Академический Документы

Профессиональный Документы

Культура Документы

Atomizer Study For Processing PGM

Загружено:

AFLAC ............Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Atomizer Study For Processing PGM

Загружено:

AFLAC ............Авторское право:

Доступные форматы

text:text 9/26/08 2:22 PM Page 155

DUNKLEY, J.J., NORVAL, D., JONES, R.T., and CHENNELLS, P. Water atomization of PGM-containing intermediate alloys. Third International

Platinum Conference ‘Platinum in Transformation’, The Southern African Institute of Mining and Metallurgy, 2008.

Water atomization of PGM-containing intermediate alloys

J.J. DUNKLEY*, D. NORVAL†, R.T. JONES‡, and P. CHENNELLS§

*Atomising Systems Ltd

†Bateman Engineering Projects

‡Mintek

§Braemore Platinum Smelters

Water atomization can be used as an effective intermediate step between the production of a

molten alloy from a smelting furnace and a leaching operation. This is especially appropriate for

alloys that are not readily crushable. Very fine particles can be produced by the impingement of

high-pressure water jets on a molten alloy stream. The use of very fine material as a feedstock for

the leaching process allows for considerable savings in residence time, reactor volume, and lower

power consumption for stirring.

Results are presented of some atomization testwork that was carried out using alloys that

contain Fe-Ni-Cu-Co and have platinum group metals (PGMs) as their most valuable constituents.

Factors relevant to the design of a commercial unit are outlined.

Water atomization testwork has shown that alloy particles as small as 20 microns can readily be

produced. The relationship between the pressure of the water jets and the size of the resulting

particles is such that the mean particle size can be halved by doubling the water pressure (over the

range of conditions of interest).

Introduction to the ConRoast process 2008, more than 37 000 tons of various PGM-containing

feed materials (UG2 concentrates, Merensky concentrates,

Mintek’s ConRoast process was developed as an revert tailings, and converter slag) have been smelted. The

environmentally cleaner and more flexible smelting process quantity of alloy produced is approximately 7.5% of the

for the production of platinum group metals (PGM).1,2 A mass of material smelted. A typical composition of the

DC arc furnace is used to smelt PGM-containing feed resulting alloy is shown in Table I. Depending on the PGM

materials (such as dead-roasted sulphide concentrates) content of the feed material, the PGM content of the alloy is

together with some carbon, thereby forming a small typically of the order of 1 000 g/t.

quantity of an iron-rich alloy that is very effective at By funding a technology development programme at

collecting the PGMs and base metals. The environmental Mintek, Braemore Platinum Smelters have obtained

advantage of the ConRoast process is that it dramatically exclusive rights to the ConRoast process for the production

decreases SO 2 emissions compared to the conventional of PGMs for a period of ten years. Braemore have

matte-smelting process (by removing essentially all of the contracted TWP Consulting to carry out various concept

sulphur in a continuous enclosed roaster upfront of the studies and bankable feasibility studies. A full

smelting). The process is also able to accommodate a wide implementation of the ConRoast process involves using a

variety of feed compositions, with no maximum limit on the fluidized bed roaster (to remove sulphur from the

amount of Cr2O3 that can be fed to the furnace, nor any concentrates prior to smelting), a DC arc furnace, and at

constraint on the minimum quantity of base metal sulphides least a base metals refinery (where the base metals are

required. This is very important for the smelting of the separated from a PGM-rich residue that provides a suitable

increasing quantities of (chromite-rich) UG2 ore currently feed for a precious metals refinery).

being mined in South Africa. Furthermore, the ConRoast The challenge that is addressed in this paper revolves

process does not require intensive cooling systems in the around finding the most appropriate way of introducing the

furnace, as the liquidus temperatures of the slag and alloy intermediate alloy product from the furnace into the

are very similar, and the operating temperature of about subsequent leaching process. Especially if the alloy is

1 600°C is very manageable.

