Академический Документы

Профессиональный Документы

Культура Документы

Ov Ed: Type 1 Masonry Support Calculation

Загружено:

share4learnИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ov Ed: Type 1 Masonry Support Calculation

Загружено:

share4learnАвторское право:

Доступные форматы

Status A Status A

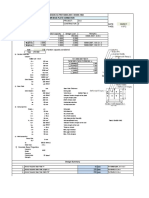

Type 1 Masonry Support Calculation

\\acs-file-sr1\Technical Server\Project W ork\R I W orks Ltd\114622 Hale W harf Phase 1\Calculations\Block A\LA700\[7CEX - T1-U-185-10

Project: Block A

d

Reference: T1/U/185/10/CH/TB

HW -0115-RI-A-CALC-7001 Revision: C02

System : 7CEX

ve

Angle

A = 60 mm

B = 90 mm

T = 5 mm

ro

R = 7.5 mm

d = 0 mm

Bracket

D = 165 mm

pp

W = 50 mm

t = 3 mm

r = 3 mm

L = 301 mm

x = 176 mm

Cg = 73.00 mm

-A

System

C = 185 mm

m = 102.5 mm

S = 0 mm

MH = 4.95 m (Masonry Height)

3

Φ = 2000 kg/m (Masonry Density)

w = 10.00 kN/m (Linear Load im posed by Masonry) Load Position = 1/3 Bearing

wB = 3.25 kN (Load per Bracket) Load Partial Factor, γ = 1.35

Y = 325 mm (Maximum Centres) Brackets/Meter = 3.08 No.

A

Mo = 20 mm (Masonry Offset) System Mass = 14.11 kg/m

Fixing Structure

M12 x 50 S/S T Head Bolt to suit 31/21 TB #REF! Channel CH

W asher

M12 Alpha ii W asher AW 2M12 σ Limit = 7 kN (W asher Shear Stress Limit)

V = 25.5 mm (Vertical Adjustment)

s

Suggested Angle Length = 1290 mm

Con = 500 mm (Concrete thickness in direction of fixing - if slab use 500mm)

tu

Top E = 75 mm (Concrete edge distance)

Bot E = 125 mm

Min Edge Distance = 75 mm

Min Spacing = 150 mm

Min Concrete Thickness = 0 mm

ta

Outputs

2

Angle Stress = 131.22 N/mm

2

Bracket Stress = 23.09 N/mm

2

W eld Stress = 32.15 N/mm

S

Angle Deflection = 0.50 mm

Bracket Horizontal Deflection = 0.01358 mm

Bracket Vertical Deflection = 0.04039 mm

System Deflection = 0.54 mm

Prepared By: Johnathan Bennett 1 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Miscellaneous

2

ESA 194908 N/mm

d

Modulus of Elasticity (Angle Component) =

2

Modulus of Elasticity (Bracket Component) ESB = 200000 N/mm

Material - Grade 304 - AISI 1.4301 Stainless Steel Material Partial Factor, γM = 1.1

ve

Angle Component - At ULS

Reaction location Lw = C + (2(M/3))/3 = 208.00 mm

Stress

ro

Langle = Lw - s - D - (T/2) = 40.50 mm

M angle = wLangle x 10³ = 546750 Nmm

pp

3

Zangle = (T² x 10³)/6 = 4167 mm

fAngle = M Angle/ZAngle = 131.22 N/mm²

Design bending stress resistance = 191 N/mm²

Angle bending stress is OK! = 69 %

-A

Deflection - At SLS

dAngle = wa³ x 10³ (1 + (3b/2a)) + w x 10³(B - (T/2))(d - R - T)²

3ESAIAngle 2ESAIAngle

a = Lw - s - D - R - T + p((R + T)/2) = 50.13 mm

b = B + D + s - Lw = 47.00 mm

4

IAngle = T³ x 10³ = 10417 mm

A

12

Therefore, deflection at the toe of the angle, dAngle = 0.50 mm

W eld - At ULS

Using 4mm fillet welds, (2 No. welds per bracket) weld leg, s = 4.00 mm

s

tW eld = s/2 = 2.828 mm

tu

Lweld(vd) = A - d - 2s 52.5 = 52.50 mm

= mm

Lweld(vi) = A-d- s - 10 44.5 = 44.50 mm

P = wY (Applied load per bracket) = 4387.5 N

ta

e = Lw - (s + D) (Load eccentricity) = 43.000 mm

Vd = P/2Lweld(vd) (Direct Shear) = 41.79 N/mm

Vi = Pe/2Lweld(vi)(0.5Lweld(vi) + 5) (Indirect Shear) = 80.75 N/mm

S

V = (Vd² + Vi²) (Resultant Shear) = 90.92 N/mm

fweld = V / tweld (W eld Stress) = 32.15 N/mm²

Prepared By: Johnathan Bennett 2 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design weld stress resistance = 249 N/mm²

