Академический Документы

Профессиональный Документы

Культура Документы

Equipment Group:: Intermediate Inspection Criteria, Well Control Equipment

Загружено:

kaleem ullah jan0 оценок0% нашли этот документ полезным (0 голосов)

173 просмотров2 страницыОригинальное название

stand pipe manifold

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

173 просмотров2 страницыEquipment Group:: Intermediate Inspection Criteria, Well Control Equipment

Загружено:

kaleem ullah janАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

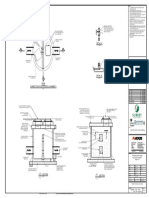

Intermediate Inspection Criteria, Well Control Equipment

Equipment Group: Stand Pipe Manifold

Drilling Contractor :

Rig Unit Number – Contractor :

Rig Unit Number – PDO :

Present Well Location :

Date :

Stand Pipe Manifold / High Pressure Lines ( 1-Yearly )

Make/Brand:

Type:

Serial Number:

Year of Manufacturing

When: Conducted by:

Last Major Maintenance

Last Intermediate Maintenance

Note :

1. No heating, welding, or cutting is allowed on any part of this equipment.

2. Welding repair work to be certified by 3rd party.

3. 3rd party is required for NDT, US and pressure testing.

4. PTW is required for pressure tests in the field.

5. Hammer unions to be inspected as per EP 2006-5393

Visual Done / Comments

Inspection Correct?

YES NO

1 Remove, degrease and pressure clean inside

and out side of pipes and manifold.

2 Dismantle hammer type connection manifold

3 Pressure clean all hammer unions.

4 Carry out visual inspection for any wear,

corrosion and wash out.

5 Visual and dimensional check of male wing

half

6 Visual and dimensional check of female

union thread half

7 Visual and dimensional check male hub

8 Visual and dimensional check of segment

9 Measure wall thickness on full length of pipes

and manifold at interval of 1mtr. (US Test

compare with original) The test points must

cover the pipes 360º of circumference.

(minimum of 1 measure point between 2

valves)

10 Measure wall thickness on inside and outside

curves of Tees and elbows.

11 Check pressure gauges against calibrated test

gauge.

9 Check to ensure that all valves are moving

freely and stem packing is in good

condition.(if not change with the OEM

spares) and handles are secured

10 Valve No-1 Ser No:

Well Control Equipment Intermediate Inspection: Stand Pipe Manifold Generated by: WCF

Page 1 of 2

11 Valve No-2 Ser No:

12 Valve No-3 Ser No:

13 Valve No-4 Ser No:

14 Valve No-5 Ser No:

15 Valve No-6 Ser No:

16 Valve No-7 Ser No:

17 Valve No-8 Ser No:

18 Valve No-9 Ser No:

19 Valve No-10 Ser No:

20 Assemble all pipes and manifold. Grease all

valves.

21 Pressure test to working pressure, complete

assembly from Mud pump with manifold, up

to goose neck

22 Isolation valve between SP 1 & SP 2 to be

tested both directions

23 Individually pressure test each valve on

manifold to working pressure.

All above Name : Company : Date : Signature :

Inspections &

Tests conducted

by :

(Authorized Third

Party Inspection

Company)

Agreed by :

(Contractor Rig

Manager)

Verified by :

(PDO Site

Representative)

Authorized by :

(Contractor DS)

Seen by :

(PDO SWE)

Well Control Equipment Intermediate Inspection: Stand Pipe Manifold Generated by: WCF

Page 2 of 2

Вам также может понравиться

- HP Hoses PDFДокумент2 страницыHP Hoses PDFKaleem UllahОценок пока нет

- Maintenance Schedule For BOP - 5131086 - 01Документ4 страницыMaintenance Schedule For BOP - 5131086 - 01franko guddiОценок пока нет

- 11 5K 5K Annular BOPДокумент4 страницы11 5K 5K Annular BOPEdwin MP0% (1)

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleДокумент2 страницыIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahОценок пока нет

- DRAFT - Requirements For Pressure TestingДокумент3 страницыDRAFT - Requirements For Pressure TestingAdhie WaelacxhОценок пока нет

- 00-24 Proper Clamps Mud HoseДокумент2 страницы00-24 Proper Clamps Mud Hoseforajistu100% (1)

- Tesco Corporation: Unit #: Date: Operating DaysДокумент1 страницаTesco Corporation: Unit #: Date: Operating Daysboy tryadiОценок пока нет

- 26" Section - Cementing - Checklist.Документ2 страницы26" Section - Cementing - Checklist.Yougchu Luan100% (1)

- Contitech HP HosesДокумент65 страницContitech HP HosesRobert FlateråsОценок пока нет

- Drillpipe and Bottom Hole Assembly StandardsДокумент2 страницыDrillpipe and Bottom Hole Assembly StandardsSasan Abbasi100% (1)

- SOP GTC 100-02-012 Lower The MastДокумент2 страницыSOP GTC 100-02-012 Lower The Mastakv9005Оценок пока нет

