Академический Документы

Профессиональный Документы

Культура Документы

Common Metallurgical Defects in Ductile Cast Iron PDF

Загружено:

sskiitbОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Common Metallurgical Defects in Ductile Cast Iron PDF

Загружено:

sskiitbАвторское право:

Доступные форматы

Common Metallurgical

Defects in Ductile Iron

Compacted Graphite Exploded Graphite Chunky Graphite Spiky Graphite

Potential Causes: Potential Causes: Potential Causes: Potential Causes:

– Low residual magnesium and/or rare earth from – Excess rare earth additions, particularly when high – Excess rare earth additions, particularly when high – Very small amounts of lead which have not been

poor nodularisation practice, high temperatures purity charges are used. Normally found in thick purity charges are used. Normally found in thick neutralised by rare earths result in spiky graphite.

or long holding time. section castings or at higher carbon equivalents. section castings or at higher carbon equivalents. This has a catastrophic effect on mechanical

– Excess sulphur in the base iron not balanced properties.

by sufficient magnesium. Note that once the rare earth addition is reduced, it may Note that once the rare earth addition is reduced, it may Bismuth, titanium and antimony can give similar

take time to dilute the residual rare earth in return metal, take time to dilute the residual rare earth in return metal, structures but can also be neutralised with rare

particularly in induction melted iron. particularly in induction melted iron. earths.

Flake Graphite

Graphite Flotation Surface Structure Nodule Alignment Carbides

Potential causes: Potential causes: Potential causes: Potential causes:

– High carbon equivalent. – Excess sulphur build-up in moulding sand. – Low carbon equivalent· – Low carbon equivalent.

– Excess pouring temperature. This causes reversion to flake as the magnesium – Under inoculation causing growth of large – Excess magnesium and/or rare earth.

– Slow cooling rate in thicker sections. in the iron reacts with the sulphur. The use of dendrites with nodules aligned between – Carbide promoting elements such as Mn, Cr, V, Mo.

– Insufficient inoculation. higher magnesium / rare earth in the nodulariser or arms of the dendrite. – Insufficient inoculation.

a cerium containing inoculant can overcome this. – High pouring temperature. – Rapid cooling rate.

Irregular Graphite Slag Inclusions Shrinkage Gas

Potential causes: Potential causes: Potential causes: Gas holes are a totally separate subject and can be

– High holding temperature. – Inadequate slag control from pouring system. – Insufficient mould strength causing dilation. influenced by melting procedures, metal handling,

– Long holding time which can result in "dead" irons. – Lack of slag traps or filter. – Inadequate feed metal available. refractory conditions, mould moisture, sand permeability,

– Poor inoculation or excessive fading of inoculation. – Low pouring temperature. – Poor gating design. core resins, hot spots near cores, slag handling, metal

– Graphite shape may be improved by a late addition – Excess additions of slag forming materials. – Excess magnesium. temperature, base metal composition, mould venting,

of a powerful speciality inoculant. – Turbulent mould filling. – Low carbon equivalent. Ti and Al contents amongst other sources.

– Under inoculation or over inoculation. Specialist advice should be sought in cases of gas once

the above have been investigated.

The photomicrograph given here shows dendrite arms

growing inside a hydrogen pinhole.

Elkem produces a complete range of nodularisers and inoculants for the treatment Preseed™ is a powerful preconditioning agent for all cast irons to improve consistency in

of ductile iron. MgFeSi alloys are available for applications such as sandwich treatments, melting and increase mechanical properties

tundish cover ladles and flow through systems. They are graded so as to be suited

for different ladle sizes. Products for in-the-mould processes are also available. Please refer to your local Elkem representative for further information on the range

of Elkem products for grey, compacted and ductile cast irons.

Ultraseed® inoculant is designed for pure Mg produced ductile iron, irons of low oxygen

and sulphur levels and dead iron which has been held for extended periods of time. Ultraseed® is a Registered Trademark of Elkem AS. Preseed™ is a trademark of Elkem AS.

This inoculant will give high nodule counts in ductile iron which is normally difficult to

inoculate and will help to prevent micro-shrinkage.

