for gasket seating Wm2 = 3.14 x b x G x y

Wm2 0.00 N Section 2-5 (c)(3)(a)

21.2.7 Total Cross Sectional Area Am is Maimum of (Am1 and Am2) Section 2-5 (d)

21.2.8 Area Am1 = Wm1 / Sbo = 41025.65842125 / 103 Am1 398.31 mm² Section 2-5 (d)

21.2.9 Area Am2 = Wm2 / Sba = 0 / 130 Am2 0.00 mm² Section 2-5 (d)

21.2.10 So Total Cross Sectional Area MAX (398.31 , 0 ) Am 398.31 mm²

21.2.11 Selected Bolt Size 1"

21.2.12 Root Area of Bolt (P-104, Table C-1, ASME B1.1 - 2003) AR 379.13 mm²

21.2.13 Minimum Number of Bolts Required Nm = Total C/S Area / Root Area of Bolts

= 398.31 / 379.13 Nm 1.05 Nos.

21.2.14 Actual Number of Bolts Provided N 3.00 Nos.

21.2.15 Total Bolt Area Ab = AR x N = 379.13 x 3 Ab 1137.39 mm²

21.2.16 Since Total Bolt Area (Ab) > Total C/S Area (Am) 1137.39 > 398.31 11.2.15 & 11.2.10

Hence Selected Bolt Size and Number of Bolt is OK

21.2.17 Flange Design Bolt Load (W)

21.2.18 Bolt Load at Operating Condition WO = Wm1 Section 2-5 (e)

= 41025.66 WO 41025.66 N

21.2.19 Bolt Load at Gasket Seating Condition WG = ( Am + Ab ) x Sa / 2)

= (398.31 + 1137.39 ) x 130 / 2 WG 99820.33 N

21.3 Flange Load Under Operating Condition

21.3.1 Total Hydrosatic End Froce H 41025.7 N 11.2.3

21.3.2 Total Hydrosatic End Froce on area inside of flange HD = 0.785 x B² x Pi Section 2-3

= 0.785 x 250^2 x 0.709 34785.3 N

21.3.3 Gasket Load H G = WO - H 41025.66 - 41025.66 HG 0.0 N Section 2-3

21.3.4 Total Joint Contact surface Compression Load HP 0.00 N 11.2.4

21.3.5 But HT = Difference Between H and HD HT = H - HD Section 2-3

HT 6240.35 N

21.4 Flange Moment Calculations

21.4.1 Total Flange Moment at Operating Condition M0 M0 = MT + MG + MD Section 2-6

= HThT + HGhG + HDhD

21.4.2 Radial distance from the bolt circle to the circle on which hD = (C - B)/2 Table 2-6

hD acts ( As PerTable 2-6) 55.00 mm

21.4.3 Radial distance from gasket load reaction to BCD hG = C - G/2 Table 2-6

hG acts ( As PerTable 2-6) 44.25 mm

21.4.4 Radial distance fromBCD to Circle on HT acts hT = (hD+ hG) / 2 Table 2-6

hG acts ( As PerTable 2-6) 49.63 mm

21.4.5 Hence M0 at Operating Condition M0 = HThT + HGhG + HDhD

= 6240.35 x 49.63 + 0 x 44.25 + 34785.31 x 55 M0 2222869.4 Nmm Section 2-6

21.4.6 Moment due to Gasket seating MG = WG ( C -G ) / 2 Section 2-6

= 99820.33 x ( 360 - 271.5 ) / 2 MG 4417049.5 Nmm

21.5 FLANGE FACTORS CALCULATIONS (AS PER TABLE 2-7.1)

21.5.1 Factor K = A/B K 1.200

21.5.2 Factor Z = (K² + 1)/(K² - 1) Z 5.545

= (1.2² + 1)/(1.2² - 1)

21.5.3 Factor Y = ( 1/K- 1) x {0.66845 + 5.71690 x [ (K²LogK)/K² - 1]} Y 10.750

= ( 1/1.2- 1) x {0.66845 + 5.71690 x [ (1.2² x Log1.2)/(1.2² - 1)]}

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 3 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.6 CALCULATION OF STRESS AT OPERATING CONDITION ( APPENDIX 2 SECTION 2-7)

( FOR LOOSE WITHOUT HUB TYPE )

21.6.1 Longitudinal Hug Stress ( As Per Section 2-7 (a)) (For Loose type flange SH = fM0 / Lg12B

SH = 0 without hub) SH 0.00 Mpa

21.6.2 Radial Flange Stress ( As Per Section 2-7 (a)) (For Loose type flange SR = ( 1.33 te + 1) M0 / L t2 B

SR = 0 without hub) SR 0.00 Mpa

21.6.3 Tangential Flange Stress ( As Per Section 2-7 (a)) ST = ( Y M0 / t2 B) - Z SR

ST = (10.75 x 2222869.35 / (45² x 250) ) - 5.545 x 0 ST 47.20 Mpa

21.7 FLANGE ALLOWABLE STRESSES & RIGIDITY

21.7.1 Allowable Flange Design Stresses at Operating Condition (Appendix 2 Section 2-8)

Is Actual <

Allowable (Mpa) Actual (Mpa)