- LPR-N Tester Valve Funcionamiento 1Документ33 страницыLPR-N Tester Valve Funcionamiento 1Александр КинтероОценок пока нет

- Check List For SOBM Take On BoardДокумент5 страницCheck List For SOBM Take On BoardVimal SinghОценок пока нет

- 13.625 Inch BOP Test Sequence.Документ1 страница13.625 Inch BOP Test Sequence.jsarmaОценок пока нет

- HH SwivelДокумент3 страницыHH SwivelHoracio LafuenteОценок пока нет

- Sidetracking PrinciplesДокумент3 страницыSidetracking PrinciplesDon BraithwaiteОценок пока нет

- Wellhead - Saquib ErbilДокумент109 страницWellhead - Saquib ErbilYasir AhmedОценок пока нет

- JZ Mechanical Drilling JarДокумент4 страницыJZ Mechanical Drilling Jarsaeed65100% (1)

- 453-Changing of BOP RamsДокумент4 страницы453-Changing of BOP RamsDian SikumbangОценок пока нет

- HT and XT Running and Handling SeminarДокумент38 страницHT and XT Running and Handling SeminarNhoj AicragОценок пока нет

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualДокумент12 страницDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartОценок пока нет

- Lot Pit CSG TestДокумент18 страницLot Pit CSG TestsrikantaLeeОценок пока нет

- Drill Pipe Spec SheetДокумент2 страницыDrill Pipe Spec SheetVijay KotiОценок пока нет

- 13.625 10K Double Cameron U BOP PDFДокумент2 страницы13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Skid Mounted Test UnitДокумент30 страницSkid Mounted Test UnitSALIM ALI AFIFFОценок пока нет

- Pipe Installation Us PDFДокумент17 страницPipe Installation Us PDFTeguh Setiono100% (1)

- BOP Certification ChecklistДокумент2 страницыBOP Certification ChecklistramptgdОценок пока нет

- Special Services Presentation - 18 June 2018 Rev 1Документ23 страницыSpecial Services Presentation - 18 June 2018 Rev 1Juan CamachoОценок пока нет

- 2-36, TMC Jar, OpДокумент15 страниц2-36, TMC Jar, OpAli HosseiniОценок пока нет

- Drilling Abbreviations For ReportingДокумент10 страницDrilling Abbreviations For ReportingLeon Monsalve100% (1)

- CP-MP-001 Mud PumpsДокумент6 страницCP-MP-001 Mud PumpsEd CalheОценок пока нет

- ISS-059 Inspection Guidlines HP HosesДокумент7 страницISS-059 Inspection Guidlines HP HosesforajistuОценок пока нет

- Tubular & Drillstring Design - Shell Well Eng. NotebookДокумент54 страницыTubular & Drillstring Design - Shell Well Eng. NotebookReza BorahОценок пока нет

- BOP Choke Man Inspection ProcedureДокумент13 страницBOP Choke Man Inspection ProcedureAhmed Imtiaz Rao100% (2)

- Facts & Myths of HardbandingДокумент3 страницыFacts & Myths of Hardbandingsdb158Оценок пока нет

- Used Sucker Rod GuidelinesДокумент2 страницыUsed Sucker Rod Guidelinesluisfilippini3Оценок пока нет

- AAX Tong MaintenanceДокумент7 страницAAX Tong MaintenanceBahman Matouri100% (1)

- 20-1701 Slips DCSДокумент7 страниц20-1701 Slips DCSRahul M.RОценок пока нет

- Type B Tubing Anchor PsДокумент1 страницаType B Tubing Anchor PsPedro Antonio Mejia SuarezОценок пока нет

- Sand Bailer / Pump BailerДокумент2 страницыSand Bailer / Pump BailerxavierОценок пока нет

- Trmaxx Series Safety Valves PDFДокумент2 страницыTrmaxx Series Safety Valves PDFArturo Treviño MedinaОценок пока нет

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Документ3 страницыDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoОценок пока нет

- 00087167Документ11 страниц00087167JohnSmith100% (1)

- Operation Manual 11-3000psi Shear Ram BopДокумент30 страницOperation Manual 11-3000psi Shear Ram BopBoedi SyafiqОценок пока нет

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallДокумент6 страницMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueОценок пока нет

- Maintenance Steps of Mud Gas SeparatorДокумент1 страницаMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- Sand Control Screen Plugging & ControlДокумент14 страницSand Control Screen Plugging & ControlQaiser HafeezОценок пока нет

- Manual: CDQ (S) Sucker Rod ElevatorsДокумент5 страницManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaОценок пока нет

- Re Entry WorkДокумент3 страницыRe Entry WorkAnilОценок пока нет

- Formation Integrity TestДокумент1 страницаFormation Integrity Testfad003100% (1)

- Cementing EquipmentДокумент12 страницCementing EquipmentETR0% (1)

- Gate Valve API 6AДокумент4 страницыGate Valve API 6ARicardo Paz SoldanОценок пока нет

