Академический Документы

Профессиональный Документы

Культура Документы

Application Worksheet Motorized Pulleys Fax: 910-794-9296: Standard Loading Conditions: Operating Conditions

Загружено:

emrah nalbant0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаrulmecea

Оригинальное название

Rulmeca_Bulk_Application_Data_sheet_20171108

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документrulmecea

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаApplication Worksheet Motorized Pulleys Fax: 910-794-9296: Standard Loading Conditions: Operating Conditions

Загружено:

emrah nalbantrulmecea

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

APPLICATION WORKSHEET: Email: sales-us@rulmeca.

com

Motorized Pulleys Fax: 910-794-9296

Complete this form and submit to Rulmeca for a power calculation and Motorized Pulley recommendation.

Contact Person ____________________________ Date ______________ Ref # ________________

Company __________________________________________________________________________

Address ___________________________________________________________________________

Phone _______________________ Fax ______________________ Email _____________________

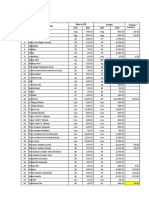

Standard Loading Conditions: Material (frictional coefficient) Operating Conditions:

Conveyor Length (ft) ____

Drive Location: head ____ tail ____

Tonnage Rate (tph) ____ o ashes, coal, dry 0.0571 Duty Cycle (Start/stops per hour) ____

Belt Speed (fpm) ____ o bauxite, ground 0.1881

Material Lift Height (ft) ____ o cement, Portland, dry 0.2120 Hours of Operation (hrs/day) ____

o cement clinker 0.1228 Days of Operation (days/week) ____

Ambient Temperature (oF) Min ____ o clay, ceramic, dry fines 0.0924

Ambient Temperature (oF) Max ____ o coal, bituminous mined 0.0754 Is this a reversing belt? ____

Initial Velocity of Material (fpm) ____ o coke, ground fine 0.0452

o cullet (broken glass) 0.0836

Number of Belt Cleaners ____ o grains, wheat, corn, rye 0.0433

Number of Belt Plows ____ o gravel, bank run 0.1145 Special Loading Conditions:

Length of Skirt Zone (ft) ____ o iron ore, 200 lbs/cu ft 0.2760

o limestone, pulverized dry 0.1280 Hopper Feeder Parameters:

Depth of Material in Skirt Zone (in) ____ o phosphate rock, dry 0.1086 Hopper Opening Width (in) ____

Number of Non-driven Pulleys ____ o salt, common, dry fine 0.0814 Hopper Opening Length (in) ____

o sand, dry, bank 0.1378

o wood chips 0.0095 No. of Hopper Openings ____

Elevation Idler Roll Type of

(ft) Diam. (in) Lagging

Material Bulk Density (pcf)

o 3,300 o 3 o Full Slider Bed Parameters:

o 5,000 o 4 o Partial o ashes, coal, wet 50 Slider Bed Length (ft) ____

o 6,600 o 5 o None o bagasse 10

o 6 o bark, wood 20 Slider Bed Material

Belt Width CEMA Type of o bauxite, ground, dry 68 (frictional coefficient)

(in) Type o bauxite, crushed 85

Take-up o beans, navy, dry 48 o steel 0.90

o beets, whole 48 o UHMW polyethylene 0.545

o 18 o A o Automatic o borax, 3” & under 70 o urethane 0.88

o 24 o B o Manual o cement, portland 99 o wood 1.00

o 30 o C o clay, ceramic, dry, fines, 80

o 36 o D o clay, dry, fines 120

o 42 o E Angle of o coal, bituminous 55

o 48 Wrap (deg) o coal, lignite 45 Sidewall & Cleated Belt Parameters:

