Академический Документы

Профессиональный Документы

Культура Документы

M6 Control Unit: Professional Manual Version 1.0

Загружено:

Jhezy Andron AndronОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

M6 Control Unit: Professional Manual Version 1.0

Загружено:

Jhezy Andron AndronАвторское право:

Доступные форматы

M6 CONTROL UNIT

Professional Manual version 1.0

Warning on the intellectual property

© 2008 HIMOINSA s.l. All rights reserved.

HIMOINSA s.l. is the owner and reserves all rights of ownership on

any text or graphic image exposed in this manual. The permission

to reproduce all or a part of this manual must be obtained by

HIMOINSA s.l. via written document.

Unauthorised use of the information given in this manual, its resale

and/or the damage to the Intellectual Property or Industrial rights

will entail the responsibilities legally established.

HIMOINSA s.l. and HIMOINSA logo are HIMOINSA trademarks in

Spain and other countries.

Unload and limitation of legal responsibility

Information given in the manual, including texts, date and/or

pictures, are supplied in their current status by HIMOINSA s.l. in

order to facilitate the access to products to its dealers and clients.

HIMOINSA s.l. is not responsible for the errors and/or omissions

that may occur in this manual and kindly recommends the commissioning

and use of the products to be carried out only by qualified

personnel.

Contents

1. INTRODUCTION ................................................................................................................. 5

2. FRONT OF THE M6 CONTROL UNIT ................................................................................ 6

3. CONNECTIONS .................................................................................................................. 9

3.1 OUTPUTS ..................................................................................................................................................................... 9

3.1.1. PREHEATING OUTPUT (PR) ........................................................................................................................... 9

3.1.2. CONTACTOR ACTIVATION OUTPUT (CON) .................................................................................................. 9

3.1.3. EXCITATION OUTPUT OF THE BATTERY CHARGE ALTERNATOR (D+) .................................................... 9

3.1.4. ALARM OUTPUT (AL) ..................................................................................................................................... 9

3.1.5. STARTING OUTPUT (ARR) ............................................................................................................................. 9

3.1.6. CONFIGURABLE STOP (PC) .......................................................................................................................... 9

3.1.7. IGNITION (PD) ................................................................................................................................................ 10

3.2 INPUTS ....................................................................................................................................................................... 10

3.2.1. ALTERNATOR VOLTAGE INPUT (GEN) ....................................................................................................... 10

3.2.2. PICK-UP INPUT (PCK)................................................................................................................................... 10

3.2.3. COMMON VOLTAGE INPUT OF THE ALTERNATOR AND PICK-UP (GCOM) ............................................ 10

3.2.4. WATER TEMPERATURE INPUT (ATA) ......................................................................................................... 10

3.2.6. FUEL RESERVE INPUT (RC) ........................................................................................................................ 10

3.2.7. AUXILIARY ALARM INPUT (AUX) ................................................................................................................. 11

3.2.8. EXTERNAL START INPUT (LT) ..................................................................................................................... 11

3.2.9. EMERGENCY STOP INPUT (PEM) ............................................................................................................... 11

3.3 USB PORT .................................................................................................................................................................. 11

4. OPERATION ...................................................................................................................... 11

4.1 STARTING THE MOTOR ............................................................................................................................................ 11

4.2 STOPPING THE MOTOR ............................................................................................................................................ 12

4.3 OPERATING MODES ................................................................................................................................................. 13

4.3.1. STOP MODE (STOP) ..................................................................................................................................... 13

4.3.2. MANUAL MODE (MAN) ................................................................................................................................. 13

3 | HIMOINSA® M6 CONTROL UNIT

Contents

4.3.3. AUTOMATIC MODE (AUT) ............................................................................................................................ 13

4.4 NOMINAL SPEED ADJUSTMENT.............................................................................................................................. 13

APPENDIX I. TABLE OF PARAMETERS ............................................................................. 14

APPENDIX II. DIMENSIONS, WIRING AND MECHANICAL PARTS ................................... 16

Inputs and Outputs .......................................................................................................................................................... 18

Electrical Characteristics ................................................................................................................................................ 19

Dimensions of the equipment ........................................................................................................................................ 20

Characteristics and installation of the equipment ........................................................................................................ 20

SYMBOLS:........................................................................................................................................................................ 21

certifications: ................................................................................................................................................................... 21

4 | HIMOINSA® M6 CONTROL UNIT

1. INTRODUCTION

The M6 control unit is an electronic monitoring, control and protection device for generator sets. The general

characteristics are as described below:

- Supply voltage 8/36V.

- Start and mode selection key.

AUTO mode. Start activated through an external start input via volt-free contact (LT).

MAN mode. Start activated by the user.

- 14 LEDs for visual indication of the status of the control unit.

- 2 control unit command buttons:

Push button to start / stop the generator set.

RESET button to reset the control unit when an alarm is detected.

- Start by voltage free contact (LT) in AUTO mode.

- Motor protection devices:

Fuel reserve.

Battery charging failure.

High motor coolant temperature.

Low oil pressure.

Auxiliary motor alarm.

Overspeeding:

o Due to electrical signal frequency of generator.

o Due to motor pick-up.

- 7 shortable transistor outputs:

3 power outputs (40A).

4 signal outputs (1A).

- USB port.