Since April 2004, Mintek has been operating a

demonstration plant3, treating approximately 1 000 tons per Table I

month in a 3 m diameter furnace running at a power level of Typical alloy composition, mass %

about 1.5 MW. The smelting operation has been in almost

continuous operation, having been interrupted only a few Element C Co Cr Cu Fe Ni S Si Total

times when other research furnace campaigns needed to

Mass % 0.05 1.3 0.18 4.6 72 14 6 0.05 98

take precedence. Over the period April 2004 to August

WATER ATOMIZATION OF PGM-CONTAINING INTERMEDIATE ALLOYS 155

text:text 9/26/08 2:22 PM Page 156

cooled slowly, it is highly resistant to any form of crushing bars (10 MPa). Today, about 80% of the world’s iron

or milling. This is not the first industrial process to face this powder, some 1 Mt/a, is produced by water atomization,

challenge, and water atomization has previously been used4 typically using ladle sizes from 30 to 110 t and atomizing

very effectively to reduce the particle size of an iron-rich speeds of 10–50 t/h. Atomizing Systems Ltd (ASL) has

alloy to a range that is highly amenable to leaching. Water supplied scores of atomizers for all sorts of metals, from

atomization provides an effective means for the production copper and silver, to Ni, Co, Fe alloys, and has worked with

of small particles, as a way of connecting pyrometallurgical Bateman Engineering Projects on the Chambishi project4,

and hydrometallurgical process steps when the alloy would which applies atomization to an Fe-Cu-Co alloy for

be too hard for milling. hydrometallurgical refining. In total, 11 projects for

atomizing in metal refining applications, including Ag, Au,

Introduction to water atomization Pt, Rh, Co, and Ni values, have been supplied. The size of

particles requested by clients has ranged from <50 μm to

If a falling stream of molten metal is impinged by jets of

sub-millimetre, and operating pressures have varied from

water, then it is broken up into droplets which rapidly

500 bar (50 MPa) to 20 bar (2 MPa).

freeze to form granules (>1 mm) or powder (<1 mm),

depending on the composition of the metal alloy, and the Compared to crushing and grinding, atomization has an

water pressure. Classical granulation uses pressures in the advantage in lacking any serious wearing parts; the water

range of 2–5 bars (200–500 kPa) and typically produces jets do the work and maintenance costs are modest. The

1–10 mm size granules. Very large flow rates can be cost of atomization is generally much less than the cost of

accommodated (in the t/min range), as pumping costs are melting, especially if drying of the product is not necessary,

modest. To make finer powders, one needs higher pressures as is normally the case for leaching feeds6.

(we find median size is approximately inversely correlated

with pressure), so it is necessary to use more controlled Choice of particle size for leaching

streams, typically from a tundish arrangement instead of a The particle size is important for two reasons:

launder as in many granulators, and to run more modest

• The finer the particles, the greater the surface area

flow rates, typically using nozzles from 3 mm to 30 mm in

diameter to give flow rates from 5 kg/min to ~500 kg/min available to contact the lixiviant; this increases the

(up to 30 t/h). Pressures range from 20 bars for coarser kinetics of the leaching stage

powders (say 0.3 mm) to 200 bars for finer powders (say • The finer the particles, the lower the agitator energy

~50 μm)5. Elements like sulphur in the melt strongly affect requirement to maintain these in suspension in the

(reduce) the required pressure by reducing melt surface leach reactors.

tension. In traditional base metals refining in the platinum

As shown in Figure 1, the atomized slurry can be industry, it is common for most (80–90%) of the particles

pumped, either directly to leach tanks, or to a dewatering fed into leaching reactors to be smaller than 75 μm in size.

system which can deliver either a thickened slurry at ~20% This enables optimum reaction kinetics, as well as allowing

moisture or a damp solid at ~5% moisture. This can then be the solid particles to be maintained in suspension in the

fed to the leach tanks if the water balance is critical. Drying reactors.

adds significant energy and cost, but may be done if, for As the particle size increases, extra energy is required to

instance, a smelter is selling to a refiner. prevent settling of the material. At a relative density around

Water atomization has been used in the production of 7, any settling in the reactors is a major concern. Once the

iron/steel powders since the 1950s, following its solid materials have settled, the only way to clean the

development in the 1930s for copper powders. Median reactor is to drain it and dig out the solids. Obviously, if

particle sizes of ~50–100 μm are readily produced from settling were to happen, this would lead to major

high-purity Fe-0.1–0.3%C melts using pressures of ~100 inefficiencies in the process.

