Академический Документы

Профессиональный Документы

Культура Документы

Grinding Labor Costs: Understanding Sheet Metal Costs

Загружено:

Joseph CureИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Grinding Labor Costs: Understanding Sheet Metal Costs

Загружено:

Joseph CureАвторское право:

Доступные форматы

UNDERSTANDING SHEET METAL COSTS

Grinding Labor Costs

Grinding costs can vary considerably with the skill of the operator and the

requirements of the customer. “Free of burrs and scratches” can mean removing

punch/laser tabs and one pass on the "timesaver". It can also mean blending the

corners of each edge and several passes through the "timesaver". The customers’

cosmetic requirements determine the grinding costs as much as anything. Here is a

typical cost breakdown:

Typical operator $45/hr

Equipment Depreciation $2/hr

Rent, 100 SF $2/hr

Punch Tooling $1/hr

Maintenance $1/hr

Electricity $1/hr

------------

Assuming 1,600 hrs billed $52/hr

Typical pricing with SG&A $60 - $70/hr

Below are some common drawing notes and the process costs to meet these

standards:

“Break all edges”: sometimes means “timesave “both sides in the flat, other times it

means grinding the edges of the formed part.

“Free of burrs and scratches”: deburr the tabs and "timesave" the outside surface

“Mill finish”: "timesave" both sides in the flat

“Class A finish”: blend all outside welded corners and orbital sand outer surfaces

“Mirror finish”: sequentially "timesave" in finer increments, grind corners and edges in

the same way to achieve a reflective surface (typically for chroming).

Follow us on …..

Http://www.ETMmfg.com 37

Вам также может понравиться

- BOMAG Original Cutting Tools PDFДокумент36 страницBOMAG Original Cutting Tools PDFchristophe laurensОценок пока нет

- Estimating-Sheet-Metal-Fabrication-Costs-v3 30 PDFДокумент1 страницаEstimating-Sheet-Metal-Fabrication-Costs-v3 30 PDFJoseph CureОценок пока нет

- Ess-Tool Tool Board Machining Guide: Please - Before You Try It Your Way, Try It Ours!Документ2 страницыEss-Tool Tool Board Machining Guide: Please - Before You Try It Your Way, Try It Ours!ray9699Оценок пока нет

- Hardware Labor Costs: Understanding Sheet Metal CostsДокумент1 страницаHardware Labor Costs: Understanding Sheet Metal CostsJoseph CureОценок пока нет

- Cost Comparison Rev 2 LQДокумент4 страницыCost Comparison Rev 2 LQB.Harish KumarОценок пока нет

- Total Drilling Cost: AC BHMT's Value PropositionДокумент23 страницыTotal Drilling Cost: AC BHMT's Value PropositionJannela yernaiduОценок пока нет

- HP347D HP457D: GB Si Al BG HR MK Ro RS Rus UaДокумент60 страницHP347D HP457D: GB Si Al BG HR MK Ro RS Rus UaAdi MОценок пока нет

- Zink ISMR TDCДокумент23 страницыZink ISMR TDChkaqlqОценок пока нет

- Non-Conventional Machining: (I) IntroductionДокумент6 страницNon-Conventional Machining: (I) IntroductionPANKWORLDОценок пока нет

- Appendix 9Документ4 страницыAppendix 9GUNTHERVEGAОценок пока нет

- Worm Gear Sets enДокумент29 страницWorm Gear Sets enmohammad khoraminiaОценок пока нет

- Catalogue Worm Gear Sets and Customised Worm Gear SetsДокумент30 страницCatalogue Worm Gear Sets and Customised Worm Gear Setsfog900Оценок пока нет

- 3.4 in Cut Optimization - Establishing Operating ConditionsДокумент38 страниц3.4 in Cut Optimization - Establishing Operating ConditionsBaljeet SinghОценок пока нет

- Metal Cutting QuestionsДокумент65 страницMetal Cutting QuestionsPratik DhandeОценок пока нет

