Академический Документы

Профессиональный Документы

Культура Документы

Caterpillar: Interpret Elevated Soot in 950L & 962L Engine Oils

Загружено:

Abner VillanuevaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Caterpillar: Interpret Elevated Soot in 950L & 962L Engine Oils

Загружено:

Abner VillanuevaАвторское право:

Доступные форматы

Process to Interpret Elevated Soot Levels in 950L and 962L Engine

Oil Samples

Introduction

This document provides a process to evaluate soot levels in 950L and 962L wheel loader engine

oil samples. This process should be followed by SOS Services Interpreters when the Soot level

exceeds the SOS Services guideline of 60 UFM.

Required Information

A complete SOS Services engine oil sample report that contains: elemental analysis, soot,

oxidation, and viscosity at 100 degrees C. The elemental analysis must include wear metals,

typical additive elements, and typical elements associated with contamination.

SOS Services Wear Tables for the 950L and 962L engines

SOS Services Guidelines

API engine oil performance level

SOS Services Interpretation Training in the analysis of engine oil samples

Detailed Information

The current SOS Services guideline for soot in used engine oil is 60 UFM. This guideline was

developed at a time when engine oils could not adequately control the wear caused by higher

levels of soot. Today, CI-4 and CK-4 diesel engine oils are designed to handle much higher

levels of soot. These modern oils can suspend large amounts of soot in the oil, and control the

wear caused by soot. Therefore, when these modern oils are used, Cat engines will safely operate

at soot levels that exceed 60 UFM.

The average 950L & 962L engine will reach 60 UFM soot at about 250 oil hours. However, soot

levels as high as 130 UFM are commonly seen on 250 hour oil samples. The average soot level

is about 130 UFM for a 500 hour oil sample. Soot levels of 150 to 175 UFM may occur on some

engines at 500 oil hours.

Interpretation Process

The following interpretation process is not new. This process is taught by Caterpillar SOS

Services trainers to Cat dealer SOS Services interpreters worldwide. This document serves as a

reminder of the process and provides an overview of oil soot levels seen on 950L and 962L

engines.

When soot exceeds 60 UFM, the interpreter should look for signs of abnormal wear or abnormal

oil condition. Abnormal wear can be identified by Fe levels that exceed the Wear Table Fe

guidelines. Wear Tables are available for the 950L and 962L engines at 250 oil hours and 500

Caterpillar: Confidential Yellow

oil hours. If the Fe results are acceptable, the interpreter should next look at the viscosity result

at 100 degrees centigrade. If the viscosity has not increased by more than 2 centistokes, then the

higher level of soot has not significantly degraded the oil.

As a final check, the interpreter should verify that the customer is using a CI-4 or CK-4 diesel

engine oil. If a Cat branded engine oil is being used, then the performance level of the oil is

known. Cat DEO is an API CI-4 oil. Cat DEO-ULS and Cat DEO-ULS SYN are API CK-4

oils. If a Cat branded oil is not in use, then the interpreter should ask the customer to verify the

performance level of the oil.

Therefore, engine oil sample results may receive a Green Alert if the Soot exceeds 60 UFM and

the oil sample results meet the criteria for acceptable wear, acceptable oil condition, and

acceptable API performance.

Summary

60 UFM is the current SOS Services guideline for Soot. It is a guideline, not an absolute limit.

950L and 962L engines frequently operate with oil Soot levels that exceed 60 UFM

Soot levels over 60 UFM require additional investigation by a trained interpreter

If the Fe wear and the viscosity are at acceptable levels, then the higher level of Soot is not a

significant problem. If the customer is using a CI-4 or CK-4 engine oil, then the oil sample may

receive a Green Alert and no further action is required by the customer.

