Академический Документы

Профессиональный Документы

Культура Документы

Actuadrotativaltek

Загружено:

Eduardo Landa GonzalezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Actuadrotativaltek

Загружено:

Eduardo Landa GonzalezАвторское право:

Доступные форматы

Spring Cylinder Rotary Actuators

TB031 RotaryAct 07(9-01).p65 1 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Introduction

High interchangeability Compact, lightweight design for

reduces spare part easy handling, limited space

requirements

Rocking piston

provides direct

connection to shaft

Actuator spring for

fail-safe operation

Sliding seal

assembly for

reliable, long-life

operation

Adjustable stroke stops

prevent excessive rotation

and reduce excessive Splined lever/shaft for

torque on shaft zero lost motion

Figure 1: Spring Cylinder Rotary Actuator Features

The Valtek® spring cylinder rotary actuator combines pneumatic and electro-pneumatic positioners are avail-

high torque and pneumatic stiffness with excellent throt- able for throttling applications.

tling capabilities. These characteristics are designed The Valtek actuator, cylinder and positioner are de-

into a lightweight, rugged and compact assembly, mak- signed for supply pressures up to 150 psi* (10.3 bar),

ing the Valtek rotary actuator the foremost choice for making very high torques attainable. The actuator uses

quarter-turn applications. The Valtek rotary actuator is a rocking piston for direct conversion of linear motion to

designed to operate the Valdisk high-performance but- rotary motion. The rocking piston assembly combined

terfly valve, the ShearStream V-notch ball valve, or other with a splined shaft and lever eliminates lost motion.

applications requiring precise rotary motion. Valtek (*See Tables I and II for limitations on certain sizes.)

2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB031 RotaryAct 07(9-01).p65 2 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Features and Advantages

The Valtek spring cylinder rotary actuator features high torques, positioning stiffness and easy maintenance to

produce a high-performance rotary actuator that excels in maintenance-free throttling and on/off control applications.

Features Advantages

Accepts up to 150 psi (10.3 bar) Achieves higher torques

air supply Obtains stiff piston positioning

Permits higher ∆P limits on valve

Rocking piston Provides direct connection to shaft

Assures zero lost motion between actuator and valve

Utilizes fewer parts

Splined shaft and lever Allows zero lost motion

Compact, lightweight, rugged Permits easy maintenance

Installs in limited space applications

Easily meets seismic requirements

Low-friction bearings Provide millions of cycles with minimal wear

Combined with direct linkage, provides very low hysteresis

Field-reversible Requires no extra parts

Permits fast, easy field reversing of air action

Requires no change of spring action

Fail-safe spring Moves actuator to failure position without pressure assistance

Air-purged, fully enclosed Prevents corrosion of linkage

transfer case Ensures safe operation

Contains external position indicator

Allows four mounting positions without retubing, changing or

adding parts

Stroke stops Allow both ends of stroke to be adjusted

Interchangeability Minimizes requirements for stocking spare parts

Reduces inventory costs

Uses identical parts in differing rotary actuator sizes

Utilizes many Valtek linear actuator parts

Spool-type four-way Provides high-performance modulating positioner control

positioner Ensures ease of calibration and maintenance due to fewer parts

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 3

TB031 RotaryAct 07(9-01).p65 3 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Stiffness and Performance

For a size 25 cylinder actuator (typical for a 2-inch DN25

valve) with a supply air pressure of 100 psi (6.9 bar), the

spring rate would be nearly 10,000 pounds per inch

(11,500 kg/cm) near the seat. As the volume under the

piston becomes smaller, the stiffness factor becomes

larger in the Valtek spring cylinder rotary actuator. The

result of the higher actuator stiffness in cylinder actua-

tors is that rotary valves can be operated in the flow-to-

close orientation without position fluctuations caused by

dynamic forces (flow fluctuations).

The spring rate for a diaphragm actuator remains the

same, regardless of diaphragm position. The equivalent

diaphragm actuator (46 in2 / 298 cm2) on the same valve

with a 3-15 psi (0.2-1 bar) signal has a spring rate of less

than 1000 pounds per inch (11.50 kg/cm). When a rotary

valve with a diaphragm actuator is operated near its

closed position, sudden changes in dynamic force can

cause the valve to slam shut.

In contrast, the stiffness of the Valtek spring cylinder rotary

Highest actuators actually increases as the closing member ap-

Mid-stroke

Stiffness proaches the seating surface (Figure 2). Thus, the Valtek

rotary actuators and rotary valves may be operated with

Figure 2: Actuator Position the valve shaft upstream or downstream.