Figure 1. Water atomization—schematic flowsheet

156 PLATINUM IN TRANSFORMATION

text:text 9/26/08 2:22 PM Page 157

Atomization carried out at a pressure of 200 bar (a difficult, but experience in many projects with far more

representative high-end operation) typically consumes valuable alloys indicates that losses are minimal in

around 20 kWh/t. Bearing in mind that a medium-size production.

smelter (say 10 MW) might produce about 1 t/h of alloy, As shown by the bottom line in Table II, the alloy shows

the energy consumed by atomization can be expected to be an almost perfect inverse relation between pressure and

less than that used by the multiple 30 kW motors that are median size, with D50 in mm x P in bar being ~4.39–4.52

used to power the agitators keeping the solids in suspension for all three trials with the same alloy composition. The last

in the leaching reactors. It makes economic sense to trial, with about one tenth of the alloy content, showed a

produce the small particle sizes resulting from water higher value of 5.28, and we would expect a sulphur-free

atomization at 200 bar pressure, so that the power to the alloy of this composition to be over 6. Figure 2, shows the

agitators can be kept low. Over the range of particle sizes data for the high-sulphur alloy corresponds to the equation:

under consideration, the power to the agitators could D = 4 496 / P

increase by as much as 50–60% as the mean particle size where D is the median particle size in microns, and P is

increases. atomizing pressure in bars.

The fairly high sulphur content of this alloy thus makes it

Atomization testwork, February 2008 relatively economical to produce powders with median

Approximately 90 kg of typical furnace alloy was shipped sizes in the 20–40 μm range.

in granular form to Atomizing Systems Limited in The particle size distributions resulting from 50 bar, 100

Sheffield, UK, and water atomizing testwork was carried bar, and 195 bar pressures are shown graphically in Figures

out in February 2008. Work was carried out on a very 3 to 5.

small-scale system, with a 25 kg melter and an atomizer

typically rated for 5–10 kg/min melt flow rates. In ASL’s Table II

experience, the results obtained on this scale are typically Operating results

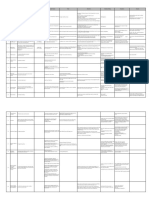

rather coarser than those achievable on a larger scale, say

over 50 kg/min. A 4 mm diameter nozzle was used for all Run No. W187 W188 W189 W190

tests, and melt flow rates were 5–7 kg/min. Alloy Shot +~15% Fe Shot Shot Heel +~90%Fe

The first attempt to melt the raw alloy granules showed it Water pressure 100 bar 195 bar 50 bar 190 bar

to be very difficult to induction-heat such small pieces in Pour temp. 1 551°C 1 550°C 1 540°C 1 622°C

the 3 kHz furnace, so an iron lump was needed to get it Malvern D50 μm 44.1 22.5 90.5 27.8

started. Thereafter, a heel was kept in the melter to facilitate Malvern D90 μm 121.6 67.3 238 98.4

melting. The final run was done with ~90% of iron added to Malvern D10 μm 14.2 7.8 28.3 8.8

Sieve % <45μm 54.2 86.2 37.5 65.0

a heel, to show the effect of the changed sulphur content.

