Академический Документы

Профессиональный Документы

Культура Документы

TASK - Clinker - Loading - in - Rake

Загружено:

saji kumar0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров2 страницы1. The document outlines the procedures for emptying wagons, loading them, and transporting the loaded wagons. It involves multiple steps of moving wagons using locomotives between stations, sealing wagons, loading clinker using equipment, covering wagons during monsoon, and weighing loaded wagons.

2. Safety measures are defined for each step, including inspections, communication protocols, use of protective equipment, and ensuring clearance during movement of heavy machinery.

3. The process aims to efficiently transport clinker from the loading site to the destination station in three lots within a 7 hour timeframe.

Исходное описание:

Оригинальное название

TASK_clinker _loading _in_rake

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1. The document outlines the procedures for emptying wagons, loading them, and transporting the loaded wagons. It involves multiple steps of moving wagons using locomotives between stations, sealing wagons, loading clinker using equipment, covering wagons during monsoon, and weighing loaded wagons.

2. Safety measures are defined for each step, including inspections, communication protocols, use of protective equipment, and ensuring clearance during movement of heavy machinery.

3. The process aims to efficiently transport clinker from the loading site to the destination station in three lots within a 7 hour timeframe.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров2 страницыTASK - Clinker - Loading - in - Rake

Загружено:

saji kumar1. The document outlines the procedures for emptying wagons, loading them, and transporting the loaded wagons. It involves multiple steps of moving wagons using locomotives between stations, sealing wagons, loading clinker using equipment, covering wagons during monsoon, and weighing loaded wagons.

2. Safety measures are defined for each step, including inspections, communication protocols, use of protective equipment, and ensuring clearance during movement of heavy machinery.

3. The process aims to efficiently transport clinker from the loading site to the destination station in three lots within a 7 hour timeframe.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

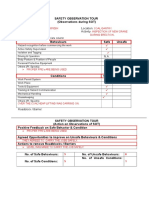

TASK ACTICITY CONTROL MEASURE

1.Empty wagons a) On information from station Master 1. Ensure full inspection of

from station to CDS ,whom instructs to Loco LOCO before use.

operator to bring empty wagons from 2.Ensure proper coupling –

LKE. Decoupling of wagons /

b) Usually Loco # 11, bring full empty loco by pointsmen

rake from LKE station at a time, 3. Use of Wheel choke to

containing 58/59 wagons. prevent roll off.

c) Loco #9, separate out first 38 boxes 4. Hooter should be used

from rest and get coupled with last 20 while crossing barrier

Wagons. both inside and outside

d) First 38 Boxes are called inside plant, the plant.

to distribute in 2 parts , first 20 5. Proper communication

Boxes in store Line and Second through mobile or Walky

18/19 boxes in Coal Line 2.It Talkie.

enables us to continuous Loading

and wagon ceiling can be done

easily.

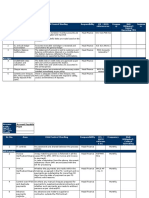

2. Placement of 1. Loco #9 , after loco # 11 made 1. Crossing gate should be

unloading wagons placement, place 20 wagons to locked before movement

loading site, where before loading of loco (specially Crusher

with claim shell sealing of wagons Gate).

done. 2. Proper guidelines was

given to loco operator by

In charge Material

handling

2.Sealing of wagons 1.Sealing of wagons done by trained and 1. Use of standard tools

side door experience labours, using rods they and tackles.

manual open the door and get check 2. Steel ladder should be

gaps in floor of wagons and seal the used for entry in wagons.

gaps with waste plastic bags if need. 3. Yard supervisor will be

Otherwise, seal the gaps in door with associated and coordinate

waste plastic bags. with labours while moving

2.Once sealing of wagons done , of loco, only.