Control valves generally are used by the process control

Torque Producing Capability

industry to regulate constantly fluctuating flows. As the The Valtek spring cylinder rotary actuator produces

dynamic forces of a flow increase or decrease, the substantially higher torque than a comparable diaphragm

control valve must remain in the same position as actuator because the cylinder operates with supply

dictated by the controller. To do this, the valve is depen- pressures up to 150 psi (10.3 bar). Throttling diaphragm

dent upon the actuator stiffness to minimize these actuators are limited to 40-60 psi (2.8-4.1 bar) thus,

position fluctuations. decreasing their torque-producing capability. Higher

actuator air supply, coupled with high-pressure air on

Actuator stiffness is defined as the ability of the actuator

both sides of the actuator piston, provide exceptional

to withstand suddenly changing dynamic fluid forces

stiffness for precise throttling control. The Valtek rotary

acting on the valve trim.

actuator stiffness is sufficient to control high pressure

Since supply air pressure is delivered to both sides of the drops and to permit the valve to throttle near the seat.

piston in the cylinder, the stiffness of the Valtek spring

cylinder rotary actuator is significantly greater than that Cam Characterizable Operation

of a diaphragm actuator.

The Valtek standard Beta positioner is provided with a

The stiffness (spring rate) is equal to the expression: reversible cam that characterizes Valdisk’s CV to either

kPA2 modified equal percent or linear performance. The

K= same cam enhances the ShearStream control valve’s

v

inherent equal percent characteristic.

Where: K = spring rate

A second rotary cam is also available. This optional cam

k = ratio of specific heat provides ShearStream valves a linear relationship of

P = supply pressure rotation with respect to the controller signal. It is revers-

A2 = piston area (in2) ible for use in air-to-close or air-to-open, fail-open appli-

v = cylinder volume under piston cations and is also linear in this mode.

4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB031 RotaryAct 07(9-01).p65 4 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Performance and Options

Speed and Sensitivity 13.8 psig

The high air-handling capacity of the positioner, com- (0.95 bar)

Input Signal

bined with relatively low cylinder volumes, produces fast on

siti

stroking speeds. High operating speed is achieved with Po

Signal

virtually no overshoot when approaching the final disc lve

Va

or ball position. At the same time, static sensitivity of the

unit is excellent. For example, as little as 0.017 psi

(0.0017 bar) is required to rotate the shaft 0.01 degrees 4.2 psig

(0.29 bar)

(the minimum detectable movement in the tests con- 0 0.0 0.50 .72 1.00

ducted) on a size 25 actuator. A signal change of only Time (seconds)

0.02 psi (0.0014 bar) is required to reverse shaft motion. Figure 4: Step Test, Size 25 Actuator

Frequency Response Declutchable Handwheel Actuator

The frequency response of Valtek cylinder actuators is The declutchable handwheel is designed to override

extremely high – generally an order of magnitude better the actuator in case of air failure or if manual operation

than comparable diaphragm actuator units. Such is desired. This unit has a special high-output worm

response is achieved through a double-acting configu- gear that develops as much torque as the standard

ration that uses pressure on both sides of the piston. Valtek pneumatic rotary actuator.

Size 25 Actuator, 9 psi ± 2 psi (0.6 bar ± 0.13 bar)

0

Relative Response dB

3

9

Degrees

12

0

Phase Angle

30

60

90

120 Figure 5: Declutchable Handwheel

150

180

Manual Handwheel Actuator

0.01 0.04 0.1 0.4 1.0 4 10

For applications requiring infrequent but reliable opera-

Frequency – Hertz tion, a high-torque, manual handwheel actuator is avail-

Figure 3: Frequency Response able. Three sizes are available to match the torque

requirements of any application. The sealed housing is

made of cast iron and filled with grease for mainte-

Hysteresis and Repeatability nance-free operation.

An important characteristic of any actuator is its ability to Heavy-duty Springs

respond to signal changes from the controller and to give For high shutoff pressure, heavy-duty springs are avail-

uniform response unaffected by decreasing or increas- able. A spring cap installed in the cylinder is used for

ing pressures. Tests have shown that both the hyster- high pressure drop applications, requiring the installa-

esis and repeatability of the spring cylinder rotary actua- tion of the longer heavy-duty spring. The same spring

tor, (with Beta positioner) are less than 0.7 percent of full can be used for both fail-open and fail-closed appli-

scale. (See Table VII: Beta Positioner Performance on cations. Dual springs are available with size 100 and

page 10.) 200 rotary actuators.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5

TB031 RotaryAct 07(9-01).p65 5 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Torque Output

Table I: Net Torque Output of Actuators at Various Supply Pressures, lbs/in (kg/cm)

Actuator Supply Degrees from Fall Position on Air Supply Loss

Size Pressure

psi bar 0 10 20 30 40 50 60 70 80 90

STD 25 150 10.3 3013 3471 3399 3916 3700 4262 3907 4501 4000 4608 3970 4573 3811 4390 3514 4048 3084 3553 2532 2917

with 140 9.7 3808 4387 3165 36467 3444 39677 3631 4183 3714 4279 3685 4245 3531 4068 3253 3747 2854 3288 2339 2695

