Академический Документы

Профессиональный Документы

Культура Документы

Reservoir - Fluid Sampling & Characterization-Key To Efficient Reservoir Management PDF

Загружено:

JesseОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reservoir - Fluid Sampling & Characterization-Key To Efficient Reservoir Management PDF

Загружено:

JesseАвторское право:

Доступные форматы

DISTINGUISHED AUTHOR SERIES

Reservoir-Fluid Sampling and Characterization—

Key to Efficient Reservoir Management

N.R. Nagarajan, M.M. Honarpour, and K. Sampath, ExxonMobil Upstream Research Company

Abstract and recovery-factor calculations and are key input to reser-

Reservoir-fluid properties play a key role in the design and voir simulations for technical evaluation of reservoir-devel-

optimization of injection/production strategies and surface opment/-depletion plans. Fluid characterization and distribu-

facilities for efficient reservoir management. Inaccurate fluid tion within the reservoir help in defining reservoir continuity

characterization often leads to high uncertainties in in-place- and communication among various zones. Interpretation of

volume estimates and recovery predictions, and hence affects well-test data and the design of surface facilities and process-

asset value. Reservoir-fluid pressure/volume/temperature ing plants require accurate fluid information and its variation

(PVT) characterization begins with acquisition of adequate with time. In addition to initial reservoir-fluid samples, peri-

volumes of representative fluid samples followed by PVT-data odic sampling is necessary for reservoir surveillance.

measurement with strict quality-assurance/quality-control Reservoir-fluid characterization consists of several key

(QA/QC) protocols and phase-behavior modeling through steps: (1) acquisition of representative samples, (2) iden-

best-practice methods. In this paper, key steps involved in tification of reliable service laboratories to perform PVT

accurate fluid characterization are discussed for a wide spec- measurements, (3) implementation of QA/QC procedures

trum of fluid types ranging from extraheavy oils to highly vola- to ensure data quality, and (4) development of mathematical

tile near-critical fluids and lean gas condensates undergoing a models to capture fluid-property changes accurately as func-

wide range of production processes from simple depletion to tions of pressure, temperature, and composition. The fluid

complex tertiary recovery. Selection of appropriate sampling type and production processes dictate the type and the vol-

methods and tools, design of tool strings, and customizing ume of required fluid data. This paper outlines recommended

procedures are demonstrated through these examples. Routine sampling techniques, PVT-data-acquisition strategies, and

and special laboratory-fluid-analysis strategies for various fluid modeling methods and presents field examples covering a

types and for different production strategies are highlighted. wide range of fluid types from heavy oils to lean gas conden-

Fluid-modeling techniques including optimum-component sates and production processes such as depletion, pressure

selection, accurate C7+ characterization, robust Gibb’s energy maintenance, and miscible recovery.

minimization, and gravity/chemical equilibrium calculations

are demonstrated through appropriate field examples. Sampling—Methods, Tools, and Recommended Practice.

The main objective of a successful sampling campaign is

Introduction to obtain representative fluid samples for determining PVT

Reservoir-fluid PVT properties are critical for efficient reser- properties. In addition to PVT samples, adequate volumes

voir management throughout the life of the reservoir, from should be collected for plant and process analysis, geochemi-

discovery to abandonment (See complementary paper by cal analysis for fluid-source identification and reservoir con-

Honarpour et al. 2006.) Reliable PVT properties of in-situ tinuity, and crude assay for refinery processes. The critical

fluids are essential for the determination of in-place volumes steps in any successful sampling program are avoiding two-

phase flow in the reservoir, minimizing fluid contamination

introduced by drilling and completion fluids, and preserving

N.R. Nagarajan, SPE, is an engineering associate at sample integrity. A sampling program should focus on the

ExxonMobil’s Upstream Research Company with 22 years key issues of selecting an appropriate sampling method and

of experience in the oil industry. He holds a PhD degree associated tools, customizing the tool string, and developing

in physics and has served on program committees and the sound sampling, sample-transfer, and QC procedures. In

Forum Series for SPE. Mehdi Matt Honarpour, SPE, is addition, specific sampling issues should be addressed related

a senior engineering adviser with ExxonMobil Upstream to fluid type and condition, saturated vs. undersaturated, and

Research Company in Houston. He holds BS, MS, and PhD fluids with nonhydrocarbon components or fluids containing

degrees in petroleum engineering from the U. of Missouri. solid-forming components such as waxes and asphaltenes.

Honarpour served as the Chairperson of SPEREE Review

Committee and as the Chairperson of the SPE Special

Copyright 2007 Society of Petroleum Engineers

Series Committee. Krishnaswamy Sampath, SPE, is the This paper, SPE 103501, is based on paper 101517 presented at the 2006 Abu Dhabi

Reservoir Division Manager at ExxonMobil’s Upstream International Petroleum Exhibition & Conference, Abu Dhabi, 5–8 November. Distinguished

Author Series articles are general, descriptive representations that summarize the state of the

Research Company in Houston. He has served on program art in an area of technology by describing recent developments for readers who are not special-

ists in the topics discussed. Written by individuals recognized as experts in the area, these articles

committees for the SPE Annual Technical Conference and provide key references to more definitive work and present specific details only to illustrate the

Exhibition and as a technical editor for SPE journals. technology. Purpose: to inform the general readership of recent advances in various areas of

petroleum engineering.

80 JPT • AUGUST 2007

Reservoir Reservoir Sampling Sampling

Fluid Type Rock Fluid Issues Methods

Saturated Drawdown/2-Phase Flow

Two-Phase Flow Surface DST

Heavy Oil Consolidated

Sand-Production

Undersaturated

Under Saturated

Under-saturated Surface Isokinetic

Emulsions

Black Oil Unconsolidated

Water Safety/Risk Concerns

Bottom Hole

Bottomhole

Near-Critical

Near-Critical High Permeability

High Permeability Nonhydrocarbons Contamination by OBM Formation

Formation Tester

Tester

Fluids

Fluids

Loss of Nonhydrocarbons

Compositional Depth-Dependent

Depth-Dependent Bottomhole

Gas-Condensate Low Permeability

Gradients Composition

Composition Conventional

Sampling-Method Selection

Job Planning Job Preparation Execution

• Tool Design • Tool Assembly • Data Monitoring

• Tool Sticking • Sample Bottles • Pressure

• Packer vs. Probe • Pump Rate

• Cleaning

• Pumpout • Fluid Quality

• Near-Wellbore Cleaning • Well Site • Contamination

Equipment

• Pumpout Volume • On-site Data

Check

• Time Evaluation

• Optimum Drawdown • Coordination

• Adjust Operating

Meeting With all

Calculation Personnel Conditions for

Successful Sample

Implementation of Successful Sampling Job

Fig. 1—Reservoir fluid sampling guidelines. OBM=oil-based mud, DST=drillstem test.

Selecting Sampling Method and Tools. The two commonly While bottomhole sampling has the advantage of capturing

used sampling methods are bottomhole and surface sampling. fluids at reservoir conditions, surface sampling operation has

Bottomhole sampling attempts to capture samples close to a potential for obtaining cleaner samples as a result of large

reservoir conditions, while surface sampling aims at captur- volumes of fluid production before sampling.

ing gas and oil samples from the separator under stable flow Because a variety of sampling tools and techniques are avail-

conditions. Separator fluids then are recombined at a mea- able, careful thought should be given to tool selection and

sured producing gas/oil ratio (GOR) to prepare representative configuration as well as sampling procedures to tailor them to

reservoir fluid. Both methods have challenges and issues that specific reservoirs and fluids. Fig. 1 provides general sampling

must be overcome to ensure high-quality samples. guidelines that consist of two parts, sampling-method selec-