Allowable

Longitudinal Hub Stress, SH Min = 1.5Sfo 237.00 0.00 YES

Radial Stress, SR Sfo 158.00 0.00 YES

Tangential Stress, ST Sfo 158.00 47.2 YES

SH + SR/2 Sfo 158.00 0.00 YES

SH + ST/2 Sfo 158.00 23.60 YES

21.7.2 Flange Rigidity at Operating Condition (Appendix 2 Section 2-14)

21.7.2.1 Flange Rigidity Factor (Table 2-14) (ForLOOSE WITHOUT HUB TYPE)

J = ( 109.4 x 2222869.35) / (198000 x 45³ x 0.2 x ln1.2) J = (109.4 x Mo) / (Efo x t2 x KL x ln K)

J 0.37

21.7.2.2 Since, Flange Rigidity Factor (J) < 1 0.37 < 1

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

21.8 CALCULATION OF STRESS AT GASKET SEATING CONDITION ( APPENDIX 2 SECTION 2-7)

( FOR LOOSE WITHOUT HUB TYPE )

21.8.1 Longitudinal Hug Stress ( As Per Section 2-7 (a)) (For Loose type flange SH = fMG / Lg12B

SH = 0 without hub) SH 0.00 Mpa

21.8.2 Radial Flange Stress ( As Per Section 2-7 (a)) (For Loose type flange SR = ( 1.33 te + 1) MG / L t2 B

SR = 0 without hub) SR 0.00 Mpa

21.8.3 Tangential Flange Stress ( As Per Section 2-7 (a)) ST = ( Y MG / t2 B) - Z SR

ST = (10.75 x 4417049.54 / (45² x 250) ) - 5.545 x 0 ST 93.8 Mpa

21.9 FLANGE ALLOWABLE STRESSES & RIGIDITY

21.9.1 Allowable Flange Design Stresses at Operating Condition (Appendix 2 Section 2-8)

Is Actual <

Allowable (Mpa) Actual (Mpa)

Allowable

Longitudinal Hub Stress, SH = 1.5SfA 282.00 0.00 YES

Radial Stress, SR SfA 188.00 0.00 YES

Tangential Stress, ST SfA 188.00 93.8 YES

SH + SR/2 SfA 188.00 0.00 YES

SH + ST/2 SfA 188.00 46.90 YES

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 4 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.9.2 Flange Rigidity at Operating Condition (Appendix 2 Section 2-14)

21.9.2.1 Flange Rigidity Factor (Table 2-14) (FOR LOOSE WITHOUT HUB TYPE)

J = ( 109.4 x 4417049.54) / (198000 x 45³ x 0.2 x ln1.2) J = (109.4 x MG) / (Efo x t3 x KL x lnK)

J 0.73

21.9.2.2 Since, Flange Rigidity Factor (J) < 1 0.73 < 1

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

21.10 FLANGE THICKNESS

21.10.1 Hence,Rquired Thickness of Flange t 45 mm

21.10.2 Hence,Rquired Hub Height h 0 mm

21.10.3 Provided O-Ring Groove 0 mm

21.10.4 Hence,Required Thickness of Flange with Groove tr 45 mm

21.10.5 Required Thickness of Flange withCorrosion Allowance tc 45 mm

21.10.6 Provided Thickness of Flange 50 mm

21.10.7 SINCE PROVIDED THICKNESS > REQUIRED THICKNESS

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 5 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

* FLANGE THICKNESS CALCULATION UNDER EXTERNAL PRESSURE

As per ASME Section VIII Div. 1, Edition 2017, Appendix 2

DESIGN DATA

LOOSE WITHOUT HUB

21.11.1 Flange Type

TYPE

21.11.2 Flange Design Pressure (EXTERNAL) Pi 0.101 Mpa

21.11.3 Flange Design Temprature TV 150 °C

21.11.4 Flange Corrosion Allowance c 0 mm

21.11.5 Flange MOC SA-965 F 316

21.11.6 Bolting MOC SA-193 Gr. B8, Class 1

21.11.7 O RING O RING

21.11.8 Allowable Stress for Flange Material at Design Temp. (i.e. at 150°C ) Sfo 158.00 Mpa

21.11.9 Allowable Stress for Flange Material at Atmospheric Temp. (i.e. at 40°C ) Sfa 188.00 Mpa

21.11.10 Allowable Stress for Bolting Material at Design Temp. (i.e. at 150°C ) Sbo 103.00 Mpa

21.11.11 Allowable Stress for Bolting Material at Atmospheric Temp. (i.e. at 40°C ) Sba 130.00 Mpa

21.11.12 O RING Seating Width N 6.5 mm

21.11.13 Basic O RING Seating Width b0 = N/2 b0 3.3 mm Appendix II, Table 2.5.2

21.11.14 Effective O RING Seating Width ( b = b0 for b0 < 6mm, b = 0.5 Sqrt(b0) for b0 > 6mm b 3.3 mm Page no. 385

21.11.15 O RING Factor m 0

21.11.16 O RING Design Seating Stress y 0

21.11.17 Outsdie Daimeter of O RING Contact Face Go 278 mm

21.11.18 O RING Load Reaction Diameter G 271.5 mm

21.11.19 Outside Diamter of Flange A 300 mm

21.11.20 Inside Diameter of Flange B 250 mm

21.11.21 Provided Thickness of Flange tf 50 mm

21.11.22 Required Thickness of Flange ( Assumed ) t 45 mm

21.11.23 Thickness of Hub at small End g0 0 mm

21.11.24 Thickness of Hub at Back of End g1 0 mm

21.11.25 Hub Length h 0 mm

21.11.26 Hub Factor h0 = Sqrt( Bg0) h0 0.00 mm

21.11.27 Bolt Circle Diameter C 360 mm

21.11.28 Raidial Distance from bolt circle point of intersection R = 0.5(C - B) - g1

of hub and back of flange R = 0.5 x ( 360 - 250 ) - 0 R 55.0 mm

21.11.29 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 150°C) Efo 198000 Mpa (Table TM-1, Page no 835

