Академический Документы

Профессиональный Документы

Культура Документы

WPS-ASME-009-1 Rev1

Загружено:

Ahmed Lepda0 оценок0% нашли этот документ полезным (0 голосов)

354 просмотров1 страницаОригинальное название

WPS-ASME-009-1 rev1.xls

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

354 просмотров1 страницаWPS-ASME-009-1 Rev1

Загружено:

Ahmed LepdaАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

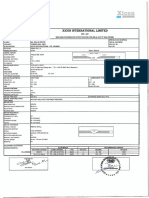

WELDING PROCEDURE SPECIFICATION(WPS)

(ASME SEC. IX)

Project : South Pars Gas Field Development(Phases 9&10) Date : 30 DEC,05

WPS No. CON-WPS-ASME-009-1 Rev. 1 JOINTS (QW-402)

PQR No. CON-PQR-ASME-016 Rev. 1 Joints Design Single V Butt Joint

Welding Process GTAW-SMAW Backing ■ No for GT ■ Yes for SM

Types Manual □ Semi-Automatic □ Automatic Backing Material or Type GTAW root passes

BASE METALS (QW-403) For LTCS+NACE

P-No. 1 G-No. 1 to P-No. 1 G-No. 1

Thickness Range 16.0≤ t ≤ 47.6 mm

Diameter Range All

FILLER METALS (QW-404)

F-No. 6&4 A-No. 1

Spec. No.(SFA) SFA : 5.28 & 5.5

AWS No.(Class) ER-80S-Ni1 & E 7018G

Size of Filler Metal 2.4,3.2, 4.0

GTAW: Up to 10.0 mm

Deposit Thickness Qualified

SMAW: Up to 37.6 mm

Trade Name OK Tigrod 13.24 Ø 2.4

OK 48.08 Ø 3.2&4.0

POSITION (QW-405) ELECTRICAL CHARACTERISTICS (QW-409)

Position ALL Current AC or DC DC

Welding Progression Up Hill Polarity, Amps & Volts(Range) DCSP & DCRP

Tungsten Electrode Size & Type 1.6 ~ 2.4 mm & EWTh-2

PREHEATING & INTERPASS TEMP. (QW-406) Transfer Mode N/A

Preheat Temp. Min. 75 º C,100º C Note (1)

Wire Feed Speed N/A

Interpass Temp. Max. 198 º C

Preheat Maintenance N/A TECHNIQUE (QW-410)

String or Weave Bead Both(Note3)

POST WELD HEAT TREATMENT (QW-407) Cleaning Method Grinding & Brushing

Temperature Range ( º C ) 610 ±10 °C Multi or Single Pass/side Multiple

Time Range 1/hr for 25mmNote(2) Single or Multiple Electrodes Single

Heating Rate ( º C ) Max.220˚C / hr/inch

Cooling Rate ( º C ) Max.275˚C / hr/inch GAS (QW-408)

Percent Composition Gas Mixture Flow Rate(l/min)

Shielding Argon 99.99% (9 ~12 )

Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRODE

Welding Filler Metal Current Volt Travel Speed

Weld Layers Others

Process Class Dia(mm) Type Polar. Amp Range(A) Range(V) Range(cm/min)

1st GTAW ER 80S-Ni1 2.4 DC SP 140 ~ 160 10 ~ 12 6~8 Heat Input

2 nd GTAW ER 80S-Ni1 2.4 DC SP 180 ~ 210 11 ~ 13 9~ 12 ≥ 13 Kj/cm

Filling SMAW E7018G Ø3.2&4.0 DCRP 120 ~ 180 21 ~ 28 8 ~ 10 ≤ 30.2 Kj/cm

Cap SMAW E7018G 3.2 DCRP 110 ~ 130 20 ~ 24 9 ~ 10

Note : 1- When wall thickness is 1"over 2- For over 1" add 2.4 minute/1mm

3- Oscillation for weave bead is < 3 time of OD electrode

Name

Signature

Date

SUBCONTRACTOR CONTRACTOR TPA/COMPANY

Page 1 of 1

Вам также может понравиться

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ1 страницаWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaОценок пока нет

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFДокумент11 страницEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaОценок пока нет