STD 120 8.3 2397 2761 2695 3105 2928 3373 3080 3548 3145 3623 3110 3583 2972 3424 2731 3146 2390 2753 1962 2260

Spring 100 6.9 1986 2288 2228 2567 2412 2779 2530 2915 2573 2964 2535 2920 2414 2781 2211 2547 1928 2221 1577 1817

80 5.5 1574 1813 1759 2026 1896 2184 1979 2280 2002 2306 1961 2259 1856 2138 1688 1945 1463 1685 1191 1372

60 4.1 1163 1340 1290 1486 1381 1591 1428 1645 1430 1647 1386 1597 1298 1495 1167 1344 1001 1153 806 929

Spring Torque 72 83 115 132 167 192 225 259 284 327 338 389 379 437 399 460 391 450 349 402

STD 25 150 10.3 2647 3049 2973 3425 3223 3713 3386 3901 3448 3972 3403 3920 3246 3739 2976 3428 2600 2995 2124 2447

with 140 9.7 2441 2812 2738 3154 2964 3415 3110 3583 3162 3643 3115 3589 2966 3416 2716 3129 2368 2728 1931 2225

HD 120 8.3 2030 2339 2270 2615 2450 2822 2558 2947 2590 2984 2542 2928 2409 2775 2195 2529 1905 2195 1552 1788

Spring 100 6.9 1618 1864 1802 2076 1934 2228 2009 2314 2020 2327 1967 2266 1850 2131 1673 1927 1441 1660 1167 1344

80 5.5 1206 1389 1333 1536 1418 1634 1457 1678 1448 1668 1392 1604 1292 1488 1151 1326 978 1127 781 900

60 4.1 795 916 865 996 902 1039 907 1045 877 1010 818 942 733 844 630 726 515 593 396 456

Spring Torque 440 507 542 624 647 745 749 863 839 967 908 1046 945 1089 937 1079 878 1011 758 873

STD 50 150 10.3 10701 12328 1198 13802 13015 14993 13751 15841 14134 16282 14089 16231 13575 15638 12568 14478 11043 12722 9035 10408

with 140 9.7 9970 11485 11157 12853 12114 13955 12798 14743 13136 15133 13083 15072 12596 14511 11653 13424 10232 11787 8365 9636

STD 120 8.3 8516 9810 9513 10959 10318 11886 10874 12527 11141 12834 11075 12758 10649 12268 9826 11320 8615 9924 7053 8125

Spring 100 6.9 7059 8132 7873 9070 8515 9809 8953 10314 9153 10544 9073 10453 8693 10014 7999 9215 6995 8058 5712 6580

80 5.5 5602 6454 6227 7174 6716 7737 7033 8102 7156 8244 7062 8135 6736 7760 6174 7112 5372 6189 4373 5038

60 4.1 4147 4777 4586 5283 4913 5660 5114 5891 5166 5951 5058 5827 4784 5511 4347 5008 3755 4326 3034 3495

Spring Torque 222 256 343 395 489 563 651 750 816 940 966 1113 1081 1245 1134 1306 1107 1275 983 1132

STD 50 150 10.3 9774 11260 10898 12555 11781 13572 12380 14262 12651 14574 12533 14438 12000 13824 11036 12713 9648 11115 7850 9043

with 140 9.7 9044 10419 10074 11605 10880 12534 11425 13162 11652 13423 11527 13279 11021 12696 10122 11661 8837 10180 7183 8275

HD 120 8.3 7591 8745 8430 9711 9083 10464 9502 10946 9657 11125 9519 10966 9073 10452 8300 9562 7216 8313 5865 6756

Spring 100 6.9 6133 7065 6790 7822 7281 8388 7585 8738 7668 8834 7516 8658 7117 8199 6473 7457 5597 6448 4527 5215

80 5.5 4678 5389 5148 5931 5481 6314 5660 6520 5671 6533 5508 6345 5163 5948 4646 5352 3974 4578 3186 3670

60 4.1 3223 3713 3505 4038 3681 4241 3741 4310 3680 4239 3501 4033 3209 3697 2821 3250 2356 2714 1846 2127

Spring Torque 1148 1323 1428 1645 1726 1988 2026 2334 2304 2654 2529 2913 2662 3067 2667 3072 2511 2893 2167 2496

STD 100 150 10.3 26194 30175 29415 33886 32022 36889 33847 38992 34730 40009 34559 39812 33234 38286 30711 35379 26943 31038 22035 25384

with 140 9.7 24385 28092 27397 31561 29784 34311 31459 36241 32253 37155 32069 36943 30831 35517 28446 32770 26936 31030 20378 23475

STD 120 8.3 20805 23967 23329 26875 25330 29180 26685 30741 27303 31453 27104 31224 25983 29932 23921 27557 20932 24114 17119 19721