David Nycz

Caterpillar S·O·S Services

13 May 2019

Caterpillar: Confidential Yellow

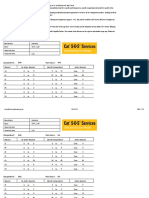

Caterpillar S•O•SSM Services

Wear table

Created 13 Dec 2018

Manufacturer CATERPILLAR

Family All

Model 950L

Product ID Prefix LXX, TNS

Compartment ENGINE

Valid Equipment 197

Valid Samples 848

Valid Fluid Hours 250

Element No Action Required Monitor Action Required

Copper 0 to 8 9 to 12 Over 12

Iron 0 to 36 37 to 46 Over 46

Chromium 0 to 2 3 to 4 Over 4

Aluminum 0 to 3 4 to 5 Over 5

Lead 0 to 2 3 to 4 Over 4

Silicon 0 to 9 10 to 11 Over 11

Tin 0 to 2 3 to 4 Over 4

Filter Criteria

Maximum Fluid Hours 700

Maximum Equipment Hours 14000

Break-In Samples Excluded True

Excluded Samples with Positive Fuel True

Excluded Samples with Positive Water True

Excluded Samples with Positive Glycol True

Excluded Samples where Sodium (Na) Exceeds PPM 25

Excluded Samples where Potassium (K) Exceeds PPM 25

Excluded Samples where Silicon (Si) Exceeds PPM 20

Starting Sample Date All

Ending Sample Date All

Specific Jobsites All

Specific Customers All

Dealers Excluded None

Mininmum Samples set at 30

Mininmum Equipment set at 3

Caterpillar: Confidential Yellow

Caterpillar S•O•SSM Services

Wear table

Created 13 Dec 2018

Manufacturer CATERPILLAR

Family All

Model 950L

Product ID Prefix LXX, TNS

Compartment ENGINE

Valid Equipment 197

Valid Samples 848

Valid Fluid Hours 500

Element No Action Required Monitor Action Required

Copper 0 to 11 12 to 14 Over 14

Iron 0 to 51 52 to 61 Over 61

Chromium 0 to 3 4 to 5 Over 5

Aluminum 0 to 4 5 to 6 Over 6

Lead 0 to 2 3 to 4 Over 4

Silicon 0 to 9 10 to 12 Over 12

Tin 0 to 2 3 to 4 Over 4

Filter Criteria

Maximum Fluid Hours 700

Maximum Equipment Hours 14000

Break-In Samples Excluded True

Excluded Samples with Positive Fuel True

Excluded Samples with Positive Water True

Excluded Samples with Positive Glycol True

Excluded Samples where Sodium (Na) Exceeds PPM 25

Excluded Samples where Potassium (K) Exceeds PPM 25

Excluded Samples where Silicon (Si) Exceeds PPM 20

Starting Sample Date All

Ending Sample Date All

Specific Jobsites All

Specific Customers All

Dealers Excluded None

Mininmum Samples set at 30

Mininmum Equipment set at 3

Caterpillar: Confidential Yellow

Caterpillar S•O•SSM Services

Wear table

Created 13 Dec 2018

Manufacturer CATERPILLAR

Family All

Model 962L

Product ID Prefix MTN, SXS

Compartment ENGINE

Valid Equipment 52

Valid Samples 310

Valid Fluid Hours 250

Element No Action Required Monitor Action Required

Copper 0 to 6 7 to 8 Over 8

Iron 0 to 43 44 to 54 Over 54

Chromium 0 to 3 4 to 5 Over 5

Aluminum 0 to 3 4 to 5 Over 5

Lead 0 to 2 3 to 4 Over 4

Silicon 0 to 8 9 to 10 Over 10

Tin 0 to 2 3 to 4 Over 4

Filter Criteria

Maximum Fluid Hours 700

Maximum Equipment Hours 14000

Break-In Samples Excluded True

Excluded Samples with Positive Fuel True

Excluded Samples with Positive Water True

Excluded Samples with Positive Glycol True

Excluded Samples where Sodium (Na) Exceeds PPM 25

Excluded Samples where Potassium (K) Exceeds PPM 25

Excluded Samples where Silicon (Si) Exceeds PPM 20

Starting Sample Date All

Ending Sample Date All

Specific Jobsites All

Specific Customers All

Dealers Excluded None

Mininmum Samples set at 30

Mininmum Equipment set at 3