Sieve D50 μm 41 ~21 58 32

This also required an increase in pour temperature, as the Sieve Std Dev 2.05 2.0 2.07 2.5

alloy melting range depends strongly on the sulphur D50 mm x P bar 4.41 4.39 4.52 5.28

content. The use of a heel made mass-balance checks very

Particle Size vs Inverse Pressure

Figure 2. Effect of (inverse) pressure and composition on powder median size

Figure 3. Particle size distribution from 50 bar pressure, D50 = 90 μm

WATER ATOMIZATION OF PGM-CONTAINING INTERMEDIATE ALLOYS 157

text:text 9/26/08 2:22 PM Page 158

Figure 4. Particle size distribution from 100 bar pressure, D50 = 44 μm

Figure 5. Particle size distribution from 195 bar pressure, D50 = 22 μm

Conclusions furnace reduction, South African patent ZA 99/1285

(26 February 1999), European patent EP 1 157 139

Water atomization testwork has shown that alloy particles B1 (9 October 2002), US patent 6,699,302 B1 (2

as small as 20 μm can readily be produced. The relationship March 2004).

between the pressure of the water jets and the size of the

resulting particles is such that the mean particle size can be 3. JONES, R.T. and KOTZE, I.J. DC arc smelting of

halved by doubling the water pressure (over the range of difficult PGM-containing feed materials, International

conditions of interest). Platinum Conference ‘Platinum Adding Value’, The

South African Institute of Mining and Metallurgy,

Sun City, South Africa, 3–7 October 2004, pp. 33–36.

Acknowledgements

4. JONES, R.T., DENTON, G.M., REYNOLDS, Q.G.,

This paper is published by permission of Atomizing PARKER, J.A.L., and VAN TONDER, G.J.J.

Systems Ltd., Bateman Engineering Projects, Braemore Recovery of cobalt from slag in a DC arc furnace at

Platinum Smelters, and Mintek. Chambishi, Zambia, SAIMM Journal, vol. 102, no. 1,

January/February 2002, pp. 5–9.

References

5. YULE, A.J. and DUNKLEY, J.J. Atomization of

1. JONES, R.T. ConRoast: DC arc smelting of dead- Melts, Clarendon Press, 1994.

roasted sulphide concentrates, Sulfide Smelting 2002,

Stephens R.L. and Sohn H.Y., (eds.), TMS. The 6. DUNKLEY, J.J., NORVAL, D., and LUDVIGSSON,

Minerals, Metals and Materials Society, Seattle, B. Melt Atomization—The Bridge from Pyro- to

17–21 February 2002, pp. 435–456. Hydro-Metallurgy, Yazawa International Symposium,

2. JONES, R.T., BARCZA, N.A., KAIURA, G., Metallurgical and Materials Processing Principles

O’CONNELL, G., and HANNAFORD, T. Treatment and Technologies, vol. 2: High-Temperature Metal

of metal sulphide concentrates by roasting and arc Production, TMS, 2003, pp. 679–687.

158 PLATINUM IN TRANSFORMATION

text:text 9/26/08 2:22 PM Page 159

David Norval

Manager Post Taphole Services/Senior Project Manager, Bateman Engineering Projects

1978—Joined Bateman as a Civil Engineer

1981 to 1987—Construction and Project manager mainly on Iron and Steel and Petrochemical

related projects

1987 to 1992—Project Manager and Deputy Construction Manager Mossgas on-land project

1993 to 1994—Operations Manager Bateman Iron & Steel Technology (Pty) Ltd with main

activities in Blast Furnace feeding systems and Blast Furnace Slag Granulation and De-Watering

systems.

1994 to 2003—Operations Director Bateman Iron & Steel Technology (Pty) Ltd with main focus

on matte and slag granulation, metal atomisation and de-watering processes General Manager Post taphole Services, a joint

venture with Mintek and Bateman for Slag, Matte and Alloy Solidification processes, tapping equipment and ladle metallurgy

and handling.

2003—Manager Post Taphole Services Pyrometallurgical Technologies, a process division within Bateman Engineering

Projects.