In bottomhole-sampling operations, adequate cleaning of tion and successful implementation. Selection of a sampling

near-wellbore regions and controlled drawdown are critical method requires a critical review of reservoir conditions, rock

for obtaining uncontaminated representative samples (Witt and fluid type, and several relevant sampling issues listed in

and Crombie 1999). Controlled drawdown helps avoid two- Fig. 1. Implementation involves details of tool selection and

phase flow in the reservoir. Downhole fluid analyzers are configuration, developing procedures, wellsite execution, and

used to monitor sample contamination and ensure single- QC. For example, the highlighted items in Fig. 1 are an exam-

phase flow prior to sample capture. Accurate calibration of ple of a near-critical-fluid sampling and demonstrate how the

these analyzers is essential for accurate estimate of contami- rock and fluid conditions and other relevant sampling issues

nation levels. In surface sampling operation, proper well con- lead to the selection of a bottomhole formation-tester sam-

ditioning with minimum drawdown is the key to acquiring pling method. Fig. 1 also shows the steps involved in the job

high-quality samples (Witt et al. 1999). Well conditioning planning and preparation. Often, operational considerations,

requires that the well be flowed at an optimum rate for an safety issues, and cost are critical in the final decision.

extended period of time with a stable producing GOR. Other

factors that affect sample quality are separator efficiency PVT Data—Requirement and QC. The objective of the PVT-

and uncertainties in surface oil- and gas-rate measurements. data-gathering phase is to obtain reliable high-quality data for

JPT • AUGUST 2007 81

DISTINGUISHED AUTHOR SERIES

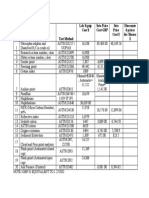

TABLE 1—PVT-DATA REQUIREMENT FOR VARIOUS FLUIDS AND PRODUCTION PROCESSES

Fluid Type Fluid Properties Reservoir and Required PVT Tests, Data, and Accuracy Supplemental

Gravity GOR C7+ Production Composition Tests/Equipment/Procedures Required Data Data Accuracy Tests

°API scf/STB mol% Processes

Heavy Oil 7–25 10–200 > 40 Depletion/ C30+, Wax, and Oil PVT—CCE, DFL, ST Pb, Rs, Bg, Bo, ,µ Pb ±50 psi

Cold Production Asphaltene, % Direct mixing cell/special proc. F(P, T, Rs) Rs, µ o ± 5%; Core-depletion tests at different rates

Solvent Flood Oil and Oil + Solvent PVT Same + Changes by solvent addition Bo, ±2% Flow tests for relative permeability

o

Waterflood Oil PVT and Water PVT Same + Bw, w, µ w F(P)

Steamflood Oil PVT + High-Temperture PVT Same + Steam properties

Black Oil 25–35 200– 20–40 Depletion C30+, Wax, and Oil PVT—CCE, DFL, ST Pb, Rs, Bg, Bo, , µ F(P) Pb ±50 psi; Flow tests for relative permeability

1,500 Waterflood Asphaltene, % Oil PVT and Water PVT Same + Bw, w, µ w F(P) Rs, µ o ± 5%;

Gasflood— Bo, o ±2%

Immiscible Oil PVT and Oil + Gas PVT Same + Changes by gas addition

HC or CO 2 Oil PVT and Gas + Oil PVT Same + P/X data (Pb, µ o, o, Bo, Same + Liquid vol% ±2% Relative permeability, slim-tube, and

Flood—Miscible Swelling and forward/ Liquid vol%) + Compositional coreflood tests for gas injection

backward contact tests changes with injected gas and P

Light Oil 35–40 1,000– 13–20 Depletion C30+, Wax, and Oil PVT—CCE, DFL, ST Pb, Rs, Bg, Bo, , µ F(P) Pb ±20 psi; Flow tests for relative permeability

2,000 Waterflood Asphaltene, % Oil PVT + Water PVT Same +µ w, w, and Bw F(P) Rs, µ o ± 5%;

Gas Injection Oil PVT + Swelling test Same + P/X data Bo, o ±2%

Near-Critical 40–50 2,000– 8–13 Depletion C30+, Wax, and Oil PVT—High Precision Pb, Rs, Bg, Bo, , µ F(P) Same Flow tests for relative permeability

Fluids—Highly 5,000 HC-Gas Injection Asphaltene, % Oil PVT + Swelling and forward/ Same + P/X Data (Pb, µ o, o, Bo and Same + Liquid vol% ±2% Relative permeability, slim-tube, and

Volatile Oil and coreflood tests for gas injection

—Miscible backward contact test Liquid vol%), and Compositional

Rich Condensate

Precision mesaurements data with gas injection

Compositional Fluid Same as above + miscibility Same as above Pb ±20 psi; Additional slim-tube and coreflood

Gradients Compositions evaluation of varying oil Rs, µ o ±5%; Bo, o ±2%; tests with injected gas

With Depth composition in the reservoir Liquid vol% ±2%

Gas Condensate >50 >5,000 <8 Depletion C20+, Wax, and Gas-Condensate PVT—CCE, Pd, Z-factors, CGR, and Pd ±50 psi; Liquid vol% ±2%; Relative permeability, slim-tube, and

Asphaltene, % CVD, ST; solubility of gas in liquid dropout; PVT changes from Z-Factor ±2%; coreflood tests for gas injection

Water Analysis water and water vaporization water vaporization CGR ± 1 STB/MMscf

Gas Injection for Nonhydrocarbon Reservoir-fluid + injection-gas Same as above + P/X data ( Pd, Bg, Same as Above Relative permeability at different

Pressure (N2, CO2, H2S) and PVT; Special 3-phase PVT-cell and CGR changes with injected gas) capillary numbers

Maintenance Sulfur Analysis with zero dead volume

reservoir evaluation and development. The PVT-data require- relations for specific oils. Also, it should be recognized that

ment depends on the fluid type and the expected development as these correlations are based on measured data and lack

and production strategies (Whitson and Brule 2000). Table 1 a thermodynamic basis, extrapolation outside the range of

provides a list of required PVT data and the needed accuracy data might contribute to large errors. However, EOS models

for various fluid types and production processes along with based on thermodynamic principles are useful for reasonable

general guidelines for designing a laboratory PVT program. extrapolation beyond the data range (Whitson and Brule

For example, extraheavy oils require customized PVT cells 2000). When cost and computational considerations dictate

and experimental procedures to accelerate the time needed for use of black-oil models for simulation studies, it is highly

attaining equilibrium conditions because of the slow gas lib- recommended to derive black-oil properties by use of EOS

eration. On the other hand, more-complex near-critical fluids fluid models tuned to laboratory data (Whitson and Brule

and miscible-gas-injection processes need special PVT tests 2000). EOS-based fluid modeling involves several critical

and precise measurement techniques to capture the complex steps including optimum-component selection by means of

phase behavior exhibited by these fluids. Gas condensates in C7+ characterization, incorporation of robust phase-equi-

the presence of water require PVT cells that can handle three- librium calculation (energy minimization) and solution

phase mixtures of gas, water, and condensate. techniques to ensure convergence, and a rigorous regression

Data Quality. Ensuring high-quality data requires routine method to tune the model to laboratory data. A brief discus-

laboratory visits, evaluation of laboratory procedures and sion of these techniques is provided, and their applications

methods, and spot QC as data become available. The QA/ are demonstrated through examples.

QC methods can range from simple graphical techniques C7+ Characterization and Component Selection. The C7+

to sophisticated material-balance calculations (Whitson and fraction of the reservoir fluid contains numerous compounds

Brule 2000). of different homologues (paraffinic, naphthenic, and aro-

matic) and plays a dominant role in determining the PVT

Fluid Modeling—Recommended Methodology. Modeling behavior of the fluid. For example, in a gas-condensate fluid,

reservoir-fluid PVT behavior is necessary for reservoir- the dewpoint pressure is a strong function of C7+ molecular

engineering calculations and simulation studies. Several weight and its relative amount in the fluid. In heavy oils, C7+

approaches including black-oil correlations, pseudocom- components dictate the viscosity behavior and control the

positional formulations, and fully compositional equation- asphaltenes- and wax-deposition characteristics. Similarly, in

of-state (EOS) methods are used to develop fluid models. volatile oils and rich condensates, the oil volumes and other

Most black-oil correlations are based on regional fluid data, properties below the saturation pressure are determined

and, therefore, caution should be exercised in choosing cor- by the amounts of intermediate and heavy components.