21.11.30 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 40°C) Efa 205666 Mpa Group G)

21.11.31 Rigidity Factor of Integral Type Flange KL 0.2

21.12 Bolt Load Required Under Internal Pressure

21.12.1 Bolted Flange Connection to be designed in two Condition

1. At Operating Condition

2. At Gasket/O Ring Seating Condition

Of thessvalues more server shall controll the design

21.12.2 Required Bolt Load Under Operating Condition Wm1 = H + HP Secction 2-5 Eq. 1

21.12.3 Total Hydrosatic End Froce H = 0.785 x G² x Pe Section 2-3

= 0.785 x 271.5^2 x 0.101 H 5847.1 N

21.12.4 Total Joint Contact Surface Compression Load HP = 2b x (3.14Gm x Pe) Section 2-5

HP 0.00 N (c)(3)(a)

21.12.5 Hence Wm1 = H + HP =5847.06759271875 + 0 Wm1 5847.07 N

21.12.6 Minimum Required initial bolt load required for gasket seating Wm2 = 3.14 x b x G x y

Wm2 0.00 N Section 2-5 (c)(3)(a)

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 6 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.12.7 Total Cross Sectional Area Am is Maimum of (Am1 and Am2) Section 2-5 (d)

21.12.8 Area Am1 = Wm1 / Sbo = 5847.06759271875 / 103 Am1 56.77 mm² Section 2-5 (d)

21.12.9 Area Am2 = Wm2 / Sba = 0 / 130 Am2 0.00 mm² Section 2-5 (d)

21.12.10 So Total Cross Sectional Area MAX (56.77 , 0 ) Am 56.77 mm²

21.12.11 Selected Bolt Size 1"

21.12.12 Root Area of Bolt (P-104, Table C-1, ASME B1.1 - 2003) AR 379.13 mm²

21.12.13 Minimum Number of Bolts Required Nm = Total C/S Area / Root Area of Bolts

= 56.77 / 379.13 Nm 0.15 Nos.

21.12.14 Actual Number of Bolts Provided N 3.00 Nos.

21.12.15 Total Bolt Area Ab = AR x N = 379.13 x 3 Ab 1137.39 mm²

21.12.16 Since Total Bolt Area (Ab) > Total C/S Area (Am) 1137.39 > 56.77 11.2.15 & 11.2.10

Hence Selected Bolt Size and Number of Bolt is OK

21.12.17 Flange Design Bolt Load (W)

21.12.18 Bolt Load at Operating Condition WO = Wm1 Section 2-5 (e)

= 5847.07 WO 5847.07 N

21.12.19 Bolt Load at Gasket Seating Condition WG = ( Am + Ab ) x Sa / 2)

= (0 + 1137.39 ) x 130 / 2 WG 73930.35 N

21.13 Flange Load Under Operating Condition

21.13.1 Total Hydrosatic End Froce H 5847.1 N 11.2.3

21.13.2 Total Hydrosatic End Froce on area inside of flange HD = 0.785 x B² x Pi Section 2-3

= 0.785 x 250^2 x 0.101 4955.3 N

21.13.3 Gasket Load H G = WO - H 5847.07 - 5847.07 HG 0.0 N Section 2-3

21.13.4 Total Joint Contact surface Compression Load HP 0.00 N 11.2.4

21.13.5 But HT = Difference Between H and HD HT = H - HD Section 2-3

HT 891.76 N

21.14 Flange Moment Calculations

21.14.1 Total Flange Moment at Operating Condition M0 M0 = HD(hD-hG)+HT(hT-hG)

Section 2-11 (a) Eq.(10)

21.14.2 Radial distance from the bolt circle to the circle on which hD = (C - B)/2 Table 2-6

hD acts ( As PerTable 2-6) 55.00 mm

21.14.3 Radial distance from gasket load reaction to BCD hG = C - G/2 Table 2-6

hG acts ( As PerTable 2-6) 44.25 mm

21.14.4 Radial distance fromBCD to Circle on HT acts hT = (hD + hG) / 2 Table 2-6

hG acts ( As PerTable 2-6) 49.63 mm

21.14.5 Hence M0 at Operating Condition M0 = HD(hD-hG)+HT(hT-hG)

= 891.76 x 49.63 + 0 x 44.25 + 4955.31 x 55 M0 58062.8 Nmm Section 2-11 (a) Eq.(10)

21.14.6 Moment due to Gasket seating MG = WG x hG Section 2-11 (a) Eq.(11)

= 73930.35 x 44.25 / 2 MG 3271418.0 Nmm

21.15 CALCULATION OF STRESS AT OPERATING CONDITION ( APPENDIX 2 SECTION 2-7)

( FOR LOOSE WITHOUT HUB TYPE )

21.15.1 Longitudinal Hug Stress ( As Per Section 2-7 (a)) (For Loose type flange SH = fM0 / Lg12B

SH = 0 without hub) SH 0.00 Mpa

21.15.2 Radial Flange Stress ( As Per Section 2-7 (a)) (For Loose type flange SR = ( 1.33 te + 1) M0 / L t2 B

SR = 0 without hub) SR 0.00 Mpa

21.15.3 Tangential Flange Stress ( As Per Section 2-7 (a)) ST = ( Y M0 / t2 B) - Z SR

ST = (10.75 x 58062.79 / (45² x 250) ) - 5.545 x 0 ST 1.23 Mpa

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 7 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.16 FLANGE ALLOWABLE STRESSES & RIGIDITY

