Академический Документы

Профессиональный Документы

Культура Документы

Steel Recycle

Загружено:

Lh KooИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Steel Recycle

Загружено:

Lh KooАвторское право:

Доступные форматы

2008 The Inherent Recycled Content of Today’s Steel

his paper provides an overview of the methods the U.S. Geological Survey. Additionally, a study pre-

T used to produce steel in North America today, and

describes steel’s inherent recycled content.

Contemporary technologies produce steel in two ways,

pared for the AISI by William T. Hogan, S.A., and Frank

T. Koelble of Fordham University is used to establish

pre- and post-consumer fractions of purchased scrap.

both of which require old steel to make new.

Individual company statistics are not applicable or

The basic oxygen furnace (BOF) process uses 25 to 35 instructive because of the open loop recycling capabili-

percent old steel to make new. It produces products— ty that the steel and iron industries enjoy, with available

such as automotive fenders, encasements of refrigera- scrap typically going to the closest melting furnace. This

tors, and packaging like soup cans, five-gallon pails, open loop recycling allows, for example, an old car to

and 55-gallon drums—whose major required character- be melted down to produce a new soup can, and then,

istic is drawability. as the new soup can is recycled, it is melted down to

produce a new car, appliance, or perhaps a structural

The electric arc furnace (EAF) process uses more than beam used to repair some portion of the Golden Gate

80 percent old steel to make new. It produces prod- Bridge.

ucts— such as structural beams, steel plates, and rein-

forcement bars—whose major required characteristic is Basic Oxygen Furnace

strength.

The basic oxygen furnace (BOF) facilities consumed a

Many are surprised to learn that steel is the world’s, as total of 13,867,000 tons of ferrous scrap in the produc-

well as North America’s, most recycled material, and in tion of 42,206,000 tons of raw steel during 2008. Based

the United States alone, almost 75 million tons of steel on U.S. Geological Survey statistics, 901,000 of these

were recycled or exported for recycling in 2008. This is ferrous scrap tons had been generated as unsalable

done for economic as well as environmental reasons. It steel product within the confines of these steelmaking

is always cheaper to recycle steel than to mine virgin sites. In the steel industry, these tons are classified as

ore and move it through the process of making new “home scrap,” but are a mix of runaround scrap and

steel. However, it should also be clearly understood that pre-consumer scrap. Estimates by the Steel Recycling

many steel applications are durables, and even though Institute identify about 80% of this home scrap as pre-

two out of every three pounds of new steel are pro- consumer scrap, equating to 721,000 tons (901,000 x

duced from old steel, the fact that cars, appliances, and 80%). Additionally, these operations reported that they

bridges last a long time makes it necessary to continue consumed 26,000 tons of obsolete scrap (buildings and

to mine virgin ore to supplement the production of new warehouses dismantled on-site at the mill) during this

steel. Economic expansion, domestically and interna- time frame. This volume is classified as post-consumer

tionally, creates additional demand that cannot be fully scrap.

met by available scrap supplies.

Unlike other competing industries, recycled content in <TURN OVER>

the steel industry is second nature. The North American

steel industry has been recycling steel scrap for over

170 years through the growth of 2,500 scrap proces- For more information, please contact

sors and some 12,500 auto dismantlers. Many of them the Steel Recycling Institute at

1-412-922-2772, or visit us online

have been in the business for more than 100 years. at www.recycle-steel.org.

The pre-consumer, post-consumer, and total recycled

content of steel products in the United States can be

determined for the calendar year 2008 using informa-

tion from the American Iron and Steel Institute (AISI),

the Institute of Scrap Recycling Industries (ISRI), and

As a result of the above, based on the total scrap con- consumer. This equates to 5,664,000 tons of pre-con-

sumed, outside purchases of scrap equate to sumer scrap (34,121,000 x 16.6%). This “prompt scrap”

12,940,000 tons [13,867,000 - (901,000 + 26,000)]. is mainly scrap generated by manufacturing processes

According to the Fordham University study, the post- for products made with steel.

consumer fraction of the purchased ferrous scrap would

be 83.4 percent, while 16.6 percent of these purchases Therefore, the total recycled content to produce the

would be pre-consumer. This equates to 2,148,000 tons 56,369,000 tons of raw steel in the EAF is:

of pre-consumer scrap (12,940,000 x 16.6%). This

“prompt scrap” is mainly scrap generated by manufac- 50,563,000 / 56,369,000= 89.7%

turing processes for products made with steel. (Total Tons Ferrous Scrap / Total Tons Raw Steel)

Therefore, the total recycled content to produce the Also, the post-consumer recycled content is:

42,206,000 tons of raw steel in the BOF is:

(34,121,000 - 5,664,000) + 77,000 = 28,534,000

13,867,000 / 42,206,000 = 32.9% and

(Total Tons Ferrous Scrap / Total Tons Raw Steel) 28,534,000 / 56,369,000 = 50.6%

(Post-Consumer Scrap / Total Tons Raw Steel)

Also, the post-consumer recycled content is:

Finally, the pre-consumer recycled content is:

(12,940,000 - 2,148,000) + 26,000 = 10,818,000

and (13,092,000 + 5,664,000) / 56,369,000 =

10,818,000 / 42,206,000 = 25.6% 18,756,000 / 56,369,000 = 33.3%

(Post-Consumer Scrap / Total Tons Raw Steel) (Pre-Consumer Scrap / Total Tons Raw Steel)

Finally, the pre-consumer recycled content is: The above discussion and calculations demonstrate

conclusively the inherent recycled content of today’s

(721,000 + 2,148,000) / 42,206,000 = steel in North America. To buy steel is to “Buy

2,869,000 / 42,206,000 = 6.8% Recycled.”