82 JPT • AUGUST 2007

TABLE 2—FIELD EXAMPLES OF FLUID SAMPLING AND CHARACTERIZATION

Fluid type/ Pressure, T, Gravity, GOR,

Process Reservoir psia °F °API scf/STB Issues Methods

Formation-fluid sampling,

Extraheavy oil Cerro Negro 1,400 130 8–9 120–130 Sampling, PVT measurements special apparatus

and procedures

Black oil/CO2 Extended PVT tests, detailed Customized tests, models

flooding Salt Creek 2,500 124 34 415

fluid characterization by rigorous techniques

Near-critical-fluid/ Sampling, high-precision Formation-fluid sampling,

2,500 to

Miscible-HC-gas Oso 6,300 232 40–45 measurements, modeling special apparatus,

4,000

injection compositional gradients gradient modeling

Water and Special PVT tests,

Gas Condensate Arun 7,100 352 55 20,000 reservoir-fluid PVT, customized

corrosion modeling

Therefore, it is important to characterize them accurately. extraheavy oil in highly unconsolidated sands. The average

Several techniques are used to lump these components into reservoir pressure and temperature range between 800 and

pseudocomponents for EOS models. The most widely used 1,450 psia and 120 and 145°F, respectively. The stock-tank oil

method is from Whitson (1983) in which the C7+ distribu- gravity is approximately 9°API. The live-oil viscosity ranges

tion is represented by a continuous gamma distribution that from 600 to 3,000 cp at reservoir conditions. The solution

is optimally discretized into a few fractions (i.e., pseudocom- GOR of the oil is 120 to 130 scf/STB. The high oil viscosity

ponents). Fluid type and the production processes involved impedes the separation of solution gas from the oil below its

further dictated the component selection. When describing true bubblepoint pressure, resulting in microbubbles of gas

near-critical fluids and miscible processes, it is important to dispersed in the oil until diffusion forces help the gas bubbles

have more intermediate and volatile components in the fluid to coalescence slowly into a distinct gas phase (Cengiz et al.

description to mimic simple revaporization and more-com- 2004). This unique behavior poses several challenges in fluid

plex condensing and vaporizing drives. Specifics of compo- sampling and PVT measurement requiring careful choice of

nent selection will be highlighted through examples. tools and procedures.

Energy Minimization and Model Optimization. Although Sampling Method, Tools, and Procedures. The objective

EOS-based fluid models predict multicomponent phase of the heavy-oil sampling program was to obtain adequate

behavior reliably, they still lack the capability to mimic volumes of representative single-phase oil samples for labo-

near-critical behavior because of mathematical singulari- ratory analysis. The following sampling challenges had to

ties encountered in this region. Therefore, more-rigorous be addressed (Reddie and Robertson 2004): adequate near-

methods such as Gibbs/Helmholtz energy minimization and wellbore cleaning to minimize sample contamination by

robust solution techniques are needed to model near-critical drilling-mud filtrate and optimal drawdown to minimize

behavior (Nagarajan et al. 1991). Application of these tech- sand production and avoid two-phase flow while mobiliz-

niques is discussed under various examples. Another critical ing the oil from the reservoir into the sample chamber.

step in fluid modeling is optimizing model parameters to During surface sampling, measurement uncertainty in the

match measured data. Generally, an EOS fluid model uses producing GOR is a concern because of large drawdown and

6 to 12 components, of which four to five are C7+ pseudo- incomplete gas separation from the oil. Another challenge

components. The result is several tens of model parameters with surface samples is the slow dissolution of gas while

(such as component-critical properties—critical pressures, recombining them to prepare reservoir fluid. Many of these

temperatures, volumes, and acentric factor—and several sampling problems can be eliminated by use of bottomhole

binary interaction coefficients) to be regressed on. Systematic sampling with a wireline formation tester having appropriate

grouping of these parameters is essential for reliable and tool selection and procedures as identified in Table 3.

faster regression. The key components of a wireline-formation-tester tool

include a variable-rate pump-out module, properly sized

Field Examples screens to prevent plugging of flow lines by sands and fines,

The fluid-characterization steps discussed above are illus- a resistivity cell, and two optical fluid analyzers to monitor

trated through field examples ranging from heavy oils to lean fluid quality and detect two-phase conditions. Single-phase

gas condensates as listed in Table 2 along with relevant fluid sample bottles should be used for sample collection to avoid

parameters, fluid-characterization challenges, and solutions. flashing the samples. The main advantage of bottomhole

sampling over surface sampling is that the former offers a

Heavy Oil—Cerro Negro Field. The Cerro Negro field in viable means to capture single-phase samples and eliminate

the Orinoco oil belt in northeastern Venezuela contains uncertainties associated with surface samples.

JPT • AUGUST 2007 83

DISTINGUISHED AUTHOR SERIES

TABLE 3—WFT TOOL DESIGN FOR HEAVY-OIL SAMPLING

Design/

Problem/Issue Requirement Tool Selection Configuration

Sand production and Optimal drawdown, Dual-packer option, Pump configured

two-phase flow Control sand production Flow-control pump, close to sampling point

when mobilizing oil Coarse/fine filters

Mud-filtrate Adequate pumpout Pump with variable High rate: cleaning,

contamination volume before sampling rate (high to low) Low rate: sampling

Fluid quality Fluid-quality monitoring, Optical fluid analyzers, Fluid analyzers positioned

Identify contaminants Resistivity cell above and below pump

Single-phase samples Sample-bottle type, Single-phase sample Close to sampling-point

adequate volumes volume, and number bottles location

A sampling-simulation program was used to estimate to double the reservoir temperature, resulting in water con-

optimum pumping rates to minimize the probability of sand tent of less than 1% in the oil.

production while mobilizing the oil under single-phase con- A direct-mixing PVT cell was custom designed to facilitate

ditions. By use of estimated reservoir and fluid parameters, faster equilibrium during PVT measurements, especially for

the pump-out volume and time required for adequate clean- measuring the bubblepoint. However, even with this PVT

ing also were estimated. Specific sampling procedures were cell, nonequilibrium measurements were likely if proper

developed to reduce the possibility of collecting nonrepre- experimental procedures were not followed. In an equilib-

sentative samples. In addition, procedures for on-site sample rium test, the pressure/volume curve exhibits a sharp change

transfer and shipping were developed to preserve sample in the slope at the bubblepoint. However, as Fig. 2a shows, it

integrity. Qualified personnel were on site to coordinate and is difficult to detect such sharp slope changes in a nonequilib-

monitor the entire sampling operation. As a result, several rium test (Cengiz et al. 2004). Monitoring pressure response

high-quality samples were captured for detailed composi- as a function of time and its rate of change in both nonequi-

tional and PVT analysis. librium (without stirring) and equilibrium (with vigorous

PVT Measurements and Modeling. Because of slow gas stirring) tests, as shown in Fig. 2b, would help identify true

liberation and dissolution in this heavy oil, special care equilibrium conditions. A sharp drop in pressure (Segment

was exercised in selecting equipment and procedures for 1 in Fig. 2b) was observed as soon as the cell volume was

sample preparation and PVT measurements (Cengiz et al. expanded, indicating the behavior of an incompressible liq-

2004). The sample preparation involved removing both free uid. As the gas slowly evolved, a gradual pressure buildup

and emulsified water from the samples by a nonchemical (Segment 2) was observed, but equilibrium condition was

method. The dewatering process consisted of pressurizing not reached even after 20 hours without stirring. However,

the sample above the reservoir pressure and subjecting it to with vigorous mixing, equilibrium condition was reached

repeated heating and cooling cycles from room temperature rapidly as indicated by Segments 3 and 4 in Fig. 2b. By this

1,100

800

1,000 4

600 1 3 5

Pressure, psia

2

Volume, cm3

900

400 Equilibrium Test 1. Expansion

Nonequilibrium

800 2. Slow Pressure Recovery

Test

(no mixing, nonequilibrium)

3. Faster Pressure Recovery

200 (vigorous mixing, faster equilibrium)

700

4. Reaching Equilibrium (constant pressure)

5. Start of Next Expansion

0 600

0 400 800 1200 1600 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0

Pressure, psia Time, hours

Fig. 2a—Equilibrium and nonequilibrium heavy-oil Fig. 2b—Pressure response vs. time near bubblepoint

bubblepoint measurement. equilibrium and nonequilibrium behavior.

