Академический Документы

Профессиональный Документы

Культура Документы

FB (Floride-Basic) : Welding Flux

Загружено:

HoangОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FB (Floride-Basic) : Welding Flux

Загружено:

HoangАвторское право:

Доступные форматы

WELDING FLUX

1. FB (FLORIDE-BASIC)

Characteristics

PWL-7101 is an agglomerated fluoride-basic type flux metallurgical behavior: silght silicon pick-up. The behavior of

manganese is neutral. Grain size: 10 to 60 mesh. Basicity: 1. 8 (biiw).

weld metal is very purity. The diffusible hydrogen content in deposited metal is less than 5m1/100g, so has very good

toughness at the low temperature, therefore, crack resistance is extremely high.

pwl-101 assures excellent weld-ability, bead appearance is beautiful, slag is extremely easy to remove. It is suitable

for submerged-arc twin-wire, tandem and multi-wire welding as well as for welding with the two-run technique, such

as in the production of large pipes. The flux has low moisture pick-up and granular stability. Flux shall be capable of

meeting the applied requirements. As the bulk density is low, so is the consumption rate. Damp flux should be redried

at 300-350°c for 2 hours

2. CS (Calcium-silicate)

is an agglomerated calcium-silicate type flux Metallurgical behavior: High silicon pick-up is obtained. When

manganese content in wire is less than 1.5%, also a manganese pick-up. Grain size: 10 to 60 mesh. Basicity:1.0

(BIIW). It has excellent welding technology properties. Regularly shaped welds are deposited without reduction of

area or interface notches. Slag detachability is good. A short slag is produced, thus allowing circumferential welding

on small-diameter workpieces without the risk of uncontrolled slag. The production of large pipes (especially spiral

pipe welding) is a typical application for this flux. Relatively high manganese pick-up is obtained, thus allowing the

flux bi be used with wires with a low Mn content. As the bulk density is low, so is the consumption rate. Damp flux

should be redried at 300-350°C for 2 hours.

3. AGGLOMERATED ALUMINATR RUTILE TYPE FLUX

is an agglomerated aluminate-rutile type flux. Metallurgical behavior: High silicon and manganese pick-up is obtained.

Grain size: 14 to 60 mesh. Basicity: 0.5 (BIIW). It has excellent welding technology properties. Regularly shaped

welds are deposited without reduction of area or interface notches. Slag detachability is very good, especially at high

speed Welding porosity scarcely occur. Its welding speed is can able to travel up to 120cm/min. It is particularly

useful for welding tube-web-tube joints of finned tubes. XUN-501 is useful for welding thin plate in single pass and

limited pass. The flux can be welded with DC+ or AC The flux has low moisture pick-up and granular stability. Flux

shall be capable of meeting the applied requirements. As the bulk density is low, so is the consumption rate. Damp

flux should be redried at 300-350°C for 2 hours.

4. Aluminate-basic.

- Aluminate basic agglomerated flux

- Good impact values in two-run and multi-run technique

- Low hydrogen content

- Very suitable for longitudinal and spiral pipe welding

- Usable up to 3 wire systems

- Fine grain version available for the thinest wall and fastest welding speed

Вам также может понравиться

- B Mason NotesДокумент5 страницB Mason Notesjsmithy456Оценок пока нет

- Partie 3Документ34 страницыPartie 3vincent.guilbault7894Оценок пока нет

- High Alumina Ceramics: 2.ceramic Page 1 of 2Документ2 страницыHigh Alumina Ceramics: 2.ceramic Page 1 of 2venka07Оценок пока нет

- John Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialsДокумент8 страницJohn Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialssadhuОценок пока нет

- Float Glass RefractoryДокумент4 страницыFloat Glass RefractorySans SenОценок пока нет

- BrassesДокумент7 страницBrassesClaudia MmsОценок пока нет

- Laiwu Jincai Welding Materials Co.,Ltd: LJ-SJ501Документ1 страницаLaiwu Jincai Welding Materials Co.,Ltd: LJ-SJ501Carlos PadillaОценок пока нет