W eld stress is OK! = 13 %

d

Bracket Component - At ULS

Sectional Properties

ve

3

Section Modulus ZBracket = 32669 mm

4

2nd Moment of area IBracket = 3005508 mm

Stress

ro

M Bracket = P(Lw- s - CG) = 592312.5 Nmm

Kr = Correction factor for flange buckling in compression = 0.7851

2

fBracket = M Bracket /( Kr x Zbracket) = 23.09 N/mm

pp

Design bending stress resistance = 191 N/mm²

12 %

Deflection - At SLS

Horizontal deflection dm ax = M a² = 0.03 mm

2 ESBIBracket

-A

Horizontal deflection dm ax = P L³ (1+3b/2a) = 0.01 mm

3 ESBIBracket 0.03

Horizontal deflection limit = 1.00 mm

Bracket horizontal deflection OK! 33.63 %

Vertical deflection dv = (D - Cg + B).tan(I) = 0.04 mm

A

Deflection through horizontal bending

height of section = 301.0 mm

Thickness = 3 mm

4

Iyy = 13635451 mm

s

Deflection dhb = = 0.01 mm

Total bracket vertical deflection = = 0.05 mm

tu

System Deflection - At SLS

System deflection D = dAngle + dv + dhb = 0.54 mm

Deflection limit at toe of angle = 1.50 mm

ta

System deflection OK! = 36 %

Fixing

Load eccentricity e = Lw - s = 208.00 mm

S

Fixing Shear Pv = wY/1000 = 3.25 kN

Fixing Tension Pt = Pv(e/(L - x)) = 6.79 kN

Fixing Resultant Pr = Pv² + Pt² = 7.53 kN

Design Fixing Shear Fv,Ed = Pv x γ = 4.39 kN

Prepared By: Johnathan Bennett 3 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design Fixing Tension Ft,Ed = Pt x γ = 9.17 kN

Characteristic Fixing ResultantFr,Ed = √Fv,Rd² + Ft,Rd² = 10.17 kN

Fixing Type = M12 x 50 S/S T Head Bolt to suit 31/21

d

Design Shear Resistance = 38.15 % Shear load OK!

Design Tension Resistance = 79.76 % Tensile load OK!

ve

W asher Type = M12 Alpha ii W asher

Characteristic Shear Resistance = 7.00 kN W asher Shear Load OK!

Safety Factor = 1.00

Combined Utilisation = 95.12 % Fixing OK!

ro

pp

-A

A

s

tu

ta

S

Prepared By: Johnathan Bennett 4 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Type 1 Masonry Support Calculation

\\acs-file-sr1\Technical Server\Project W ork\R I W orks Ltd\114622 Hale W harf Phase 1\Calculations\Block A\LA700\[7CF - T1-U-185-10-

Project: Block A

d

Reference: T1/U/185/10/CH/TB

HW -0115-RI-A-CALC-7001 Revision: C02

System : 7CF

ve

Angle

A = 50 mm

B = 90 mm

T = 5 mm

ro

R = 7.5 mm

d = 0 mm

Bracket

D = 165 mm

pp

W = 50 mm

t = 3 mm

r = 3 mm

L = 276 mm

x = 176 mm

Cg = 73.00 mm

-A

System

C = 185 mm

m = 102.5 mm

S = 0 mm

MH = 4.95 m (Masonry Height)

3

Φ = 2000 kg/m (Masonry Density)

w = 10.00 kN/m (Linear Load im posed by Masonry) Load Position = 1/3 Bearing

wB = 2.75 kN (Load per Bracket) Load Partial Factor, γ = 1.35

Y = 275 mm (Maximum Centres) Brackets/Meter = 3.64 No.

A

Mo = 20 mm (Masonry Offset) System Mass = 14.41 kg/m

Fixing Structure

M12 x 50 S/S T Head Bolt to suit 31/21 TB #REF! Channel CH

W asher

M12 Alpha ii W asher AW 2M12 σ Limit = 7 kN (W asher Shear Stress Limit)

V = 25.5 mm (Vertical Adjustment)

s

Suggested Angle Length = 1090 mm

Con = 500 mm (Concrete thickness in direction of fixing - if slab use 500mm)

tu

Top E = 75 mm (Concrete edge distance)