Elkem AS, Foundry Products Division, Hoffsveien 65 b, P.O. Box 5211 Majorstua, N-0303 Oslo, Norway, www.foundry.elkem.com

Вам также может понравиться

- Chunky GraphiteДокумент16 страницChunky GraphitesachinguptachdОценок пока нет

- Common Metallurgical Defects in Grey Cast Irons 2Документ1 страницаCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiОценок пока нет

- Common Metallurgical Defects in Ductile Iron EnglishДокумент1 страницаCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessОценок пока нет

- SG Iron CompositionДокумент5 страницSG Iron CompositionamirgukharОценок пока нет

- Common Metallurgical Defects in Grey Iron English (1Документ1 страницаCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- Seminar S.G IronДокумент32 страницыSeminar S.G Ironravikataria02Оценок пока нет

- 50 Casting DefectsДокумент49 страниц50 Casting DefectsmohammadОценок пока нет

- Common Metallurgical Defects in Ductile Iron English (1Документ1 страницаCommon Metallurgical Defects in Ductile Iron English (1sateeshkori100% (2)

- Surface Graphite Degeneration in Ductile Iron CastДокумент8 страницSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarОценок пока нет

- Common Metallurgical Defects in Ductile IronДокумент1 страницаCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- Poor Nodularity in Ductile IronДокумент2 страницыPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- SG Iron ProductionДокумент20 страницSG Iron ProductionShreyashri Nayak100% (1)

- GraphiteStructuresInCI PDFДокумент1 страницаGraphiteStructuresInCI PDFAnonymous B3I6zYNhqdОценок пока нет

- Mapa MetalograficoДокумент1 страницаMapa MetalograficoBreno DellaОценок пока нет

- Shrinkage in Ductile IronДокумент5 страницShrinkage in Ductile Ironkarthikkanda100% (1)

- Recovery of Magnesium in A Ductile Iron Process.: AbstractДокумент8 страницRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazОценок пока нет

- ELMAGДокумент2 страницыELMAGthomazfabricioОценок пока нет

- Selection of Inoculants For Grey Cast IronДокумент2 страницыSelection of Inoculants For Grey Cast Ironarnaldorcr8646Оценок пока нет

- Sampling of Liquid Cast IronДокумент2 страницыSampling of Liquid Cast Ironarnaldorcr8646Оценок пока нет

- Carbide Dissolution in Thin Wall Ductile Iron PDFДокумент8 страницCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdОценок пока нет

- Late Metal Stream InoculationДокумент2 страницыLate Metal Stream Inoculationarnaldorcr8646Оценок пока нет

- Elkem 13 Compacted Graphite IronДокумент2 страницыElkem 13 Compacted Graphite Ironmarcotulio123Оценок пока нет

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- Casting Defect - Fissure DefectsДокумент3 страницыCasting Defect - Fissure Defectsvivek1312Оценок пока нет

- Technical InformationДокумент78 страницTechnical InformationCarlos Barrachina Martínez100% (2)

- 26-ELKEM Poster-Graphite Structures in Cast IronsДокумент1 страница26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENОценок пока нет

- Effect of Bismuth in Ductile IronДокумент4 страницыEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- S.G.Iron GuidelinesДокумент28 страницS.G.Iron GuidelinesTarun Chakraborty100% (3)

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- Elkem 04 Inoculation PracticesДокумент2 страницыElkem 04 Inoculation Practicesmarcotulio123Оценок пока нет

- Common Metallurgical Defects in Grey Cast IronДокумент9 страницCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Elkem 07 Magnesiun Contents in Ductile IronДокумент2 страницыElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Оценок пока нет

- Factors Influencing The Recovery and Addition of MagnesiumДокумент4 страницыFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Оценок пока нет

- Ductile Dross Formation MonitoringДокумент27 страницDuctile Dross Formation MonitoringsachinguptachdОценок пока нет

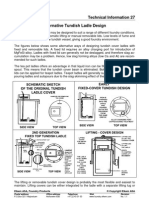

- Alternative Tundish Ladle DesignДокумент2 страницыAlternative Tundish Ladle Designarnaldorcr8646Оценок пока нет

- Cerium in Ductile IronДокумент2 страницыCerium in Ductile Ironvivek1312100% (2)

- Elkem 10 Tundish Cover Ladle NodularizationДокумент2 страницыElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Оценок пока нет

- Magnesium Contents in Ductile IronДокумент2 страницыMagnesium Contents in Ductile Ironarnaldorcr8646Оценок пока нет