- WPS CuNiДокумент4 страницыWPS CuNiSripathyОценок пока нет

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSДокумент1 страницаPT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanОценок пока нет

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedОценок пока нет

- WPQ Template (Asme Ix) No LogoДокумент4 страницыWPQ Template (Asme Ix) No LogorcpretoriusОценок пока нет

- Welding Procedure Specification "WPS": O O O OДокумент1 страницаWelding Procedure Specification "WPS": O O O OAli MoosaviОценок пока нет

- WPS-Shell To Tubesheet (CS-SS)Документ1 страницаWPS-Shell To Tubesheet (CS-SS)suria qaqcОценок пока нет

- PQRДокумент2 страницыPQRSreenivas Kamachi Chettiar100% (1)

- Wps For Ss 304Документ3 страницыWps For Ss 304Sajit PillaiОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- PQR Template (Asme)Документ2 страницыPQR Template (Asme)jok1974Оценок пока нет

- QW-483 BlankДокумент2 страницыQW-483 BlankCraftyBob100% (1)

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpДокумент1 страницаPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarОценок пока нет

- Wps FormatДокумент12 страницWps FormatGohilakrishnan ThiagarajanОценок пока нет

- NPCIL Tube Fitting SpecificationsДокумент22 страницыNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreДокумент3 страницыWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Документ2 страницы(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPQ PDFДокумент0 страницWPQ PDFstanleyОценок пока нет

- WPSДокумент6 страницWPSNur Wijianto100% (1)

- PQR TipsДокумент4 страницыPQR TipsWaqas WaqasОценок пока нет

- WPQ Formats NEWДокумент4 страницыWPQ Formats NEWMANABENDRA MAITRAОценок пока нет

- WPS PQR For S 1 S Piping 02Документ5 страницWPS PQR For S 1 S Piping 02ravi00098Оценок пока нет

- WPS - PQR (Sa516 GR.70)Документ4 страницыWPS - PQR (Sa516 GR.70)miltonangulomorrisОценок пока нет

- PQR REV. 2010a Interactive FormДокумент2 страницыPQR REV. 2010a Interactive FormcosmicbunnyОценок пока нет

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Документ3 страницыAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzHОценок пока нет

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Документ4 страницыPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluОценок пока нет

- Wps - Asme Ix - Gtaw - Plat SteДокумент6 страницWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraОценок пока нет

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- Welding Procedure Specification For GTAW & GMAWДокумент4 страницыWelding Procedure Specification For GTAW & GMAWanh thoОценок пока нет

- WPS For Carbon Steel THK 7.11 GTAWДокумент1 страницаWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Welder ID Card BRE KarahaДокумент5 страницWelder ID Card BRE KarahaHerruSetiawan100% (1)

- 1015 To Hastelloy VickoДокумент14 страниц1015 To Hastelloy Vickovgestantyo100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- WPS, PQR, WPQ PoojaДокумент10 страницWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- WPS PQR 12Документ9 страницWPS PQR 12Ranjan KumarОценок пока нет

- Clad PQRДокумент5 страницClad PQRRinshadОценок пока нет

- WPQДокумент10 страницWPQayoki100% (3)

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- Fermi Lab Orbital Welding ProcedureДокумент2 страницыFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- WPS PQR PDFДокумент23 страницыWPS PQR PDFtomj9104Оценок пока нет

- Wps Is 2062 GR B Butt-OkДокумент2 страницыWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- WPQT CertificateДокумент104 страницыWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- ASME IX Sample WPS GTAW SMAWДокумент1 страницаASME IX Sample WPS GTAW SMAWDeepak ShrivastavОценок пока нет

- PQR 014 (Qualified Sa 106 GR BДокумент5 страницPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Wps Gmaw SawДокумент2 страницыWps Gmaw Sawupedro26Оценок пока нет

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- Sa 516 GR 70Документ2 страницыSa 516 GR 70Idil FitriОценок пока нет

- Asme IxДокумент1 страницаAsme IxAxel Navarro AlbinesОценок пока нет

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTДокумент1 страницаWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaОценок пока нет