Bot E = 125 mm

Min Edge Distance = 75 mm

Min Spacing = 150 mm

Min Concrete Thickness = 0 mm

ta

Outputs

2

Angle Stress = 131.22 N/mm

2

Bracket Stress = 19.54 N/mm

2

W eld Stress = 41.47 N/mm

S

Angle Deflection = 0.50 mm

Bracket Horizontal Deflection = 0.01491 mm

Bracket Vertical Deflection = 0.03771 mm

System Deflection = 0.54 mm

Prepared By: Johnathan Bennett 1 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Miscellaneous

2

ESA 194908 N/mm

d

Modulus of Elasticity (Angle Component) =

2

Modulus of Elasticity (Bracket Component) ESB = 200000 N/mm

Material - Grade 304 - AISI 1.4301 Stainless Steel Material Partial Factor, γM = 1.1

ve

Angle Component - At ULS

Reaction location Lw = C + (2(M/3))/3 = 208.00 mm

Stress

ro

Langle = Lw - s - D - (T/2) = 40.50 mm

M angle = wLangle x 10³ = 546750 Nmm

pp

3

Zangle = (T² x 10³)/6 = 4167 mm

fAngle = M Angle/ZAngle = 131.22 N/mm²

Design bending stress resistance = 191 N/mm²

Angle bending stress is OK! = 69 %

-A

Deflection - At SLS

dAngle = wa³ x 10³ (1 + (3b/2a)) + w x 10³(B - (T/2))(d - R - T)²

3ESAIAngle 2ESAIAngle

a = Lw - s - D - R - T + p((R + T)/2) = 50.13 mm

b = B + D + s - Lw = 47.00 mm

4

IAngle = T³ x 10³ = 10417 mm

A

12

Therefore, deflection at the toe of the angle, dAngle = 0.50 mm

W eld - At ULS

Using 4mm fillet welds, (2 No. welds per bracket) weld leg, s = 4.00 mm

s

tW eld = s/2 = 2.828 mm

tu

Lweld(vd) = A - d - 2s 42.5 = 42.50 mm

= mm

Lweld(vi) = A-d- s - 10 34.5 = 34.50 mm

P = wY (Applied load per bracket) = 3712.5 N

ta

e = Lw - (s + D) (Load eccentricity) = 43.000 mm

Vd = P/2Lweld(vd) (Direct Shear) = 43.68 N/mm

Vi = Pe/2Lweld(vi)(0.5Lweld(vi) + 5) (Indirect Shear) = 108.87 N/mm

S

V = (Vd² + Vi²) (Resultant Shear) = 117.31 N/mm

fweld = V / tweld (W eld Stress) = 41.47 N/mm²

Prepared By: Johnathan Bennett 2 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design weld stress resistance = 249 N/mm²

W eld stress is OK! = 17 %

d

Bracket Component - At ULS

Sectional Properties

ve

3

Section Modulus ZBracket = 32669 mm

4

2nd Moment of area IBracket = 3005508 mm

Stress

ro

M Bracket = P(Lw- s - CG) = 501187.5 Nmm

Kr = Correction factor for flange buckling in compression = 0.7851

2

fBracket = M Bracket /( Kr x Zbracket) = 19.54 N/mm

pp

Design bending stress resistance = 191 N/mm²

10 %

Deflection - At SLS

Horizontal deflection dm ax = M a² = 0.02 mm

2 ESBIBracket

-A

Horizontal deflection dm ax = P L³ (1+3b/2a) = 0.01 mm

3 ESBIBracket 0.02

Horizontal deflection limit = 1.00 mm

Bracket horizontal deflection OK! 39.53 %

Vertical deflection dv = (D - Cg + B).tan(I) = 0.04 mm

A

Deflection through horizontal bending

height of section = 276.0 mm

Thickness = 3 mm

4

Iyy = 10512288 mm

s

Deflection dhb = = 0.01 mm

Total bracket vertical deflection = = 0.04 mm

tu

System Deflection - At SLS

System deflection D = dAngle + dv + dhb = 0.54 mm

Deflection limit at toe of angle = 1.50 mm

ta

System deflection OK! = 36 %

Fixing

Load eccentricity e = Lw - s = 208.00 mm

S

Fixing Shear Pv = wY/1000 = 2.75 kN

Fixing Tension Pt = Pv(e/(L - x)) = 7.68 kN

Fixing Resultant Pr = Pv² + Pt² = 8.16 kN

Design Fixing Shear Fv,Ed = Pv x γ = 3.71 kN

Prepared By: Johnathan Bennett 3 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design Fixing Tension Ft,Ed = Pt x γ = 10.37 kN

Characteristic Fixing ResultantFr,Ed = √Fv,Rd² + Ft,Rd² = 11.01 kN

Fixing Type = M12 x 50 S/S T Head Bolt to suit 31/21

d

Design Shear Resistance = 32.28 % Shear load OK!