Spring 100 6.9 17226 19844 19271 22200 20859 24030 21914 25245 22368 25768 22119 25481 21134 24346 19394 22342 16920 19492 13808 15907

80 5.5 13640 15713 15200 17510 16399 18892 17153 19760 17413 20060 17133 19737 16296 18773 14878 17139 12915 14878 10485 12079

60 4.1 10055 11583 11139 12832 11929 13742 12391 14274 12472 14368 12159 14007 11447 13187 10350 11923 8901 10254 7167 8256

Spring Torque 704 811 1049 1208 1461 1683 1913 2204 2370 2730 2783 3206 3088 3557 3225 3715 3135 3612 2775 3197

STD 100 150 10.3 24678 28429 27231 31370 29008 33417 29925 34474 29917 34464 28969 33373 27058 31171 24266 27954 20699 23845 16483 18988

with 140 9.7 22881 26359 25195 29025 26771 30840 27539 31725 27459 31633 26475 30499 24632 28376 22001 25345 18691 21532 14832 17086

Dual 120 8.3 19304 22238 21127 24338 22317 25709 22784 26247 22507 25928 21490 24756 19782 22789 17472 20128 14680 16911 11563 13321

Springs 100 6.9 15713 18101 17070 19665 17847 20560 18012 20750 17567 20237 16518 19029 14946 17218 12956 14925 10674 12296 8245 9498

80 5.5 12130 13974 12999 14975 13385 15420 13248 15262 12612 14529 11538 13292 10101 11636 8432 9714 6662 7675 4927 5676

60 4.1 8545 9844 8939 10298 8921 10277 8483 9772 7673 8840 6558 7555 5257 6056 3910 4504 2662 3067 1611 1856

Spring Torque 2217 2554 3256 3751 4485 5167 5831 6718 7185 8277 8405 9683 9299 10712 9691 11165 9407 10837 8316 9580

STD 200 80 5.5 27695 31905 31132 35864 33903 39056 35838 41285 36820 42417 36663 42236 35280 40643 32620 37578 28633 32985 23416 26976

with 70 4.8 24156 27828 27119 31241 29480 33961 31134 35866 31916 36767 31730 36553 30501 35137 28139 32416 25670 29572 20206 23277

STD 60 4.1 20595 23725 23091 26601 25069 28879 26406 30420 27014 31120 26813 30889 25699 29605 24656 28404 20697 23843 16926 19499

Spring 50 3.5 17051 19643 19072 21971 20643 23781 21696 24994 22126 25489 21876 25201 20897 24073 19173 22087 16724 19266 13646 15720

Spring Torque 704 811 1049 1208 1461 1683 1913 2204 2370 2730 2783 3206 3088 3557 3225 3715 3135 3612 2775 3197

STD 200 80 5.5

26192 30173 28930 33327 30894 35590 31940 36795 32005 36870 31052 35772 29104 33528 26177 30156 22393 25797 17887 20606

with 70 4.8

22636 26077 24918 28706 26467 30490 27214 31351 27122 31245 26136 30109 24302 27996 21693 24990 18420 21220 14650 16877

Dual 60 4.1

19094 21996 20889 24064 22056 25409 22505 25926 22217 25594 21198 24420 19499 22463 17208 19824 14445 16641 11370 13098

Springs 50 3.5

15538 17900 16872 19437 17629 20309 17779 20481 17326 19960 16275 18749 14709 16945 12735 14671 10478 12071 8083 9312

Spring Torque 2217 2554 3256 3751 4485 5167 5831 6717 7185 8277 8405 9683 9299 10712 9691 11164 9407 10837 8316 9580

NOTE: For air-to-open/fail-closed actuators the 0° position shown above corresponds to the disc or ball being seated.

For air-to-close/fail-open actuators the 90° position shown above corresponds to the disc or ball being seated.

*Size 200 actuator limited to 80 psi (5.5 bar) air supply pressure

6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB031 RotaryAct 07(9-01).p65 6 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Specifications

Table II: Rotary Actuator Data

*Actuator Max Upper Lower

Actuator Stroke Moment Air Spring Spring Cylinder Cylinder Shipping

Size Arm Supply Design Rate Area Area Weight**

in cm in cm psi barlb/in kg/cm in2 cm2 in2 cm2 lbs kg

STD 180 207

25 1.88 4.8 0.94 2.4 150 10.3 23.76 153.3 23.07 148.8 30 14

HD (Cap) 222 256

STD 164 189

50 3.25 8.3 1.63 4.1 150 10.3 47.17 304.3 46.07 297.2 60 27

HD (Cap) 235 271

STD 300 346

100 4.00 10.2 2.00 5.1 150 10.3 95.03 613.1 93.26 601.7 160 73

DUAL 885 1020

200 4.00 10.2 2.00 5.1 80 5.5 STD 300 346 188.69 1217.4 186.92 1206 265 120

DUAL 885 1020

* Valve in closed position

** Estimated, including Beta positioner

Table III: Actuator Specifications Table V: Materials of Construction

Type Cylinder with positive spring Yoke Ductile iron

action Transfer Case Anodized aluminum

Sizes 25, 50, 100 and 200

Splined Lever Arm Ductile iron

Spring Single (std.), heavy-duty,

Designs dual Stem 416 stainless steel

Action Field-reversible: air-to-open, Bearings Filament-wound fiberglass with

air-to-close PTFE liner

Operating Pressure Up to 150 psi** (10.3 bar) Sliding Seal Delrin 100, aluminum

Temperature Range -40° - 350°F* (-40° - 177°C) Retaining Ring Cadmium-plated steel