- Mechanism of Metal Cutting (05-5-2022)Документ123 страницыMechanism of Metal Cutting (05-5-2022)Mohd MishaqОценок пока нет

- Common Machining Operations: KalpakjianДокумент22 страницыCommon Machining Operations: Kalpakjianirinuca12Оценок пока нет

- N 1997 Anderson - Chance - Fargo - Hipotronics - Kerite - Ohio Brass: OvemberДокумент16 страницN 1997 Anderson - Chance - Fargo - Hipotronics - Kerite - Ohio Brass: OvemberramsesiОценок пока нет

- Welding Series CostДокумент3 страницыWelding Series CostkrazygreaseОценок пока нет

- Rotary Blast Hole DrillsДокумент4 страницыRotary Blast Hole DrillsRodolfoОценок пока нет

- Non-Traditional Machining Processes: ME 355, Introduction To Manufacturing ProcessesДокумент22 страницыNon-Traditional Machining Processes: ME 355, Introduction To Manufacturing ProcessesKalai ArasanОценок пока нет

- Common Machining Operations: KalpakjianДокумент22 страницыCommon Machining Operations: KalpakjianRodrigo FilhoОценок пока нет

- Quick Start GuideДокумент11 страницQuick Start GuideDaniel NituОценок пока нет

- Amfd 1065R1Документ4 страницыAmfd 1065R1s.hussain.bashaОценок пока нет

- SA-1073 SP-174 16in KYM633PXDX SN 5340150 Performance FlierДокумент1 страницаSA-1073 SP-174 16in KYM633PXDX SN 5340150 Performance Flierkiller shaОценок пока нет

- Sunstone Dual Pulse CD Welders DatasheetДокумент2 страницыSunstone Dual Pulse CD Welders DatasheetBrown EmmanuelОценок пока нет

- Accessories EncoderДокумент5 страницAccessories Encoderkasim leeОценок пока нет

- Total Drilling CostДокумент23 страницыTotal Drilling CostDavid SantoОценок пока нет

- Syntho-Glass FX Datasheet (Rev 1. - 12.31.09)Документ2 страницыSyntho-Glass FX Datasheet (Rev 1. - 12.31.09)Masood KhanОценок пока нет

- Disco Automatic Dicing SawДокумент23 страницыDisco Automatic Dicing SawAnthony GalayОценок пока нет

- Appendix 3. Costs Related To Road Construction/ImprovementДокумент13 страницAppendix 3. Costs Related To Road Construction/ImprovementgenergiaОценок пока нет

- Manual Servicio JVC UX-G45BДокумент41 страницаManual Servicio JVC UX-G45Bschumi_kaiserОценок пока нет

- Estimating EarthworkДокумент34 страницыEstimating Earthworkashikur rahmanОценок пока нет

- Cutter Blade Reference GuideДокумент12 страницCutter Blade Reference GuideThePrintManОценок пока нет

- Component Data - Processing CostДокумент1 страницаComponent Data - Processing CostZarana BhattОценок пока нет

- Junk Mill Bit With Interchangeable Inserts2010Документ13 страницJunk Mill Bit With Interchangeable Inserts2010naiouamОценок пока нет

- Master Cut CatalogДокумент125 страницMaster Cut Cataloggabriel_127971761Оценок пока нет

- MastercutCatalog PDFДокумент125 страницMastercutCatalog PDFOscar Huberto Salazar HerreraОценок пока нет

- RF 35Документ3 страницыRF 35Isra NazeerОценок пока нет

- Electrical Rubber Mat SpecificationДокумент1 страницаElectrical Rubber Mat Specificationpankajbhatt376Оценок пока нет

- Portable Welding and Cutting AutomationДокумент4 страницыPortable Welding and Cutting AutomationRoyal Friady HalimОценок пока нет

- Surround: Sound ReceiverДокумент65 страницSurround: Sound ReceiverNathan PietersОценок пока нет