Design Tension Resistance = 90.13 % Tensile load OK!

ve

W asher Type = M12 Alpha ii W asher

Characteristic Shear Resistance = 7.00 kN W asher Shear Load OK!

Safety Factor = 1.00

Combined Utilisation = 96.66 % Fixing OK!

ro

pp

-A

A

s

tu

ta

S

Prepared By: Johnathan Bennett 4 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Type 1 Masonry Support Calculation

\\acs-file-sr1\Technical Server\Project W ork\R I W orks Ltd\114622 Hale W harf Phase 1\Calculations\Block A\LA700\[7DC - T1-U-73-6-CH

Project: Block A

d

Reference: T1/U/73/6/CH/TB

HW -0115-RI-A-CALC-7001 Revision: C02

System : 7DC

ve

Angle

A = 50 mm

B = 80 mm

T = 5 mm

ro

R = 7.5 mm

d = 0 mm

Bracket

D = 43 mm

pp

W = 50 mm

t = 3 mm

r = 3 mm

L = 276 mm

x = 176 mm

Cg = 14.70 mm

-A

System

C = 73 mm

m = 102.5 mm

S = 0 mm

MH = 2.95 m (Masonry Height)

3

Φ = 2000 kg/m (Masonry Density)

w = 6.00 kN/m (Linear Load im posed by Masonry) Load Position = 1/2 Masonry

wB = 2.25 kN (Load per Bracket) Load Partial Factor, γ = 1.35

Y = 375 mm (Maximum Centres) Brackets/Meter = 2.67 No.

A

Mo = 30 mm (Masonry Offset) System Mass = 7.30 kg/m

Fixing Structure

M12 x 50 S/S T Head Bolt to suit 31/21 TB #REF! Channel CH

W asher

M12 Alpha ii W asher AW 2M12 σ Limit = 7 kN (W asher Shear Stress Limit)

V = 25.5 mm (Vertical Adjustment)

s

Suggested Angle Length = 1490 mm

Con = 500 mm (Concrete thickness in direction of fixing - if slab use 500mm)

tu

Top E = 75 mm (Concrete edge distance)

Bot E = 125 mm

Min Edge Distance = 75 mm

Min Spacing = 150 mm

Min Concrete Thickness = 0 mm

ta

Outputs

2

Angle Stress = 154.55 N/mm

2

Bracket Stress = 160.74 N/mm

2

W eld Stress = 61.37 N/mm

S

Angle Deflection = 0.70 mm

Bracket Horizontal Deflection = 0.00358 mm

Bracket Vertical Deflection = 0.50680 mm

System Deflection = 1.21 mm

Prepared By: Johnathan Bennett 1 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Miscellaneous

2

ESA 187657 N/mm

d

Modulus of Elasticity (Angle Component) =

2

Modulus of Elasticity (Bracket Component) ESB = 140609 N/mm

Material - Grade 304 - AISI 1.4301 Stainless Steel Material Partial Factor, γM = 1.1

ve

Angle Component - At ULS

Reaction location Lw = C + M/2 = 125.00 mm

Stress

ro

Langle = Lw - s - D - (T/2) = 79.50 mm

M angle = wLangle x 10³ = 643950 Nmm

pp

3

Zangle = (T² x 10³)/6 = 4167 mm

fAngle = M Angle/ZAngle = 154.55 N/mm²

Design bending stress resistance = 191 N/mm²

Angle bending stress is OK! = 81 %

-A

Deflection - At SLS

dAngle = wa³ x 10³ (1 + (3b/2a)) + w x 10³(B - (T/2))(d - R - T)²

3ESAIAngle 2ESAIAngle

a = Lw - s - D - R - T + p((R + T)/2) = 89.13 mm

b = B + D + s - Lw = -2.00 mm

4

IAngle = T³ x 10³ = 10417 mm

A

12

Therefore, deflection at the toe of the angle, dAngle = 0.70 mm

W eld - At ULS

Using 4mm fillet welds, (2 No. welds per bracket) weld leg, s = 4.00 mm

s

tW eld = s/2 = 2.828 mm

tu

Lweld(vd) = A - d - 2s 42.5 = 42.50 mm

= mm

Lweld(vi) = A-d- s - 10 34.5 = 34.50 mm

P = wY (Applied load per bracket) = 3037.5 N

ta

e = Lw - (s + D) (Load eccentricity) = 82.000 mm

Vd = P/2Lweld(vd) (Direct Shear) = 35.74 N/mm

Vi = Pe/2Lweld(vi)(0.5Lweld(vi) + 5) (Indirect Shear) = 169.87 N/mm

S

V = (Vd² + Vi²) (Resultant Shear) = 173.59 N/mm

fweld = V / tweld (W eld Stress) = 61.37 N/mm²

Prepared By: Johnathan Bennett 2 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design weld stress resistance = 249 N/mm²