5 | HIMOINSA® M6 CONTROL UNIT

2. FRONT OF THE M6 CONTROL UNIT

On the front of the M6 control unit there is:

- 2 buttons for control unit operation in manual mode:

START button. The START button is used to engage the starting and stopping of the control

unit in manual mode (mode selection key in the MAN position):

o Start motor: with the motor stopped and in manual mode, press once to start the

motor.

o Stop motor with cooling: with motor running and in manual mode, press once to

stop the motor with cooling.

o Stop motor without cooling: with motor running and in manual mode, press twice to

stop the motor without cooling.

RESET button. The RESET button allows the user to reset the generator set after an alarm has

been detected.

- Operating mode selection key (MAN/STOP/AUT). The mode selection key on the M6 control unit

allows the operating mode of the control unit to be selected:

STOP mode: stops the motor and turns off the control unit.

MAN mode: activates the control unit and sets the manual operating mode (control of genset

via buttons).

AUT mode: activates the control unit and sets the auto operating mode, with the motor

activated by means of the external start input via voltage free contact (LT).

6 | HIMOINSA® M6 CONTROL UNIT

- 14 LEDs to indicate status:

ALARM LEDS

Icon Alarm Description

Light signal via the flashing fuel reserve alarm detection LED. The light

Fuel reserve signal will remain active as long as the alarm condition continues (RC input

of the control unit).

Light signal via the flashing alarm LED detecting a failure in the battery

Battery charging alternator failure charger via the input D+. The LED will remain active until the control unit is

reset by pressing the RESET button.

Light signal via the flashing auxiliary motor alarm detection LED. The light

signal will remain active as long as the alarm condition continues (control

Auxiliary motor unit AUX input). The control unit is reset by pressing the RESET button.

The auxiliary motor alarm causes the motor to stop immediately without

cooling.

Light signal via the flashing emergency stop alarm detection LED. The light

signal will remain active as long as the alarm condition continues (control

Emergency stop unit PEM input). The control unit is reset by pressing the RESET button.

The emergency stop alarm causes the motor to stop immediately without

cooling.

Light signal via the flashing overspeeding alarm detection LED. The light

indicator will remain active until the motor has been stopped and the

control unit has been reset by pressing the RESET button. The

overspeeding alarm causes the motor to stop immediately without cooling.

Overspeeding The overspeeding alarm is only managed if the nominal motor speed has

been adjusted (sec. 3.3).

The overspeeding LED also indicates if the nominal speed of the control

unit has not been adjusted, via the flashing of the LED when the M6 control

unit is switched on with the motor stopped.

Light signal via the flashing low oil pressure alarm detection LED. The light

indicator will remain active until the motor has been stopped and the

Low oil pressure.

control unit has been reset by pressing the RESET button. The low oil

pressure alarm causes the motor to stop immediately without cooling.

Light signal via the flashing high water temperature alarm detection LED.

The light signal will remain active as long as the alarm condition continues

High water temperature (control unit ATA input). The control unit is reset by pressing the RESET

button. The high water temperature alarm causes the motor to stop

immediately without cooling.

Light signal via the flashing motor failure alarm detection LED. The light

Motor failure signal will remain active as long as the alarm condition continues. The

control unit is reset by pressing the RESET button.

Light signal via the flashing start motor failure alarm detection LED. The

Starting failure light signal will remain active as long as the alarm condition continues. The

control unit is reset by pressing the RESET button.

7 | HIMOINSA® M6 CONTROL UNIT

STATUS LEDS

Icon Alarm Description

Power supply Light signal via an LED on the control unit.

Light signal via an LED flashing during the preheating phase of starting the

Preheating

motor.

Light signal via an LED flashing during the cooling phase of stopping the

Cooling and motor stop

motor.

Light signal via an LED flashing with the activation of the genset's external

Starting free of voltage

start input via volt-free contact (LT).

Motor running Light signal via the flashing of the motor running detection LED.

8 | HIMOINSA® M6 CONTROL UNIT

3. CONNECTIONS

3.1 OUTPUTS

3.1.1. PREHEATING OUTPUT (PR)

The preheating output (PR) of the M6 control unit is a high power shortable output (40 A) which regulates the

heating process of the motor's spark plugs during the starting process. The activation time of the preheating

output can be set (parameter 4). The preheating output can also be used to control stopping due to the

excitation of motors which use PE/PS type control (parameter 15 value 2).

3.1.2. CONTACTOR ACTIVATION OUTPUT (CON)

The contactor output (CON) activates a programmable time (parameter 5) after detecting the motor is running

in order to ensure stabilisation of the motor before enabling the charging of the generator set.

3.1.3. EXCITATION OUTPUT OF THE BATTERY CHARGE ALTERNATOR (D+)

The battery charge alternator excitation output (D+) of the M6 control unit is responsible for driving the battery

charge alternator during the starting process via a starting pulse at a programmable time interval

(parameter 14).

3.1.4. ALARM OUTPUT (AL)

The M6 control unit activates the alarm output (AL) upon the detection of any active error and remains active

until the system has been reset by pressing the RESET key. Furthermore, the M6 control unit also activates the

alarm output (AL) before starting the motor in automatic operation mode by means of the external start via volt-

free contact (LT).

3.1.5. STARTING OUTPUT (ARR)

The motor starting output (ARR) of the M6 control unit is a high power shortable output (40 A) which activates

the starter. The motor starting output (ARR) remains active until a condition is detected while the motor is

running for a programmable maximum time (parameter 3).

3.1.6. CONFIGURABLE STOP (PC)

The configurable motor stop output (PC) of the M6 control unit is a high power shortable output (40 A) that

controls the stopping of the motor and is interconnected with the emergency stop input (PEM) of the control

unit. The configurable motor stop output (PC) can be configured so that it controls motors according to four

different start/stop modes (parameter 15):

PR/PD (parameter 15 value 0): The configurable motor stop output (PC) for motors with PR/PD

control is activated 500 minutes after the preheating output has been deactivated, which occurs when

the motor stop command has been given.