permission was given by labours for

loading process

3.Loading of wagons 1. Wagons are placed within range of 1. Nobody should allow to

from claim shell & claim shell boom and pay loader with stand in the range of boom

pay loader its lift bucket fills clinker. of claim shell or pay loader

2. Operation of claim shell and pay path.

loader should follow separate SOP to 2. Claim shell operator and

be referred. Pay loader operator should

3. Carrying capacity of wagons of type of follow SOP applied to the

wagons and filling clinker based on operation of their machine.

route ( refer to Annexure 1) 3. standard PPE should be

4. Based on past experience, clinker is used by this operators

loaded on no. of bucket of claim shell 4. By horn sound , operator

/pay loader in operation. informs completion of

5. Yard Supervisor with Third party clinker filling.

supervisor coordinate with Pointsmen 5. While moving forward

while moving forward after filling wagons, hooter sound ON

wagons, ask loco operator to pull by the Points men standing

wagon forward one of three wagons at there.

time. 6. While pulling another lot

6. Usually in three Lot clinker is filled , after completion of previous

20 wagons, each , last lot containing ! lot. Pointsment should

8/20 wagons apply wheel choke in 1st

box to avoid wagon roll off.

4. Tarpaulin cover in 1. During the period of Monsoon, 1. Since Wagon cap

Monsoon period Tarpaulin covering done over the covering is done

clinker rake to protect clinker from manually, all the safety

rain. aspects should be looked

2. After the loading done, Loco #11 will after by the contractor

carry loaded wagon in Railway Yard under how trained

where, at a time, 20 boxes are subject persons are used to cover

to tarpaulin cover manually done by the wagon cap.

business partners. 2. Used of standard ladder

3. Preparation of nylon ropes and steel and necessary PPE

wire were lifted from plant to site. should be weared by the

4. Specified dimension wagon caps persons deployed for this

were subject to cover the wagon tie, job to prevent slip or fall ,

tightly by nylon rope, the sides of the fall from height etc by

cap were tied with steel wire. applying all standard

norms of FPE.

5. Shifting of Loaded 1.Loco # 11 ,usually deployed to carry 1. While moving along the

wagons to LKE loaded wagon with or without tracks LOCO operators

tarpaulin to LKE in 3 lots and should aware about the

assemble their in full loaded rake. persons involve in

2.The loaded period was given 7 hrs, covering wagon cap,

from the period where indent was Hooter should

placed to last boxes shunted. continuously bowled and

3. Weightment of rake done at SWM Rly motion of loco in reduced

way station on RLY WB and its weight speed.

is considered as Final weight and 2. Once confirmed by Rate

considered as INVOICE WEIGHT. contract contractor of

covering done and

manpower separate out,

then only LOCO shunting

is allowed.,

3. However in NON

Monsoon period , LOCO

just shunt inside the

plant and carry to LKE.,

Вам также может понравиться

- 1983 Mhlume Rota Tipper Cane Offloading System PDFДокумент4 страницы1983 Mhlume Rota Tipper Cane Offloading System PDFbonginkosi mathunjwaОценок пока нет

- TTM 2000 RezeoДокумент403 страницыTTM 2000 RezeoFlo FloОценок пока нет

- Lifting Plan For Equipment - MMSPДокумент14 страницLifting Plan For Equipment - MMSPClifford100% (2)

- SHESOP013-2 - Loading and Unloading - TLokДокумент5 страницSHESOP013-2 - Loading and Unloading - TLokakmalul adabiОценок пока нет

- Pamphlet On Unloading of Long Welded Panels - FinalДокумент4 страницыPamphlet On Unloading of Long Welded Panels - FinalashokОценок пока нет

- Seam 213Документ8 страницSeam 213John Gonzaga EscuadroОценок пока нет

- Mooring Operations and Unmooring OperationsДокумент30 страницMooring Operations and Unmooring OperationsK.Prassindren S.KumarasingamОценок пока нет