(Pre-Consumer Scrap / Total Tons Raw Steel)

Understanding the recycled content of BOF and EAF

Electric Arc Furnace steels, one should not attempt to select one steel pro-

ducer over another on the basis of a simplistic compar-

The electric arc furnace (EAF) facilities consumed a ison of relative scrap usage or recycled content. Rather

total of 50,563,000 tons of ferrous scrap in the produc- than providing an enhanced environmental benefit,

tion of 56,369,000 tons of raw steel during 2008. Based such a selection could prove more costly in terms of

on U.S. Geological Survey adjusted statistics, total life cycle assessment energy consumption or other

16,365,000 of these ferrous scrap tons had been gen- variables. Steel does not rely on “recycled content” pur-

erated as unsalable steel product within the confines of chasing to incorporate or drive scrap use. It already

these steelmaking sites. Again, in the steel industry, happens because of the economics. Recycled content

these tons are classified as “home scrap,” but are a mix for steel is a function of the steelmaking process itself.

of runaround scrap and pre-consumer scrap. Estimates

by the Steel Recycling Institute identify about 80% of After its useful product life, regardless of its BOF or EAF

this home scrap as pre-consumer scrap, equating to origin, steel is recycled back into another steel product.

13,092,000 tons (16,365,000 x 80%). Additionally, Thus steel with more than 80 percent recycled content

these operations reported that they consumed 77,000 cannot be described as environmentally superior to

tons of obsolete scrap (buildings and warehouses dis- steel with 30 percent recycled content. This is not con-

mantled on-site at the mill) during this time frame. This tradictory because they are both complementary parts

volume is classified as post-consumer scrap. of the total interlocking infrastructure of steelmaking,

product manufacture, scrap generation and recycling.

As a result, based on the total scrap consumed, outside The recycled content of EAF relies on the embodied

purchases of scrap equate to 34,121,000 tons energy savings of the steel created in the BOF. Steel is

[50,563,000 - (16,365,000 + 77,000)]. According to the truly the most recycled material.

Fordham University study, the post-consumer fraction

of the purchased ferrous scrap would be 83.4 percent,

Updated: December 2009

while 16.6 percent of these purchases would be pre-

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- MSDS Strata Bond W S Comp A 2020-09-03 enДокумент7 страницMSDS Strata Bond W S Comp A 2020-09-03 encarlos_salas80Оценок пока нет

- River Engineering - 1Документ36 страницRiver Engineering - 1Edu4civil EngineeringОценок пока нет

- FGD by BHELДокумент20 страницFGD by BHELVibhas Kumar100% (1)

- Biomass Energy Generation by PTMДокумент24 страницыBiomass Energy Generation by PTMLh KooОценок пока нет

- Cleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasДокумент16 страницCleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasLh KooОценок пока нет

- HPA Aerobic Colony CountДокумент14 страницHPA Aerobic Colony CountHMVMCОценок пока нет

- Aco Rainwater Outlets BrochureДокумент32 страницыAco Rainwater Outlets Brochurerajkumar_chinniah100% (1)

- EvaporationДокумент37 страницEvaporationVimal KumarОценок пока нет

- Sewage Treatment PlantДокумент4 страницыSewage Treatment Plantsherwin827Оценок пока нет

- DBR PDDДокумент13 страницDBR PDDMEERAОценок пока нет

- Ozone Treatment of Cooling Tower WaterДокумент26 страницOzone Treatment of Cooling Tower WaterLh KooОценок пока нет

- Dow Completes Merger With Rohm and HaasДокумент2 страницыDow Completes Merger With Rohm and HaasLh KooОценок пока нет

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Документ2 страницыTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooОценок пока нет

- YBPPGA (1) Aug 2011 PDFДокумент6 страницYBPPGA (1) Aug 2011 PDFLh KooОценок пока нет

- D NanoTronДокумент2 страницыD NanoTronLh KooОценок пока нет

- Peristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Документ1 страницаPeristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Lh KooОценок пока нет

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Документ2 страницыTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooОценок пока нет

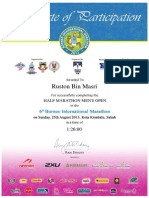

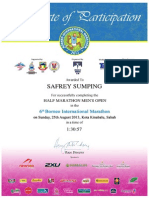

- BIM Half Marathon Men Open 12Документ1 страницаBIM Half Marathon Men Open 12Lh KooОценок пока нет