PR/PE (parameter 15 value 1): The configurable motor stop output (PC) for motors with PR/PE

control is activated during a programmable time interval (parameter 7) when the motor stop command

has been given. In this configuration, the emergency stop input (PEM) of the control unit must be

wired to the negative terminal of the battery and the emergency stop button must be wired to the

auxiliary input of the (AUX) alarm.

PE/PD (parameter 15 value 2): The configurable motor stop output (PC) for motors with PE/PD

control is activated 500 minutes after the preheating output (PR) has been deactivated, which occurs

when the motor stop command has been given. This output is used to enable the motor sensors. The

preheating output (PR) of the control unit is responsible for executing the motor stop by activating the

stop by excitation process.

PULL/HOLD (parameter 15 value 3): The motor start control set in PULL/HOLD mode uses the

configurable output (PC) as PULL signal (40 A) which is activated for a fixed time of 1 second during

9 | HIMOINSA® M6 CONTROL UNIT

starting. The IGNITION output (PD) is used as HOLD signal (2 A) which remains active while the

motor is running.

3.1.7. IGNITION (PD)

The IGNITION output (PD) is activated 500 minutes after the preheating output has been deactivated, which

occurs when the motor stop command has been given. The IGNITION output (PD) is interconnected with the

emergency stop input (PEM) of the control unit.

For motors configured with the starting control mode PULL/HOLD (parameter 15 value 3), the IGNITION output

(PD) is also activated during starting in the motor preheating phase.

3.2 INPUTS

3.2.1. ALTERNATOR VOLTAGE INPUT (GEN)

The alternator voltage input is used to calculate the electrical signal frequency of the generator (parameter 16

value 0). To do this 2-phases of the alternator are connected between the GEN and GCOM inputs of the control

unit in gensets with more than one phase or 1 phase and the neutral of the alternator between the GEN and

GCOM inputs of the control unit in single phase gensets.

3.2.2. PICK-UP INPUT (PCK)

The pickup input is used to calculate the motor rotation speed (parameter 16 value 1). To do this the motor

pickup signal is connected to the PCK and GCOM terminals of the control unit.

3.2.3. COMMON VOLTAGE INPUT OF THE ALTERNATOR AND PICK-UP (GCOM)

Common input for reading the alternator voltage frequency and motor speed according to the programming of

the control unit (parameter 16). Only one of the two signals can be wired to the terminal of the GCOM input of

the M6 control unit.

3.2.4. WATER TEMPERATURE INPUT (ATA)

Input connected to the motor coolant temperature thermostat which tells the control unit that a high water

temperature alarm has occurred. The polarity of the ATA input is configurable (parameter 23). The high motor

temperature alarm has a visual signal provided by the alarm LED on the front of the M6 control unit. The

high motor temperature alarm causes the motor to stop immediately.

3.2.5. LOW OIL PRESSURE INPUT (BPA)

Input connected to the motor oil pressure switch which tells the control unit that a low oil pressure alarm has

occurred. The polarity of the BPA input is configurable (parameter 24). The low oil pressure alarm has a visual

signal provided by the alarm LED on the front of the M6 control unit. The low oil pressure alarm causes

the motor to stop immediately.

3.2.6. FUEL RESERVE INPUT (RC)

Input connected to the fuel tank gauge which tells the control unit that a fuel reserve alarm has occurred. The

polarity of the RC input is configurable (parameter 27). The fuel reserve alarm has a visual signal provided by

the alarm LED on the front of the M6 control unit. The action taken by the M6 control unit after detecting the

fuel reserve alarm is programmable (parameter 18).

10 | HIMOINSA® M6 CONTROL UNIT

3.2.7. AUXILIARY ALARM INPUT (AUX)

Input connected to any sensor which tells the control unit that a motor auxiliary alarm has occurred. The polarity

of the AUX input is configurable (parameter 25). The motor auxiliary alarm has a visual signal provided by the

alarm LED on the front of the M6 control unit. The motor auxiliary alarm causes the motor to stop

immediately.

3.2.8. EXTERNAL START INPUT (LT)

Digital signal for connecting a volt-free contact forcing the starting of the genset when the M6 control unit is in

automatic mode. The polarity of the LT input is configurable (parameter 26). The external start input has a

visual signal provided by the status LED on the front of the M6 control unit.

3.2.9. EMERGENCY STOP INPUT (PEM)

Digital signal for connecting an emergency stop that tells the control unit that an immediate stop of the motor

must be performed without cooling. The emergency stop alarm has a visual signal provided by the alarm LED

on the front of the M6 control unit.

3.3 USB PORT

Allows the programming of certain parameters, in addition to the reading of the internal hour counter (total and

partial) and alarm history through a PC.

4. OPERATION

4.1 STARTING THE MOTOR

With motor stopped and no alarms, when starting the motor, the M6 control unit proceeds to perform the

following operations:

Preheating of the motor. With the preheating process enabled (parameter 19 value 1), the control unit

activates the preheating output (PR) in motors for PR/PD and PR/PE control (parameter 15 values 0

and 1) for the set time (parameter 3) with visual indication via the LED on the front of the control

unit.

Enabling the starting of the motor. Enabling the starting of the motor is done via the IGNITION

output (PD) of the M6 control unit and the CONFIGURABLE STOP output (PC) for motor configurations

PR/PD and PE/PD (parameter 15 value 0 and 2).