84 JPT • AUGUST 2007

L1—Oil

CO2

L2—CO2 Rich Oil

V—Hydrocarbon Gas + CO2

Liquid Phase

P1

Vapor Phase

Pressure, psi

Critical Point

-V

-V

P1

L1

L1

Mole Fraction CO2 C13+

C2–C13

(a) (b)

Fig. 3—CO2+oil pressure/composition and ternary diagrams at T>120ºF.

approach of ensuring equilibrium, the true bubblepoint pres- late viscosity as functions of pressure, temperature, and GOR

sure was measured repeatedly within approximately 50 psi. are needed to capture large variations of heavy-oil viscosity

Similar procedures were followed in other PVT tests. throughout the operating conditions.

A capillary-flow viscometer was used to measure the oil

viscosity. Because the oil is saturated at each pressure step in Black Oil—Salt Creek Reservoir. The Salt Creek field in

the differential-liberation experiment, small pressure drops west Texas is a carbonate reservoir in the Permian Basin

in the capillary viscometer caused by the flow will liberate containing medium-gravity oil (35°API). The initial reser-

the gas. Therefore, it was necessary to conduct several vis- voir pressure and temperature were 2,199 psia and 124°F,

cosity measurements above the saturated pressure and use respectively. The initial GOR of the oil was 415 scf/STB

an extrapolation technique to determine the viscosity at the and the live-oil viscosity was 0.8 cp. The fluid exhibited a

desired differential-liberation pressure. bubblepoint pressure of 1,620 psia at 124°F. The reservoir

PVT-data interpretation and modeling for heavy oils was initially produced by depletion, pressure maintenance,

require reliable pseudoization of C7+ components because and gas recycling, followed by waterflood and infill drill-

a majority of components in heavy oils fall in this range ing (Bishop et al. 2004). High remaining oil saturations in

(Romero et al. 2001). Solid-forming compounds, such as several parts of the reservoir after waterflood prompted an

wax and asphaltenes, should be characterized properly for evaluation of CO2-miscible-flooding potential to recover

flow assurance needs. Rigorous viscosity models that corre- some of the remaining oil. Significant solubility of CO2 in the

CO2 L1—Oil

L2—CO2 Rich Oil

V—Hydrocarbon Gas + CO2

-L2

Liquid Phase

L1

P1

Pressure, psi

Vapor Phase

2

-L

V

2-

L1

L1

-L

P1 -L

2-

V L1

-V

L1

L1-V

L2-V

Mole Fraction CO2 C13+ C2–C13

(a) (b)

Fig. 4—CO2+oil pressure/composition and ternary diagrams at T<120ºF.

JPT • AUGUST 2007 85

DISTINGUISHED AUTHOR SERIES

5,000

100% Liquid Points: Laboratory Data

80% Liquid

4,000

70% Liquid

60% Liquid

Pressure, psia

50% Liquid

3,000

40% Liquid

2,000

1,000

0

0 10 20 30 40 50 60 70 80 90

CO2 Concentration, mol%

Fig. 5—Swelling-test data for CO2 miscibile process.

oil enhances the recovery through oil swelling and viscosity tions in the two-phase region also were measured at several

reduction (Stalkup. 1984). CO2 also vaporizes intermediate pressures as functions of CO2 concentration. Fig. 5 shows a

components leading to multicontact miscibility and high measured P/X diagram for liquid-volume changes as a func-

recoveries (Stalkup. 1984). A systematic PVT-data-acquisi- tion of both pressure and composition. In slim-tube tests,

tion and modeling study was undertaken for Salt Creek to the effluent-fluid compositions were measured in addition

evaluate recovery efficiency to CO2 flooding. to the conventional measurement of recovery and gas break-

CO2+Oil Phase Behavior. A typical phase behavior exhib- through. This information was used for dynamic tuning of

ited by CO2+oil mixtures at both high (>120°F) and low the reservoir-fluid model for simulation. The minimum mis-

(<120°F) temperatures, respectively, is displayed in Figs. 3 cibility pressure for CO2 injection, the residual-oil saturation

and 4 through pressure/composition (P/X) and ternary for miscible flood, and the effluent-fluid compositions were

diagrams (Bishop et al. 2004). Depending on the pressure, measured in a series of flow tests.

temperature, and composition, CO2+oil mixtures can exhibit Fluid Modeling. To model Salt Creek CO2 processes, it

near-critical behavior including multiphase equilibrium rang- was necessary to split the C7+ fraction into a large number of

ing from simple two-phase liquid/vapor (Figs. 3a and 3b) to pseudocomponents for the EOS model. Pseudocomponents

more-complex two- or three-phase liquid/liquid or liquid/liq- were generated by lumping components in small ranges of

uid/vapor equilibrium (Figs. 4a and 4b). As shown in Fig. 3, carbon numbers (e.g., C7–C9, C10–C13, C14–C16, ...). This

the CO2+oil phase boundary in the critical region is steep. type of detailed C7+ description was necessary to capture

The fluid properties also vary significantly in this region with vaporization of intermediate components as high as C20 to

small changes in operating conditions or fluid composition. C25 by the dense CO2-rich phase. A Helmholtz energy-mini-

PVT tests for evaluating CO2-injection processes should be mization procedure in terms of molar densities was used to

designed to acquire high-precision compositional and PVT identify correct phase equilibrium solutions (Nagarajan et

data for modeling this complex phase behavior. The data al. 1991). The Helmholtz energy minimization formulation

interpretation and modeling are equally challenging. converges to true solutions by avoiding difficulties encoun-

PVT Data Requirement. The basic PVT tests comprised tered while using Gibbs energy-minimization as functions

constant-composition expansion, differential liberation, and of mole numbers and molar volume. Predicted P/X diagram

multistage-separator tests to describe the oil PVT behavior and liquid volumes agreed well with the measurements, as

as a function of reservoir and surface conditions. Additional shown in Fig. 5. In addition to tuning the fluid model to

PVT tests including swelling-test and multicontact experi- equilibrium PVT data, the slim-tube and coreflood data were

ments, and slim-tube and coreflood tests were conducted used in a 1D simulator to fine-tune the EOS model under

to acquire both equilibrium PVT data on CO2+Salt Creek flow conditions.

oil mixtures and dynamic-flow data with CO2 as displacing

fluid. Several CO2+oil mixtures with CO2 concentrations Near-Critical Fluid—Oso Field. The 2Y2 reservoir of the

ranging from a few mole percent to as high as 70 mol% Oso field offshore Nigeria contains a highly undersaturated

were used in swelling tests measuring saturation pressures, near-critical fluid (El-Mandouh et al. 1993). The initial res-

density, and viscosity as functions of pressure and CO2 con- ervoir pressure and temperature were 6,300 psia and 232°F,

centration. The liquid/vapor volume fractions and composi- respectively. The high relief of the reservoir and the near-

86 JPT • AUGUST 2007

Fig. 7—Ternary diagram for Oso fluid and injection gas.