21.16.1 Allowable Flange Design Stresses at Operating Condition (Appendix 2 Section 2-8)

Is Actual <

Allowable (Mpa) Actual (Mpa)

Allowable

Longitudinal Hub Stress, SH 1.5Sfo 237.00 0.00 YES

Radial Stress, SR Sfo 158.00 0.00 YES

Tangential Stress, ST Sfo 158.00 1.2 YES

SH + SR/2 Sfo 158.00 0.00 YES

SH + ST/2 Sfo 158.00 0.62 YES

21.16.2 Flange Rigidity at Operating Condition (Appendix 2 Section 2-14)

21.16.2.1 Flange Rigidity Factor (Table 2-14) (ForLOOSE WITHOUT HUB TYPE)

J = ( 109.4 x 58062.79) / (198000 x 45³ x 0.2 x ln1.2) J = (109.4 x Mo) / (Efo x t3 x KL x lnK)

J 0.01

21.16.2.2 Since, Flange Rigidity Factor (J) < 1 0.01 < 1

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

21.17 CALCULATION OF STRESS AT GASKET SEATING CONDITION ( APPENDIX 2 SECTION 2-7)

( FOR LOOSE WITHOUT HUB TYPE )

21.17.1 Longitudinal Hug Stress ( As Per Section 2-7 (a)) (For Loose type flange SH = fMG / Lg12B

SH = 0 without hub) SH 0.00 Mpa

21.17.2 Radial Flange Stress ( As Per Section 2-7 (a)) (For Loose type flange SR = ( 1.33 te + 1) MG / L t2 B

SR = 0 without hub) SR 0.00 Mpa

21.17.3 Tangential Flange Stress ( As Per Section 2-7 (a)) ST = ( Y MG / t2 B) - Z SR

ST = (10.75 x 3271417.99 / (45² x 250) ) - 5.545 x 0 ST 69.5 Mpa

21.18 FLANGE ALLOWABLE STRESSES & RIGIDITY

21.18.1 Allowable Flange Design Stresses at Operating Condition (Appendix 2 Section 2-8)

Is Actual <

Allowable (Mpa) Actual (Mpa)

Allowable

Longitudinal Hub Stress, SH 1.5SfA 282.00 0.00 YES

Radial Stress, SR SfA 188.00 0.00 YES

Tangential Stress, ST SfA 188.00 69.5 YES

SH + SR/2 SfA 188.00 0.00 YES

SH + ST/2 SfA 188.00 34.73 YES

21.18.2 Flange Rigidity at Operating Condition (Appendix 2 Section 2-14)

21.18.2.1 Flange Rigidity Factor (Table 2-14) (ForSba)

J = ( 109.4 x 3271417.99) / (198000 x 45³ x 0.2 x ln1.2) J = (109.4 x MG) / (Efo x t3 x KL x lnK)

J 0.54

21.18.2.2 Since, Flange Rigidity Factor (J) < 1 0.54 < 1

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

21.19 FLANGE THICKNESS

21.19.1 Hence,Rquired Thickness of Flange t 45 mm

21.19.2 Hence,Rquired Hub Height h 0 mm

21.19.3 Provided O-Ring Groove 0 mm

21.19.4 Hence,Required Thickness of Flange with Groove tr 45 mm

21.19.5 Required Thickness of Flange withCorrosion Allowance tc 45 mm

21.19.6 Provided Thickness of Flange 50 mm

21.19.7 SINCE PROVIDED THICKNESS > REQUIRED THICKNESS

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 8 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.19A FLANGE WELDING CACULATIONS

21.19A.1 t

tf

1

2 of Max t

0.7C

Reference Fig. 2-4 (4)

21.19A.2 Nominal Thickness of Shell tn 6 mm

21.19A.3 Nominal Thickness of g0 g0 0 mm

21.19A.4 Maximum of ( 2g0 ) & 6 mm tX 6 mm

21.19A.5 tn or tX, Whichever is less c 6 mm

21.19A.6 Required Upper side groove weld leg 6 mm

21.19A.7 Provided Upper side groove weld leg 6 mm

21.19A.8 Since, Provided Weld >= Required Weld

HENCE DESIGN IS SAFE

21.19A.12 Required Lower side Fillet weld thorat 4.2 mm

21.19A.13 Required Lower side Fillet weld leg 6.00 mm

21.19A.14 Provided Lower side Fillet weld leg 6 mm

21.19A.15 Since, Provided Weld >= Required Weld

HENCE DESIGN IS SAFE

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 9 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

* FLANGE THICKNESS CALCULATION UNDER HYDROSTATIC TEST PRESSURE

As per ASME Section VIII Div. 1, Edition 2017, Appendix 2

DESIGN DATA

LOOSE WITHOUT HUB

21.20.1 Flange Type

TYPE

21.20.2 Flange Design Pressure (EXTERNAL) Pi 1.128 Mpa

21.20.3 Flange Design Temprature TV 150 °C

21.20.4 Flange Corrosion Allowance c 0 mm

21.20.5 Flange MOC SA-965 F 316

21.20.6 Bolting MOC SA-193 Gr. B8, Class 1

21.20.7 O RING O RING

21.20.8 Yield Strength for Flange Material at Test Temprature Sfay 283.00 Mpa

21.20.9 90 % of Yield Strength for Flange Material at Test Temprature Sfay 254.70 Mpa