Starting the motor (ARR). For a maximum time (parameter 3), the starting output (ARR) of the M6

control unit is activated until some of the enabled starting conditions have been detected:

o Generator frequency (parameter 16 value 0). The motor is considered started when the

generator frequency exceeds a certain percentage (parameter 11) of the nominal frequency of

the genset.

o Motor speed (parameter 16 value 1). The motor is considered started when the motor speed

exceeds a certain percentage (parameter 11) of the nominal motor speed.

o Alternator voltage (parameter 21 value 1). The motor is considered started when a certain

battery charging alternator voltage (60% of the battery voltage) is exceeded.

If during the set time no motor starting is detected, the control unit waits for a period of time (parameter

2) before retrying to start. Once a certain number of starts has been exceeded without detecting any

start condition (parameter 1), the control unit activates the Starting Failure alarm with a visual signal via

the LED on the front of the control unit.

11 | HIMOINSA® M6 CONTROL UNIT

During motor starting, the excitation of the battery charging alternator is carried out through the D+

output for a programmable period of time (parameter 14). Once the excitation of the alternator has been

completed, the measurement module monitors the correct functioning of the battery charging alternator.

If a fault is detect in the battery charging alternator, the Alternator Failure alarm is activated with a

visual signal via the LED on the front of the control unit.

The configurable stop output (PC) of the control unit is used in motors for PR/PULL control (parameter

15 value 3) to energize the motor solenoid by activating a pulse for a duration of 1 second during the

start process.

Charging activation. Once any motor starting condition has been detected, the control unit waits for a

set time (parameter 5) for the activation of charging through the contactor output (CON) of the control

unit.

4.2 STOPPING THE MOTOR

With the motor started, when stopping the motor, the M6 control unit proceeds to perform the following

operations:

Deactivating charging. The M6 control unit deactivates the contactor output (CON) to release the

charging of the generator set.

Cooling the motor. Once free of charging, the motor will continue running for a programmable cooling

time (parameter 6). If any alarm is detected, the M6 control unit performs an immediate stop without

cooling the motor.

Motor stop. After the motor cooling time has passed, the IGNITION output (PD) of the M6 control unit

is deactivated and, depending on the motor configuration (parameter 15) the following occurs:

o Deactivation of the CONFIGURABLE STOP output (PC) for motor configurations PR/PD and

PE/PD (parameter 15 value 0 and 2).

o Activation of the CONFIGURABLE STOP output (PC) for motor configurations PR/PE

(parameter 15 value 1) for a configurable time (parameter 7).

o Activation of the PREHEATING output (PR) for motor configurations PE/PD (parameter 15

value 2) for a configurable time (parameter 7).

Detection of stopped motor.

The M6 control unit considers the motor stopped when none of the programmed start conditions are

detected. Regarding conditions of motor stopped, the following can be selected:

o Generator frequency (parameter 16 value 0). The motor is considered stopped when the

generator frequency is zero.

o Motor speed (parameter 16 value 1). The motor is considered stopped when the motor speed

is zero.

o Low Oil Pressure Input (parameter 22). The motor is considered stopped when the motor oil

pressure switch connected to the low oil pressure input (BPA) is closed.

o Battery charging alternator voltage (parameter 21 value 1). The motor is considered stopped

when the battery charging alternator voltage is less than a certain voltage (60% of the battery

voltage).

12 | HIMOINSA® M6 CONTROL UNIT

4.3 OPERATING MODES

The M6 control unit is turned on by turning the key on the control panel to either the MAN or AUTO position.

Before going into operation, the control unit performs a check indicated by the lighting up sequence of the LEDs

at the front.

4.3.1. STOP MODE (STOP)

By selecting the STOP mode, the control unit orders the generator set motor to stop in a controlled manner if it

is in operation and, after checking that it has stopped, proceeds to switch off the control unit.

4.3.2. MANUAL MODE (MAN)

When selecting the MAN mode, starting and stopping the generator set is controlled via the START button on

the control panel.

By pressing the START the motor is ordered to start immediately if the motor is stopped, indicated by the LED

not being lit.

If the START button is pressed while the genset is in operation, indicated by the LED lit at the front of the

M6 control unit, the genset is stopped by disconnecting the genset load via the deactivation of the contactor

output (CON) of the control unit and proceeding to engage the cooling process indicated by the LED lit at

the front of the M6 control unit.

If the START button is pressed when the motor is in the process of cooling, indicated by the LED at the

front of the M6 control unit, an immediate stop is carried out, cancelling the motor cooling process.

4.3.3. AUTOMATIC MODE (AUT)

When selecting the AUT mode, the starting and stopping of the generator set is controlled by means of the

external start input via volt-free contact (LT) of the M6 control unit.

With the closure of the volt-free contact, the control unit commands the generator set motor to start.

With the opening of the volt-free contact, the control unit commands the generator set motor to stop with

cooling.

4.4 NOMINAL SPEED ADJUSTMENT

To set the nominal motor speed, used to detect overspeeding and that the motor is running, it is necessary to

perform the following procedure:

1. The LED on the M6 control unit is flashing to indicate that the control unit has no nominal motor

speed programmed.

2. Start the motor and wait for it to stabilise until it reaches its nominal speed.

3. Hold down the RESET button for 5 seconds.

4. The LED on the M6 control unit turns off to indicate that the process is complete.

5. Management of the overspeeding alarm is enabled (parameter 17 value 1).

6. To reset the setting to nominal speed it is necessary hold down the RESET button for 5 seconds with

the motor stopped. After completing this procedure, management of the overspeeding alarm is

disabled (parameter 17 value 1).