Longer equilibration times and high-precision measurements

were necessary to capture steep changes in fluid properties

Fig. 6—Oso fluid and injection-gas phase diagram. that occurred with small changes in pressure, temperature,

or composition. A swelling test was conducted to define the

critical nature of the fluid contributed to substantial fluid P/X phase-boundary and fluid-property changes resulting

gradients with depth. Early in the development planning, from gas injection. The measured-P/X diagram of Oso fluid

hydrocarbon-gas injection was identified as a necessary with injection gas in Fig. 6 shows that with small additions

production scheme for pressure maintenance and improved of injected gas, the in-situ fluid is in a critical region. Ternary

recovery through near-miscible processes. diagrams at several intermediate pressures (P1> P2> P3) con-

Several key fluid-characterization issues were investi- structed with measured swelling data and EOS calculations

gated for their effect on recovery factors as part of scoping, are shown in Fig. 7. These diagrams were used to evaluate

planning, and development studies. Fluid characteriztion various injection strategies.

addressed the following issues: The reservoir pressure at which gas injection begins, along

• Acquisition of representative samples at various depths with the injection and production rates, affect the thermody-

to quantify initial fluid gradients and for PVT studies. namic path taken by the reservoir fluid during depletion and,

• PVT measurements to capture near-critical behavior, hence, the resulting recovery mechanism. For example, if gas

evaluate gas-injection strategies, and design the surface- injection begins at the initial reservoir pressure of 6,300 psia

separator train. and production takes the path marked A–A′ in Fig. 6 and

• Fluid modeling to predict observed near-critical behavior the corresponding two-phase region marked P1 in Fig. 7, the

and property changes during gas injection. hydrocarbon fluid will remain a single-phase throughout the

• Development of thermodynamically consistent composi- injection process, leading to a first-contact miscible process.

tional-gradient models for use in reservoir studies. During this process, the fluid changes from a volatile oil to

Sampling. Sampling Oso reservoir fluid posed significant a gas condensate as it crosses the critical region in a single-

challenges because the fluid was near-critical. The near-criti- phase state. However, if the injection begins at a lower pres-

cal nature of the fluid required careful design and execution sure, P2, the fluid enters the two-phase region to the right

of sampling because small variations in the fluid pressure and of the critical point close to the cricondenbar, path B–B′ in

temperature can cause significant changes in fluid composi- Fig. 6 and the ternary diagram corresponding to P2 in Fig. 7.

tion, particularly near the saturation pressure. Representative As the fluid enters the two-phase region, a small amount of

fluid sampling required strict isolation of sampling intervals oil will drop out. As gas injection continues, this oil will re-

because the fluid properties varied over depth. During the sur- evaporate and will be recovered at the surface. Finally, if the

face-sampling operation, low drawdown, complete phase sep- gas injection begins at a lower pressure, P3 the fluid enters

aration in the surface equipment, and accurate measurement the two-phase region along path C–C′ in Fig. 6 to the left

of oil and gas rates were critical for obtaining representative of the critical point and the corresponding ternary diagram

GOR for laboratory recombination. Both bottomhole wireline- at P3 in Fig. 7. In this process, multicontact miscibility will

formation-tester- and surface-sampling methods were used to develop. As gas injection continues, the faster-moving gas

collect several reservoir-fluid samples from different depths. phase will be continually enriched by vaporizing intermedi-

PVT Data Requirement. Near-critical PVT measurements ate components (vaporizing-gas drive) until the gas phase

required expertise in measuring, analyzing, and interpret- becomes first-contact miscible with the oil. This analysis was

ing the data in addition to state-of-the-art PVT equipment. used to optimize the development plan.

JPT • AUGUST 2007 87

DISTINGUISHED AUTHOR SERIES

−9,000

Points are measured data

C7+ C1

True Vertical Depth, ft subsea Lines are predictions

−9,500

Oso Saturation Pressure and Reservoir Pressure With Depth

−9,000

True Vertical Depth, feet subsea

Points are data/

Lines are predictions

−9,500

−10,000 Saturation Reservoir

−10,000 Pressure Pressure

−10,500

−10,500 −11,000

−11,500

4,000 4,500 5,000 5,500 6,000 6,500 7,000

Pressure, psia

−11,000

−11,500

5 15 25 35 45 55 65 75

Composition, mol%

Fig. 8—Compositional-gradient and fluid-property variations as a function of depth—Oso.

Fluid Modeling. The near-critical nature of Oso fluids, equilibrium model in the EOS and the results are shown in

coupled with strong compositional gradients, demands Fig. 8. The predicted methane and C7+ compositional varia-

robust compositional fluid models (Høier and Whitson tions agreed well with the data. The inset in Fig. 8 shows

2001). An EOS fluid model was developed following similar that computed saturation-pressure variations with depth

steps outlined in the previous example. The C7+ fraction was agree with laboratory measurements. The PVT data and the

divided into an adequate number of volatile components to EOS model were used to provide guidelines for designing

capture the near-critical behavior. The EOS calculations were surface-separator trains. Because of the near-critical nature of

performed with energy minimization and robust solution the fluid, the number of separator stages and the stage-sepa-

techniques (Nagarajan et al. 1991). The EOS model also was rator pressures had to be optimized to maximize recovery of

required to capture observed compositional gradients, which surface liquids. A series of multistage-separator simulations

was accomplished by modifying the chemical-equilibrium were performed to evaluate sensitivity of the liquid yield to

equation to include the gravitational effect through a grav- the number of stages and stage pressures. Fig. 9 shows the

ity/chemical equilibrium model (Høier and Whitson 2001). sensitivity of liquid yield to the number of stages and the

The compositional gradients and the resulting fluid-prop- stage pressures. Two to four stages of separation are necessary

erty variations were predicted by use of the gravity/chemical to maximize recovery of surface liquids. However, increasing

300

Liquid Yield vs. Separator Pressure in a

275

3-Satge Separation

Three-Stage Separation

Process

Process

290

CGR, STB/MMscf

Yield (STB/MMSCF)

First Stage

250

CGR, STB/MMscf

285 Second Stage

Third Stage

Condensate

280

225

275

0 400 800 1200

1,200 1,600

1600

Separatore

Separator Pressure

Pressure, (psia)

psia

200

1 2 3 4 5 6

Number of Stages

Fig. 9—PVT-based separator design to maximize liquid yield—near-critical-fluid example.

88 JPT • AUGUST 2007

30 8

Points are measured data

100°F Lines are EOS predictions

Condensate Dropout, vol%

Water Content, mol% 6

20

200°F 4

10

2

350°F

0 0

0 2,000 4,000 6,000 8,000

Pressure, psia

Fig. 10—Water content and condensate-dropout characteristics of Arun gas.

the number of stages beyond four affected the yield nega- bottomhole (352°F), wellhead (200°F), and surface (100°F)

tively. In addition, Fig. 9 shows that if a three-stage-separator temperatures during reservoir depletion. Generally, the CWR

train is selected, the second- and third-stage pressures must is controlled by the condensate-dropout characteristics dur-

be selected precisely to maximize surface-liquid recovery. ing the early stages of depletion. But, as the reservoir pressure

declines below dewpoint pressure, the CWR falls more rap-

Gas Condensate—Arun Field. The Arun Field in Indonesia idly as a result of decreasing condensate volume (caused by

is a high-temperature lean-gas-condensate reservoir with liquid dropout in the reservoir) and increasing water volume

surface-liquid yields of approximately 50 to 55 STB/MMscf (caused by increased water vaporization). In Fig. 11 at 352°F,

(Pathak et al. 2004). The original reservoir pressure was the condensate volume is zero until the reservoir pressure

7,100 psig at 352°F. Initially, Arun gas contained significant drops below the dewpoint pressure, then it increases with

amounts of vaporized water (4 mol%) and CO2 (16 mol%). declining reservoir pressure, going through a maximum,

Accurate characterization of gas-condensate/water phase and finally decreasing as a result of revaporization at lower

behavior through an EOS was essential to predict water-pro- pressures. The water volume, however, increases slowly at

duction levels and corrosion potential. first and then rapidly as a result of an increased rate of water

PVT Data and Model. A PVT program was initiated to vaporization at lower pressures and subsequent condensa-

study gas/water and gas-condensate/water phase behavior tion in the wellbore. At 200°F (wellhead) in Fig. 11, the

as functions of pressure and temperature (Ng and Robinson condensate volume initially increases as a result of both the

1986; Ng et al. 1988). A specially designed visual PVT cell pressure and temperature drop in the wellbore. However,

was used to measure the amount of water vapor in the gas increased water vaporization during reservoir depletion

phase and the condensate/water volumetric behavior as and subsequent condensation at the wellhead cause a larger

a function of reservoir, wellbore, and surface conditions. increase in water volume resulting in a sharp drop in CWR.