* Ambient temperatures greater than 180° F (82° C) require Piston Anodized aluminum

flourocarbon O-rings. Ambient temperatures below -40° F

(-40° C) require fluorosilicone O-rings.

Cylinder Anodized aluminum

** See Table II for limitations on certain actuators. O-ring Nitrile (std.)

Actuator Spring Coated steel (rust-proof)

Table IV: Spring Button Painted steel or cadmium-plated

Stroking Speeds with Positioner*

Time in Seconds Ordering Information

Actuator for 90° Rotation Actuator When ordering individual rotary actuators, the following

Size 1 Stroke

/4-in. Tubing 3/8-in.Tubing information must be provided:

(standard) (optional) in cm 1. Operating conditions, throttling or on/off.

25 (std.) 1.0 1.0 1.88 4.8 2. Maximum air supply pressure.

50 (std.) 3.5 3.5 3.25 8.3 3. Valve rotation in degrees.

100 (std.) 9.5 9.0 4.00 10.2 4. Actuator torque required at both ends of rotation.

* Beta positioner stroking valve to fail position. Consult factory 5. Positioner and input signal range, if needed.

for speeds faster than those shown above. 6. Stroking time requirements, if critical.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 7

TB031 RotaryAct 07(9-01).p65 7 12/19/02, 3:23 PM

Valtek Spring Cylinder Rotary Actuators

Dimensions

Table VIII: Rotary Actuator Dimensions (inches/mm)

Size C* E F FF G H J M N P R S** Press.

(act) (std. or (extended Conn.

dual spring) spring)

1

25 6.7 171 6.0 152 13.1 332 16.5 420 5.6 142 1.1 29 6.5 165 10.0 254 9.8 248 2.6 67 6.9 176 6.8 171 /4 NPT

1

50 6.7 171 8.0 203 17.2 437 23.5 598 6.7 170 2.0 50 9.1 232 12.0 305 10.3 260 3.4 86 9.1 230 6.8 171 /4 NPT

3

100 6.7 171 11.0 279 22.9 583 N/A N/A 9.1 230 2.4 61 12.5 318 18.0 457 12.8 324 5.4 137 10.4 263 6.8 171 /4 NPT

3

200 6.7 171 11.0 279 23.6 599 N/A N/A 9.1 230 2.4 61 17.5 445 18.0 457 12.8 324 5.4 137 10.4 263 6.8 171 /4 NPT

*7.8/198 on size 100 and 200 actuators, 16-inch (DN 400) and larger valves.

**7.9/202 on size 50 actuators and 8, 10-inch (DN 200, 250) valves; 9.4/238 on size 100, 200 actuators and 8,10,12-inch (DN 200, 250, 300) valves; 11.3/286 on size 100, 200

actuators and 16-inch (DN 400) and larger valves.

NOTE: Disassembly clearance (E) includes lifting ring on sizes 25 and 50

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its

intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance of Flowserve products.

The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe

use of Flowserve products in connection with the specific application.

While the information and specifications contained presented in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter

with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject

to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any of its worldwide operations or offices.

For more information, contact:

For more information about Flowserve, contact www.flowserve.com or call USA 972 443 6500

Regional Headquarters 12, av. du Québec, B.P. 645 104 Chelsea Parkway

91965, Courtaboeuf Cedex, Boothwyn, PA 19061 USA

1350 N. Mt. Springs Prkwy. France Phone 610 497 8600

Springville, UT 84663 Phone (33 1) 60 92 32 51 Facsimile 610 497 6680

Phone 801 489 8611 Facsimile (33 1) 60 92 32 99

Facsimile 801 489 3719 1300 Parkway View Drive

Quick Response Centers Pittsburgh, PA 15205 USA

12 Tuas Avenue 20 Phone 412 787 8803

Republic of Signapore 638824 5114 Railroad Street Facsimile 412 787 1944

Phone (65) 862 3332 Deer Park, TX 77536 USA

Facsimile (65) 862 4940 Phone 281 479 9500

Facsimile 281 479 8511

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

8 VLATB031-07 © 2001 Flowserve Corporation. Flowserve and Valtek

FCD are registered

Flowserve trademarks

Corporation, of Flowserve

Valtek Control Products,Corporation.