WATER ATOMIZATION OF PGM-CONTAINING INTERMEDIATE ALLOYS 159

text:text 9/26/08 2:22 PM Page 160

160 PLATINUM IN TRANSFORMATION

Вам также может понравиться

- Use of Hydrometallurgy in Direct Processing of Base Metal PGM ConcentratsДокумент14 страницUse of Hydrometallurgy in Direct Processing of Base Metal PGM ConcentratsAFLAC ............Оценок пока нет

- Estimating Gold Plating Thickness and ContentsДокумент8 страницEstimating Gold Plating Thickness and ContentsAFLAC ............Оценок пока нет

- Electrochemical Study of Gold Cementation Onto CopperДокумент2 страницыElectrochemical Study of Gold Cementation Onto CopperAFLAC ............100% (1)

- PlatinumillsДокумент9 страницPlatinumillsAFLAC ............Оценок пока нет

- Auto Catalyst Wash CoatДокумент5 страницAuto Catalyst Wash CoatAFLAC ............Оценок пока нет

- 2016-03-17 - Moneysaver - Lewis-Clark EditionДокумент20 страниц2016-03-17 - Moneysaver - Lewis-Clark EditionDavid ArndtОценок пока нет

- Intec Gold Process Description Oct 2008 - 2Документ6 страницIntec Gold Process Description Oct 2008 - 2AFLAC ............100% (2)

- What Happens When You Breath Niric Acid FumesДокумент4 страницыWhat Happens When You Breath Niric Acid FumesAFLAC ............Оценок пока нет

- Converting PGM Colored Salts With ZincДокумент3 страницыConverting PGM Colored Salts With ZincAFLAC ............100% (2)

- Alkaline Sulfide Recovery of GoldДокумент13 страницAlkaline Sulfide Recovery of GoldAFLAC ............100% (1)

- Aure8 InQuartation Gold Refining EquipmentДокумент6 страницAure8 InQuartation Gold Refining EquipmentAFLAC ............100% (1)

- Method To Convert Silver Sulphide Into Metalic SilverДокумент9 страницMethod To Convert Silver Sulphide Into Metalic SilverAFLAC ............100% (3)

- Refining and Treatment of Palladium From Secondary ResourcesДокумент7 страницRefining and Treatment of Palladium From Secondary ResourcesAFLAC ............Оценок пока нет

- Gold Recovery Butyl DiglymeДокумент20 страницGold Recovery Butyl Diglymecfowen100% (1)

- Catalytic ConvertersДокумент14 страницCatalytic Convertersmonabansal143099Оценок пока нет

- Monolithic Chip Capacitors Source of Palladium and SilverДокумент4 страницыMonolithic Chip Capacitors Source of Palladium and SilverNoreen Castardo- MontemayorОценок пока нет

- PDFДокумент6 страницPDFNinaОценок пока нет

- Iodine Clock ReactionДокумент2 страницыIodine Clock ReactionDina Mohd HalidiОценок пока нет

- Scrap 2Документ1 страницаScrap 2api-313323348Оценок пока нет

- Practical Applications of Specific Gravity Determination To Platinum Jewelery Manufacturing. (The Uses and Limitations of The Archimedes Principle.)Документ10 страницPractical Applications of Specific Gravity Determination To Platinum Jewelery Manufacturing. (The Uses and Limitations of The Archimedes Principle.)AFLAC ............Оценок пока нет

- Touchstone Method of Gold Testing.Документ18 страницTouchstone Method of Gold Testing.Mohiuddin Al KadriОценок пока нет

- This Should Also Never Be Attempted IndoorsДокумент11 страницThis Should Also Never Be Attempted IndoorsezrentsОценок пока нет

- Urea PurificationДокумент9 страницUrea PurificationAFLAC ............Оценок пока нет

- Afftech Abstract Manual 10000pc AutomatedДокумент50 страницAfftech Abstract Manual 10000pc AutomatedAFLAC ............100% (1)

- Silver Chloride Dissolution in ARДокумент5 страницSilver Chloride Dissolution in ARAFLAC ............Оценок пока нет

- Inquarting Gold NotesДокумент5 страницInquarting Gold NotesAFLAC ............Оценок пока нет

- Separating The Six Platinum MetalsДокумент9 страницSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Vautin ProcessДокумент4 страницыVautin ProcessAFLAC ............Оценок пока нет

- Rare Earths'Документ2 страницыRare Earths'SGAL62SCRIBDОценок пока нет

- Aqua RegiaДокумент2 страницыAqua Regiakamal100% (1)