- 26-ELKEM - Poster-Graphite Structures in Cast IronsДокумент1 страница26-ELKEM - Poster-Graphite Structures in Cast IronsSalvador Rocha100% (2)

- Shrinkage in Iron CastingsДокумент10 страницShrinkage in Iron CastingskarthikkandaОценок пока нет

- Defects in Ductile IronДокумент12 страницDefects in Ductile IronSerdar çevikОценок пока нет

- BCIRA Broadsheet 41Документ4 страницыBCIRA Broadsheet 41Justin Dixon100% (1)

- Manganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronДокумент30 страницManganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronNetoОценок пока нет

- A367-11 Standard Test Methods of Chill Testing of Cast Iron PDFДокумент4 страницыA367-11 Standard Test Methods of Chill Testing of Cast Iron PDFCarlos Guillermo Somoza Alvarenga100% (1)

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFДокумент23 страницы1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Fading of InoculationДокумент2 страницыFading of Inoculationarnaldorcr8646Оценок пока нет

- Feeding Steel and Ductile Iron CastingДокумент22 страницыFeeding Steel and Ductile Iron Castingjosemiguelzu100% (1)

- Cast IronДокумент15 страницCast IronJohnОценок пока нет

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronДокумент2 страницыPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Оценок пока нет

- S.G IronДокумент6 страницS.G IronQasim BarkatОценок пока нет

- Recommended Target Analysis For Ductile IronДокумент2 страницыRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- Composition of Grey Cast IronДокумент2 страницыComposition of Grey Cast IronPranil GhatageОценок пока нет

- Ferroalloy Storage Bin DesignДокумент2 страницыFerroalloy Storage Bin Designarnaldorcr8646Оценок пока нет

- Home About Us Products Quality Control Representation Useful Links Contact UsДокумент5 страницHome About Us Products Quality Control Representation Useful Links Contact Ustushak mОценок пока нет

- 5 Mechanisms Graphite Nucleation Cast IronДокумент2 страницы5 Mechanisms Graphite Nucleation Cast Ironmarcotulio123Оценок пока нет

- Dokumen - Tips - 28 Elkemposter Common Metallurgical Defects in Ductile Irons PDFДокумент2 страницыDokumen - Tips - 28 Elkemposter Common Metallurgical Defects in Ductile Irons PDFMD ISMAILОценок пока нет

- Common Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageДокумент1 страницаCommon Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageJoao LuisОценок пока нет

- 2014 - 11 - Chemical Composition of Ductile Iron PDFДокумент24 страницы2014 - 11 - Chemical Composition of Ductile Iron PDFfelipeОценок пока нет

- Chunky GraphiteДокумент16 страницChunky GraphitesachinguptachdОценок пока нет

- III Product & Process DesignДокумент134 страницыIII Product & Process DesignsskiitbОценок пока нет

- Assessing and Diagnosing Shoulder Injuries in Pediatric and Adolescent PatientsДокумент6 страницAssessing and Diagnosing Shoulder Injuries in Pediatric and Adolescent PatientsOmar LaikОценок пока нет

- Section 1 Management and Leadership PDFДокумент149 страницSection 1 Management and Leadership PDFmhmshabanОценок пока нет

- Chapter 5. System Reliability and Reliability Prediction.: Problems & SolutionsДокумент29 страницChapter 5. System Reliability and Reliability Prediction.: Problems & Solutionsdialauchenna100% (1)

- II Quality SystemsДокумент113 страницII Quality SystemssskiitbОценок пока нет

- ACFrOgBPJ3YJ2anJ YD5fyOWBfC6vNfTS9fZLT TIVe8o3FnF79uq4YyHPxuZSK1zr4drwUqG2iL6g1lGvhdMtPJw0dyAvjtp4gNIR8HbRsxOndz Yc0QHuZLgcFGNzr7 EsXQgIXFrmaB3qE7ajДокумент1 страницаACFrOgBPJ3YJ2anJ YD5fyOWBfC6vNfTS9fZLT TIVe8o3FnF79uq4YyHPxuZSK1zr4drwUqG2iL6g1lGvhdMtPJw0dyAvjtp4gNIR8HbRsxOndz Yc0QHuZLgcFGNzr7 EsXQgIXFrmaB3qE7ajsskiitbОценок пока нет