21.20.10 Yield Strength for Bolting Material at Test Temprature Say 207.00 Mpa

21.20.11 90 % of Yield Strength for Bolting Material at Test Temprature Say 186.30 Mpa

21.20.12 O RING Seating Width N 6.5 mm

21.20.13 Basic O RING Seating Width b0 = N/2 b0 3.3 mm Appendix II, Table 2.5.2

21.20.14 Effective O RING Seating Width ( b = b0 for b0 < 6mm, b = 0.5 Sqrt(b0) for b0 > 6mm b 3.3 mm Page no. 385

21.20.15 O RING Factor m 0

21.20.16 O RING Design Seating Stress y 0

21.20.17 Outsdie Daimeter of O RING Contact Face Go 278 mm

21.20.18 O RING Load Reaction Diameter G 271.5 mm

21.20.19 Outside Diamter of Flange A 300 mm

21.20.20 Inside Diameter of Flange B 250 mm

21.20.21 Provided Thickness of Flange tf 50 mm

21.20.22 Required Thickness of Flange ( Assumed ) t 45 mm

21.20.23 Thickness of Hub at small End g0 0 mm

21.20.24 Thickness of Hub at Back of End g1 0 mm

21.20.25 Hub Length h 0 mm

21.20.26 Hub Factor h0 = Sqrt( Bg0) h0 0.00 mm

21.20.27 Bolt Circle Diameter C 360 mm

21.20.28 Raidial Distance from bolt circle point of intersection R = 0.5(C - B) - g1

of hub and back of flange R = 0.5 x ( 360 - 250 ) - 0 R 55.0 mm

21.20.29 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 150°C) Efo 198000 Mpa (Table TM-1, Page no 835

21.20.30 Modulus of Elasitcity for the Flange at Design Temp. (i.e. at 40°C) Efa 205666 Mpa Group G)

21.20.31 Rigidity Factor of Integral Type Flange Ki 0.2

21.21 Bolt Load Required Under Internal Pressure

21.21.1 Bolted Flange Connection to be designed At Gasket Seating Condition of these values more servere shall controll the design

21.21.2 Required Bolt Load Under Operating Condition Wm1 = H + HP Secction 2-5 Eq. 1

21.21.3 Total Hydrosatic End Froce H = 0.785 x G² x Pi Section 2-3

= 0.785 x 271.5^2 x 1.128 H 65301.9 N

21.21.4 Total Joint Contact Surface Compression Load HP = 2b x (3.14Gm x Pi)

HP 0.00 N (c)(3)(a)

21.21.5 Hence Wm1 = H + HP =65301.90341175 + 0 Wm1 65301.90 N

21.21.6 Minimum Required initial bolt load required for gasket seating Wm2 = 3.14 x b x G x y

Wm2 0.00 N Section 2-5 (c)(3)(a)

21.21.7 Total Cross Sectional Area Am is Maimum of (Am1 and Am2) Section 2-5 (d)

21.21.8 Area Am1 = Wm1 / Sbo = 65301.9 / 207 Am1 315.47 mm² Section 2-5 (d)

21.21.9 Area Am2 = Wm2 / Sba = 0 / 186.3 Am2 0.00 mm² Section 2-5 (d)

21.21.10 So Total Cross Sectional Area MAX (315.47 , 0 ) Am 315.47 mm²

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 10 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.21.11 Selected Bolt Size 1"

21.21.12 Root Area of Bolt (P-104, Table C-1, ASME B1.1 - 2003) AR 379.13 mm²

21.21.13 Minimum Number of Bolts Required Nm = Total C/S Area / Root Area of Bolts

= 315.47 / 379.13 Nm 0.83 Nos.

21.21.14 Actual Number of Bolts Provided N 3.00 Nos.

21.21.15 Total Bolt Area Ab = AR x N = 379.13 x 3 Ab 1137.39 mm²

21.21.16 Since Total Bolt Area (Ab) > Total C/S Area (Am) 1137.39 > 315.47 11.2.15 & 11.2.10

Hence Selected Bolt Size and Number of Bolt is OK

21.21.17 Flange Design Bolt Load (W)

21.21.19 Bolt Load at Gasket Seating Condition WG = ( Am + Ab ) x Sa / 2)

= (315.47 + 1137.39 ) x 186.3 / 2 WG 135333.74 N

21.22 Flange Load Under Operating Condition

21.22.1 Moment due to Gasket seating MG = WG ( C -G ) / 2 Section 2-6

= 135333.74 x ( 360 - 271.5 ) / 2 MG 5988517.8 Nmm

21.23 FLANGE FACTORS CALCULATIONS (AS PER TABLE 2-7.1)

Factor K = A/B K 1.200

21.23.50 Factor Z = (K² + 1)/(K² - 1) Z 5.545

= (1.2² + 1)/(1.2² - 1)

21.23.51 Factor Y = ( 1/K- 1) x {0.66845 + 5.71690 x [ (K²LogK)/K² - 1]} Y 10.750

= ( 1/1.2- 1) x {0.66845 + 5.71690 x [ (1.2² x Log1.2)/1.2² - 1]}

21.24 CALCULATION OF STRESS AT GASKET SEATING CONDITION ( APPENDIX 2 SECTION 2-7)

( FOR LOOSE WITHOUT HUB TYPE )