- Methodology of Hard Shoulder: - 1 - VKLR - QmeДокумент4 страницыMethodology of Hard Shoulder: - 1 - VKLR - QmeBalaji ManneОценок пока нет

- Pamphlet On Long Haul Train OperationДокумент5 страницPamphlet On Long Haul Train OperationPraveen BhatiОценок пока нет

- Monitor The Loading, Stowage, SecuringДокумент3 страницыMonitor The Loading, Stowage, SecuringNakiri AliceОценок пока нет

- MS - Gondola System Rev 2Документ6 страницMS - Gondola System Rev 2Non Etabas Gadnatam100% (1)

- Method Statement To Construct Concrete RoadДокумент2 страницыMethod Statement To Construct Concrete RoadSyafiq ZakiОценок пока нет

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightДокумент1 страницаInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarОценок пока нет

- Contoh Soal Dan Pembahasan Analisa Operasional Konstruksi 4Документ5 страницContoh Soal Dan Pembahasan Analisa Operasional Konstruksi 4saocy vidyaОценок пока нет

- Vehicle Inspection SheetДокумент1 страницаVehicle Inspection Sheetcad curОценок пока нет

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Документ7 страницJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VargheseОценок пока нет

- Cargo Handling and StowageДокумент24 страницыCargo Handling and StowageDudy Achmad Abdul Gafar100% (1)

- HSAC Transporter Tote Transfer ChecklistДокумент1 страницаHSAC Transporter Tote Transfer ChecklistPat BОценок пока нет

- B TC Installation 2Документ19 страницB TC Installation 2TanveerОценок пока нет

- Tugas 5 PAOK - 25022069 - Saocy VidyaДокумент6 страницTugas 5 PAOK - 25022069 - Saocy Vidyasaocy vidyaОценок пока нет

- Baggage Handling at HeathrowДокумент2 страницыBaggage Handling at Heathrownameetamahato6759Оценок пока нет

- SED - T4203 - Unit 3 - Bulk Carriers 2Документ4 страницыSED - T4203 - Unit 3 - Bulk Carriers 2Ashutosh SinghОценок пока нет

- Thermal Power Plant Micro For LaluДокумент1 страницаThermal Power Plant Micro For LaluVideo CloudОценок пока нет

- B1c Cargo Handle StowДокумент24 страницыB1c Cargo Handle Stowpandey_adesh21470Оценок пока нет

- Picking Up Pipe (Floorman) : Cormorant Alpha Drilling Operations GuideДокумент9 страницPicking Up Pipe (Floorman) : Cormorant Alpha Drilling Operations GuidealiОценок пока нет

- Lifting Plan Checklist and Method Statement SkeletonДокумент7 страницLifting Plan Checklist and Method Statement SkeletonPronoia EnterprisesОценок пока нет

- Carriage of Grain Safe ProcedureДокумент3 страницыCarriage of Grain Safe Proceduressabih75Оценок пока нет

- Exceptional EquipmentДокумент6 страницExceptional Equipmentnawlen nawlenОценок пока нет

- Handlingtanks Jan2008Документ5 страницHandlingtanks Jan2008anil simonОценок пока нет

- Contractor Crane Topple Incident: Preliminary: Investigation OngoingДокумент10 страницContractor Crane Topple Incident: Preliminary: Investigation OngoingElsayed ElberryОценок пока нет

- Long Haul Train OperationДокумент5 страницLong Haul Train OperationSharad SahuОценок пока нет

- Anchoring Procedure 1Документ8 страницAnchoring Procedure 1pgupta71Оценок пока нет

- SOP For Mobile CraneДокумент1 страницаSOP For Mobile CraneloganathanОценок пока нет

- Group 2 (Buatan Port)Документ11 страницGroup 2 (Buatan Port)imeldaelisabeth0% (1)

- PKI Method StatementДокумент2 страницыPKI Method StatementYvoj OñisacОценок пока нет