W eld stress is OK! = 25 %

d

Bracket Component - At ULS

Sectional Properties

ve

3

Section Modulus ZBracket = 2655 mm

4

2nd Moment of area IBracket = 75135 mm

Stress

ro

M Bracket = P(Lw- s - CG) = 335036.25 Nmm

Kr = Correction factor for flange buckling in compression = 0.7851

2

fBracket = M Bracket /( Kr x Zbracket) = 160.74 N/mm

pp

Design bending stress resistance = 191 N/mm²

84 %

Deflection - At SLS

Horizontal deflection dm ax = M a² = 0.82 mm

2 ESBIBracket

-A

Horizontal deflection dm ax = P L³ (1+3b/2a) = 0.00 mm

3 ESBIBracket 0.82

Horizontal deflection limit = 1.00 mm

Bracket horizontal deflection OK! 0.71 %

Vertical deflection dv = (D - Cg + B).tan(I) = 0.51 mm

A

Deflection through horizontal bending

height of section = 276.0 mm

Thickness = 3 mm

4

Iyy = 10512288 mm

s

Deflection dhb = = 0.00 mm

Total bracket vertical deflection = = 0.51 mm

tu

System Deflection - At SLS

System deflection D = dAngle + dv + dhb = 1.21 mm

Deflection limit at toe of angle = 1.50 mm

ta

System deflection OK! = 81 %

Fixing

Load eccentricity e = Lw - s = 125.00 mm

S

Fixing Shear Pv = wY/1000 = 2.25 kN

Fixing Tension Pt = Pv(e/(L - x)) = 3.78 kN

Fixing Resultant Pr = Pv² + Pt² = 4.39 kN

Design Fixing Shear Fv,Ed = Pv x γ = 3.04 kN

Prepared By: Johnathan Bennett 3 of 3 Date: 06/11/2019

Status A Status A

Status A Status A

Design Fixing Tension Ft,Ed = Pt x γ = 5.10 kN

Characteristic Fixing ResultantFr,Ed = √Fv,Rd² + Ft,Rd² = 5.93 kN

Fixing Type = M12 x 50 S/S T Head Bolt to suit 31/21

d

Design Shear Resistance = 26.41 % Shear load OK!

Design Tension Resistance = 44.32 % Tensile load OK!

ve

W asher Type = M12 Alpha ii W asher

Characteristic Shear Resistance = 7.00 kN W asher Shear Load OK!

Safety Factor = 1.00

Combined Utilisation = 58.07 % Fixing OK!

ro

pp

-A

A

s

tu

ta

S

Prepared By: Johnathan Bennett 4 of 3 Date: 06/11/2019

Status A Status A

Вам также может понравиться

- Ov Ed: Type 1 M Asonry Support CalculationДокумент12 страницOv Ed: Type 1 M Asonry Support Calculationshare4learnОценок пока нет

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayДокумент1 страницаEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sОценок пока нет

- S2 Slab Calculation PDFДокумент1 страницаS2 Slab Calculation PDFashishОценок пока нет

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Документ2 страницыDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashОценок пока нет

- Channel Design AISCДокумент9 страницChannel Design AISCRajveer SinghОценок пока нет

- UNI - Z241 - 17 - 5 - 600x300 ModifiedДокумент23 страницыUNI - Z241 - 17 - 5 - 600x300 ModifiedpaulaОценок пока нет

- Slab DesignДокумент3 страницыSlab DesignPrayush RajbhandariОценок пока нет

- 10 Ton SIngle Girder 7.62 M Span DesignДокумент4 страницы10 Ton SIngle Girder 7.62 M Span DesignAdeeb ShahzadaОценок пока нет

- Appendix A3Документ6 страницAppendix A3Thomas Stephen100% (1)

- Beam Column ConnectionДокумент2 страницыBeam Column ConnectionHAZIRACFS SURATОценок пока нет

- Seafastening For Pelikan - 12mm Thickness PlateДокумент12 страницSeafastening For Pelikan - 12mm Thickness PlateHafidОценок пока нет

- 05-1 Base Plate-FixedДокумент49 страниц05-1 Base Plate-FixedJames AugustineОценок пока нет

- Design of Rib One WayДокумент1 страницаDesign of Rib One WayChidambaram SethumahadevanОценок пока нет

- Section Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Документ8 страницSection Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Lavender HoneyОценок пока нет