- Induction Furnaces LiningДокумент20 страницInduction Furnaces LiningAkash Sharma100% (1)

- Term Paper Mec 208Документ20 страницTerm Paper Mec 208lksingh1987Оценок пока нет

- HV 800Документ1 страницаHV 800rockyandianaОценок пока нет

- Copper AlloysДокумент4 страницыCopper AlloysMuhammed SulfeekОценок пока нет

- Format Classtest 3 IronsДокумент5 страницFormat Classtest 3 IronsVaibhav BhosaleОценок пока нет

- Silica Ramming MassДокумент17 страницSilica Ramming Masssagar kashinath kodle100% (1)

- Sand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityДокумент13 страницSand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityEmba MadrasОценок пока нет

- Forming and heat treatment of copper-nickelsДокумент1 страницаForming and heat treatment of copper-nickelssatnamОценок пока нет

- Sermaloy J Diffused Slurry Aluminide Coating: AdvantagesДокумент1 страницаSermaloy J Diffused Slurry Aluminide Coating: Advantagesbigsteve9088Оценок пока нет

- Aluminium 5052 Product Data SheetДокумент2 страницыAluminium 5052 Product Data SheetPraveen ThomasОценок пока нет

- Oerlikon BLUESHIELD Submerged Arc Welding Fluxes & WiresДокумент1 страницаOerlikon BLUESHIELD Submerged Arc Welding Fluxes & WiresSungJun ParkОценок пока нет

- Electrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyДокумент5 страницElectrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyShobhit MauryaОценок пока нет

- LM6 Alloy DetailДокумент4 страницыLM6 Alloy DetaildsoОценок пока нет

- LM6 Alloy Detail PDFДокумент4 страницыLM6 Alloy Detail PDFramashishОценок пока нет

- NST Products English TextsДокумент14 страницNST Products English TextsAnonymous 9PIxHy13Оценок пока нет

- Ok10 81LДокумент1 страницаOk10 81LRavi GuptaОценок пока нет

- Giúdice, 2004, Combinational Use of Extenders With Lamellar ZincДокумент14 страницGiúdice, 2004, Combinational Use of Extenders With Lamellar Zinccyclo DreamОценок пока нет

- BS2L99 Alloy DetailДокумент2 страницыBS2L99 Alloy Detailcharles_boyle_3Оценок пока нет

- Ferritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesДокумент4 страницыFerritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesrkukgОценок пока нет

- 5 SawДокумент13 страниц5 SawKartik BhararaОценок пока нет

- Alwasy Step Ahead in TechnologyДокумент2 страницыAlwasy Step Ahead in TechnologyjtpmlОценок пока нет

- Welding Galvanized SteelДокумент5 страницWelding Galvanized SteelAsian Celebs FunОценок пока нет

- Fcaw - Ebg InoxidableДокумент14 страницFcaw - Ebg InoxidablemsalinasaguilarОценок пока нет

- Technical Sheet Ag55Sn: The Above Data Are Subject To Change Without Notice by StellaДокумент1 страницаTechnical Sheet Ag55Sn: The Above Data Are Subject To Change Without Notice by StellaAntonis VentourisОценок пока нет

- Advantages and Disadvantages of Magnesium Cored Wire and Tundish Ladle ProcessesДокумент2 страницыAdvantages and Disadvantages of Magnesium Cored Wire and Tundish Ladle ProcessesAdrià BorregoОценок пока нет

- Submerged Arc Welding Fluxes BasicityДокумент3 страницыSubmerged Arc Welding Fluxes Basicitylram70Оценок пока нет

- High strength materials for prestressed concreteДокумент7 страницHigh strength materials for prestressed concreteBryan EweОценок пока нет

- Improving The Sink Roll Life in Galvalume Using Material AT101 & The Various Thermal-Spray Coating On SS3l6L Roll SurfaceДокумент5 страницImproving The Sink Roll Life in Galvalume Using Material AT101 & The Various Thermal-Spray Coating On SS3l6L Roll SurfaceAnil SharmaОценок пока нет