- Recovery Plan For CraneДокумент2 страницыRecovery Plan For CraneKen LeongОценок пока нет

- ch8 PDFДокумент70 страницch8 PDFOscar Sacases PlanasОценок пока нет

- Preparations To Arrive PortДокумент3 страницыPreparations To Arrive Portshyam subramaniОценок пока нет

- LG20-40DT User ManualДокумент76 страницLG20-40DT User ManualLuzioNetoОценок пока нет

- 2015225144249info Memo - Crane InfraДокумент18 страниц2015225144249info Memo - Crane InfraAbhishek GadatiaОценок пока нет

- Cargo Work: Gross Vulume Occupied by Cargo Weight of CargoДокумент3 страницыCargo Work: Gross Vulume Occupied by Cargo Weight of CargoAbu Syeed Md. Aurangzeb Al MasumОценок пока нет

- Sugar Production: Unit 01Документ10 страницSugar Production: Unit 01Hari kantОценок пока нет

- Cargo Work and Lifting GearДокумент12 страницCargo Work and Lifting GearhutsonianpОценок пока нет

- 10 B Bulk Cargo Transfer Check List FormДокумент6 страниц10 B Bulk Cargo Transfer Check List Formasdasd0% (1)

- 6.1.6 Loading and Unloading When Using Load CarriersДокумент37 страниц6.1.6 Loading and Unloading When Using Load Carriersmirano81Оценок пока нет

- Truck Loading Checklist - DraftДокумент1 страницаTruck Loading Checklist - DraftSaïd Ben AbdallahОценок пока нет

- Crane Erection Work SWMДокумент4 страницыCrane Erection Work SWMSanjay GuptaОценок пока нет

- Inspect and Report Defect and Damage To Cargo SpacesДокумент1 страницаInspect and Report Defect and Damage To Cargo SpacesRisq FirmansyahОценок пока нет

- Release: 2.0 Effective: 06/02/04 Derby Fire Department Standard Operating Procedure Number 06 Truck Company OperationsДокумент7 страницRelease: 2.0 Effective: 06/02/04 Derby Fire Department Standard Operating Procedure Number 06 Truck Company OperationsRagu RamsinghОценок пока нет

- CargoДокумент14 страницCargoMahamiОценок пока нет

- Group 2 Bunkering Procedure 29052021Документ9 страницGroup 2 Bunkering Procedure 29052021Ranets MamondoleОценок пока нет

- Excavator OperationДокумент6 страницExcavator OperationRussellОценок пока нет

- Ace-Lp-005 Frog LP Rev - 1Документ11 страницAce-Lp-005 Frog LP Rev - 1AzerОценок пока нет

- General Guidelines and Dimensions Step 2: Unpacking The BaysДокумент2 страницыGeneral Guidelines and Dimensions Step 2: Unpacking The BaysamirbahramОценок пока нет

- Jsa of Boiler Drum LiftingДокумент10 страницJsa of Boiler Drum LiftingGyanendra Narayan NayakОценок пока нет

- SPM DetailsДокумент14 страницSPM DetailsBanjoОценок пока нет

- The Efficient Port: The Commonwealth and International Library: Social Administration, Training, Economics, and Production DivisionОт EverandThe Efficient Port: The Commonwealth and International Library: Social Administration, Training, Economics, and Production DivisionОценок пока нет

- Cargo Handling and the Modern Port: The Commonwealth and International Library of Science Technology Engineering and Liberal StudiesОт EverandCargo Handling and the Modern Port: The Commonwealth and International Library of Science Technology Engineering and Liberal StudiesОценок пока нет

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasОт EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasРейтинг: 5 из 5 звезд5/5 (11)

- Bombers' Training, and Application of Same in Trench WarfareОт EverandBombers' Training, and Application of Same in Trench WarfareОценок пока нет

- Unloading by TrucksДокумент2 страницыUnloading by Truckssaji kumarОценок пока нет