Tel. USA 801 489 8611

TB031 RotaryAct 07(9-01).p65 8 12/19/02, 3:23 PM

Вам также может понравиться

- Agrocompact f60 f70 f80 f90 Repair ManualДокумент520 страницAgrocompact f60 f70 f80 f90 Repair ManualZik Servis78% (9)

- Lp7516 User ManualДокумент30 страницLp7516 User ManualEduardo Landa GonzalezОценок пока нет

- HYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)Документ4 страницыHYUNDAI A4AF3, A4BF3 (Accent 2000-2007, Matrix 2003 ) 4 SPEED FWD With Lock Up (Electronic Control)ArturoОценок пока нет

- AixamДокумент156 страницAixamdockerwatsonОценок пока нет

- ValtekДокумент20 страницValtekhugolm9-1100% (1)

- DS 3410 3415 3420Документ47 страницDS 3410 3415 3420Israel ColinaОценок пока нет

- 7.5L EngineДокумент32 страницы7.5L EngineSalvador Gasca100% (1)

- Ingersoll Rand SSR M Series CompressorДокумент12 страницIngersoll Rand SSR M Series CompressorNaser100% (1)

- Spring Cylinder Rotary ActuatorДокумент12 страницSpring Cylinder Rotary ActuatorLuis Gustavo HernandezОценок пока нет

- Flowserve Mark OneДокумент20 страницFlowserve Mark OnetinozasableОценок пока нет

- Vlentb0001-02-Aq (LR)Документ20 страницVlentb0001-02-Aq (LR)Milos BajicОценок пока нет

- Flowserve - BrochureДокумент12 страницFlowserve - BrochureNurul LailyahОценок пока нет

- Valtek Mark One Control Valves Valtek Mark One Control ValvesДокумент21 страницаValtek Mark One Control Valves Valtek Mark One Control ValvesMgc ElektronikОценок пока нет

- Valtek Maxflo: Control ValvesДокумент11 страницValtek Maxflo: Control Valvessaroat moongwattanaОценок пока нет

- Flowserve Valdisk TX3Документ8 страницFlowserve Valdisk TX3RodrigoAndrés Cepeda PérezОценок пока нет

- Actuador Lineal ValtekДокумент16 страницActuador Lineal ValtekEduardo Landa GonzalezОценок пока нет

- VTL SeriesДокумент10 страницVTL Seriesxojoga9602Оценок пока нет

- TT OpEXL Eccentric Plug Rotary Valve BrochureДокумент16 страницTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezОценок пока нет

- 100 007 528c - RotaryActuator215Документ20 страниц100 007 528c - RotaryActuator215Andrean SuryaОценок пока нет

- Valdisk Manual PDFДокумент12 страницValdisk Manual PDFNag RajОценок пока нет

- 216 Rotary Actuators: Heavy Duty, Torque Generating Devices Designed For Precise Servo-Control ApplicationsДокумент20 страниц216 Rotary Actuators: Heavy Duty, Torque Generating Devices Designed For Precise Servo-Control ApplicationsSachin PatelОценок пока нет

- BFW AiravatДокумент4 страницыBFW Airavatyraju88Оценок пока нет

- VLATB110-Rack & Pinion & Scotch Yoke Actuators TBДокумент18 страницVLATB110-Rack & Pinion & Scotch Yoke Actuators TBBoy AlfredoОценок пока нет

- Kinetrol - QTR Turn Valve Spring ReturnДокумент3 страницыKinetrol - QTR Turn Valve Spring ReturnLeoОценок пока нет

- Christensen 140: Surface Core Drilling RigДокумент12 страницChristensen 140: Surface Core Drilling RigAriel100% (2)

- Diamond Power IR-3Z: Furnace Wall SootblowerДокумент4 страницыDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcОценок пока нет

- Experience High Performance Across A Broad Range of ApplicationsДокумент12 страницExperience High Performance Across A Broad Range of ApplicationsOlegario PalmaОценок пока нет

- Positioner Serie XL - Vlatb048Документ16 страницPositioner Serie XL - Vlatb048Felipe Gamboa GálvezОценок пока нет

- pcr200 FurkawaДокумент8 страницpcr200 FurkawaadheetteeaОценок пока нет

- ISIC Heavy Duty Pneumatic ActuatorДокумент14 страницISIC Heavy Duty Pneumatic Actuatoraizat91.acisОценок пока нет

- Eccentric Plug Valve (Rotary Globe)Документ8 страницEccentric Plug Valve (Rotary Globe)Giovanni PetrizzoОценок пока нет

- E101 3236 IR 3Z SootblowerДокумент4 страницыE101 3236 IR 3Z SootblowerKartika SuryawanОценок пока нет

- The Axial Flow Valve: Class 300/600Документ12 страницThe Axial Flow Valve: Class 300/600julio cesar ramirez gonzalezОценок пока нет