- Ebay Gold RecoveryДокумент11 страницEbay Gold RecoveryAFLAC ............90% (10)

- Auto Catalytic ConverterДокумент4 страницыAuto Catalytic ConverterAFLAC ............0% (1)

- Eco-Goldex O Series ResourcesДокумент4 страницыEco-Goldex O Series Resourcesjhoan100% (2)

- Aqua Regia: From Wikipedia, The Free EncyclopediaДокумент5 страницAqua Regia: From Wikipedia, The Free EncyclopediaImpossible Raj100% (1)

- Gold TestingДокумент8 страницGold TestingGill Elmgren80% (5)

- THE CLASSICAL FIRE ASSAY PROCESSДокумент8 страницTHE CLASSICAL FIRE ASSAY PROCESSboanerges wino patty100% (1)

- Refining ProcessesДокумент191 страницаRefining ProcessesOmar Taha100% (1)

- Production of Pure Platinum and Palladium From DoreДокумент4 страницыProduction of Pure Platinum and Palladium From DoreLựuLiềuLìОценок пока нет

- Catalytic Converter PlatinumДокумент128 страницCatalytic Converter Platinumadamprince2100% (1)

- Mineralogy 101 Chemical TestsДокумент22 страницыMineralogy 101 Chemical TestsAFLAC ............Оценок пока нет

- The Clarkson Study Fine Gold RecoveryДокумент51 страницаThe Clarkson Study Fine Gold Recoverysoutheasterngold100% (16)

- The History of Touchstone Testing For GoldДокумент5 страницThe History of Touchstone Testing For GoldAFLAC ............100% (1)

- Gold Recovery Correctly - 12 Steps - InstructablesДокумент22 страницыGold Recovery Correctly - 12 Steps - InstructableskeethanОценок пока нет

- Concentration of Precious Metals During Their Recovery From Electronic WasteДокумент11 страницConcentration of Precious Metals During Their Recovery From Electronic WasteChrisОценок пока нет

- Electrolytic Silver Refining ProcessДокумент8 страницElectrolytic Silver Refining ProcessPamo Caytano100% (1)

- Palladium Refining TutorialДокумент9 страницPalladium Refining Tutorialdgodfather3150% (2)

- Assessment of The Recovery of Gold and PalladiumДокумент162 страницыAssessment of The Recovery of Gold and PalladiumJatindra Kumar PradhanОценок пока нет

- Liquid GoldДокумент9 страницLiquid GoldAFLAC ............Оценок пока нет

- Recovering Gold & Other Precious Metals from Electronic ScrapОт EverandRecovering Gold & Other Precious Metals from Electronic ScrapРейтинг: 3 из 5 звезд3/5 (6)

- Precious Metals 1982: Proceedings of the Sixth International Precious Metals Institute Conference, Held in Newport Beach, California, June 7 - 11, 1982От EverandPrecious Metals 1982: Proceedings of the Sixth International Precious Metals Institute Conference, Held in Newport Beach, California, June 7 - 11, 1982M.I. El GuindyРейтинг: 5 из 5 звезд5/5 (1)

- Finding Gold in Washington State: Third Edition -2015От EverandFinding Gold in Washington State: Third Edition -2015Оценок пока нет

- A Fast Easy Way to Recover gold from Integrated Circuit ChipsОт EverandA Fast Easy Way to Recover gold from Integrated Circuit ChipsОценок пока нет

- Recover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldОт EverandRecover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldОценок пока нет

- Recovering Silver From Photographic MaterialsДокумент32 страницыRecovering Silver From Photographic MaterialsAFLAC ............100% (5)

- Metal Content of Modern United States CoinsДокумент8 страницMetal Content of Modern United States CoinsAFLAC ............100% (2)

- Escraper's Refiners Cheat SheetДокумент7 страницEscraper's Refiners Cheat SheetAFLAC ............100% (21)

- Gold in Processor ChipsДокумент24 страницыGold in Processor ChipsAFLAC ............100% (9)