o 54 Troughing o coke, 45 Sidewall & cleat height (in) ____

o 60 Idler Spac- o corn, ear, 56

o 66 ing (ft) o 180 o cullet, 120 Thickness of sidewall (in) ____

o 72 o 200 o gravel, bank run, 100 Distance between cleats (in) ____

o 84 o 3.0 o 210 o iron ore, 200 Thickness of cleats (in) ____

o 96 o 3.5 o 220 o iron ore pellets 130

o Other o 4.0 o 240 o limestone, crushed 90

_____ o 4.5 o 360 o paper pulp stock 60 Tripper Design Parameters:

o 5.0 o phosphate rock 85

o potash salts 80 Tripper Length (ft) ____

Type of Belt Belt Carcass o rock, crushed, 145 Tripper Material Lift Height (ft) ____

o rock, soft, 110 Number of Tripper Belt Cleaners ____

o 1 ply, 160 piw o rye, 46

o fabric o sale, common dry, fine, 80 Tripper Skirt Zone Length (ft) ____

o 2 ply, 225 piw o

o 3 ply, 330 piw steel cord o sand, bank, damp, 130 Depth of Material in Skirt Zone (in) ____

o 4 ply, 440 piw o sand, bank, dry, 110 No. of Tripper Non-driven Pulleys ____

o sand, foundry, 100

o sawdust 13

Material o sewage sludge, moist, 55

o soybeans, whole, 50 Additional Comments:

Maximum lump size (in) ____ o sugar, raw, cane, 65 _________________________________

Surcharge angle (degrees) ____ o taconite pellets 130

o traprock, 2-3” lumps, 110 _________________________________

Size consist: o wheat, cracked, 45 _________________________________

___% fines ___% max lump size o wood chips 30

www.rulmecacorp.com 5 TC101: 11/17

Вам также может понравиться

- Pile Foundation-10Документ28 страницPile Foundation-10M4 04 HOK WattanakОценок пока нет

- 10-Straw-ENG - CormallДокумент12 страниц10-Straw-ENG - CormallAli HusseiniОценок пока нет

- Tabel 1. Tensile Strength Dan Tegangan Desain Beberapa Jenis Bahan Pada Berbagai Suhu DesainДокумент7 страницTabel 1. Tensile Strength Dan Tegangan Desain Beberapa Jenis Bahan Pada Berbagai Suhu DesainKemuel MatthewОценок пока нет

- MATERIAL SHEET Raigad-Dsr-2015-16-PwdДокумент30 страницMATERIAL SHEET Raigad-Dsr-2015-16-PwdVikasОценок пока нет

- Stock HouseДокумент27 страницStock HousePrince Kumar100% (1)

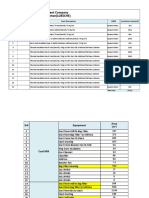

- Subject: Bill of Quantity Scope of Works Description Qty Unit Unit Cost AmountДокумент5 страницSubject: Bill of Quantity Scope of Works Description Qty Unit Unit Cost AmountMarites AmorsoloОценок пока нет

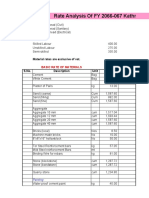

- Civil Rate AnalysisДокумент40 страницCivil Rate Analysisrayguntan0% (2)

- UntitledДокумент11 страницUntitledzaxaxazОценок пока нет

- Flyer Heron ENДокумент2 страницыFlyer Heron ENDavid SoonОценок пока нет

- Material Balance & Process Flow Sheet of PlantДокумент13 страницMaterial Balance & Process Flow Sheet of PlantAnkit AswalОценок пока нет

- Carpets Catalogue 2020Документ582 страницыCarpets Catalogue 2020yonatan fikruОценок пока нет

- ds1058 Appendix.aДокумент7 страницds1058 Appendix.aZia Ur RehmanОценок пока нет

- Ruby SpecsДокумент1 страницаRuby SpecsLalet BistОценок пока нет

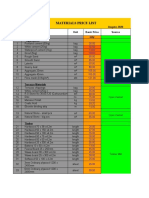

- Materials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e AggregatesДокумент19 страницMaterials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e Aggregatesmissowusu100% (1)