- ACFrOgBPJ3YJ2anJ YD5fyOWBfC6vNfTS9fZLT TIVe8o3FnF79uq4YyHPxuZSK1zr4drwUqG2iL6g1lGvhdMtPJw0dyAvjtp4gNIR8HbRsxOndz Yc0QHuZLgcFGNzr7 EsXQgIXFrmaB3qE7ajДокумент1 страницаACFrOgBPJ3YJ2anJ YD5fyOWBfC6vNfTS9fZLT TIVe8o3FnF79uq4YyHPxuZSK1zr4drwUqG2iL6g1lGvhdMtPJw0dyAvjtp4gNIR8HbRsxOndz Yc0QHuZLgcFGNzr7 EsXQgIXFrmaB3qE7ajsskiitbОценок пока нет

- Risk: Definition: Effect of Uncertainties On Objectives (ISO 31000:2018)Документ40 страницRisk: Definition: Effect of Uncertainties On Objectives (ISO 31000:2018)sskiitbОценок пока нет

- Lec24 PDFДокумент69 страницLec24 PDFsskiitbОценок пока нет

- CRE: ASQ Certified Reliability Engineer - Full: Question ResultsДокумент60 страницCRE: ASQ Certified Reliability Engineer - Full: Question ResultssskiitbОценок пока нет

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Документ4 страницыForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Maryam ZahraОценок пока нет

- Design Construction Rev 4M June 14 Module 12Документ74 страницыDesign Construction Rev 4M June 14 Module 12sskiitbОценок пока нет

- Cretest 1Документ34 страницыCretest 1ajith_cvaОценок пока нет

- V Conti ImprovementДокумент118 страницV Conti ImprovementsskiitbОценок пока нет

- Process - 14 Arc Welding - MODULE 14Документ52 страницыProcess - 14 Arc Welding - MODULE 14sskiitbОценок пока нет

- Module 12 - Design & Construction - Rev 5 - May 15Документ107 страницModule 12 - Design & Construction - Rev 5 - May 15sskiitb100% (1)

- Animal RiddleДокумент1 страницаAnimal RiddlesskiitbОценок пока нет

- Final - Advertisement (0192015) PDFДокумент9 страницFinal - Advertisement (0192015) PDFsskiitbОценок пока нет

- Casting ProcessesДокумент20 страницCasting ProcessesMartin KagoОценок пока нет

- Met 03R Steel Making Alloy Steels - Rev 2 Module 3Документ50 страницMet 03R Steel Making Alloy Steels - Rev 2 Module 3sskiitbОценок пока нет

- Gas Cutting WLDNG Process - 06 - Module 6Документ100 страницGas Cutting WLDNG Process - 06 - Module 6sskiitb100% (1)

- SNT TC 1A Vs CP 189Документ1 страницаSNT TC 1A Vs CP 189sskiitbОценок пока нет

- Failure Analysis Fundamental CausesДокумент12 страницFailure Analysis Fundamental Causesoquintero99Оценок пока нет

- Metal Joining - 02 - Heat Flow in WeldingДокумент31 страницаMetal Joining - 02 - Heat Flow in Weldingdjsun_Оценок пока нет

- Module 12 - Design & Construction - Rev 5 - May 15Документ107 страницModule 12 - Design & Construction - Rev 5 - May 15sskiitb100% (1)

- Electron Beam Welding Process App PDFДокумент6 страницElectron Beam Welding Process App PDFsskiitbОценок пока нет

- Welding QAДокумент40 страницWelding QAsskiitbОценок пока нет

- Zinc-Nickel Alloy Plating Has Hit The U.S. Scene. Who Is Doing It, and Why? - .Документ6 страницZinc-Nickel Alloy Plating Has Hit The U.S. Scene. Who Is Doing It, and Why? - .sskiitbОценок пока нет

- metals ملاحظاتДокумент10 страницmetals ملاحظاتAbeer AlaaliОценок пока нет

- Igcse structure question cement reactionДокумент2 страницыIgcse structure question cement reactiondanielphilip68Оценок пока нет

- Niton XL3 T LibraryДокумент3 страницыNiton XL3 T LibraryB_Vieira100% (1)

- Instant Download Biochemistry 1st Edition Miesfeld Test Bank PDF Full ChapterДокумент32 страницыInstant Download Biochemistry 1st Edition Miesfeld Test Bank PDF Full Chaptertectlyunchurchij8f100% (5)