Caterpillar: Confidential Yellow

Caterpillar S•O•SSM Services

Wear table

Created 13 Dec 2018

Manufacturer CATERPILLAR

Family All

Model 962L

Product ID Prefix MTN, SXS

Compartment ENGINE

Valid Equipment 52

Valid Samples 310

Valid Fluid Hours 500

Element No Action Required Monitor Action Required

Copper 0 to 7 8 to 10 Over 10

Iron 0 to 63 64 to 74 Over 74

Chromium 0 to 3 4 to 5 Over 5

Aluminum 0 to 4 5 to 6 Over 6

Lead 0 to 2 3 to 4 Over 4

Silicon 0 to 7 8 to 9 Over 9

Tin 0 to 2 3 to 4 Over 4

Filter Criteria

Maximum Fluid Hours 700

Maximum Equipment Hours 14000

Break-In Samples Excluded True

Excluded Samples with Positive Fuel True

Excluded Samples with Positive Water True

Excluded Samples with Positive Glycol True

Excluded Samples where Sodium (Na) Exceeds PPM 25

Excluded Samples where Potassium (K) Exceeds PPM 25

Excluded Samples where Silicon (Si) Exceeds PPM 20

Starting Sample Date All

Ending Sample Date All

Specific Jobsites All

Specific Customers All

Dealers Excluded None

Mininmum Samples set at 30

Mininmum Equipment set at 3

Caterpillar: Confidential Yellow

Вам также может понравиться

- EOR & Wax Preventative (THIS)Документ25 страницEOR & Wax Preventative (THIS)Lee Hunter JrОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Mobiltherm 605Документ2 страницыMobiltherm 605jrprocesos80% (5)

- Crude OilДокумент51 страницаCrude OilJeyaraj Anand100% (6)

- Equilibrium, Acids, Bases, Redox and Organic ChemistryДокумент3 страницыEquilibrium, Acids, Bases, Redox and Organic ChemistryMichelle TingОценок пока нет

- Lurgi Biodiesel Info and References May 2004Документ33 страницыLurgi Biodiesel Info and References May 2004Muhammad FakhruddinОценок пока нет

- Rop 10 Ton Per Day Internal Tanpa LahanДокумент26 страницRop 10 Ton Per Day Internal Tanpa Lahanhadi prasetio100% (1)

- Rare Metal Extraction by Chemical Engineering Techniques: International Series of Monographs on Chemical EngineeringОт EverandRare Metal Extraction by Chemical Engineering Techniques: International Series of Monographs on Chemical EngineeringРейтинг: 1 из 5 звезд1/5 (1)

- 3406 CAT Wear LimitДокумент16 страниц3406 CAT Wear LimitDany LeaОценок пока нет

- Metals and AlloysДокумент49 страницMetals and Alloysmasterdol1983Оценок пока нет

- Caterpillar - Tablas de Desgaste de Todos Los EquiposДокумент1 808 страницCaterpillar - Tablas de Desgaste de Todos Los EquiposMarcelo RiverosОценок пока нет

- Límites Condenatorios CATДокумент2 662 страницыLímites Condenatorios CATHECTORОценок пока нет

- 797F Wear Tables For Extended Drains 18mar2019Документ10 страниц797F Wear Tables For Extended Drains 18mar2019Abner VillanuevaОценок пока нет

- Critical lubrication for high speed Wire Rod MillsДокумент19 страницCritical lubrication for high speed Wire Rod MillsAnkit UjjwalОценок пока нет

- Internship ReportДокумент18 страницInternship ReportMuhammad QasimОценок пока нет

- Steam TurbineДокумент56 страницSteam Turbinegirish_nonie77% (26)

- Process Audit in Cement IndustryДокумент64 страницыProcess Audit in Cement IndustryNITITN ASNANIОценок пока нет

- Sulfuric Acid HandbookДокумент44 страницыSulfuric Acid Handbookramsrivatsan50% (2)

- Allmineral SIMAДокумент39 страницAllmineral SIMAkselvan_1Оценок пока нет

- Wear Debris PDFДокумент2 178 страницWear Debris PDFJuan De la cruz EncarnacionОценок пока нет