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightДокумент1 страницаInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarОценок пока нет

- Sop For Operation of EotДокумент2 страницыSop For Operation of Eotsaji kumarОценок пока нет

- Standard Operating Procedures 1Документ1 страницаStandard Operating Procedures 1saji kumarОценок пока нет

- Dammurage Study FormatДокумент2 страницыDammurage Study Formatsaji kumarОценок пока нет

- Heo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain ShellДокумент6 страницHeo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain Shellsaji kumarОценок пока нет

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Документ3 страницыPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarОценок пока нет

- SOP - 22 - Preparation of Activated GypsumДокумент2 страницыSOP - 22 - Preparation of Activated Gypsumsaji kumarОценок пока нет

- 1.1 Program KymoreДокумент2 страницы1.1 Program Kymoresaji kumarОценок пока нет

- North - PV Var - Summary LK MarДокумент3 страницыNorth - PV Var - Summary LK Marsaji kumarОценок пока нет

- 1.microscopy - Glass Content in Slag SOPДокумент1 страница1.microscopy - Glass Content in Slag SOPsaji kumarОценок пока нет

- Ot SlipДокумент1 страницаOt Slipsaji kumarОценок пока нет

- BH15/SN23 BH15/SN30Документ17 страницBH15/SN23 BH15/SN30saji kumarОценок пока нет

- B K Singh Sot Dec06Документ1 страницаB K Singh Sot Dec06saji kumarОценок пока нет

- Compliance Checklist - PlantДокумент36 страницCompliance Checklist - Plantsaji kumarОценок пока нет

- M.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: ActivityДокумент2 страницыM.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: Activitysaji kumarОценок пока нет

- Please Tick in Appropriate Column: Roadblock / BarrierДокумент1 страницаPlease Tick in Appropriate Column: Roadblock / Barriersaji kumarОценок пока нет

- Chapter 3a Geometry of CrystalsДокумент72 страницыChapter 3a Geometry of Crystalssaji kumar100% (1)

- Visit To DelhiДокумент11 страницVisit To Delhisaji kumarОценок пока нет

- Procurement Process Guide V 5.0 - Final CompressedДокумент114 страницProcurement Process Guide V 5.0 - Final Compressedsaji kumar100% (1)

- Mines Bore Hole Sample Analysis Test Results (Durg)Документ4 страницыMines Bore Hole Sample Analysis Test Results (Durg)saji kumarОценок пока нет

- Bridge Structures: N.Sadasivam 060901008Документ27 страницBridge Structures: N.Sadasivam 060901008Sada SivamОценок пока нет

- Geometri Jalan Raya 3 Diagram SuperelevasiДокумент10 страницGeometri Jalan Raya 3 Diagram SuperelevasiAyu KrismaОценок пока нет

- Electrical Networks Standard Track Bonding For Signalling and Traction Return CurrentДокумент34 страницыElectrical Networks Standard Track Bonding For Signalling and Traction Return CurrentSivaji KotipalliОценок пока нет

- Types of Intersection of Roads PDFДокумент15 страницTypes of Intersection of Roads PDFkenjam89mbОценок пока нет

- A Poem in Steel The Victoria Falls BridgeДокумент4 страницыA Poem in Steel The Victoria Falls BridgeAsdar AzisОценок пока нет

- NIST 0001 Rev B - Structure Gauge EnvelopesДокумент32 страницыNIST 0001 Rev B - Structure Gauge Envelopes4493464Оценок пока нет

- Al Ko Genuine Parts Catalog (Lit 775 00al)Документ42 страницыAl Ko Genuine Parts Catalog (Lit 775 00al)YC CarieloОценок пока нет

- RailwaySignalling 2019 LeseprДокумент26 страницRailwaySignalling 2019 Leseprmarlo100% (1)