- Chemical Resistance of PlasticsДокумент2 страницыChemical Resistance of PlasticsAFLAC ............100% (2)

- Platinum Group Metals and CompoundsДокумент72 страницыPlatinum Group Metals and CompoundsAFLAC ............100% (7)

- Gold Chip Price Guide With Current Precious Metals PricesДокумент9 страницGold Chip Price Guide With Current Precious Metals PricesAvi Oziel SEO Toronto Internet Marketing - Toronto Web Design - Social Media Toronto100% (6)

- Assay Room Setup DFCДокумент14 страницAssay Room Setup DFCAFLAC ............Оценок пока нет

- PGM Catalyst Handbook USAДокумент93 страницыPGM Catalyst Handbook USAAFLAC ............Оценок пока нет

- CRL. Hamilton, D. Methods of Conserving Archaeological Material From Underwater Sites. 1999Документ110 страницCRL. Hamilton, D. Methods of Conserving Archaeological Material From Underwater Sites. 1999Trinidad Pasíes Arqueología-Conservación100% (1)

- Silver Cleaning and ConservationДокумент14 страницSilver Cleaning and ConservationAFLAC ............Оценок пока нет

- The Boy ChemistДокумент323 страницыThe Boy ChemisteshomitesОценок пока нет

- Basic Filtration ConceptsДокумент3 страницыBasic Filtration ConceptsAFLAC ............Оценок пока нет

- Gold and Silversmiths 1911Документ68 страницGold and Silversmiths 1911AFLAC ............Оценок пока нет

- Mine Ore and Gold Scams Paul Jones McDermitt NVДокумент4 страницыMine Ore and Gold Scams Paul Jones McDermitt NVAFLAC ............Оценок пока нет

- Matching Your Crucible To Your ApplicationДокумент9 страницMatching Your Crucible To Your ApplicationAFLAC ............100% (3)

- Separating The Six Platinum MetalsДокумент9 страницSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Mine Scams Gold OreДокумент30 страницMine Scams Gold OreAFLAC ............Оценок пока нет

- Nickel TestingДокумент1 страницаNickel TestingAFLAC ............Оценок пока нет

- Recovering Precious Metals From Waste Liquid ResiduesДокумент394 страницыRecovering Precious Metals From Waste Liquid ResiduesAFLAC ............100% (12)

- What Happens When You Breath Niric Acid FumesДокумент4 страницыWhat Happens When You Breath Niric Acid FumesAFLAC ............Оценок пока нет

- Smelting SilverДокумент15 страницSmelting Silverminerales&materialesОценок пока нет

- Silver Recovery With NaOH IIДокумент4 страницыSilver Recovery With NaOH IIAFLAC ............100% (1)

- Osterberg's E-Tower Gold RecoveryДокумент1 страницаOsterberg's E-Tower Gold RecoveryAFLAC ............100% (1)

- Process For Silver Recovery From Digital FilmsДокумент7 страницProcess For Silver Recovery From Digital FilmsAFLAC ............100% (1)

- Catalytic Converter Weights and PGM ContentДокумент39 страницCatalytic Converter Weights and PGM ContentAFLAC ............67% (6)

- Method To Convert Silver Sulphide Into Metalic SilverДокумент9 страницMethod To Convert Silver Sulphide Into Metalic SilverAFLAC ............100% (3)

- Calm Morrison HokeДокумент1 страницаCalm Morrison HokeAFLAC ............Оценок пока нет

- Properties of Gold ColloidsДокумент13 страницProperties of Gold ColloidsAFLAC ............100% (1)

- Morphology and Roughness of Silver Deposit Formed by CementationДокумент10 страницMorphology and Roughness of Silver Deposit Formed by CementationAFLAC ............Оценок пока нет

- Stainless steel electrode AWS specifications guideДокумент11 страницStainless steel electrode AWS specifications guideTito FernandezОценок пока нет

- Brinell& Rockwell User's ManualДокумент37 страницBrinell& Rockwell User's ManualBharath TrichyОценок пока нет