- 11249-Ispat Indo-500 Mill Rolling Mill BДокумент1 страница11249-Ispat Indo-500 Mill Rolling Mill BBahtiar YudhistiraОценок пока нет

- S.O.S - Mining ForumДокумент32 страницыS.O.S - Mining ForumTC BengalonОценок пока нет

- Turbine Oil PresentationДокумент30 страницTurbine Oil PresentationVahidОценок пока нет

- GasguideДокумент2 страницыGasguideJulio Cesar VazquezОценок пока нет

- PKSC - Joint Presentation PDFДокумент78 страницPKSC - Joint Presentation PDFbrunoОценок пока нет

- ESM - AEON9000sp Oil Sampling and Analysis: Control Your Compressed Air Costs !Документ36 страницESM - AEON9000sp Oil Sampling and Analysis: Control Your Compressed Air Costs !Nhân NgọcОценок пока нет

- Type The Company NameДокумент18 страницType The Company NameMuhammad QasimОценок пока нет

- Steam Generation PptДокумент18 страницSteam Generation Pptabhikumar.ajОценок пока нет

- 07468-Ispatindo-Cellar 1 Rolling MillДокумент1 страница07468-Ispatindo-Cellar 1 Rolling MillBahtiar YudhistiraОценок пока нет

- Grasas John DeereДокумент4 страницыGrasas John DeereGustavo GonzalezОценок пока нет

- Timken Mill Grease NLGI 1 Resists Water WashoutДокумент2 страницыTimken Mill Grease NLGI 1 Resists Water WashoutThe WorshipperОценок пока нет

- Catschool 1: Prereforming CatalystsДокумент32 страницыCatschool 1: Prereforming CatalystsAbubakar SiddiqОценок пока нет

- THE LAST TURBINE OIL YOU'LL EVER NEEDДокумент4 страницыTHE LAST TURBINE OIL YOU'LL EVER NEEDAhmad ButtОценок пока нет

- Triton 5005 EXDДокумент3 страницыTriton 5005 EXDCarlosОценок пока нет

- Normal-Samco 4 966H-25-10-2022Документ3 страницыNormal-Samco 4 966H-25-10-2022Tamer MohamedОценок пока нет

- Tabla de Desgaste 797FДокумент3 страницыTabla de Desgaste 797FAlonso Huanqui CondoriОценок пока нет

- 355 S DetectorДокумент4 страницы355 S DetectorFaizal ThelordImmortal100% (1)

- 启动锅炉说明书Auxiliary boiler manualДокумент32 страницы启动锅炉说明书Auxiliary boiler manualAr Riaz100% (1)

- Marine Fuel Specification and Test Methods Day 1Документ82 страницыMarine Fuel Specification and Test Methods Day 1riveraalvinОценок пока нет

- Acme Fluid Systems: One Stop Shop For Strainers & FiltersДокумент23 страницыAcme Fluid Systems: One Stop Shop For Strainers & FiltersArpitОценок пока нет

- Industrial Projects Company Profile and Presentation-RedДокумент19 страницIndustrial Projects Company Profile and Presentation-RedMazaharul IslamОценок пока нет

- Impreglon 410M DataSheetДокумент2 страницыImpreglon 410M DataSheetMehrad LahutiОценок пока нет

- Refractory Heahting Cylcle.Документ29 страницRefractory Heahting Cylcle.Learnscoop Inc.Оценок пока нет

- ScrubberДокумент4 страницыScrubberjaviermartinmariaОценок пока нет

- BRO LubricantsAnalyisДокумент8 страницBRO LubricantsAnalyisHenta DwyОценок пока нет

- Product Data Sheet: Mobil Jet Oil IIДокумент2 страницыProduct Data Sheet: Mobil Jet Oil IIGiang NguyenОценок пока нет

- Saudi Pak TowerДокумент8 страницSaudi Pak TowerHamza EllahiОценок пока нет

- (Grade 1.5) GR181-EN-Timken-Spec-SheetДокумент2 страницы(Grade 1.5) GR181-EN-Timken-Spec-SheetnacerОценок пока нет