- WPS for Gas Field Development WeldingДокумент2 страницыWPS for Gas Field Development WeldingAhmed LepdaОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ3 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS-ASME-007-1 Rev0Документ1 страницаWPS-ASME-007-1 Rev0Ahmed LepdaОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ2 страницыWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWДокумент8 страницPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromОценок пока нет

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeДокумент2 страницыWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraОценок пока нет

- Pwps Jo Wps Asme 016 Rev.001Документ2 страницыPwps Jo Wps Asme 016 Rev.001Bagandi ManurungОценок пока нет

- 6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Документ3 страницы6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Ahmed LepdaОценок пока нет

- 5187901TechArticleWebDocLR PDFДокумент7 страниц5187901TechArticleWebDocLR PDFoggay94Оценок пока нет

- Structural ShapesДокумент21 страницаStructural ShapesjeefryОценок пока нет

- Perforated Expanded Catalog NewДокумент16 страницPerforated Expanded Catalog NewAhmed LepdaОценок пока нет

- 8 FFDДокумент129 страниц8 FFDAhmed LepdaОценок пока нет

- Cafco Fendolite Mii Application Guidelines PDFДокумент23 страницыCafco Fendolite Mii Application Guidelines PDFTanmay GorОценок пока нет

- A Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresДокумент24 страницыA Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresHowo4DieОценок пока нет

- 1 Updated 2159 MergedДокумент2 страницы1 Updated 2159 MergedAhmed LepdaОценок пока нет

- NDT Salary Survey 2018 Highlights Continued GrowthДокумент27 страницNDT Salary Survey 2018 Highlights Continued GrowthAhmed LepdaОценок пока нет

- Simultaneous Operations (SIMOPS)Документ156 страницSimultaneous Operations (SIMOPS)Ahmed Lepda100% (3)

- What Every Engineer Should Know AboutДокумент217 страницWhat Every Engineer Should Know AboutGurpreet Singh DhunnaОценок пока нет

- Cafco Fendolite Mii - Data Sheet - LRДокумент3 страницыCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- Cafco Fendolite Mii - Data Sheet - LRДокумент3 страницыCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- Parts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesДокумент2 страницыParts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesMaria AndreeaОценок пока нет

- Animal Signal Sheet PDFДокумент2 страницыAnimal Signal Sheet PDF유웃Оценок пока нет

- 24 Sample ChapterДокумент14 страниц24 Sample ChapterRomyMohanОценок пока нет

- Cafco ® Fendolite Mii: Application GuideДокумент27 страницCafco ® Fendolite Mii: Application GuideAhmed LepdaОценок пока нет

- 24 Sample ChapterДокумент14 страниц24 Sample ChapterRomyMohanОценок пока нет

- Design and MaterialДокумент40 страницDesign and MaterialRavishankarОценок пока нет

- Astm A 153 PDFДокумент4 страницыAstm A 153 PDFmahmoud hegazy100% (5)

- Addressing Anchors (Steelwise Article On Anchor Bolt Fixes)Документ3 страницыAddressing Anchors (Steelwise Article On Anchor Bolt Fixes)Justin UyarОценок пока нет

- Carbon and Alloy Steel Nuts (Metric) : Standard Specification ForДокумент9 страницCarbon and Alloy Steel Nuts (Metric) : Standard Specification ForAhmed LepdaОценок пока нет

- Steel WiseДокумент5 страницSteel WisepicottОценок пока нет

- Add To Favorites Contact Us SearchДокумент4 страницыAdd To Favorites Contact Us SearchAhmed LepdaОценок пока нет

- English Math Revision KG1: Math Numbers & Shapes LinksДокумент9 страницEnglish Math Revision KG1: Math Numbers & Shapes LinksAhmed LepdaОценок пока нет

- Astm A 563 14pdf PDFДокумент18 страницAstm A 563 14pdf PDFSathish KumarОценок пока нет

- AISC - Bolts TCQ Up Side or DownДокумент1 страницаAISC - Bolts TCQ Up Side or DownAhmed LepdaОценок пока нет

- A 325M - 03 PDFДокумент7 страницA 325M - 03 PDFsergioОценок пока нет

- MTC 17022021063931Документ1 страницаMTC 17022021063931Ahmed LepdaОценок пока нет