The process described is valid for the detection of speed, generator frequency as well as motor pick-up.

13 | HIMOINSA® M6 CONTROL UNIT

APPENDIX I. TABLE OF PARAMETERS

PARAMETER DESCRIPTION VALUE RANGE

Number of starts.

1 Number of starting retries automatically performed by the control unit 4 1..10

before signalling a starting failure.

Time between starts.

2 5” 3”..15”

Time between starting retries.

Start time.

3 Maximum activation time of the motor start output before any motor 5” 2”..30”

starting condition is detected.

Preheating time.

Maximum activation time of the motor preheating output (PR) during the

motor starting process.

4 Special case with 3 second delay between activation of the configurable 8” 0”..180”

stop (PC) and start (ARR) outputs for motors with control type PR/PD:

preheating process enabled by programming a value of 0 for the

preheating time.

Contactor activation time.

5 Motor stabilization time from the moment the motor is detected in 5” 1”..30”

operation until the activation of the genset contactor output (CON).

Cooling time.

6 Time that the motor remains in operation without load after the genset 120” 2”..1800”

has been commanded to stop.

Stop time.

7 Activation time of the solenoid used to stop the motor in order to cause 10” 1”..30”

the stopping of the generator set with motor configuration type PR/PE

and PE/PD.

Low oil pressure delay.

8 Time interval from the moment the starting of the motor is detected until 15” 0”..60”

the low oil pressure alarm is managed to ensure the stabilisation of the

oil pressure switch.

High temperature water delay.

9 Time interval from the moment the starting of the motor is detected until 1” 0”..60”

the high temperature water alarm is managed to ensure the stabilisation

of the coolant temperature thermostat.

Motor auxiliary alarm input delay.

Time interval from the moment the starting of the motor is detected until

10 the motor auxiliary alarm is managed for the stabilisation of the motor 5” 0”..60”

sensor connected to the motor auxiliary alarm input (AUX) of the M6

control unit.

Frequency threshold for starting detection.

Percentage of genset nominal speed at which point the motor is

11 considered to be started. If the process of adjusting the nominal 30 0..100%

frequency of the genset has not been completed, the control unit will

consider the motor to be started from a frequency of 20 Hz.

Overspeeding detection threshold.

12 Percentage of genset nominal speed at which point the genset 16 0..100%

overspeeding alarm is detected.

14 | HIMOINSA® M6 CONTROL UNIT

Alarm activation time.

13 Activation time of the AL output upon detection of a genset alarm. If set 0 0..600

to zero, the output will remain active indefinitely until the genset is reset

by pressing the RESET button or by turning off the control unit.

Excitation time of the battery charging alternator.

Excitation time of the battery charging alternator during the motor starting 1''..29''

14 process. At the end of this time, controls will begin to check the level of 3 (Always less

voltage supplied by the battery charging alternator, the detection of the than the

motor starting condition and to verify the proper functioning of the starting time)

generator set's battery charging regulator.

0:PR/PD

Motor configuration.

1:PR/PE

15 Configuration of the preheating (PR) and configurable stop (PC) outputs 0

2:PE/PD

of the motor control unit.

3:PR/PULL

Selection of motor speed reading.

0:Generator

16 Method for calculating the motor speed by generator frequency or motor 0

1:Pickup

pickup.

17 Enabling the motor overspeeding alarm. 0

Motor stop due to low fuel reserve alarm.

18 0

Management of the fuel reserve alarm.

Enabling preheating.

Special case with 3 second delay between activation of the configurable 0: Not active

19 0

stop (PC) and start (ARR) outputs for PR/PD type motors: preheating 1: Active

process enabled by programming a value of 0 for the preheating time.

20 Enabling cooling time. 0

21 Detection of motor in operation for battery charging alternator. 1

22 Detection of stop due to low oil pressure. 0

23 Polarity of high water temperature input (ATA). 0

24 Polarity of low oil pressure input (BPA). 0 0: Normally open

(NO)

25 Polarity of motor auxiliary input (AUX). 0

1: Normally closed

26 Polarity of volt-free input (LT). 0 (NC)

27 Polarity of fuel reserve input (RC). 0

15 | HIMOINSA® M6 CONTROL UNIT

APPENDIX II. DIMENSIONS, WIRING AND MECHANICAL PARTS

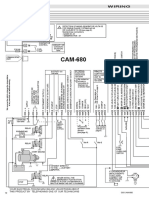

Figure 1: M6 Control Unit.

16 | HIMOINSA® M6 CONTROL UNIT

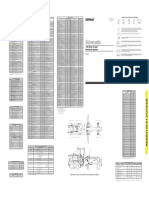

Figure 2: M6 Control Unit Connections.

The equipment must be isolated or disconnected before connecting the voltage input for the generator, as there

is a risk of danger.

The USB connector complies with the standard 2.0.

2

To power the control unit it is recommended that a cable be used with a cross-section of 1 mm .

17 | HIMOINSA® M6 CONTROL UNIT

2

A cable with a diameter of 2.5 mm must be used for +BAT, ARR, PR and PC connections. For the rest of the

2

connections it is recommended that a cable be used with a diameter of 1 mm .

INPUTS AND OUTPUTS

SIGNAL DESCRIPTION TYPE CHARACTERISTICS

POWER SUPPLY

836V Positive battery terminal Power supply Module supply voltage from 8 to 36V.