- Guide to LOCTITE GC 10 Solder Paste PerformanceДокумент51 страницаGuide to LOCTITE GC 10 Solder Paste PerformanceVICTOR MARCOSОценок пока нет

- ASTM D 445 Viscosity Standard for Petroleum ProductsДокумент3 страницыASTM D 445 Viscosity Standard for Petroleum ProductsIan JoeОценок пока нет

- NFCДокумент46 страницNFCLuptongaОценок пока нет

- Pehp0002 02Документ2 страницыPehp0002 02Manuel Moreno GalarzaОценок пока нет

- Kaolite-2500li EngДокумент2 страницыKaolite-2500li EngLuis EscobedoОценок пока нет

- Xử lý lưu huỳnh các phân đoạn dầuДокумент26 страницXử lý lưu huỳnh các phân đoạn dầuĐứcc TruyềnnОценок пока нет

- Axens Catalysts and Adsorbents: Advanced Solutions and ServicesДокумент9 страницAxens Catalysts and Adsorbents: Advanced Solutions and ServicesMo OsОценок пока нет

- Grasa Multiproposito CatДокумент2 страницыGrasa Multiproposito Catrolex21Оценок пока нет

- ATA ReportДокумент10 страницATA Reportshaker MahmoudОценок пока нет

- Analys Lub Oil PDFДокумент1 страницаAnalys Lub Oil PDFdinar rosandyОценок пока нет

- E Oil RefineryДокумент8 страницE Oil RefineryHamidreza AbriОценок пока нет

- Refinery Good ConditionДокумент55 страницRefinery Good ConditionhjgjhfОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SerialДокумент57 страницHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SerialAbner VillanuevaОценок пока нет

- Health Lab Results Summary ReportДокумент114 страницHealth Lab Results Summary ReportAbner VillanuevaОценок пока нет

- SamplesДокумент114 страницSamplesAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SerialДокумент14 страницHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SerialAbner VillanuevaОценок пока нет

- Action Required Equipment Health Lab ReportsДокумент79 страницAction Required Equipment Health Lab ReportsAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Modelasset Id Asset SerialДокумент26 страницHealth Lab No. Lab Date Sampled Date Modelasset Id Asset SerialAbner VillanuevaОценок пока нет

- SamplesДокумент25 страницSamplesAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент58 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент78 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SerialДокумент42 страницыHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SerialAbner VillanuevaОценок пока нет

- Health Monitor Records for Equipment 420F RE-1012 LBS00204Документ57 страницHealth Monitor Records for Equipment 420F RE-1012 LBS00204Abner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Modelasset Id Asset SeriaДокумент24 страницыHealth Lab No. Lab Date Sampled Date Modelasset Id Asset SeriaAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Modelasset Id Asset SerialДокумент25 страницHealth Lab No. Lab Date Sampled Date Modelasset Id Asset SerialAbner VillanuevaОценок пока нет

- Health Lab Reports for Asset 980L CF-E0001Документ93 страницыHealth Lab Reports for Asset 980L CF-E0001Abner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SeriaДокумент25 страницHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SeriaAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент77 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab Reports for Construction EquipmentДокумент27 страницHealth Lab Reports for Construction EquipmentAbner VillanuevaОценок пока нет

- Samples (Total)Документ103 страницыSamples (Total)Abner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Samples (Total) - Abril - 2021Документ161 страницаSamples (Total) - Abril - 2021Abner VillanuevaОценок пока нет

- Health Lab Report Equipment StatusДокумент91 страницаHealth Lab Report Equipment StatusAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент58 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент60 страницHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset IDДокумент42 страницыHealth Lab No. Lab Date Sampled Date Model Asset IDAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SerialДокумент18 страницHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SerialAbner VillanuevaОценок пока нет

- Health Lab No. Lab Date Sampled Date Model Asset ID Asset SerialДокумент42 страницыHealth Lab No. Lab Date Sampled Date Model Asset ID Asset SerialAbner VillanuevaОценок пока нет