- Staircase PDFДокумент1 страницаStaircase PDFSanjeev SanjeevОценок пока нет

- DownloadДокумент2 страницыDownloadaneeshp_4Оценок пока нет

- RCC Design of Heel-Slab: Input DataДокумент2 страницыRCC Design of Heel-Slab: Input DataAnkitaОценок пока нет

- Blind Flange With StiffenersДокумент4 страницыBlind Flange With Stiffenersshahid khan100% (1)

- Annex-1: Foundation Design: Footing D E S I G N Rea C Ti o N SДокумент21 страницаAnnex-1: Foundation Design: Footing D E S I G N Rea C Ti o N SSudip ShresthaОценок пока нет

- Design of Sign Board Gantry 20.2 M SpanДокумент10 страницDesign of Sign Board Gantry 20.2 M SpanVrusha BendarОценок пока нет

- 6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Документ81 страница6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Omprakash KhodkeОценок пока нет

- Pipe Guide and Welding Connection - h150x125x14x8.5Документ13 страницPipe Guide and Welding Connection - h150x125x14x8.5BenchОценок пока нет

- Slab DesignДокумент4 страницыSlab DesignRubina HannureОценок пока нет

- Base Plate - Silo Supporting R1Документ10 страницBase Plate - Silo Supporting R1soumi bhattacharyaОценок пока нет

- Eccentric FootingДокумент3 страницыEccentric FootingVarunn VelОценок пока нет

- Design Project Sructure Type Engineer: Load and Resistance Factor Design (LRFD)Документ5 страницDesign Project Sructure Type Engineer: Load and Resistance Factor Design (LRFD)Jose royОценок пока нет

- Welding CheckingДокумент1 страницаWelding Checkingxlw955597Оценок пока нет

- Roof Slab of Guard RoomДокумент3 страницыRoof Slab of Guard RoomAditya KumarОценок пока нет

- 14 M Steel Bridge - Floor Plate Capacity CheckДокумент2 страницы14 M Steel Bridge - Floor Plate Capacity CheckvibishnanОценок пока нет

- Anchor Bolt Size Check For Legged Supported Vessels: Item No.: Active CarbonДокумент2 страницыAnchor Bolt Size Check For Legged Supported Vessels: Item No.: Active Carbonmih150% (2)

- Baja 1Документ25 страницBaja 1Ruddy ChoiruddynОценок пока нет

- Momen End Plate CS 675Документ12 страницMomen End Plate CS 675Jose royОценок пока нет

- Design of Slab Base For Axial Load and Moment Connection E Is Greater Than 1 by 3Документ2 страницыDesign of Slab Base For Axial Load and Moment Connection E Is Greater Than 1 by 3debashish sarkarОценок пока нет

- Ooo Ooo Oooooooooo Oooo Ooooooooo Oo OooДокумент3 страницыOoo Ooo Oooooooooo Oooo Ooooooooo Oo Oootejaswini shahapurkarОценок пока нет

- Bridge Sliding End and Fixed End-CIFB03Документ7 страницBridge Sliding End and Fixed End-CIFB03Sai SushankОценок пока нет

- RCC Design of Toe-Slab: Input DataДокумент2 страницыRCC Design of Toe-Slab: Input DataAnkitaОценок пока нет

- End Plate Moment Connection (Bolt)Документ72 страницыEnd Plate Moment Connection (Bolt)mengxiao74Оценок пока нет

- Binder 1Документ68 страницBinder 1Anh KyОценок пока нет

- Spreader Bar Calculation Arrangement Beam Details SHSHF 150 X 150 X 9Документ1 страницаSpreader Bar Calculation Arrangement Beam Details SHSHF 150 X 150 X 9Nasrul AdliОценок пока нет

- RCC Detail Design of Bridge No.-422Документ6 страницRCC Detail Design of Bridge No.-422shashibhushan singhОценок пока нет

- Gantry Grider FinalДокумент8 страницGantry Grider Finalasvenk309Оценок пока нет

- 9.3 Strut Design ISMB (Hor)Документ7 страниц9.3 Strut Design ISMB (Hor)24x7civilconsultantОценок пока нет

- Base Plate DesignДокумент20 страницBase Plate DesignMohammad KasimОценок пока нет

- Corbel DesignДокумент3 страницыCorbel DesignLim EcОценок пока нет

- Staging Design For Bridge SlabДокумент10 страницStaging Design For Bridge SlabRajarathinam RajamanickamОценок пока нет

- Slab DesignДокумент4 страницыSlab DesigndulancivilОценок пока нет

- Standard Tech SpecДокумент3 страницыStandard Tech SpecBhuvan GanesanОценок пока нет

- Idn - 4Документ5 страницIdn - 4Anh KyОценок пока нет

- Typical & Corner Ucw ReportДокумент24 страницыTypical & Corner Ucw ReportPrasad kapureОценок пока нет