- Wa380 1 1994 (D1e)Документ8 страницWa380 1 1994 (D1e)Plstina RamsОценок пока нет

- CB 434DДокумент12 страницCB 434DAbraham Huacasi100% (1)

- Siemens Aqua-Lator Aerator CatalogДокумент16 страницSiemens Aqua-Lator Aerator CatalogAlexVelasquezQОценок пока нет

- Type of Rotor SystemДокумент6 страницType of Rotor SystemAhmadFaisalОценок пока нет

- Vw0811 Actuation OxlerДокумент2 страницыVw0811 Actuation OxlerAhmed KhairiОценок пока нет

- D85ESS-2A: With Steering Clutch/Brake SystemДокумент8 страницD85ESS-2A: With Steering Clutch/Brake SystemVidya SagarОценок пока нет

- Gflo - Globe ValveДокумент20 страницGflo - Globe ValveVarun PatelОценок пока нет

- D41ep 6Документ12 страницD41ep 6Abdul MansooriОценок пока нет

- Top Drive22157614Документ11 страницTop Drive22157614consultor rbpssОценок пока нет

- Eh1100 3Документ7 страницEh1100 3Alfonso BerRamОценок пока нет

- KINETROL Rotary ActuatorДокумент56 страницKINETROL Rotary ActuatorJoseОценок пока нет

- GWS THERN TA10 Air WinchesДокумент4 страницыGWS THERN TA10 Air WinchesKiat LimОценок пока нет

- CM20170405 41563 50972Документ24 страницыCM20170405 41563 50972abiud lira osorioОценок пока нет

- D85ess 2aДокумент8 страницD85ess 2aahmadfaathirОценок пока нет

- EC700BДокумент12 страницEC700Badelmomoura100% (2)

- Goulds LF 3171: Low Flow, High Head Vertical Sump PumpДокумент4 страницыGoulds LF 3171: Low Flow, High Head Vertical Sump PumpPaul CastroОценок пока нет

- Hydraulic ExcavatorДокумент16 страницHydraulic Excavatorиван ТрояновОценок пока нет

- CM20170405 41563 50972Документ22 страницыCM20170405 41563 50972Rafael MartinezОценок пока нет

- DozerДокумент4 страницыDozerbipin kumarОценок пока нет

- BHMN 35002 Camflex BR 19377B 0620 EnglishДокумент12 страницBHMN 35002 Camflex BR 19377B 0620 EnglishMario LopezОценок пока нет

- BD355Документ4 страницыBD355ruby100% (1)

- Gea 19377 Masoneilan 35002 Camflex Valve Brochure PDFДокумент12 страницGea 19377 Masoneilan 35002 Camflex Valve Brochure PDFN SОценок пока нет

- Manual S 821 826Документ4 страницыManual S 821 826Javi González100% (1)

- Cco RDV Prod. Lit. - en A4 - 121019Документ2 страницыCco RDV Prod. Lit. - en A4 - 121019SergeiОценок пока нет

- ActuatorДокумент8 страницActuatorsebastianОценок пока нет

- Series BDV ValvesДокумент20 страницSeries BDV ValvesMuhammad NaeemОценок пока нет

- RNP Actuator Metso NewДокумент11 страницRNP Actuator Metso NewOGPE-AMC1Оценок пока нет

- Wemco PresentationДокумент50 страницWemco PresentationCesar RjszvlОценок пока нет

- SF6 Circuit Breakers For Out D 040126.HTML AvsДокумент4 страницыSF6 Circuit Breakers For Out D 040126.HTML AvsLinh VănОценок пока нет

- Scheda Tecnica WA75Документ4 страницыScheda Tecnica WA75Stephane BarilОценок пока нет

- AquaJet 2015 Singlepages WebДокумент6 страницAquaJet 2015 Singlepages WebestyОценок пока нет

- Listade Parameyrso MSDF 65R. PARAMETROS BASCULA DE MAIZ Y ADITIVOДокумент9 страницListade Parameyrso MSDF 65R. PARAMETROS BASCULA DE MAIZ Y ADITIVOEduardo Landa GonzalezОценок пока нет

- Type 8510 and 8510B Eccentric Disc Control Valves (EMA)Документ20 страницType 8510 and 8510B Eccentric Disc Control Valves (EMA)Eduardo Landa GonzalezОценок пока нет

- Valtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyДокумент4 страницыValtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyEduardo Landa GonzalezОценок пока нет

- Actuador Valtek PDFДокумент8 страницActuador Valtek PDFEduardo Landa GonzalezОценок пока нет

- Asco TodasДокумент36 страницAsco TodasEduardo Landa GonzalezОценок пока нет

- Actuador Lineal ValtekДокумент16 страницActuador Lineal ValtekEduardo Landa GonzalezОценок пока нет