The results showed that water content of the reservoir gas At 100°F (surface), the CWR behaves in a similar manner

increased four-fold from approximately 4 mol% at 7,100 psig as at the wellhead. However, the crossover of condensate

to approximately 16 mol% at 1,000 psig as shown in Fig. 10 and water volumes (CWR =1) occurs at the surface (pink

(Ng and Robinson 1986). This relation corresponds to water curve) much earlier (reservoir pressure of 4,000 psia) than

production increasing from 6.5 STB/MMscf at the initial res- at the wellhead, green curve (reservoir pressure 2,800 psia).

ervoir conditions to 75 STB/MMscf as the reservoir pressure The implication is that the potential for corrosion is high in

declined to 1,000 psig (Pathak et al. 2004). This information the surface equipment in the early stages of depletion. The

is critical for designing optimum water-handling facilities and corrosion potential may increase toward the wellhead and

for corrosion management. Fig. 10 also shows condensate downhole with reservoir pressure decline.

dropout at different reservoir, wellbore, and surface condi- In the Arun reservoir, water vaporization and three-phase

tions, indicating an initially increasing condensate dropout water/condensate/gas volumetric behavior were modeled

with declining pressure and temperature, peaking approxi- with a three-parameter Peng-Robinson EOS. Because a cubic

mately 2,500 psia, and dropping off at lower pressures as a equation does not model a polar compound such as water

result of condensate revaporization (Ng et al. 1988). accurately, the critical properties of water were modified on

Fig. 11 combines the volumetric behavior of condensate the basis of the coordination number to match laboratory

and water in terms of condensate/water ratio (CWR) at the data. Further, special binary-interaction parameters for water

JPT • AUGUST 2007 89

DISTINGUISHED AUTHOR SERIES

5.00

4.00

CWR, vol/vol 200°F (Wellhead)

3.00

352°F (Near Bottomhole)

2.00

100°F (Surface)

1.00

0.00

0 1,000 2,000 3,000 4,000 5,000 6,000 7,000

Reservoir Pressure, psia

Fig. 11—CWR of produced gas in the wellbore as reservoir pressure declines.

were used in the tuning process. The EOS-model matches are DFL = differential liberation

shown in Figs. 10 and 11 as solid lines. DST = drillstem test

EOS = equation of state

Conclusions GOR = gas/oil ratio

Fluid characterization strongly affects in-place-volume, HC = hydrocarbon

recovery-factor, injectivity/productivity, and well-deliverabil- OBM = oil-based mud

ity calculations. Accurate fluid characterization minimizes PVT = pressure/volume/temperature

technical uncertainties and, thus, provides a reliable repre- P/X = pressure/composition

sentation of the asset value. Four field examples containing QA = quality assurance

fluids from extraheavy oil to lean gas condensates undergo- QC = quality control

ing different production processes were presented to high- ST = separator test

light key steps in fluid sampling and characterization.

1. Fluid-sampling programs must be tailored to the fluid Nomenclature

type, reservoir-rock and -fluid conditions, and fluid distribu- Bo = oil formation volume factor

tion. Special tools and procedures with strict QC will ensure Bg = gas formation volume factor

obtaining high-quality representative samples. Bw = water formation volume factor

2. The fluid type and production processes dictate PVT- F(P) = function of pressure

data requirements, measurement methods, and data accu- F(T) = function of temperature

racy. Laboratory methods and procedures must be tailored to F(Rs) = function of solution gas/oil ratio

specific fluids with expert QA/QC. p = pressure

3. The C7+ components must be characterized accurately pb = bubblepoint pressure

for EOS-component selection. Rigorous modeling methods, pd = dewpoint pressure

such as energy minimization, and robust solution techniques Rs = solution GOR

are needed to model near-critical fluids and processes. T = temperature

4. Reliable compositional-gradient models are needed to Vl = volume of liquid

capture fluid-property variations in reservoirs with high Z = gas deviation factor

relief and/or near-critical fluids. μo = viscosity of oil

μw = viscosity of water

Acknowledgments ro = density of oil

We gratefully acknowledge the support and encouragement rw = density of water

of ExxonMobil Upstream Research Company, ExxonMobil

Production Company, ExxonMobil Oil Indonesia, Mobil References

Producing Nigeria, and ExxonMobil de Venezuela. Bishop, D.L., Williams, M.E., Gardner, S.E., Smith, D.P., and

Cochrane, T.D. 2004. Vertical Conformance in a Mature Carbonate

Acronyms CO2 Flood: Salt Creek Field Unit, Texas. Paper SPE 88720-

CCE = constant-composition expansion MS presented at the SPE Abu Dhabi International Petroleum

CGR = condensate/gas ratio Exhibition and Conference, Abu Dhabi, UAE, 10–13 October.

CVD = constant-volume depletion DOI: 10.2118/88720-MS.

CWR = condensate/water ratio

90 JPT • AUGUST 2007

Cengiz, S., Robertson, C., Kalpacki, B., and Gupta, D. 2004. A Study

of Heavy Oil Solution Gas Drive for Hamaca Field: Depletion

Studies and Interpretations. Paper SPE 86967-MS presented at the

SPE International Thermal Operations and Heavy Oil Symposium

and Western Regional Meeting, Bakersfield, California, 16–18

March. DOI: 10.2118/86967-MS.

El-Mandouh, M.S., Bette, S., Heinemann, R.F., Ogiamien, E.B.,

and Bhatia, S.K. 1993. Full-Field Compositional Simulation of

Reservoirs of Complex Phase Behavior. Paper SPE 25249-MS pre-

sented at the 12th SPE Symposium on Reservoir Simulation, New

Orleans, 28 February–3 March. DOI: 10.2118/25249-MS.

Høier, L., and Whitson, C.H. 2001. Compositional Grading—

Theory and Practice. SPEREE 4(6): 525. SPE 74714-PA. DOI:

10.2118/74714-PA.

Honarpour, M.M., Nagarajan, N.R., and Sampath, K. 2006. Rock/

Fluid Characterization and Their Integration–Implication on

Reservoir Management. JPT 58(9): 120. SPE 103358-MS. DOI:

10.2118/103358-MS

Nagarajan, N.R., Cullick, A.S. and Griewank, A. 1991. New

Strategy for Phase Equilibrium and Critical Point Calculations by

Thermodynamic Energy Analysis; Part I. Stability Analysis and

Flash; Part II. Critical Point Calculations. Fluid Phase Equilibria

62(3): 211.

Ng, H.-J., and Robinson, D.B. 1986. The Influence of Water and

Carbon Dioxide on the Phase Behavior and Properties of a

Condensate Fluid. Paper SPE 15401 presented at the SPE Annual

Technical Conference and Exhibition, New Orleans, 5–8 October.

DOI: 10.2118/15401-MS.

Ng, H.-J., Robinson, D.B., Nagarajan, N.R., Rastogi, S.C., and

Hasan, N. 1988. Phase Behavior of Retrograde Gas Condensate-

Water System Under High Pressure and Temperature Conditions.

Paper presented at the Indonesian Petroleum Congress, Jakarta.

Pathak, P., Fidra, Y., Kahar, Z., Agnew, M., and Hidayat, D. 2004. The

Arun Gas Field in Indonesia: Resource Management of a Mature

Field. Paper SPE 87042-MS presented at the SPE Asia Pacific

Conference on Integrated Modelling for Asset Management,

Kuala Lumpur, 29–30 March. DOI: 10.2118/87042-MS.

Reddie, D.R. and Robertson, C.R. 2004. Innovative Reservoir Fluid

Sampling Systems. Paper SPE 86951-MS presented at the SPE

International Thermal Operations and Heavy Oil Symposium and

Western Regional Meeting, Bakersfield, California, 16–18, March.

DOI: 10.2118/86951-MS.

Romero, D.J., Fernandez, B., and Rojas, G. 2001. Thermodynamic

Characterization of a PVT of Foamy Oil. Paper SPE 69724-MS

presented at the SPE International Thermal Operations and

Heavy Oil Symposium, Parlamar, Margarita Island, Venezuela,

12–14 March. DOI: 10.2118/69724-MS.