- Ceridust TP 5091 For UV-curable Coatings With A Silk Finish: Exactly Your ChemistryДокумент2 страницыCeridust TP 5091 For UV-curable Coatings With A Silk Finish: Exactly Your ChemistryMaximiliano MackeviciusОценок пока нет

- Biochemical Processes: Activity 3Документ2 страницыBiochemical Processes: Activity 3Althea ValenzuelaОценок пока нет

- Practical No 10 - Natural IndicatorsДокумент6 страницPractical No 10 - Natural Indicatorscarbon dioОценок пока нет

- APC Notes 2Документ84 страницыAPC Notes 2srisuji14Оценок пока нет

- Olin - EPoxy Resin CatalogДокумент12 страницOlin - EPoxy Resin CatalogkamalnandreОценок пока нет

- Nitrogen ChemistryДокумент3 страницыNitrogen ChemistryjammyjammersОценок пока нет

- An in Vitro Study of The PH of Three CalciumДокумент5 страницAn in Vitro Study of The PH of Three CalciumRamona MateiОценок пока нет

- Electrochemical Reactivation (EPR) For Detecting Sensitization of AISI Type 304 and 304L Stainless SteelsДокумент9 страницElectrochemical Reactivation (EPR) For Detecting Sensitization of AISI Type 304 and 304L Stainless SteelsJORGE ARTURO TORIBIO HUERTAОценок пока нет

- Kemidant L PlusДокумент2 страницыKemidant L PlusKarolina SaavedraОценок пока нет

- Bourne 2003Документ38 страницBourne 2003Gopal KasatОценок пока нет

- Matpr D 20 09686 - R1Документ39 страницMatpr D 20 09686 - R1Omar Al-KubasiОценок пока нет

- Gas ConcentrationsДокумент10 страницGas ConcentrationsHadrien FaryalaОценок пока нет

- Science: Quarter 1 - Matter Module 7: Concentration of SolutionsДокумент37 страницScience: Quarter 1 - Matter Module 7: Concentration of SolutionsCore GirlОценок пока нет

- Chemistry f4 Presentation-Introducing ChemistryДокумент17 страницChemistry f4 Presentation-Introducing ChemistrynoorkeyoОценок пока нет

- WCH03 01 MSC 20150812Документ24 страницыWCH03 01 MSC 20150812lolomg90Оценок пока нет

- Determination of Vitamin Content in Sample Tablets by TitrationДокумент2 страницыDetermination of Vitamin Content in Sample Tablets by TitrationmagicianchemistОценок пока нет

- Pharchem LecДокумент15 страницPharchem LecNinna San Juan100% (1)

- Phase Diagram (Two Phase For Water-Phenol)Документ8 страницPhase Diagram (Two Phase For Water-Phenol)Sham J. HamaОценок пока нет

- Questions For Well Life Cycle SessionДокумент17 страницQuestions For Well Life Cycle SessionShubham PatelОценок пока нет

- Research Progress On Sustainability of Key Tire MaДокумент28 страницResearch Progress On Sustainability of Key Tire MasagarОценок пока нет

- Coco Gly PDFДокумент8 страницCoco Gly PDFАнна МарчукОценок пока нет

- Aldehyde, Ketones and Carboxylic AcidДокумент18 страницAldehyde, Ketones and Carboxylic AcidPRADEEP CОценок пока нет

- Decomposition of Sodium ChlorateДокумент3 страницыDecomposition of Sodium Chlorateعبد القادر حدادОценок пока нет

- Artigo 13 - Preparation of A New Low-Cost Substrate Prepared From Drinking Water Treatment SludgeДокумент12 страницArtigo 13 - Preparation of A New Low-Cost Substrate Prepared From Drinking Water Treatment SludgeJuscimara RodriguesОценок пока нет

- DAFTAR PUSTAKA CobaДокумент5 страницDAFTAR PUSTAKA Cobawhite shadowОценок пока нет

- Pre FormulationДокумент13 страницPre FormulationCm MouliОценок пока нет

- BuyersДокумент1 страницаBuyerscesartovarОценок пока нет

- Dr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane CoatingДокумент4 страницыDr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane Coatingkkundan52Оценок пока нет