-BAT Negative battery terminal Power supply Module supply negative

DIGITAL INPUTS

RC Fuel reserve Input NPN digital input

BPA Low oil pressure Input NPN digital input

ATA High water temperature Input NPN digital input

LT External start Input NPN digital input

PEM Emergency stop Input NPN digital input

AUX Motor auxiliary input Input NPN digital input

PICK-UP / GENERATOR INPUT

GCOM Common Input Pick-up and alternator voltage common input

PCK Pick-up Input PICK-UP input

GEN Generator Input Alternator voltage input

HIGH VOLTAGE PNP OUTPUTS

+BAT Positive battery terminal Power supply Digital outputs supply voltage

ARR Starting Output PNP digital output of power

PR Preheating Output PNP digital output of power

PC Configurable stop Output PNP digital output of power

PNP OUTPUTS

D+ Alternator excitation Output PNP digital output

AL Alarm Output PNP digital output

CON Contactor Output PNP digital output

PD Ignition Output PNP digital output

18 | HIMOINSA® M6 CONTROL UNIT

ELECTRICAL CHARACTERISTICS

Symbol Parameter Conditions Minimum Typical Maximum Unit

Power supply (terminals 836V, –BAT, +BAT)

836V Module supply voltage 8 36 VDC

+BAT Power supply of the outputs 8 36 VDC

IBAT Supply current 836V=12V 20 60 mA

IBAT Supply current 836V=24V 10 50 mA

PBAT Power consumption 1 W

NPN digital inputs (terminals RC, BPA, ATA, LT, PEM, AUX)

VIN Input voltage -0,7 40 V

VIL Low level input voltage 1 V

VIH High level input voltage 5 V

IIL Low level input current VIN = 0V 2 2,5 mA

IIH High level input current VIN = 24V 0 100 uA

Pick-Up / Generator input sensor (terminals GCOM, PCK, GEN)

VIN Pick-Up input voltage 4 30 VDC

FIN Pick-Up input frequency 200 2500 8000 Hz

VIN Generator input voltage 180 480 VAC

FIN Generator input frequency 45 66 Hz

Power PNP outputs (terminals ARR, PR, PC)

VO Output voltage +BAT V

IO Output current T = 1s 40 A

IO Output current T = 10s 20 A

IO Output current T= 15 A

PNP outputs (terminals D+, AL, PD, CON)

VO Output voltage +BAT V

IO Output current 1 A

RD+ Output resistance D+ 49,5

Environmental conditions and protection of the enclosure

Tª Operating temperature -40 +70 ºC

HR Relative humidity No 80 %

condensation

IP Degree of Protection *see note 1 65

Note 1: IP 65 on the front of the control unit when installed on the control panel with the sealing gasket

provided.

The control unit must be mounted at the front of an electrical panel, if possible in the centre to allow easy

wiring.

There are no special ventilation requirements due to the low power consumed by the control unit.

All outputs must be provided with the corresponding inductive current disconnection devices (diodes, varistors,

RC filters, etc…).

The wiring for manoeuvres should be kept at a sufficient distance from high electric fields: at least two metres of

power lines of up to 600A and 1 metre of power lines over 600A.

19 | HIMOINSA® M6 CONTROL UNIT

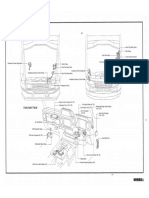

DIMENSIONS OF THE EQUIPMENT

CHARACTERISTICS AND INSTALLATION OF THE EQUIPMENT

The equipment is included within the measurement category CAT III 600V for measurements performed in the

building installation.

Disconnection means should be incorporated to the fixed installation in accordance with installation regulations.

Such means must have contact separation for all poles that provide full disconnection in category III

overvoltage conditions.

The disconnecting means must be accessible by the user. The negative terminal of the battery, electrical panel

chassis and generator chassis must all be earthed.

After installation, the connection terminals of the Pick-Up / Generator sensor input (terminals GCOM, PCK,

GEN) should not be accessible.

If the equipment is handled in a way not specified by the manufacturer, the equipment's protection devices

could become compromised.

The surface areas of the equipment and the external face should be cleaned with a damp cloth.

This equipment can generate the risk of danger if handled improperly.

It must be installed by qualified personnel. It is necessary to consult

the equipment's documentation.

ATTENTION: risk of danger.

20 | HIMOINSA® M6 CONTROL UNIT

SYMBOLS:

SYMBOL DESCRIPTION

Equipment with Class II protection against electric shock. Equipment protected

by double insulation or reinforced insulation.

Attention. Consult the manufacturer's documentation.

Direct current.

CERTIFICATIONS:

Electromagnetic Compatibility Directive

2004/108/EEC. Product Standard UNE-EN 61326-1

Low Voltage Directive 2006/95/EEC. Product

Standard 61010-1

21 | HIMOINSA® M6 CONTROL UNIT

HIMOINSA HEADQUARTERS

Ctra. Murcia - San Javier, km. 23,6 | 30730 SAN JAVIER (Murcia) Spain

Tel.+34 968 19 11 28 +34 902 19 11 28

Fax +34 968 19 12 17 Export fax +34 968 33 43 03

Manufacture facilities:

SPAIN • FRANCE • INDIA • CHINA • USA

Subsidiaries:

ITALY | PORTUGAL | POLAND | GERMANY | SINGAPORE

UAE | MEXICO | PANAMA | ARGENTINA

info@himoinsa.com | www.himoinsa.com

22 | HIMOINSA® M6 CONTROL UNIT

Вам также может понравиться

- Gu601a En0507 PDFДокумент30 страницGu601a En0507 PDFChhoan Nhun100% (2)