21.24.1 Longitudinal Hug Stress ( As Per Section 2-7 (a)) (For Loose type flange SH = fMG / Lg12B

SH = 0 without hub) SH 0.00 Mpa

21.24.2 Radial Flange Stress ( As Per Section 2-7 (a)) (For Loose type flange SR = ( 1.33 te + 1) MG / L t2 B

SR = 0 without hub) SR 0.00 Mpa

21.24.3 Tangential Flange Stress ( As Per Section 2-7 (a)) ST = ( Y MG / t2 B) - Z SR

ST = (10.75 x 5988517.78 / (45² x 250) ) - 5.545 x 0 ST 127.2 Mpa

21.25 FLANGE ALLOWABLE STRESSES & RIGIDITY

21.25.1 Allowable Flange Design Stresses at Operating Condition (Appendix 2 Section 2-8)

Is Actual <

Allowable (Mpa) Actual (Mpa)

Allowable

Longitudinal Hub Stress, SH 1.5SfA 382.05 0.00 YES

Radial Stress, SR SfA 254.70 0.00 YES

Tangential Stress, ST SfA 254.70 127.2 YES

SH + SR/2 SfA 254.70 0.00 YES

SH + ST/2 SfA 254.70 63.58 YES

21.25.2 Flange Rigidity at Operating Condition (Appendix 2 Section 2-14)

21.25.2.1 Flange Rigidity Factor (Table 2-14) (ForSfay)

J = ( 109.4 x 5988517.78) / (205666 x 45³ x 0.2 x ln1.2) J = (109.4 x MG) / (EfA x t3 x KL x lnK)

J 0.96

21.25.2.2 Since, Flange Rigidity Factor (J) < 1 0.96 < 1

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

CHAPTER CONTD. NEXT PAGE

DOC NO. DC-JB1

PREPARED BY RAHUL 25/03/2020

CHAPTER 21

JOB NO. JB1

SHEET NO. 11 OF 11

APPROVED BY RAHUL 25/03/2020

REV. 0

Remark/Code

Ref. Cha./Cla.

Ref.

21.10 FLANGE THICKNESS

21.26.1 Hence,Rquired Thickness of Flange t 45 mm

21.26.2 Hence,Rquired Hub Height h 0 mm

21.26.3 Provided O-Ring Groove 0 mm

21.26.4 Hence,Required Thickness of Flange with Groove tr 45 mm

21.26.5 Required Thickness of Flange withCorrosion Allowance tc 45 mm

21.26.6 Provided Thickness of Flange 50 mm

21.26.7 SINCE PROVIDED THICKNESS > REQUIRED THICKNESS

HENCE PROVIDED THICKNESS OF FLANGE IS SAFE

END OF CHAPTER

Вам также может понравиться

- Sample FLG CalcДокумент6 страницSample FLG CalcameyyammaiОценок пока нет

- Optional Integral With Hub Type Body Flange CalculationДокумент13 страницOptional Integral With Hub Type Body Flange Calculation9913489806Оценок пока нет

- AD 2000 HesapДокумент11 страницAD 2000 HesapBaşarŞenОценок пока нет

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Документ32 страницыPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoОценок пока нет

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGДокумент12 страницAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhaleОценок пока нет

- Calcu Nozzle NeckДокумент15 страницCalcu Nozzle Necksachmaya0% (1)

- Check 18Документ6 страницCheck 18Anonymous qBwHKusОценок пока нет

- Ferrofab Fze: Collar Bolt Sizing CalculationДокумент2 страницыFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- Max Allowable Nozzle LoadДокумент1 страницаMax Allowable Nozzle Loaddskr fkshОценок пока нет

- Pressure Vessel ExampleДокумент48 страницPressure Vessel ExamplemohamedОценок пока нет

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsДокумент1 страницаCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrОценок пока нет

- Branch RF CalcДокумент6 страницBranch RF CalcHarish Harish0% (1)

- Base Ring (Welded) - Vertical Vessel REV.1Документ3 страницыBase Ring (Welded) - Vertical Vessel REV.1dskr fkshОценок пока нет

- Pressure Design Straight Pipe (Run Pipe)Документ6 страницPressure Design Straight Pipe (Run Pipe)gembirasekaliОценок пока нет

- WIND MOMENT (Per API-650 SECTION 5.11)Документ9 страницWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- New - Reinforcement of NozzleДокумент24 страницыNew - Reinforcement of NozzleVaniya GoelОценок пока нет

- Agitator Nozzle Load Data SheetДокумент1 страницаAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBEОценок пока нет

- Rectangular Tank (With Horizontal Stiffner)Документ5 страницRectangular Tank (With Horizontal Stiffner)DURGAIRAJ100% (1)

- Swing Bolt CalculationДокумент2 страницыSwing Bolt CalculationNicolaSavili100% (2)

- Figure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9Документ4 страницыFigure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9met-calcОценок пока нет

- Pressure Vessel Design ASME Sec. VIIIДокумент37 страницPressure Vessel Design ASME Sec. VIIIprayogo1010Оценок пока нет

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Документ2 страницыBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikОценок пока нет

- Nozzle Calculations 01Документ32 страницыNozzle Calculations 01Rohith V VОценок пока нет

- Skirt Support Analysis TransportДокумент5 страницSkirt Support Analysis TransportHunnymijie NorОценок пока нет