- Road Map To No 1 PackagingДокумент17 страницRoad Map To No 1 PackagingAbdul WasayОценок пока нет

- 1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Документ2 страницы1B2 - 1 300x400 - Critical: Page 1/2 Legion 5 23/02/2023 23/02/2023 23/02/2023Mouris alamamussОценок пока нет

- Updated Project StatementДокумент3 страницыUpdated Project StatementlitonОценок пока нет

- AMM - Chap 13 - Production and Operating Cost of Ag MachinesДокумент28 страницAMM - Chap 13 - Production and Operating Cost of Ag MachinesJohn CennaОценок пока нет

- Roll Form Strander - NEWДокумент8 страницRoll Form Strander - NEWAbdul HarisОценок пока нет

- Rev o Lu Tion: Medium Chrome Tool SteelДокумент6 страницRev o Lu Tion: Medium Chrome Tool SteelX800XLОценок пока нет

- Nad T 751Документ64 страницыNad T 751peter_davies_7Оценок пока нет

- Katalog Wire Mesh SteelindonesiaДокумент2 страницыKatalog Wire Mesh Steelindonesiarisiana_limuriaОценок пока нет

- Observed Construction Productivity Norms: Crude & Hydrotreating ComplexДокумент2 страницыObserved Construction Productivity Norms: Crude & Hydrotreating Complexprasobh911Оценок пока нет

- Dip Brazing: Parts To Be Dip Brazed AreДокумент10 страницDip Brazing: Parts To Be Dip Brazed AreRavin SinghОценок пока нет

- Manufacturing Kishore Lecture 2 3Документ41 страницаManufacturing Kishore Lecture 2 3Teiborlin MarngarОценок пока нет

- High-Speed Milling of Hard MetalsДокумент4 страницыHigh-Speed Milling of Hard Metalsbogdangabriel1985Оценок пока нет

- MillingДокумент105 страницMillingsai mohanОценок пока нет

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresДокумент3 страницыDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelОценок пока нет

- The Economics of HardfacingДокумент6 страницThe Economics of Hardfacingemad sabri100% (1)

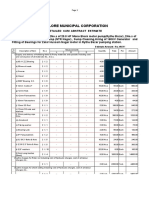

- Nellore Municipal Corporation: Estimate Amount: Rs. #REF!Документ3 страницыNellore Municipal Corporation: Estimate Amount: Rs. #REF!Raja Sankar ChowdaryОценок пока нет

- The Impact of Health Care Inflation On Part CostsДокумент1 страницаThe Impact of Health Care Inflation On Part CostsJoseph CureОценок пока нет

- Hardware Material Costs: Understanding Sheet Metal CostsДокумент1 страницаHardware Material Costs: Understanding Sheet Metal CostsJoseph CureОценок пока нет

- Estimating-Sheet-Metal-Fabrication-Costs-v3 19 PDFДокумент1 страницаEstimating-Sheet-Metal-Fabrication-Costs-v3 19 PDFJoseph CureОценок пока нет

- Estimating-Sheet-Metal-Fabrication-Costs-v3 10 PDFДокумент1 страницаEstimating-Sheet-Metal-Fabrication-Costs-v3 10 PDFJoseph CureОценок пока нет

- Candidate Guide For Certification and Re-CertificationДокумент42 страницыCandidate Guide For Certification and Re-CertificationJoseph Cure100% (1)

- Wear Resistance of High Chromium White Cast Iron For Coal Grinding RollsДокумент9 страницWear Resistance of High Chromium White Cast Iron For Coal Grinding RollsJoseph CureОценок пока нет

- Astm g65 TestДокумент1 страницаAstm g65 TestJoseph CureОценок пока нет

- Advanced Welding Processes For Transmission Pipelines ArticleДокумент17 страницAdvanced Welding Processes For Transmission Pipelines ArticleJoseph Cure50% (2)