- CMD 2 ManualДокумент30 страницCMD 2 ManualAbdul Manan60% (5)

- Dst4600a User Manual.Документ49 страницDst4600a User Manual.elcumanes79% (14)

- Avr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Документ2 страницыAvr Conversion Instructions: FITTING KIT 45-0054 FOR USE WITH SX440 AVR Part No. E000-24030Jose Pirulli100% (1)

- Auto-Start Digital Controller CEM6 IngДокумент12 страницAuto-Start Digital Controller CEM6 IngJaffer Hussain50% (2)

- CUMINS PS0500 Service Manual PDFДокумент33 страницыCUMINS PS0500 Service Manual PDFnoor alam ShaikhОценок пока нет

- S 6476Документ5 страницS 6476mnezami100% (1)

- CAM-680 20 It - PMDДокумент1 страницаCAM-680 20 It - PMDLam Phat Dat100% (2)

- Smart Tech ShogunДокумент7 страницSmart Tech ShogunBruno Mariano100% (1)

- Dst4400 EngДокумент20 страницDst4400 EngFrancisco Stonly Amador Rodriguez33% (3)

- EIMДокумент3 страницыEIMjuanlukaОценок пока нет

- Manuale AC3000 04 08 EN PDFДокумент9 страницManuale AC3000 04 08 EN PDFSOSОценок пока нет

- DST 4601 Technical ManualДокумент103 страницыDST 4601 Technical ManualPetar Markov100% (2)

- Guard Evolution: Operation ManualДокумент38 страницGuard Evolution: Operation ManualJaffer HussainОценок пока нет

- General Information: Drilling Template (MM)Документ4 страницыGeneral Information: Drilling Template (MM)Bruno MarianoОценок пока нет

- SX440 Manual enДокумент4 страницыSX440 Manual enAnsoriОценок пока нет

- DSE4610 DSE4620 Operators Manual PDFДокумент86 страницDSE4610 DSE4620 Operators Manual PDFChristopher100% (3)

- Power WizardДокумент5 страницPower WizardMuhamadAzrinAbdullahОценок пока нет

- 6000TMДокумент39 страниц6000TMnam vo100% (3)

- Himoinsa PHG7-CEMДокумент107 страницHimoinsa PHG7-CEMCharlie Rebaño100% (10)

- Dse 5110 DiagramsДокумент1 страницаDse 5110 DiagramsUlises Ismael Quezada Martínez100% (2)

- Dse720 Installation Instructions PDFДокумент2 страницыDse720 Installation Instructions PDFanon_56872395775% (16)

- DST 4400Документ86 страницDST 4400Ramzi100% (5)

- PS0500 ManualДокумент40 страницPS0500 ManualEdson Souza de Jesus88% (34)

- Pramac Generator AC01-MT-GB4 NEW - OptimizadaДокумент56 страницPramac Generator AC01-MT-GB4 NEW - OptimizadaGreg Carlos80% (25)

- Manual Do PCC 1301Документ125 страницManual Do PCC 1301O mecanico100% (4)

- QC1001Документ62 страницыQC1001nicoss69100% (1)

- Lixise lxc6310Документ33 страницыLixise lxc6310Hector CabreraОценок пока нет

- Gc315 ManualДокумент219 страницGc315 ManualAhmed Hamdy100% (1)

- M7 Manual - Eng GEДокумент84 страницыM7 Manual - Eng GEBruno Mariano75% (12)

- User Manual Commander C-08 - GB PDFДокумент76 страницUser Manual Commander C-08 - GB PDFbac89% (9)

- EAAM025900ZAДокумент44 страницыEAAM025900ZABruno Mariano100% (11)

- GU610A Genset ControllerДокумент33 страницыGU610A Genset ControllerNay SoeОценок пока нет

- GCM01 Ing ST 10-10-05Документ11 страницGCM01 Ing ST 10-10-05Kaiser IqbalОценок пока нет

- AVR - DSR Manual Rev02 PDFДокумент32 страницыAVR - DSR Manual Rev02 PDFAhmed Kotb50% (2)

- 2001 Control Panel (GB)Документ2 страницы2001 Control Panel (GB)Phillip Smith81% (16)

- CTI Transfer Panel: Technical Instruction ManualДокумент40 страницCTI Transfer Panel: Technical Instruction ManualMed Mad75% (8)

- Power Wizard 1.1 & 1.1+.xlsx: Download NowДокумент5 страницPower Wizard 1.1 & 1.1+.xlsx: Download NowFulgence Randrianirina67% (3)

- 509 ManualДокумент54 страницы509 ManualBruno Mariano33% (9)

- Cea7 PDFДокумент11 страницCea7 PDFLutionnn100% (12)

- BGC-2 Installation Instructions 4189340302 UKДокумент45 страницBGC-2 Installation Instructions 4189340302 UKJuanilloОценок пока нет

- TE809-A Instructions ManualДокумент48 страницTE809-A Instructions ManualMostafa Shanna100% (1)

- InteliLite AMF20-25Документ2 страницыInteliLite AMF20-25albertooliveira100% (2)

- MANUAL CENTRAL M6 - Rev1-F PDFДокумент24 страницыMANUAL CENTRAL M6 - Rev1-F PDFFrancisco Mosquera Lopez75% (4)

- CM2A/3A Series: User'S ManualДокумент26 страницCM2A/3A Series: User'S ManualPIKO MOBОценок пока нет

- MANUAL CENTRAL M6 - Rev1-FДокумент24 страницыMANUAL CENTRAL M6 - Rev1-FRuddy Fabrizio Galvez JustinianoОценок пока нет