- ASME PCC-1 - Assembly Bolt Stress & Torque DeterminationДокумент11 страницASME PCC-1 - Assembly Bolt Stress & Torque Determinationndrarly100% (1)

- Bolt Torque Calculations 1 PDFДокумент1 страницаBolt Torque Calculations 1 PDFshazanОценок пока нет

- Compress CalculationДокумент106 страницCompress CalculationKrupal Patel100% (1)

- .Документ7 страниц.Darshan Panchal100% (1)

- Rectangular Flange DesignДокумент3 страницыRectangular Flange Designshazan100% (5)

- Saddle Reaction Summary - For Empty CaseДокумент12 страницSaddle Reaction Summary - For Empty CasesridharОценок пока нет

- ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Документ2 страницыASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Mr Incognito100% (1)

- FatigueLife FEA PDFДокумент43 страницыFatigueLife FEA PDFAbigail SommersetОценок пока нет

- WRC 107, WRC 297 Co MP PDFДокумент11 страницWRC 107, WRC 297 Co MP PDFkarthickmectr100% (2)

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Документ2 страницыBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikОценок пока нет

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Документ4 страницыFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcОценок пока нет

- Platform Weight Calculator (Vertical Vessel)Документ11 страницPlatform Weight Calculator (Vertical Vessel)Sky LarksОценок пока нет

- Saddle Support Design of Horizontal Vessels As Per Asme Section Viii, Div.2Документ6 страницSaddle Support Design of Horizontal Vessels As Per Asme Section Viii, Div.2SISIR KR BARMAN0% (1)

- PD5500 - 133 - RectangularFlange CalculationДокумент9 страницPD5500 - 133 - RectangularFlange CalculationDarshan PanchalОценок пока нет

- Design of Large Opening Nozzle by Bulletin WRC-107Документ12 страницDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZОценок пока нет

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Документ2 страницыPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayОценок пока нет

- Shell and Tube HE CalculationДокумент16 страницShell and Tube HE CalculationPradip ShindeОценок пока нет

- Weld Shear Stress Check For FAVID Clips Welded On CladДокумент3 страницыWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniОценок пока нет

- Flange Pad CalcsДокумент4 страницыFlange Pad CalcstomОценок пока нет

- Flat Plate - Roark & YoungДокумент15 страницFlat Plate - Roark & YoungPrasad Pingle0% (1)

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Документ3 страницыWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- Wind Seismic Calculation DataДокумент8 страницWind Seismic Calculation Dataaknauriyal2013Оценок пока нет

- API 650 RF Pad Calculation PDFДокумент1 страницаAPI 650 RF Pad Calculation PDFRakeshОценок пока нет

- Flange DesignДокумент23 страницыFlange DesignNirmalkumarОценок пока нет

- 300 - F&D Head Design Tool Ver E4.01Документ1 страница300 - F&D Head Design Tool Ver E4.01Mo ZeroОценок пока нет

- Rectangular Flange 070122Документ4 страницыRectangular Flange 070122bytestefОценок пока нет

- Curb AngleДокумент1 страницаCurb Angle940623015859Оценок пока нет

- U-V-673 - Manual Flange and GussetДокумент8 страницU-V-673 - Manual Flange and GussetDarshan PanchalОценок пока нет

- RCC92 Ribbed Slabs (Tables)Документ7 страницRCC92 Ribbed Slabs (Tables)Cioabla BogdanОценок пока нет

- RCC92 Ribbed Slabs (Tables)Документ9 страницRCC92 Ribbed Slabs (Tables)christi SОценок пока нет

- RCC92 Ribbed Slabs (Tables)Документ8 страницRCC92 Ribbed Slabs (Tables)lucianduОценок пока нет

- Rcc95 Continuous Beams (Tables)Документ7 страницRcc95 Continuous Beams (Tables)Eric Villenas100% (1)

- D Concretestruc N20Документ8 страницD Concretestruc N20kuttyОценок пока нет

- RIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsДокумент8 страницRIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsShekh Muhsen Uddin AhmedОценок пока нет

- RCC95 Continuous Beams (Tables)Документ7 страницRCC95 Continuous Beams (Tables)Mohammad Twaha JaumbocusОценок пока нет

- Alloy C Torispherical Dished End CalculationДокумент7 страницAlloy C Torispherical Dished End Calculation9913489806Оценок пока нет

- Alloy C Shell Thickness CalculationДокумент9 страницAlloy C Shell Thickness Calculation9913489806Оценок пока нет

- PV Elite Adding A MaterialДокумент11 страницPV Elite Adding A Material9913489806Оценок пока нет

- Boiler Calucation SheetДокумент84 страницыBoiler Calucation Sheet9913489806Оценок пока нет

- Weld Map (17007 Ab)Документ22 страницыWeld Map (17007 Ab)9913489806100% (2)

- Boiler Calucation SheetДокумент84 страницыBoiler Calucation Sheet9913489806Оценок пока нет

- HIL 10033 2500U D 012 ModelДокумент1 страницаHIL 10033 2500U D 012 Model9913489806Оценок пока нет

- Sample TEMA FIXED TUBE Type Heat Exchanger ReportДокумент67 страницSample TEMA FIXED TUBE Type Heat Exchanger Report9913489806Оценок пока нет

- Sample Heat Exchanger U-TUBE ReportДокумент66 страницSample Heat Exchanger U-TUBE Report9913489806Оценок пока нет

- Sample Fixed Tubesheet Heat Exchanger ReportДокумент73 страницыSample Fixed Tubesheet Heat Exchanger Report9913489806Оценок пока нет