- Student Guide Path To Periodic Table PDFДокумент2 страницыStudent Guide Path To Periodic Table PDFAlmiah AlfaroukОценок пока нет

- Case Studies: 2.6.1 Lithium Carbonate (Li CO) TabletsДокумент3 страницыCase Studies: 2.6.1 Lithium Carbonate (Li CO) TabletsMinh PhươngОценок пока нет

- Iron OreДокумент9 страницIron OreAnimesh SharmaОценок пока нет

- Active Soldering of ITO To Copper: Welding ResearchДокумент3 страницыActive Soldering of ITO To Copper: Welding ResearchtazzorroОценок пока нет

- The Periodic Table OverviewДокумент4 страницыThe Periodic Table OverviewSIAM PLAZ YTОценок пока нет

- Determination of Some Heavy Metals in Selected Cosmetic Products Sold in Kano Metropolis, NigeriaДокумент4 страницыDetermination of Some Heavy Metals in Selected Cosmetic Products Sold in Kano Metropolis, NigeriaKintanОценок пока нет

- 12 ExperimentДокумент61 страница12 ExperimentSajimon Abraham Ramachanattu PatnaОценок пока нет

- Electrolyte and Nonelectrolyte SolutionДокумент5 страницElectrolyte and Nonelectrolyte SolutionHediarta Widiana PutraОценок пока нет

- Metals and Non Metals 1Документ34 страницыMetals and Non Metals 1Alessandra myrnaОценок пока нет

- Chem 16 LE1 Questions CompleteДокумент4 страницыChem 16 LE1 Questions CompleteJemima BianОценок пока нет

- Appendix G - Standard Thermodynamic Properties For Selected Substances - ChemistryДокумент16 страницAppendix G - Standard Thermodynamic Properties For Selected Substances - ChemistryAri CleciusОценок пока нет

- Flashcards Topic 10 Metals CIE Chemistry IGCSEДокумент99 страницFlashcards Topic 10 Metals CIE Chemistry IGCSEoscarbecОценок пока нет

- 1 Metallurgy SB 2023Документ39 страниц1 Metallurgy SB 2023Bella CakieОценок пока нет

- Spring GradesДокумент2 страницыSpring GradesReddy Sadhana0% (1)

- 10 IGCSE Coordinated Science Mock Examination 2014 - Paper 6 Mark SchemeДокумент5 страниц10 IGCSE Coordinated Science Mock Examination 2014 - Paper 6 Mark SchemepixelhoboОценок пока нет

- Kinetic Studies On Surface Segregation of Manganese During Annealing of Low-Carbon SteelДокумент7 страницKinetic Studies On Surface Segregation of Manganese During Annealing of Low-Carbon Steelharish_158Оценок пока нет

- 0620 s15 QP 62Документ12 страниц0620 s15 QP 62Mohammed Murtada0% (1)

- GR 9 NS (English) June 2023 Question PaperДокумент18 страницGR 9 NS (English) June 2023 Question PaperagangdayimaniОценок пока нет

- Inorg Part 2Документ118 страницInorg Part 2Lady RicaОценок пока нет

- Chem Lec Reviewer Pre FinalДокумент10 страницChem Lec Reviewer Pre FinalVon MaraОценок пока нет

- Factors Affecting Silicomanganese Production Using Manganese Rich SlagДокумент9 страницFactors Affecting Silicomanganese Production Using Manganese Rich SlagbamboОценок пока нет

- Desta Life SciencesДокумент60 страницDesta Life SciencesDelwis Healthcare Pvt LtdОценок пока нет

- Quantitative Analysis of Potassium and Sodium in UrineДокумент2 страницыQuantitative Analysis of Potassium and Sodium in UrineidownloadbooksforstuОценок пока нет

- Test Report: Destiny Retail Mall Developers Private LimitedДокумент3 страницыTest Report: Destiny Retail Mall Developers Private LimitedAbhijit KarpeОценок пока нет

- 0620 - s08 - QP - 5 Past PaperДокумент8 страниц0620 - s08 - QP - 5 Past PaperMatthew LiОценок пока нет

- Properties of Pig Iron: UsesДокумент10 страницProperties of Pig Iron: UsesMahrukh SaleemОценок пока нет