- DSE704 Manual PDFДокумент15 страницDSE704 Manual PDFEduardo DavidОценок пока нет

- Dse704 Manual PDFДокумент15 страницDse704 Manual PDFJulio Hinostroza AlarconОценок пока нет

- Arburg 221 ManualДокумент92 страницыArburg 221 ManualZeljko Djukic73% (15)

- YL80C ManualДокумент25 страницYL80C ManualmrperikОценок пока нет

- Generator ControllerДокумент21 страницаGenerator ControllerBrianHazeОценок пока нет

- Operation Manual: Vertical Machining CenterДокумент27 страницOperation Manual: Vertical Machining CenterAmauriGarciaОценок пока нет

- MANUAL SMARTGEN HGM6100 - v2.0 - enДокумент24 страницыMANUAL SMARTGEN HGM6100 - v2.0 - enManuel Otero100% (2)

- Eaom-36r Eng v05Документ8 страницEaom-36r Eng v05Khaled KamelОценок пока нет

- Auto Start / Instrumentation Generator Control Module - Pvs1Документ12 страницAuto Start / Instrumentation Generator Control Module - Pvs1FAOUZIОценок пока нет

- MR Service ManualДокумент42 страницыMR Service ManualqdzungОценок пока нет

- Powerview : Model Pv101-C User'S GuideДокумент52 страницыPowerview : Model Pv101-C User'S GuideYipper ShnipperОценок пока нет

- Emcp 3 1Документ150 страницEmcp 3 1victoros27Оценок пока нет

- Dse703 ManualДокумент15 страницDse703 Manualroozbehxox100% (1)

- Ananda Cangoo Noon BuckleДокумент26 страницAnanda Cangoo Noon BuckleMilos MilentijevicОценок пока нет

- WheelHorse Engine Electrical Service ManualДокумент50 страницWheelHorse Engine Electrical Service ManualKevins Small Engine and Tractor Service0% (1)

- Fiat Punto Wiring DiagramsДокумент11 страницFiat Punto Wiring Diagramszilexo88% (8)

- C2.2 Sebu8137-04 MДокумент36 страницC2.2 Sebu8137-04 MMd Sh100% (1)

- 181-630-14 hm80Документ24 страницы181-630-14 hm80Taylor TaylorОценок пока нет

- AC Ripple VoltageДокумент5 страницAC Ripple VoltageAgung Sugeng RiyadiОценок пока нет

- TBM Gen GS01Документ2 страницыTBM Gen GS01rohit tiwariОценок пока нет

- Magicar 9000BДокумент13 страницMagicar 9000BDavid MartinОценок пока нет

- Escavadora 110Документ678 страницEscavadora 110Gilberto TorresОценок пока нет

- Charging SystemsДокумент70 страницCharging Systemsmarwa100% (1)

- Electronic Wiring Diagram Zafira MY 2001 PDFДокумент315 страницElectronic Wiring Diagram Zafira MY 2001 PDFAdrian Chippendale100% (1)

- MR - Engine 1104D Assembly & Disasembly PDFДокумент138 страницMR - Engine 1104D Assembly & Disasembly PDFmliugongОценок пока нет

- Etacs BLДокумент74 страницыEtacs BLMohd FairusОценок пока нет

- SSP 287 Audi A8 2003 Electrical ComponentsДокумент96 страницSSP 287 Audi A8 2003 Electrical ComponentsKevin Huang67% (3)

- Alternadores Delco RemyДокумент21 страницаAlternadores Delco RemyosmeОценок пока нет

- Service Manual Marine EnginesДокумент95 страницService Manual Marine Engineslexxa3210% (1)

- Ic RegulatorДокумент19 страницIc RegulatorFatah FatanОценок пока нет

- 14H ASE SchematicДокумент2 страницы14H ASE SchematicNovakurniawan100% (1)

- Avaliação Mecanico 1 (Ingles)Документ13 страницAvaliação Mecanico 1 (Ingles)Júlia Campos100% (1)

- 450 Dxi Wiring Numbers PDFДокумент32 страницы450 Dxi Wiring Numbers PDFvaleriy100% (4)

- Electronic Systems MegatechДокумент5 страницElectronic Systems Megatechluis albertoОценок пока нет

- Virjendra KumarДокумент23 страницыVirjendra KumarsarbjeetОценок пока нет

- Korean Vehicles Daewoo Hyundai Kia: Replacement Parts CatalogueДокумент63 страницыKorean Vehicles Daewoo Hyundai Kia: Replacement Parts CatalogueVolodiyaОценок пока нет

- '90-'92 70-Series Wiring ManualДокумент82 страницы'90-'92 70-Series Wiring ManuallukasОценок пока нет

- TM 9-2920-258-30&P Alternator M 109Документ76 страницTM 9-2920-258-30&P Alternator M 109Thoukididis ThoukididouОценок пока нет

- Group 5 - Electrical SystemДокумент402 страницыGroup 5 - Electrical SystemTyler Lee71% (14)

- Alternator (Automotive)Документ4 страницыAlternator (Automotive)Cornel BicaОценок пока нет

- PDI ChecklistДокумент2 страницыPDI ChecklistAmmar Baig80% (5)

- Circuit Diagram Fiat 500 DДокумент1 страницаCircuit Diagram Fiat 500 DAlex WebОценок пока нет

- 20KVAДокумент63 страницы20KVAeichermguptaОценок пока нет

- MS008 Operation ManualДокумент116 страницMS008 Operation ManualSergio ZamoranoОценок пока нет