Stalkup Jr., F.I. 1984. Miscible Displacement. Henry Doherty

Monograph Series. SPE of AIME: Richardson, Texas. 8.

Whitson, C.H. 1983. Characterizing Hydrocarbon Plus Fractions.

SPEJ 23(4): 683. DOI: 10.2118/12233-PA

Whitson, C.H. and Brule, M. 2000. Phase Behavior: Monograph

Series. SPE: Richardson, Texas. 20.

Witt, C.J. and Crombie, A. 1999. A Comparison of Wireline and

Drillstem Test Fluid Samples From a Deep Water Gas-Condensate

Exploration Well. Paper SPE 56714-MS presented at the SPE

Annual Technical Conference and Exhibition, Houston, 3–6

October. DOI: 10.2118/56714-MS. JPT

JPT • AUGUST 2007 91

Вам также может понравиться

- Dynamic Description Technology of Fractured Vuggy Carbonate Gas ReservoirsОт EverandDynamic Description Technology of Fractured Vuggy Carbonate Gas ReservoirsОценок пока нет

- Low Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsОт EverandLow Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsОценок пока нет

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsОт EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsОценок пока нет

- SPE-28589 Merril and Hartman A Comparison of Equation of State Tuning MethodsДокумент16 страницSPE-28589 Merril and Hartman A Comparison of Equation of State Tuning MethodsSolenti D'nouОценок пока нет

- Quantifying Uncertainty in Subsurface SystemsОт EverandQuantifying Uncertainty in Subsurface SystemsCéline ScheidtОценок пока нет

- PETSOC 09-07-18.PDF Gas Condensate Reservoir PerformanceДокумент7 страницPETSOC 09-07-18.PDF Gas Condensate Reservoir Performanceswaala4real0% (1)

- Co2 Brine PVTДокумент13 страницCo2 Brine PVTsolimase1351Оценок пока нет

- Deepwater Sedimentary Systems: Science, Discovery, and ApplicationsОт EverandDeepwater Sedimentary Systems: Science, Discovery, and ApplicationsJon R. RotzienОценок пока нет

- Reservoir Stimulation Application 1694755812Документ205 страницReservoir Stimulation Application 1694755812Ezra WangkeОценок пока нет

- 5 34-10-17 PVT Analysis of Bottom Hole SampleДокумент21 страница5 34-10-17 PVT Analysis of Bottom Hole SampleswpuxiaofanОценок пока нет

- SC RE Chap4 - Phase BehaviourДокумент68 страницSC RE Chap4 - Phase BehaviourweldsvОценок пока нет

- Relative Permeability Up-Scaling Examples Using Eclipse SoftwareДокумент7 страницRelative Permeability Up-Scaling Examples Using Eclipse SoftwarecarlosОценок пока нет

- SPE30714 Fevang WhitsonДокумент16 страницSPE30714 Fevang WhitsonMohamed El KikiОценок пока нет

- SPE-160127-MS Kuparuk River Unit Field - The First 30 YearsДокумент13 страницSPE-160127-MS Kuparuk River Unit Field - The First 30 YearsGilbert OmittaОценок пока нет

- Paper Heavy Oil SamplingДокумент6 страницPaper Heavy Oil SamplingLatorreMОценок пока нет

- Reservoir Engineering For Geologist A. OverviewДокумент4 страницыReservoir Engineering For Geologist A. OverviewRalmerAlanaPutraОценок пока нет

- Review of Gas Injection Projects in CaliforniaДокумент12 страницReview of Gas Injection Projects in CaliforniaVoodoo ChildОценок пока нет

- Curtis H. WhitsonДокумент18 страницCurtis H. WhitsonglsancorОценок пока нет

- Reservoir Simulation ReportДокумент38 страницReservoir Simulation ReportValar MorghulisОценок пока нет

- PVT ModellingДокумент6 страницPVT ModellingFan JackОценок пока нет

- Reservoir ModelДокумент16 страницReservoir ModelÖmer Faruk ÇalıovaОценок пока нет

- Thermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsОт EverandThermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsОценок пока нет

- EXP FluidAnalysis A4Документ8 страницEXP FluidAnalysis A4welltest2012Оценок пока нет

- Empirical Correlations To Predict Gas - CondensateДокумент9 страницEmpirical Correlations To Predict Gas - CondensateAysel NaibovaОценок пока нет

- Assisted History Matching for Unconventional ReservoirsОт EverandAssisted History Matching for Unconventional ReservoirsОценок пока нет

- Effects of Reservoir Heterogeneity in Laminated ReservoirsДокумент3 страницыEffects of Reservoir Heterogeneity in Laminated ReservoirsErik Andres Garcia VillarroelОценок пока нет

- CO2 Content in Brine Under Pressure 084Документ11 страницCO2 Content in Brine Under Pressure 084Mari ParguilОценок пока нет

- Thesis DidanaliДокумент36 страницThesis DidanaliHemenMoОценок пока нет

- C o U R S e N o - PENG 331 Reservoir EngineeringДокумент3 страницыC o U R S e N o - PENG 331 Reservoir Engineeringtassili17Оценок пока нет

- XTraining WTI HalfDay ZK PDFДокумент63 страницыXTraining WTI HalfDay ZK PDFFernando OlaveoОценок пока нет

- 0 Welcome Intro''Документ9 страниц0 Welcome Intro''Lija BinuОценок пока нет

- Reservoir Fluid Sampling (Lulav Saeed)Документ15 страницReservoir Fluid Sampling (Lulav Saeed)Lulav BarwaryОценок пока нет

- Artificial Lift: Making Your Electrical Submersible Pumps Talk To YouДокумент19 страницArtificial Lift: Making Your Electrical Submersible Pumps Talk To Youamramazon88Оценок пока нет

- Pore-Throat Sizes in Sand StonesДокумент12 страницPore-Throat Sizes in Sand StonesSouvik DeОценок пока нет

- Oil Fingerprinting For Production Allocation PDFДокумент4 страницыOil Fingerprinting For Production Allocation PDFrahulscribd007Оценок пока нет

- Method Predicts Well Bore ScaleДокумент8 страницMethod Predicts Well Bore ScaleAnonymous JJ29r2oCОценок пока нет

- Development of A Correlation For The Estimation of Condensate To Gas Ratio and Other Key Gas Properties From Density Molecular WeightДокумент18 страницDevelopment of A Correlation For The Estimation of Condensate To Gas Ratio and Other Key Gas Properties From Density Molecular WeightDorothyNRОценок пока нет

- Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityДокумент2 страницыMaintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityEggi Septi YuliantoОценок пока нет

- Reservoir Simulation: Lecture 1: IntroductionДокумент19 страницReservoir Simulation: Lecture 1: IntroductionOmer IkhlasОценок пока нет

- Staged Design of An EOR Pilot PDFДокумент8 страницStaged Design of An EOR Pilot PDFelfatihОценок пока нет

- Flow Units From Conventional To Tight Gas To Shale Gas To Tight Oil To Shale Oil ReservoirsДокумент31 страницаFlow Units From Conventional To Tight Gas To Shale Gas To Tight Oil To Shale Oil ReservoirsKyle PongОценок пока нет

- Microbial Enhancement of Oil Recovery - Recent AdvancesОт EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesОценок пока нет

- DR Bennion-Relative PermeabilityДокумент37 страницDR Bennion-Relative PermeabilityaliОценок пока нет

- Oilfield Review 2Документ17 страницOilfield Review 2Luis Alberto Colan GarciaОценок пока нет

- Chapter 4 EOS FДокумент32 страницыChapter 4 EOS FjeffierОценок пока нет

- Reservoir Performance and PredictionДокумент33 страницыReservoir Performance and PredictionBishal SarkarОценок пока нет

- 59 34-10-16 Special Core Analysis Study Vol1Документ110 страниц59 34-10-16 Special Core Analysis Study Vol1Anonymous cjIvFJHОценок пока нет