- Technical Information: Model EJA Series Fieldbus Communication TypeДокумент57 страницTechnical Information: Model EJA Series Fieldbus Communication TypeEduardo Landa GonzalezОценок пока нет

- Sensores de PHДокумент8 страницSensores de PHEduardo Landa GonzalezОценок пока нет

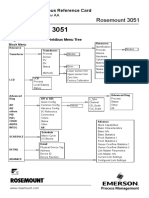

- Rosemount 3051: F Fieldbus Reference CardДокумент2 страницыRosemount 3051: F Fieldbus Reference CardEduardo Landa GonzalezОценок пока нет

- Sensores de Conductividad de ContactoДокумент12 страницSensores de Conductividad de ContactoEduardo Landa GonzalezОценок пока нет

- Guide To Using The Hach Digital Gateway: Hach Company, Box 389, Loveland, Colorado 80539 / USAДокумент2 страницыGuide To Using The Hach Digital Gateway: Hach Company, Box 389, Loveland, Colorado 80539 / USAEduardo Landa GonzalezОценок пока нет

- Compare Netto Jetjo Mei 2023Документ58 страницCompare Netto Jetjo Mei 2023Adian PanggabeanОценок пока нет

- Df200ap E01 015 (9900B-45325)Документ100 страницDf200ap E01 015 (9900B-45325)Jorge LopesОценок пока нет

- Turbo Generator & Its AuxiliariesДокумент89 страницTurbo Generator & Its AuxiliariesPapun ScribdОценок пока нет

- Tata Sumo Grande New DICOR / TURBO (Revision)Документ142 страницыTata Sumo Grande New DICOR / TURBO (Revision)xtempОценок пока нет

- Washer: Continuous Weave On Outer Mesh Panel (One Edge) Staggered 150 MM Pattern Hog Rings or Clips (Both Edges)Документ1 страницаWasher: Continuous Weave On Outer Mesh Panel (One Edge) Staggered 150 MM Pattern Hog Rings or Clips (Both Edges)JUAN RULFOОценок пока нет

- Useful EquationsДокумент3 страницыUseful EquationsAal KhalidОценок пока нет

- Turbo Charger Jet Engines Springers MДокумент50 страницTurbo Charger Jet Engines Springers MMolay Karmakar100% (2)

- Goodman ARUF Air Handler SpecsДокумент8 страницGoodman ARUF Air Handler SpecsEdward PeñaОценок пока нет

- OBD-2 20codesДокумент10 страницOBD-2 20codessan moedano100% (1)

- Control Valves - HydraulicsДокумент15 страницControl Valves - HydraulicsAhmad RazaОценок пока нет

- Special ToolsДокумент3 страницыSpecial ToolsBoss Tom HandsmenОценок пока нет

- MR Valve Guide, SealДокумент15 страницMR Valve Guide, SealbejoythomasОценок пока нет

- Faw FD280Документ427 страницFaw FD280farshot fish100% (1)

- Partes de Patines JOSTДокумент2 страницыPartes de Patines JOSTalejandroОценок пока нет

- '09 KLX150 C9F Title: This Catalog Covers: Grid No. This Grid CoversДокумент79 страниц'09 KLX150 C9F Title: This Catalog Covers: Grid No. This Grid CoversJohan CahyantoОценок пока нет

- Section 13E - Engine Fuel System PDFДокумент18 страницSection 13E - Engine Fuel System PDFrobbertmdОценок пока нет

- Common Rail Systems With Up To 2,000 Bar For Off-Highway ApplicationsДокумент2 страницыCommon Rail Systems With Up To 2,000 Bar For Off-Highway ApplicationsVladimirAgeevОценок пока нет

- PNet Doc Status With ET Remarks 23 Dec 2011Документ20 страницPNet Doc Status With ET Remarks 23 Dec 2011niginpОценок пока нет

- 1104c-44t For Bachoe LoaderДокумент154 страницы1104c-44t For Bachoe LoaderAgus Yulfizar100% (4)

- 1957-1967 250cc Crusader To Continental GTДокумент96 страниц1957-1967 250cc Crusader To Continental GTroyceОценок пока нет

- YMSFXC (018-060) BAAM - X Listado de Partes Indoor Solo FrioДокумент14 страницYMSFXC (018-060) BAAM - X Listado de Partes Indoor Solo Friomissael.alvramОценок пока нет

- Trans CodesДокумент13 страницTrans CodesJohn Allen100% (1)

- Equipment Rental Computed Operated HourДокумент14 страницEquipment Rental Computed Operated HourAlan MilanОценок пока нет

- Module 10 - 2 Hydraulic Power PacksДокумент63 страницыModule 10 - 2 Hydraulic Power PacksJaphet GabatanОценок пока нет

- Pro 4850 Install Guide PDFДокумент32 страницыPro 4850 Install Guide PDFAugusto RadaelliОценок пока нет