- Pump Guide Metals New ArticleДокумент2 страницыPump Guide Metals New Articleanon_857546621Оценок пока нет

- C PLATE TdsДокумент1 страницаC PLATE TdsEdwin TacoОценок пока нет

- Meeting Low Temperature Property Specifications in Ductile IronДокумент2 страницыMeeting Low Temperature Property Specifications in Ductile Ironالسيد ابراهيم عبدالعزيز عبداللهОценок пока нет

- Ductile Cast IronДокумент23 страницыDuctile Cast IronManicharanОценок пока нет

- Sigmacover 280 LT: Description Principal CharacteristicsДокумент2 страницыSigmacover 280 LT: Description Principal CharacteristicsEngTamerОценок пока нет

- Sulphur 2Документ8 страницSulphur 2Siddharth GuptaОценок пока нет

- L32B SawДокумент13 страницL32B SawCrocodileОценок пока нет

- Metal Roofing Fundamentals - Rob HaddockДокумент8 страницMetal Roofing Fundamentals - Rob HaddockNimish PrabhukhanolkarОценок пока нет

- 570 950mpa High Tensile Strength SteelДокумент32 страницы570 950mpa High Tensile Strength SteelCarlos PadillaОценок пока нет

- Duplex Stainless SteelsДокумент19 страницDuplex Stainless SteelsdinaksОценок пока нет

- Aluminum 5083Документ2 страницыAluminum 5083razormebackОценок пока нет

- 18a LCP Ultradeckr 700Документ6 страниц18a LCP Ultradeckr 700Aru VijayОценок пока нет

- Brass: Sales@columbiametals - Co.ukДокумент2 страницыBrass: Sales@columbiametals - Co.uktrongtuan87Оценок пока нет

- A Technical Service of Eastern Alloys, Inc.: KirksiteДокумент1 страницаA Technical Service of Eastern Alloys, Inc.: KirksitesatyendraОценок пока нет

- Ductle Iron Spec2Документ18 страницDuctle Iron Spec2윤병택Оценок пока нет

- Ferrocement and Its Application To ConstructionДокумент5 страницFerrocement and Its Application To ConstructionAnwar HussainОценок пока нет

- Atomizer Study For Processing PGMДокумент6 страницAtomizer Study For Processing PGMAFLAC ............Оценок пока нет

- ASMe Sec2 PartcДокумент53 страницыASMe Sec2 PartcSARSAN NDTОценок пока нет

- Zinc Flake CoatingsДокумент1 страницаZinc Flake CoatingsDinh TuОценок пока нет

- Soldadura SawДокумент18 страницSoldadura SawanselmoОценок пока нет

- SOUDOKAY STRIP CLADDING PROCESSДокумент20 страницSOUDOKAY STRIP CLADDING PROCESSVirjibhai khokhaniОценок пока нет

- Technical Team Plan For Week 48 Rev. 08 Base On Personal Plan Rev. Date 26 Nov. 2012Документ5 страницTechnical Team Plan For Week 48 Rev. 08 Base On Personal Plan Rev. Date 26 Nov. 2012HoangОценок пока нет

- Post Weld Heat TreatmentДокумент2 страницыPost Weld Heat TreatmentgullenariОценок пока нет

- WELDING PROCEDURE QUALIFICATION TRAVELERДокумент8 страницWELDING PROCEDURE QUALIFICATION TRAVELERHoangОценок пока нет

- CE Mark and DoP - QHPSДокумент2 страницыCE Mark and DoP - QHPSHoangОценок пока нет

- INTERTHERM228GRISPARTAДокумент9 страницINTERTHERM228GRISPARTAHoangОценок пока нет

- CWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsДокумент2 страницыCWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsHoangОценок пока нет