- Corrosion in Petroleum RefiningДокумент22 страницыCorrosion in Petroleum RefiningKen Wells100% (4)

- Afm E308-16 Afm E308h-16Документ13 страницAfm E308-16 Afm E308h-16Julio Cesar Lazcano PintoОценок пока нет

- GT Drilling Bits 6aug FinalДокумент46 страницGT Drilling Bits 6aug FinalRanjith Premadasan100% (1)

- Set A Multiple Choice Questions Metals and Non-MetalsДокумент7 страницSet A Multiple Choice Questions Metals and Non-MetalsskandhaОценок пока нет

- Duplex Ss Welding PDF FreeДокумент8 страницDuplex Ss Welding PDF Freeel_sharkawy2011Оценок пока нет

- 01 084r34 PDFДокумент60 страниц01 084r34 PDFviniciuspariz100% (1)

- Standard Specification For: Designation: B167 11Документ9 страницStandard Specification For: Designation: B167 11mahfuzОценок пока нет

- Sulphuric Acid Anodising of en AC-46500 CastДокумент9 страницSulphuric Acid Anodising of en AC-46500 CastgnanasekarОценок пока нет

- High Energy Ball Milling Process For Nanomaterial SynthesisДокумент4 страницыHigh Energy Ball Milling Process For Nanomaterial SynthesisKajal MIshraОценок пока нет

- Bolt Depot - Bolt Grade Markings and Strength Chart PDFДокумент3 страницыBolt Depot - Bolt Grade Markings and Strength Chart PDFBrooke CraigОценок пока нет

- L3 - Connectors-in-Fpd 1Документ47 страницL3 - Connectors-in-Fpd 1ALAA IBRAHIM IBRAHIMОценок пока нет

- Api 571-1Документ11 страницApi 571-1Raghavan100% (1)

- Astm e 1251Документ11 страницAstm e 1251anon_708301878Оценок пока нет

- Unit 2 - Ferrous MetalsДокумент208 страницUnit 2 - Ferrous MetalsPreethiОценок пока нет

- Smarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaДокумент251 страницаSmarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaAvinash SiwachОценок пока нет

- RINA Pt. D Material and TestingДокумент240 страницRINA Pt. D Material and TestingRichard AlcaldeОценок пока нет

- DTU New Syllabus For MEДокумент83 страницыDTU New Syllabus For MEHari SreyasОценок пока нет

- 55 Aluminum-Zinc Alloy Coated Steel Grade Data SheetsДокумент3 страницы55 Aluminum-Zinc Alloy Coated Steel Grade Data SheetsChar GB buatОценок пока нет

- Progress in Aerospace Sciences: Xuesong Zhang, Yongjun Chen, Junling HuДокумент13 страницProgress in Aerospace Sciences: Xuesong Zhang, Yongjun Chen, Junling HuJeisson BuesaquilloОценок пока нет

- NBIMS-US V3 2.4.4.12 OmniClass Table 41 MaterialsДокумент22 страницыNBIMS-US V3 2.4.4.12 OmniClass Table 41 Materialsmahmoud mokhtarОценок пока нет

- Forbes 1950 Metallurgy in AntiquityДокумент497 страницForbes 1950 Metallurgy in Antiquitymontoc100% (4)

- CorrosionДокумент79 страницCorrosionAnonymous zTUWsMОценок пока нет

- Seminar Report On Cast IronДокумент48 страницSeminar Report On Cast IronPulkit bajaj100% (3)

- D0679sci Part1 QR 2020 FinalДокумент20 страницD0679sci Part1 QR 2020 FinalEND GAMINGОценок пока нет

- Ferrous Alloys: Printed: September Author: R. KattusДокумент34 страницыFerrous Alloys: Printed: September Author: R. KattussunsirОценок пока нет

- Spring SteelДокумент2 страницыSpring Steelvaishu1502Оценок пока нет

- Welding ProcessesДокумент28 страницWelding ProcessesAnaswarpsОценок пока нет