- Lab. EquipmentДокумент12 страницLab. EquipmentSk Sabir HossainОценок пока нет

- Order: Orgone Accumulators (Oracs)Документ4 страницыOrder: Orgone Accumulators (Oracs)bergadlerОценок пока нет

- Waferline Equipment List: Polysilicon To WafersДокумент6 страницWaferline Equipment List: Polysilicon To Wafersindian21rОценок пока нет

- Insulation BOQ Area Wise (Square MTR.)Документ12 страницInsulation BOQ Area Wise (Square MTR.)Atiq_2909Оценок пока нет

- DRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CДокумент2 страницыDRIVE POWER CALCULATION OF BELT CONVEYOR - GLOBAL COAL - Part 1CBimal DeyОценок пока нет

- Revised Reformulated Sor 2012-13 in Light of G.o.ms - NO.118Документ54 страницыRevised Reformulated Sor 2012-13 in Light of G.o.ms - NO.118seshukvsОценок пока нет

- Procemin 2015 Understanding The Slag Cooling Phenomenon and Its Impact On The Slag Flotation Process.Документ28 страницProcemin 2015 Understanding The Slag Cooling Phenomenon and Its Impact On The Slag Flotation Process.Nereo SpenglerОценок пока нет

- Brief Introduction of UHMWPEДокумент3 страницыBrief Introduction of UHMWPEFatima NusserОценок пока нет

- Casting - Solidification.Документ3 страницыCasting - Solidification.__Caro26__Оценок пока нет

- Micro PelletisationДокумент32 страницыMicro PelletisationArup SarkarОценок пока нет

- General SpecficationsДокумент6 страницGeneral SpecficationsesooОценок пока нет

- Uns C51000Документ2 страницыUns C51000nazgulОценок пока нет

- Material Characteristics PDFДокумент4 страницыMaterial Characteristics PDFELTIPAZOОценок пока нет

- Preliminary BoqДокумент30 страницPreliminary BoqOpira JohnОценок пока нет

- Hdpe Pipe SpecsДокумент8 страницHdpe Pipe SpecsSushil WadiyeОценок пока нет

- Insulation BOQ Area Wise (Square MTR.)Документ11 страницInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanОценок пока нет

- WRD Schedule of Rates 03-04Документ100 страницWRD Schedule of Rates 03-04Mohanraj SОценок пока нет

- Cooling Pad MaterialДокумент2 страницыCooling Pad MaterialParvez KhanОценок пока нет

- Improving Reformer Pigtail Reliability - Nitrogen+Syngas2014Документ7 страницImproving Reformer Pigtail Reliability - Nitrogen+Syngas2014Jean-Noël LerouxОценок пока нет

- Measurement of Pipe Line Lokrigola-IДокумент5 страницMeasurement of Pipe Line Lokrigola-ISamsul AlamОценок пока нет

- Data 10 AlangadДокумент141 страницаData 10 AlangadJude JosephОценок пока нет

- Material Break Down-WallДокумент45 страницMaterial Break Down-WallSudip GhimireОценок пока нет

- Design of A Deep Tube WellДокумент3 страницыDesign of A Deep Tube Wellsourav100% (3)

- KP Sharma EstimateДокумент31 страницаKP Sharma EstimateSudip GhimireОценок пока нет

- Design CriteriaДокумент21 страницаDesign CriteriaDick Anthony MabaoОценок пока нет

- Gaddani Covered CourtДокумент136 страницGaddani Covered CourtErnestОценок пока нет

- Presentasi Conveyor PDFДокумент23 страницыPresentasi Conveyor PDFWirsa RinekoОценок пока нет

- Spira X Sarco Fig 14Документ2 страницыSpira X Sarco Fig 14Jacobus CalvelageОценок пока нет

- AMP Photo ListДокумент10 страницAMP Photo ListBudi Jaya Equipment100% (1)