- 6.ASNT UT Level 2Документ1 страница6.ASNT UT Level 2HoangОценок пока нет

- CE Mark and DoP - QHPSДокумент2 страницыCE Mark and DoP - QHPSHoangОценок пока нет

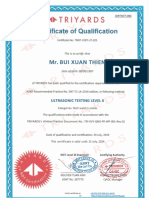

- Cer Rtifica Ate: Mr. B Bui Xuan N Thien of of PTSC M Mechanic Cal and C Construct Tion Co., LTDДокумент1 страницаCer Rtifica Ate: Mr. B Bui Xuan N Thien of of PTSC M Mechanic Cal and C Construct Tion Co., LTDHoangОценок пока нет

- ANSI Pipe Schedule Chart: Pipe Weight Conversion FormulaДокумент6 страницANSI Pipe Schedule Chart: Pipe Weight Conversion FormulaHoangОценок пока нет

- CWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsДокумент2 страницыCWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsHoangОценок пока нет

- Renewal and Recertification Requirements for Welding InspectorsДокумент1 страницаRenewal and Recertification Requirements for Welding InspectorsAhmedA.HassanОценок пока нет

- Review of Fatigue Assessment Procedures For Welded Aluminium StructuresДокумент25 страницReview of Fatigue Assessment Procedures For Welded Aluminium StructuresHoangОценок пока нет

- Controlling Hydrogen-Induced Cracking: Entering The Weld PoolДокумент3 страницыControlling Hydrogen-Induced Cracking: Entering The Weld PoolHoangОценок пока нет

- Filler Material Selection GuideДокумент32 страницыFiller Material Selection GuidemaknileОценок пока нет

- Inconel Alloy 625Документ18 страницInconel Alloy 625Gustavo Palacios100% (1)

- DIN EN 10277-2 Bright Steel 1999Документ11 страницDIN EN 10277-2 Bright Steel 1999Hans GoetheОценок пока нет

- Formula Weld CalculateДокумент6 страницFormula Weld CalculateHoangОценок пока нет

- Welding ASTM A514 or A514MДокумент3 страницыWelding ASTM A514 or A514MHoangОценок пока нет

- 5 Keys Selecting Filler Metal For Welding ProjectДокумент2 страницы5 Keys Selecting Filler Metal For Welding ProjectHoangОценок пока нет

- Steels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsДокумент2 страницыSteels - Carbon Steels, Mild Steel, Carbon-Manganese Steels, Alloys Steels, Low-Alloy Steels and Micro-Alloy SteelsHoangОценок пока нет

- Grain SizeДокумент3 страницыGrain SizeHoangОценок пока нет

- Liquid Penetrant TestingДокумент20 страницLiquid Penetrant TestingFDS_03Оценок пока нет

- Flow Chart - Storage & ID Stainless SteelДокумент3 страницыFlow Chart - Storage & ID Stainless SteelHoangОценок пока нет

- Alloying Elements EffectsДокумент2 страницыAlloying Elements EffectsTabish ShaikhОценок пока нет

- MV1062 Checklist - Final Inspection-11-Nov-2016Документ3 страницыMV1062 Checklist - Final Inspection-11-Nov-2016HoangОценок пока нет

- Tính Toán Tốc Độ Cấp dâyДокумент5 страницTính Toán Tốc Độ Cấp dâyHoangОценок пока нет

- INTERTHERM228GRISPARTAДокумент9 страницINTERTHERM228GRISPARTAHoangОценок пока нет

- Penetration Caculate PDFДокумент7 страницPenetration Caculate PDFHoangОценок пока нет

- Sample ItpДокумент4 страницыSample ItpWijayanto BekasiОценок пока нет

- Electropolished Tube - Electropolished Stainless Steel Tubing - Electropolish Tube - Rensa TubesДокумент13 страницElectropolished Tube - Electropolished Stainless Steel Tubing - Electropolish Tube - Rensa TubesRupesh surveОценок пока нет

- Me8073 Design For Manufacturing EnglishДокумент1 страницаMe8073 Design For Manufacturing EnglishNAVEEN KUMARОценок пока нет