- D MicroTronДокумент2 страницыD MicroTronLh KooОценок пока нет

- TDS Cond Conversion ChartДокумент2 страницыTDS Cond Conversion ChartLh KooОценок пока нет

- BIM Half Marathon Men Open 19Документ1 страницаBIM Half Marathon Men Open 19Lh KooОценок пока нет

- BIM Half Marathon Men Open 18Документ1 страницаBIM Half Marathon Men Open 18Lh KooОценок пока нет

- BIM Half Marathon Men Open 16Документ1 страницаBIM Half Marathon Men Open 16Lh KooОценок пока нет

- BIM Half Marathon Men Open 15Документ1 страницаBIM Half Marathon Men Open 15Lh KooОценок пока нет

- BIM Half Marathon Men Open 14Документ1 страницаBIM Half Marathon Men Open 14Lh KooОценок пока нет

- BIM Half Marathon Men Open 11Документ1 страницаBIM Half Marathon Men Open 11Lh KooОценок пока нет

- BIM Half Marathon Men Open 13Документ1 страницаBIM Half Marathon Men Open 13Lh KooОценок пока нет

- BIM Half Marathon Men Open 9Документ1 страницаBIM Half Marathon Men Open 9Lh KooОценок пока нет

- BIM Half Marathon Men Open 6Документ1 страницаBIM Half Marathon Men Open 6Lh KooОценок пока нет

- BIM Half Marathon Men Open 3Документ1 страницаBIM Half Marathon Men Open 3Lh KooОценок пока нет

- BIM Half Marathon Men Open 1Документ1 страницаBIM Half Marathon Men Open 1Lh KooОценок пока нет

- BIM Half Marathon Men Open 5Документ1 страницаBIM Half Marathon Men Open 5Lh KooОценок пока нет

- BIM Half Marathon Men Open 8Документ1 страницаBIM Half Marathon Men Open 8Lh KooОценок пока нет

- BIM Half Marathon Men Open 7Документ1 страницаBIM Half Marathon Men Open 7Lh KooОценок пока нет

- BIM Half Marathon Men Open 2Документ1 страницаBIM Half Marathon Men Open 2Lh KooОценок пока нет

- BIM Half Marathon Men Open 4Документ1 страницаBIM Half Marathon Men Open 4Lh KooОценок пока нет

- Hi-Temp 1027 PDFДокумент4 страницыHi-Temp 1027 PDFquiron2014Оценок пока нет

- Chapter 4 Drainage DesignДокумент47 страницChapter 4 Drainage DesignhamzaОценок пока нет

- Wre Micro ProjectДокумент16 страницWre Micro ProjectTejas DeoreОценок пока нет

- Hydroponic Fodder Training DetailsДокумент2 страницыHydroponic Fodder Training DetailspipestressОценок пока нет

- 10 Geography MapsДокумент45 страниц10 Geography MapsSiddharth KabirОценок пока нет

- MSDS BitacrylДокумент4 страницыMSDS Bitacryledi100% (1)

- 1 VXDZ X9 Z2 RVДокумент694 страницы1 VXDZ X9 Z2 RVRohit SahОценок пока нет

- Mediterranean SeaДокумент36 страницMediterranean SeaKarl GustavОценок пока нет

- Assignment 2 (Ecw567) - Ec2206c2Документ15 страницAssignment 2 (Ecw567) - Ec2206c2Amin ShahromОценок пока нет

- Ata 38 Water and WasteДокумент38 страницAta 38 Water and WasteSantiago MolinaОценок пока нет

- NSTPДокумент2 страницыNSTPJed AbadОценок пока нет

- Survey of ProkaryotesДокумент25 страницSurvey of ProkaryotesBryan JanierОценок пока нет

- Eliwana Iron Ore Mine Project: Environmental Review DocumentДокумент527 страницEliwana Iron Ore Mine Project: Environmental Review Documentsrinu441Оценок пока нет

- Lesson Plan Water CycleДокумент2 страницыLesson Plan Water Cyclediana bulawitОценок пока нет

- WG Biogas 06 18 D497 Final RecommendationmДокумент26 страницWG Biogas 06 18 D497 Final RecommendationmhthxuanОценок пока нет

- Automated Hydroponics Greenhouse: Regulation of PH and NutrientsДокумент49 страницAutomated Hydroponics Greenhouse: Regulation of PH and NutrientsarnuОценок пока нет

- JAGNA ELA CapDev 2013 2016Документ59 страницJAGNA ELA CapDev 2013 2016Shella Santiago100% (2)

- Case StudyДокумент15 страницCase StudyAvinash YadavОценок пока нет

- Corsi 2001Документ8 страницCorsi 2001CostelCosОценок пока нет

- UDFCD Pipe Material Tech Memo 2010Документ181 страницаUDFCD Pipe Material Tech Memo 2010Paul GeorgeОценок пока нет