- 1 Tiffany Quotation of 1 2 Years Spare Parts of 40tph Animal Feed Line RICHIДокумент4 страницы1 Tiffany Quotation of 1 2 Years Spare Parts of 40tph Animal Feed Line RICHIzemengineeringservicesОценок пока нет

- Estimate Engr Petate 2Документ2 страницыEstimate Engr Petate 2jimanalo 15Оценок пока нет

- 1685 Rawlplug en 4all Universal PlugДокумент4 страницы1685 Rawlplug en 4all Universal PlugNG Wee JunОценок пока нет

- 13bentonit SlurryДокумент44 страницы13bentonit SlurryBishow KCОценок пока нет

- Project of Gang Saw Processing Plant For Marble: 1.LANDДокумент6 страницProject of Gang Saw Processing Plant For Marble: 1.LANDSudheer VarakalaОценок пока нет

- ATONProductGroup DataSheet ENДокумент4 страницыATONProductGroup DataSheet ENDavidLeeОценок пока нет

- Reformulared SoR For The Year 2008-09Документ19 страницReformulared SoR For The Year 2008-09T T RAMA RAOОценок пока нет

- QCJ1TQ 2Документ1 страницаQCJ1TQ 2JOSE CANTEROОценок пока нет

- Lead PДокумент7 страницLead PsaОценок пока нет

- Soil Bearing Capacity InfoДокумент1 страницаSoil Bearing Capacity InfoShivaprakash PrakashОценок пока нет

- Anchor T6 Elematic Tec TD en 01Документ1 страницаAnchor T6 Elematic Tec TD en 01Kasia GosławskaОценок пока нет

- 602 Ssab Toolox Machining Rec 6 PDFДокумент20 страниц602 Ssab Toolox Machining Rec 6 PDFRodolfoMarín100% (1)

- RFQ Civil Lab Eqpt 4Документ7 страницRFQ Civil Lab Eqpt 4abdul basitОценок пока нет

- Durgapur Steel PlantДокумент33 страницыDurgapur Steel Plantpremsukh100% (1)

- Civil Engineering DepartmentДокумент35 страницCivil Engineering Departmentahmad akramОценок пока нет

- Reformulated SoR For The Year 2012-13Документ295 страницReformulated SoR For The Year 2012-13D V BHASKARОценок пока нет

- Shrink Disc MAV 2008 Standard Duty: FeaturesДокумент6 страницShrink Disc MAV 2008 Standard Duty: Featuresemrah nalbantОценок пока нет

- DS SugarProcessing VL 1214 ENGДокумент2 страницыDS SugarProcessing VL 1214 ENGemrah nalbantОценок пока нет

- Shrink Disc MAV 2208 Heavy Duty: FeaturesДокумент4 страницыShrink Disc MAV 2208 Heavy Duty: Featuresemrah nalbantОценок пока нет

- Waste Water Treatment: Slide Valves VLДокумент2 страницыWaste Water Treatment: Slide Valves VLemrah nalbantОценок пока нет

- Doga Rulman Dana Gözü S.B.gennДокумент31 страницаDoga Rulman Dana Gözü S.B.gennemrah nalbantОценок пока нет

- Calculation Methods - Conveyor BeltsДокумент20 страницCalculation Methods - Conveyor BeltsPickMe AltheaОценок пока нет

- Doga Rulman Dana Gözü S.B.gennДокумент31 страницаDoga Rulman Dana Gözü S.B.gennemrah nalbantОценок пока нет

- Yeni Microsoft Word BelgesiДокумент1 страницаYeni Microsoft Word Belgesiemrah nalbantОценок пока нет

- Feww Dorat Rtal KombatДокумент1 страницаFeww Dorat Rtal Kombatemrah nalbantОценок пока нет

- Feww Dorat Rtal Kombat: DadadaДокумент1 страницаFeww Dorat Rtal Kombat: Dadadaemrah nalbantОценок пока нет