- Beam Design: Design By: Engr. Zulkiflee M. TaugДокумент1 страницаBeam Design: Design By: Engr. Zulkiflee M. Taugking taugОценок пока нет

- Elastomeric Bearing 21.6mДокумент8 страницElastomeric Bearing 21.6mnaresh KUMARОценок пока нет

- Lifting Lug Excel SheetДокумент8 страницLifting Lug Excel Sheetshazan67% (3)

- Whalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MДокумент1 страницаWhalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MWilliam ProvidoОценок пока нет

- Lifting Design Using Rebars: Details of PanelДокумент3 страницыLifting Design Using Rebars: Details of PanelAsaru Deen100% (2)

- Design As Per IS 800-2007 (Jindal) (20131011)Документ11 страницDesign As Per IS 800-2007 (Jindal) (20131011)Pruthviraj JuniОценок пока нет

- Fin Glass 6 PDFДокумент6 страницFin Glass 6 PDFEIWAA100% (1)

- Calculation For Crack WidthДокумент48 страницCalculation For Crack Widthpearl kachhawahОценок пока нет

- Retaining Wall - 8m With Traffic LoadДокумент17 страницRetaining Wall - 8m With Traffic LoadDev lamichhaneОценок пока нет

- Beam & Column Design For ShearДокумент7 страницBeam & Column Design For ShearEngineeri TadiyosОценок пока нет

- Cylindrical Compression Helix Springs For Suspension SystemsОт EverandCylindrical Compression Helix Springs For Suspension SystemsОценок пока нет

- Skanska Supply Chain Bim GuidanceДокумент4 страницыSkanska Supply Chain Bim Guidanceshare4learnОценок пока нет

- CDE - Collaborative BIMДокумент16 страницCDE - Collaborative BIMshare4learnОценок пока нет

- Shoring Manual For Sheeted Excavations 2018Документ124 страницыShoring Manual For Sheeted Excavations 2018share4learn100% (1)

- Deflections Document Final 27 AprilДокумент16 страницDeflections Document Final 27 Aprilshare4learnОценок пока нет

- Strength Training For Lower-Back Pain Outside OnlineДокумент7 страницStrength Training For Lower-Back Pain Outside Onlineshare4learnОценок пока нет

- Horizontal Book Screen 1Документ62 страницыHorizontal Book Screen 1share4learnОценок пока нет

- UK Government BIM Working GroupДокумент47 страницUK Government BIM Working Groupshare4learnОценок пока нет

- Ov Ed: SMB System C 1,5 KG EN 13374-A-B ( 15°)Документ2 страницыOv Ed: SMB System C 1,5 KG EN 13374-A-B ( 15°)share4learnОценок пока нет

- LAB-STT-ZZ-XX-RP-C-0010 - Flood Risk Assessment - C01 PDFДокумент47 страницLAB-STT-ZZ-XX-RP-C-0010 - Flood Risk Assessment - C01 PDFshare4learnОценок пока нет

- Megashor Metric MS01 2Документ93 страницыMegashor Metric MS01 2share4learnОценок пока нет

- Application Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-TДокумент9 страницApplication Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-Tshare4learnОценок пока нет

- Industry CPD: Modelling Buildings For Seismic AnalysisДокумент4 страницыIndustry CPD: Modelling Buildings For Seismic Analysisshare4learnОценок пока нет

- IFC-guide Export EN 20200401 R2Документ44 страницыIFC-guide Export EN 20200401 R2share4learnОценок пока нет

- Bearing Capacity of The Working Platform With Kinematic MethodДокумент6 страницBearing Capacity of The Working Platform With Kinematic Methodshare4learnОценок пока нет

- Subgrade Reaction Modulus (KS) of Clayey SoilsДокумент26 страницSubgrade Reaction Modulus (KS) of Clayey Soilssofronije2005100% (1)

- Ole Bengt Berard ThesisДокумент237 страницOle Bengt Berard Thesisshare4learnОценок пока нет

- PPR Ov Ed: B.6 B.5 B.4 B.3 B.6 B.5 B.4 B.3Документ1 страницаPPR Ov Ed: B.6 B.5 B.4 B.3 B.6 B.5 B.4 B.3share4learnОценок пока нет

- Ground Bearing Concrete Slabs - Chapter 2Документ37 страницGround Bearing Concrete Slabs - Chapter 2share4learn100% (1)

- 5 Tomi Henttinen BIM in FinlandДокумент28 страниц5 Tomi Henttinen BIM in Finlandshare4learnОценок пока нет