- 181215-CCECC-MAX-DCRP-BR-18-F-0601 Resubmission of Method Statement For Handing, Stacking and Transportation of SleepersДокумент34 страницы181215-CCECC-MAX-DCRP-BR-18-F-0601 Resubmission of Method Statement For Handing, Stacking and Transportation of SleepersArman ShohelОценок пока нет

- Rizal in Hongkong, Japan, USA PDFДокумент49 страницRizal in Hongkong, Japan, USA PDFChristian Lee100% (1)

- Hyperloop Technologies Inc. Business ConfidentialДокумент34 страницыHyperloop Technologies Inc. Business ConfidentialAMITH LAWRENCEОценок пока нет

- Avoiding Stairs Tube GuideДокумент16 страницAvoiding Stairs Tube GuideWОценок пока нет

- ERC Safety Requirement of Railway ProjectДокумент29 страницERC Safety Requirement of Railway ProjectAmanuelGirmaОценок пока нет

- Project 1Документ72 страницыProject 1Harshil HundiaОценок пока нет

- RTG CRANE - Rubber Tyred Gantry Crane in US and UK - Port OperatorДокумент16 страницRTG CRANE - Rubber Tyred Gantry Crane in US and UK - Port Operatorred patriotОценок пока нет

- Kajian Potensi Lanskap Untuk Pengembangan Wisata Sejarah Kota MedanДокумент7 страницKajian Potensi Lanskap Untuk Pengembangan Wisata Sejarah Kota MedanydrОценок пока нет

- End Stops Series Brochure ENДокумент20 страницEnd Stops Series Brochure ENedark2009Оценок пока нет

- Berlin in Your Pocket GuideДокумент43 страницыBerlin in Your Pocket GuideacockramОценок пока нет

- (NE) RIS & RDS Delegate BookletДокумент15 страниц(NE) RIS & RDS Delegate Bookletishita pantОценок пока нет

- Sitras DSG - Pi - 203 - 76Документ4 страницыSitras DSG - Pi - 203 - 76Luteca TecaОценок пока нет

- ETicket - ETicketing - Haryana RoadwaysДокумент2 страницыETicket - ETicketing - Haryana RoadwaysAnonymous sigetQОценок пока нет

- 10035-STR-RPT-0001 - DBR - Straight and Mild Curve R3Документ68 страниц10035-STR-RPT-0001 - DBR - Straight and Mild Curve R3darshanОценок пока нет

- Research Article: Investigation On Derailment of Empty Wagons of Long Freight Train During Dynamic BrakingДокумент19 страницResearch Article: Investigation On Derailment of Empty Wagons of Long Freight Train During Dynamic BrakingHASSANE HOTAITОценок пока нет

- S1 Not (A Xor B) S2 Not D or (C and D) S S2 and (E Xor S1)Документ11 страницS1 Not (A Xor B) S2 Not D or (C and D) S S2 and (E Xor S1)oussama elkaissiОценок пока нет

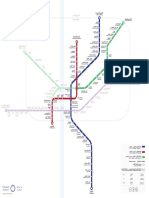

- Metro Map - October 2020Документ1 страницаMetro Map - October 2020Mixmixmix MixОценок пока нет

- Railway Courses 11.15Документ3 страницыRailway Courses 11.15Maam Gie RanayОценок пока нет

- Design / Construction Interface Manual Part 3: Guideway: Cairo, 6 of October City, MonorailДокумент63 страницыDesign / Construction Interface Manual Part 3: Guideway: Cairo, 6 of October City, MonorailMohamed Adel100% (1)

- Saudi Aramco'S: Scaffold Tagging SystemДокумент37 страницSaudi Aramco'S: Scaffold Tagging SystemKhaled Ismail100% (4)

- Rail Alignment Geometric DesignДокумент52 страницыRail Alignment Geometric DesignMeg TОценок пока нет

- Blackfriars Bridge Display BoardДокумент1 страницаBlackfriars Bridge Display BoardthamestunnelОценок пока нет