- 3hea 801 212-001Документ26 страниц3hea 801 212-001Arno JürissonОценок пока нет

- Qc Manager, Oil and Gas ExperienceДокумент25 страницQc Manager, Oil and Gas ExperienceniranjanvengadОценок пока нет

- Weld Fit-Up Verification: Employee TrainingДокумент10 страницWeld Fit-Up Verification: Employee TrainingMohammad RizwanОценок пока нет

- ONGC Graduate Trainee Exam 2012 Preparation GuideДокумент19 страницONGC Graduate Trainee Exam 2012 Preparation GuideAnand ShankaranОценок пока нет

- 1 - Practical Application of Robot SafetyДокумент68 страниц1 - Practical Application of Robot Safetydavev2005100% (1)

- Instruction Book Iqan-Xa2: Publ No HY17-8385-IB/UK Edition 0505Документ38 страницInstruction Book Iqan-Xa2: Publ No HY17-8385-IB/UK Edition 0505Munawar DoankОценок пока нет

- BR Company ProfileДокумент31 страницаBR Company ProfilearefОценок пока нет

- Drawing of Weld SymbolsДокумент17 страницDrawing of Weld SymbolsSteranskoОценок пока нет

- Welding Handbook ESABДокумент529 страницWelding Handbook ESABErdinc_Bal_1026100% (8)

- AWS - PASS Pocket Series - The Professional's Advisor - Welding of Stainless Steels - Campbell 1999Документ92 страницыAWS - PASS Pocket Series - The Professional's Advisor - Welding of Stainless Steels - Campbell 1999Arnold Jose Batista RodriguezОценок пока нет

- Astm A380 A380m 13Документ6 страницAstm A380 A380m 13Asmaa TarekОценок пока нет

- Installation Instruction E-Slide E-Straight Crossing 2021-03Документ2 страницыInstallation Instruction E-Slide E-Straight Crossing 2021-03Dan STEFANОценок пока нет

- Welding Procedure Specification (WPS) : N.A N.AДокумент1 страницаWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiОценок пока нет

- ISOI005-Catalogue EPI 2021Документ27 страницISOI005-Catalogue EPI 2021CUPIDON flavelОценок пока нет

- CV - Format For EngineersДокумент3 страницыCV - Format For EngineersA Y ONОценок пока нет

- Produk E-KatalogДокумент15 страницProduk E-KatalogAnonymous ihk5Hm0Оценок пока нет

- Boiler Types and Parts GuideДокумент29 страницBoiler Types and Parts GuideAJITSPATILОценок пока нет

- Ep-Gis 36-300 - b04Документ33 страницыEp-Gis 36-300 - b04Matteo ColomboОценок пока нет

- Iso 9606 4 1999Документ11 страницIso 9606 4 1999Lino Alves InácioОценок пока нет

- Corner PostДокумент14 страницCorner PostTeguh Nugraha Kusnan100% (1)

- Process Equipment Design Chapter 4 - Pressure Vessel Part 1 - Revision 1Документ51 страницаProcess Equipment Design Chapter 4 - Pressure Vessel Part 1 - Revision 1Naresh Ganison100% (1)

- Soldering & WeldingДокумент82 страницыSoldering & WeldingRachita Arora100% (1)

- Copper Development Association: Aluminium Bronze - Essential For IndustryДокумент16 страницCopper Development Association: Aluminium Bronze - Essential For IndustryirinaОценок пока нет

- Pipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectДокумент2 страницыPipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectPRAKASH PANDEYОценок пока нет

- Teromatec 400 English Manual PDFДокумент24 страницыTeromatec 400 English Manual PDFex-2156100% (1)

- Shell's Post-Weld Heat Treatment GuideДокумент17 страницShell's Post-Weld Heat Treatment GuideSiva RamОценок пока нет

- Filler Metals Chemical Industry enДокумент16 страницFiller Metals Chemical Industry enrakeshbablooОценок пока нет