- The Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsДокумент12 страницThe Correlation Between The CBR and Shear Strength in Unsaturated Soil Conditionsshare4learnОценок пока нет

- Behavior of Deep Excavation With Diaphragm WallДокумент351 страницаBehavior of Deep Excavation With Diaphragm Wallshare4learn100% (1)

- Construction and Material-V: Reinforced BrickworkДокумент41 страницаConstruction and Material-V: Reinforced BrickworkRoshan MauryaОценок пока нет

- Converter 25 AprilДокумент660 страницConverter 25 Apriljyoti upadhyayОценок пока нет

- Group 1 Report Cast in Place and Precast Slab TypesДокумент55 страницGroup 1 Report Cast in Place and Precast Slab TypesAlwyn RamosОценок пока нет

- UNISEM - SITEMODIFICATION Rev1 - Endorsed PDFДокумент5 страницUNISEM - SITEMODIFICATION Rev1 - Endorsed PDFCalvin TehОценок пока нет

- Case Studies On Strengthening of Concrete and Masonry StructuresДокумент10 страницCase Studies On Strengthening of Concrete and Masonry StructuresMohamed El-GoharyОценок пока нет

- Steel Beams Astm A36Документ4 страницыSteel Beams Astm A36Wala LangОценок пока нет

- Pile Cap - WikipediaДокумент2 страницыPile Cap - Wikipediaindrajit sodhaОценок пока нет

- 36564840768Документ3 страницы36564840768Mohamed AbdullaОценок пока нет

- Hot StopДокумент30 страницHot StopaОценок пока нет

- Chenab Bridge: P.Anil Kumar 1005-15-741508Документ20 страницChenab Bridge: P.Anil Kumar 1005-15-741508vsballaОценок пока нет

- Echartered Engineering Competency Claims - Example C 01082013Документ27 страницEchartered Engineering Competency Claims - Example C 01082013lwise86Оценок пока нет

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheДокумент8 страницCincom Evolution Line: Sliding Headstock Type Automatic CNC LatheAmy GriffinОценок пока нет

- WSH CS-25 Concrete Construction 351031 7Документ6 страницWSH CS-25 Concrete Construction 351031 7mdelacruzОценок пока нет

- Flat Slab Formwork Falsework1Документ80 страницFlat Slab Formwork Falsework1Amin ZuraiqiОценок пока нет

- Bill of Materials: Project Location OwnerДокумент15 страницBill of Materials: Project Location OwnerAnn MoralesОценок пока нет

- Vicat Apparatus PrimoДокумент10 страницVicat Apparatus PrimoMoreno, Leanne B.Оценок пока нет

- EG04-W-19 Tech Specs PilingДокумент16 страницEG04-W-19 Tech Specs Pilingbharat shindeОценок пока нет

- Use of Sugarcane Bagasse Ash As A FineДокумент4 страницыUse of Sugarcane Bagasse Ash As A FineShimbarlu AtwiksonОценок пока нет

- Project Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago CityДокумент7 страницProject Specification: Title: Bruna Bautista Ville CPM Location: Rizal Santiago Citymelvin bautistaОценок пока нет

- 1oq17at030-Mirza Sohaib (Final Portfolio)Документ18 страниц1oq17at030-Mirza Sohaib (Final Portfolio)mirza sohaibОценок пока нет

- IEM Form of Contract (For Civil Engineering, Mechanical and Electrical Engineering Works)Документ1 страницаIEM Form of Contract (For Civil Engineering, Mechanical and Electrical Engineering Works)Vincent 2020Оценок пока нет

- Aggregate Impact TestДокумент4 страницыAggregate Impact Testrajusanju82% (11)

- CPM 1Документ160 страницCPM 1Maria Rose Giltendez - BartianaОценок пока нет

- Selkirk Ultra Temp Chimney Installation GuideДокумент6 страницSelkirk Ultra Temp Chimney Installation GuidepaulpaulОценок пока нет

- GEART ArchitectureДокумент24 страницыGEART ArchitecturejammyОценок пока нет

- Obra C RFQ For Remaining Boundary Wall Work PC AC BOQ (20220624)Документ1 страницаObra C RFQ For Remaining Boundary Wall Work PC AC BOQ (20220624)ashutoshpathakcivilОценок пока нет

- Optimization of Steam-CuringДокумент15 страницOptimization of Steam-CuringvardhangargОценок пока нет

- Cost Estimating PDFДокумент38 страницCost Estimating PDFascom asОценок пока нет

- LS-2141 L2 Material PlanДокумент1 страницаLS-2141 L2 Material Planvin ssОценок пока нет

- Construction and Building MaterialsДокумент12 страницConstruction and Building MaterialsKhams TaghaОценок пока нет