- PV Enineering EHX - OutДокумент144 страницыPV Enineering EHX - Out9913489806Оценок пока нет

- 2015.135001.mechanical Estimating and CostingДокумент204 страницы2015.135001.mechanical Estimating and Costing9913489806100% (1)

- Thermal 3TPH 12Kg FO Fired Boiler R0Документ6 страницThermal 3TPH 12Kg FO Fired Boiler R09913489806Оценок пока нет

- Cost 3 TPH 12kg Fo Fired Boiler p0Документ3 страницыCost 3 TPH 12kg Fo Fired Boiler p09913489806Оценок пока нет

- IS 6533-Part-2:1989 Chimney Design CodeДокумент28 страницIS 6533-Part-2:1989 Chimney Design CodeVivek Premji100% (3)

- Saddle DesignДокумент17 страницSaddle Design9913489806Оценок пока нет

- To Clear Out The PV Elite Registry Key:: Start Run, Regedit EnterДокумент2 страницыTo Clear Out The PV Elite Registry Key:: Start Run, Regedit Enter9913489806Оценок пока нет

- Flanged Ball Trunnion ValvesДокумент24 страницыFlanged Ball Trunnion ValvesMahdi DalyОценок пока нет

- Packinglist Unit 5Документ24 страницыPackinglist Unit 5francisco alberto molina garciaОценок пока нет

- 605 04Документ9 страниц605 04CHRISTIAN ZAVALA100% (1)

- APV PHE Zephyr 1014 03 01 2012 GB PDFДокумент2 страницыAPV PHE Zephyr 1014 03 01 2012 GB PDFKiran MahadanaОценок пока нет

- 1.8T Engine Tightening TorquesДокумент10 страниц1.8T Engine Tightening TorquesTian LotterОценок пока нет

- Komatsu Hydraulic Excavator Pc150 6k Shop ManualДокумент20 страницKomatsu Hydraulic Excavator Pc150 6k Shop Manualcynthia100% (38)

- Hino J05E-TH Workshop ManualДокумент278 страницHino J05E-TH Workshop ManualAimHighОценок пока нет

- Part Katalog X Ride PDFДокумент45 страницPart Katalog X Ride PDFAndre STAОценок пока нет

- FZ6-S 2008 PDFДокумент77 страницFZ6-S 2008 PDFhectorОценок пока нет

- Elliot Turbine ManualДокумент49 страницElliot Turbine ManualScribdTranslationsОценок пока нет

- Scotch-W Scotch-Weld ProductДокумент24 страницыScotch-W Scotch-Weld ProductAnca AnghelОценок пока нет

- EN Stauff One G Flanges 2014 PDFДокумент74 страницыEN Stauff One G Flanges 2014 PDFcaballero_tigreОценок пока нет

- Rotary Screw Spare Parts Book Apr09 PDFДокумент47 страницRotary Screw Spare Parts Book Apr09 PDFRamon Sanhueza75% (4)

- Air Vent For Liquid Systems - AE14Документ12 страницAir Vent For Liquid Systems - AE14Mohamed Osama El GendiОценок пока нет

- Journal of Pressure Vessel Technology VolumeДокумент4 страницыJournal of Pressure Vessel Technology VolumeMukil DevОценок пока нет

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionДокумент4 страницыGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковОценок пока нет

- Eaton LOFMET Filter Cartridges TechnicalDataSheet EN LowRes PDFДокумент2 страницыEaton LOFMET Filter Cartridges TechnicalDataSheet EN LowRes PDFluisОценок пока нет

- Checklist - Expansion Joint - Non Pressure Parts Drgs.Документ3 страницыChecklist - Expansion Joint - Non Pressure Parts Drgs.Ramalingam Prabhakaran100% (2)

- Ka 15 AccesoriosДокумент87 страницKa 15 AccesoriosNery AndrésОценок пока нет

- Tumbler Test For Coal: Standard Test Method ofДокумент4 страницыTumbler Test For Coal: Standard Test Method ofMenna MoustafaОценок пока нет

- C210 WML 201Документ13 страницC210 WML 201Efrén SantínОценок пока нет

- Gasket Installation TrainingДокумент10 страницGasket Installation TrainingEBPENICHE6400Оценок пока нет

- CVP Model ManualДокумент28 страницCVP Model ManualvictorОценок пока нет

- CLJOC-FAC-WPK-40-0158 WP For Vessel Inspection of Glycol Coalescer (MAD-2445) On CPP - Rev.0Документ25 страницCLJOC-FAC-WPK-40-0158 WP For Vessel Inspection of Glycol Coalescer (MAD-2445) On CPP - Rev.0chuminhОценок пока нет

- 2003-2006 Kia Opirus - Engine Mechanical System PDFДокумент131 страница2003-2006 Kia Opirus - Engine Mechanical System PDFprueba2Оценок пока нет

- Curtain Wall Fabrication Manual 1 2Документ69 страницCurtain Wall Fabrication Manual 1 2Suruthi Dasan67% (3)

- Belleville Springs CatalogДокумент40 страницBelleville Springs CatalogManoj100% (1)

- Instruction Manual 11Документ58 страницInstruction Manual 11makinerz techОценок пока нет

- Ez FisherДокумент36 страницEz FisherAlejandra NeiraОценок пока нет

- Sums of FlangesДокумент19 страницSums of FlangesRADHE GRAPHICS100% (1)