- Low Salinity Thesis 2014 Behruz Shaker ShiranДокумент134 страницыLow Salinity Thesis 2014 Behruz Shaker ShiranPondok Huda100% (1)

- Reservoir Analysis PlanДокумент9 страницReservoir Analysis PlanmayankОценок пока нет

- Type II RegressionДокумент8 страницType II RegressionjpmarocoОценок пока нет

- 3025 GeoSoftware PowerLog Well Log Analysis BrochureДокумент4 страницы3025 GeoSoftware PowerLog Well Log Analysis Brochure2032086Оценок пока нет

- Reservoir Fluid Properties RequiredДокумент25 страницReservoir Fluid Properties Requiredninoska217608Оценок пока нет

- Alternative Shaly Sands Water Saturation Equations ComparisonДокумент32 страницыAlternative Shaly Sands Water Saturation Equations ComparisonKartiko WibowoОценок пока нет

- Practical Petroleum Geochemistry for Exploration and ProductionОт EverandPractical Petroleum Geochemistry for Exploration and ProductionОценок пока нет

- Oil CorrelationsДокумент20 страницOil CorrelationsGaby GalletaОценок пока нет

- A Petrophysical Evaluation of Capillary Pressure For A Naturally Fractured Tight Gas Sandstone Reservoir A Case StudyДокумент150 страницA Petrophysical Evaluation of Capillary Pressure For A Naturally Fractured Tight Gas Sandstone Reservoir A Case StudyBeatriz Velásquez LeónОценок пока нет

- DHC 11 12 2021Документ1 страницаDHC 11 12 2021JesseОценок пока нет

- Lab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $Документ1 страницаLab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $JesseОценок пока нет

- Section 3.a Civil (3) FOR BUILDING WORKДокумент3 страницыSection 3.a Civil (3) FOR BUILDING WORKJesseОценок пока нет

- DHC 09 04 2022.Документ1 страницаDHC 09 04 2022.JesseОценок пока нет

- Alto SaxophoneДокумент9 страницAlto SaxophoneJesse100% (2)

- Iso 17025 - Corrective Action Request Form (Completed)Документ1 страницаIso 17025 - Corrective Action Request Form (Completed)JesseОценок пока нет

- Iso 17025 - Corrective Action Request Form (Completed)Документ1 страницаIso 17025 - Corrective Action Request Form (Completed)Jesse100% (1)

- PVTsimHelp 20Документ197 страницPVTsimHelp 20JesseОценок пока нет

- SPS - Technical Spec.Документ2 страницыSPS - Technical Spec.JesseОценок пока нет

- Hydrates: by Sherry Oyagha 28 August, 2020Документ45 страницHydrates: by Sherry Oyagha 28 August, 2020JesseОценок пока нет

- WeatherfordLabs Reservoir Fluid AnalysisДокумент7 страницWeatherfordLabs Reservoir Fluid AnalysisJesseОценок пока нет

- Heptanes PlusДокумент15 страницHeptanes PlusJesseОценок пока нет

- General Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesДокумент28 страницGeneral Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesJesseОценок пока нет

- Construction Quality Control Plan Draft - Rev0 - 27feb09Документ24 страницыConstruction Quality Control Plan Draft - Rev0 - 27feb09JesseОценок пока нет

- KDC HSE-IIPPManual v.2015Документ156 страницKDC HSE-IIPPManual v.2015JesseОценок пока нет

- Challenges During Operation and Shutdown of Waxy Crude PipelinesДокумент13 страницChallenges During Operation and Shutdown of Waxy Crude PipelinesJesseОценок пока нет

- Assignment On Industrial Relation of BDДокумент12 страницAssignment On Industrial Relation of BDKh Fahad Koushik50% (6)

- Brochure PVM enДокумент36 страницBrochure PVM enBenny Kurniawan LimОценок пока нет

- Aerated Static Pile Composting (ASP) VS Aerated (Turned) Windrow CompostingДокумент2 страницыAerated Static Pile Composting (ASP) VS Aerated (Turned) Windrow CompostingRowel GanzonОценок пока нет

- TUF-2000M User Manual PDFДокумент56 страницTUF-2000M User Manual PDFreinaldoОценок пока нет

- A Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional CoresДокумент13 страницA Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional Coresmsmsoft90Оценок пока нет

- Ge Washing Machine ManualДокумент52 страницыGe Washing Machine Manuallillith1723Оценок пока нет

- Management Thoughts Pramod Batra PDFДокумент5 страницManagement Thoughts Pramod Batra PDFRam33% (3)

- The Price of Peace by A. LAWRENCE LOWELДокумент4 страницыThe Price of Peace by A. LAWRENCE LOWELeden galasОценок пока нет

- IEC947-5-1 Contactor Relay Utilization CategoryДокумент1 страницаIEC947-5-1 Contactor Relay Utilization CategoryipitwowoОценок пока нет

- Pas 38 Pas 41 Pas 40Документ12 страницPas 38 Pas 41 Pas 40Leddie Bergs Villanueva VelascoОценок пока нет

- Business and Finance TerminologyДокумент15 страницBusiness and Finance TerminologyKat KatОценок пока нет

- Metric MIL-STD-1504C (USAF) 01 March 2007 Supersedes MIL-STD-1504B 8 June 1989Документ11 страницMetric MIL-STD-1504C (USAF) 01 March 2007 Supersedes MIL-STD-1504B 8 June 1989HenryОценок пока нет

- 150 67-Eg1Документ104 страницы150 67-Eg1rikoОценок пока нет

- User's Guide: Smartpack2 Master ControllerДокумент32 страницыUser's Guide: Smartpack2 Master Controllermelouahhh100% (1)

- Bonus 6 - Mastering ASP - NET Core SecurityДокумент147 страницBonus 6 - Mastering ASP - NET Core SecurityDark Shadow100% (1)

- 2 Days Meat Processing Training Program (Kalayaan Laguna)Документ2 страницы2 Days Meat Processing Training Program (Kalayaan Laguna)Jals SaripadaОценок пока нет

- 1-Page TimeBoxing Planner v2.0Документ2 страницы1-Page TimeBoxing Planner v2.0ash.webstarОценок пока нет

- Read Me - CADWorx Plant 2019 SP2 HF1Документ4 страницыRead Me - CADWorx Plant 2019 SP2 HF1Himanshu Patel (Himan)Оценок пока нет

- Single Line DiagramДокумент1 страницаSingle Line DiagramGhanshyam Singh100% (2)

- Business PlanДокумент11 страницBusiness PlanIsaac ManarinОценок пока нет

- RODEL LUZ y ONG, Petitioner, People of The Philippines, Respondent. FactsДокумент1 страницаRODEL LUZ y ONG, Petitioner, People of The Philippines, Respondent. FactsBee Raagas100% (1)

- Woman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekДокумент11 страницWoman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekManish RanaОценок пока нет

- Land Surveying Chapter 2 Leveling p1Документ66 страницLand Surveying Chapter 2 Leveling p1Azrul ZulwaliОценок пока нет

- Harrod-Domar ModelДокумент13 страницHarrod-Domar ModelsupriyatnoyudiОценок пока нет

- Editing Packs I Maybe Will NeedДокумент3 страницыEditing Packs I Maybe Will NeedMijo SusićОценок пока нет

- 24th SFCON Parallel Sessions Schedule (For Souvenir Program)Документ1 страница24th SFCON Parallel Sessions Schedule (For Souvenir Program)genesistorres286Оценок пока нет

- Honeywell Aquatrol 2000 PDFДокумент60 страницHoneywell Aquatrol 2000 PDFvsilickasОценок пока нет

- Vishnu Institute of Technology: V2V CommunicationsДокумент22 страницыVishnu Institute of Technology: V2V CommunicationsBhanu PrakashОценок пока нет

- PDF of Proposed Museum ProjectДокумент145 страницPDF of Proposed Museum ProjectHarshita ParnamiОценок пока нет

- 2.how To Boost Your Coating SalesДокумент23 страницы2.how To Boost Your Coating SalesAjaz Noor KhattakОценок пока нет