- Hydraulic SealsДокумент1 страницаHydraulic Sealsemrah nalbantОценок пока нет

- Hydraulic SealsДокумент1 страницаHydraulic Sealsemrah nalbantОценок пока нет

- FF 45Документ1 страницаFF 45emrah nalbantОценок пока нет

- IBEC BPL System ArchitectureДокумент2 страницыIBEC BPL System ArchitectureAleksandar ConevОценок пока нет

- Urban Jungle 8Документ3 страницыUrban Jungle 8Angel Medez GonzalezОценок пока нет

- 110Q Pump Catalog SheetДокумент2 страницы110Q Pump Catalog SheetJohnОценок пока нет

- Labor Relations LawsДокумент20 страницLabor Relations LawsREENA ALEKSSANDRA ACOPОценок пока нет

- A.R. Meenakshi v. State of Tamil Nadu, (Madras)Документ9 страницA.R. Meenakshi v. State of Tamil Nadu, (Madras)J VenkatramanОценок пока нет

- GNDДокумент16 страницGNDDEAN TENDEKAI CHIKOWOОценок пока нет

- MS Word Lecture NotesДокумент11 страницMS Word Lecture NotesMoguriОценок пока нет

- ManualДокумент36 страницManual2009tamerОценок пока нет

- FDI and FIIДокумент17 страницFDI and FIIsharathОценок пока нет

- Decisions Made by The DecisionДокумент2 страницыDecisions Made by The Decisionneil arellano mutiaОценок пока нет

- NCAA Safety Bulletin 23-4 - AprilДокумент21 страницаNCAA Safety Bulletin 23-4 - AprilAОценок пока нет

- SAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThisДокумент21 страницаSAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThissunnguyenОценок пока нет

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectДокумент10 страницMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiОценок пока нет

- XJ600SJ 1997Документ65 страницXJ600SJ 1997astracatОценок пока нет

- SIFI-131 Fire Protection in Electrical Equipment RoomsДокумент8 страницSIFI-131 Fire Protection in Electrical Equipment RoomsemiljanlazeОценок пока нет

- 010 Informed Search 2 - A StarДокумент20 страниц010 Informed Search 2 - A StarRashdeep SinghОценок пока нет

- 1LG4253-4AA60 Datasheet enДокумент1 страница1LG4253-4AA60 Datasheet enanm bОценок пока нет

- A Review of The Accounting CycleДокумент46 страницA Review of The Accounting CycleRОценок пока нет

- C10G - Hardware Installation GD - 3 - 12 - 2014Документ126 страницC10G - Hardware Installation GD - 3 - 12 - 2014Htt Ếch CốmОценок пока нет

- Account Statement 060922 051222Документ51 страницаAccount Statement 060922 051222allison squad xXОценок пока нет

- Latex Hints and TricksДокумент24 страницыLatex Hints and TricksbilzinetОценок пока нет

- Bizagi Podcast TranscriptДокумент6 страницBizagi Podcast TranscriptHortencia RodriguezОценок пока нет

- Theories of International TradeДокумент33 страницыTheories of International Tradefrediz79Оценок пока нет

- Roger Rabbit:, Forest Town, CA 90020Документ3 страницыRoger Rabbit:, Forest Town, CA 90020Marc TОценок пока нет

- Tutorial MailchimpДокумент334 страницыTutorial MailchimpLeandroSabado100% (1)

- Bodie8ce FormulaSheet PDFДокумент24 страницыBodie8ce FormulaSheet PDFSandini Dharmasena PereraОценок пока нет

- Project DescriptionДокумент5 страницProject DescriptionM ShahidОценок пока нет

- Surface Treatments & Coatings Ref: S. KalpakjianДокумент22 страницыSurface Treatments & Coatings Ref: S. KalpakjianjojoОценок пока нет

- CIVIL1Документ213 страницCIVIL1kokueiОценок пока нет

- Pabon v. NLRCДокумент4 страницыPabon v. NLRCHaniyyah FtmОценок пока нет