- Electron Spin Resonance (Esr) SpectrosДокумент18 страницElectron Spin Resonance (Esr) SpectrosIndarto Al-kimia100% (1)

- A Simple Model For Quantisation Effects IN Heavily-Doped Silicon Mosfets at Inversion ConditionsДокумент4 страницыA Simple Model For Quantisation Effects IN Heavily-Doped Silicon Mosfets at Inversion ConditionsmodasshirОценок пока нет

- Prodinfo Antox-75-E Eng FinalДокумент2 страницыProdinfo Antox-75-E Eng FinalKumar RamanОценок пока нет

- Quiz 1 Fundamental PetroleumДокумент4 страницыQuiz 1 Fundamental PetroleumMuhammad Amran50% (2)

- Product Data Booklet Fibertec Ultimate HDD Coating SystemДокумент8 страницProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Оценок пока нет

- Onion Cell Structure Under MicroscopeДокумент2 страницыOnion Cell Structure Under MicroscopeAnirudh100% (1)

- Energy Balance and Thermo PresentationДокумент83 страницыEnergy Balance and Thermo Presentationca2n27Оценок пока нет

- Feasibility Study of Cumene ProductionДокумент4 страницыFeasibility Study of Cumene ProductionIntratec SolutionsОценок пока нет

- On Water Cycle With Unlocking of DifficultiesДокумент38 страницOn Water Cycle With Unlocking of DifficultiesShirly Basilio100% (1)

- The Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFДокумент452 страницыThe Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFJim Leonard100% (2)

- PCA Ion Exchange Membranes - Technical Data SheetДокумент2 страницыPCA Ion Exchange Membranes - Technical Data Sheettestuser010% (1)

- Nanotechnology Applications and Its Importance in Various FieldsДокумент24 страницыNanotechnology Applications and Its Importance in Various FieldsSuresh ShahОценок пока нет

- Factors Affecting Rate of EvaporationДокумент22 страницыFactors Affecting Rate of EvaporationShimnu MoneОценок пока нет

- 12.elastic ConstantsДокумент18 страниц12.elastic ConstantsaderancОценок пока нет

- Week No.2 - CLO-1 Size ReductionДокумент18 страницWeek No.2 - CLO-1 Size ReductionkhalifaОценок пока нет

- SuperPur Product InformationДокумент1 страницаSuperPur Product InformationRamОценок пока нет

- Corrosion of Iron: An Electrochemical ProcessДокумент5 страницCorrosion of Iron: An Electrochemical ProcessVickyОценок пока нет

- Contrac BloxДокумент4 страницыContrac Bloxwahyu99Оценок пока нет

- How To Make Black PowderДокумент7 страницHow To Make Black Powder8mhno100% (1)

- 85 TPH CFBC Boiler Operation and Maintenance ManualДокумент152 страницы85 TPH CFBC Boiler Operation and Maintenance ManualAamirMalik100% (1)

- IEEE Xplore - SearchResultДокумент4 страницыIEEE Xplore - SearchResultSalman KhanОценок пока нет

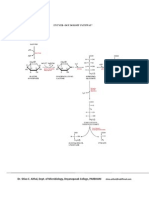

- Entner Duodroff PathwayДокумент2 страницыEntner Duodroff PathwayDr. SHIVA AITHALОценок пока нет

- Properties of Matter PresentationДокумент9 страницProperties of Matter PresentationMica Ela MañoОценок пока нет

- Chapter 7 PDFДокумент36 страницChapter 7 PDFRbtl BañosОценок пока нет

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionДокумент3 страницы1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaОценок пока нет

- Problem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of AДокумент8 страницProblem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ARadica AyuОценок пока нет

- Sample Paper For ChemistryДокумент23 страницыSample Paper For ChemistryAmit joshiОценок пока нет

- 1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereДокумент4 страницы1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDavid Hernández EscobarОценок пока нет

- LP2 SCI-12 MICROBIO LABORATORY-fINALДокумент21 страницаLP2 SCI-12 MICROBIO LABORATORY-fINALJOHNERROL CARCELLARОценок пока нет

- Common Causes of Tire Coupling FailuresДокумент8 страницCommon Causes of Tire Coupling FailuresIgor San Martín PeñalozaОценок пока нет