- Manual de Partes y Mantenimiento Llave Hidraúlica ZQ127Документ25 страницManual de Partes y Mantenimiento Llave Hidraúlica ZQ127sebastián BohórquezОценок пока нет

- EXTENDED Well Control ChecklistДокумент14 страницEXTENDED Well Control ChecklistAdam InesОценок пока нет

- Certificate of Inspection/ Certificat de Inspectie Sucker Rod Elevator/ Elevator Tiji de PompareДокумент2 страницыCertificate of Inspection/ Certificat de Inspectie Sucker Rod Elevator/ Elevator Tiji de Pompareteodorescu MARIUSОценок пока нет

- Griffith Double Acting Hydraulic-Mechanical Drilling Jar - Series 431-428-440-441-480-411-437 - Operating Manual PDFДокумент0 страницGriffith Double Acting Hydraulic-Mechanical Drilling Jar - Series 431-428-440-441-480-411-437 - Operating Manual PDFMEUBROОценок пока нет

- What You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItДокумент3 страницыWhat You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItShoaib KhalilОценок пока нет

- Varel Mining CatalogДокумент24 страницыVarel Mining CatalogEmerson Phocco Yauli100% (1)

- High Pressure Lines PDFДокумент3 страницыHigh Pressure Lines PDFKaleem UllahОценок пока нет

- Mud Pump - High Pressure Lines PDFДокумент7 страницMud Pump - High Pressure Lines PDFKaleem UllahОценок пока нет

- Chapter 2. Economics: Economic JustificationДокумент12 страницChapter 2. Economics: Economic Justificationkaleem ullah janОценок пока нет

- Chapter 3. Shale Shakers: Principle of OperationДокумент34 страницыChapter 3. Shale Shakers: Principle of Operationkaleem ullah janОценок пока нет

- Chapter 5. Degassers: Table 5.1 Ranking of Degasser Models Manufacturer TypeДокумент4 страницыChapter 5. Degassers: Table 5.1 Ranking of Degasser Models Manufacturer Typekaleem ullah janОценок пока нет

- Chapter 4. Shaker Screens: Separation PerformanceДокумент10 страницChapter 4. Shaker Screens: Separation Performancekaleem ullah janОценок пока нет

- WDI Toolpusher Reference Manual Hydraulics: © 2008 Weatherford International. All Rights ReservedДокумент46 страницWDI Toolpusher Reference Manual Hydraulics: © 2008 Weatherford International. All Rights Reservedkaleem ullah janОценок пока нет

- Chapter 1. IntroductionДокумент2 страницыChapter 1. Introductionkaleem ullah janОценок пока нет

- Image Processing Based Toll Automation Technique Using ANPR 1Документ6 страницImage Processing Based Toll Automation Technique Using ANPR 1kaleem ullah janОценок пока нет

- MimicDet Bridging The Gap BetweenДокумент16 страницMimicDet Bridging The Gap Betweenkaleem ullah janОценок пока нет

- MimicDet Bridging The Gap BetweenДокумент16 страницMimicDet Bridging The Gap Betweenkaleem ullah janОценок пока нет

- M 1 Toll Rates Peshawar Islamabad KM 161 3Документ7 страницM 1 Toll Rates Peshawar Islamabad KM 161 3kaleem ullah janОценок пока нет

- M 3 Toll Rates Lahore Abdul Hakeem KM 228 2Документ7 страницM 3 Toll Rates Lahore Abdul Hakeem KM 228 2kaleem ullah janОценок пока нет

- (Eng) Prohibitions That Are Taken Too LightlyДокумент53 страницы(Eng) Prohibitions That Are Taken Too Lightlyobl97Оценок пока нет

- Activity4 PDFДокумент2 страницыActivity4 PDFUrsap BuddyОценок пока нет

- Toll ReferenceДокумент5 страницToll ReferenceManikantaswamy TОценок пока нет

- Stuck Pipe Self Learning CourseДокумент65 страницStuck Pipe Self Learning Courseafreis29100% (2)

- Geological Disaster Recognition On Optical Remote Sensing Images Using Deep Learning PDFДокумент10 страницGeological Disaster Recognition On Optical Remote Sensing Images Using Deep Learning PDFkaleem ullah janОценок пока нет

- Ex 4 1 FSC Part2 Ver 2 3 1 PDFДокумент10 страницEx 4 1 FSC Part2 Ver 2 3 1 PDFSikandar KhanОценок пока нет

- Pakistan Drill-In Fluids PresentationДокумент28 страницPakistan Drill-In Fluids Presentationkaleem ullah janОценок пока нет

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESДокумент3 страницыIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janОценок пока нет

- Asme B16.4 2006 PDFДокумент30 страницAsme B16.4 2006 PDFКонстантинПаечкинОценок пока нет

- Instrumentation Design BasisДокумент49 страницInstrumentation Design BasisJayesh Sangani100% (3)

- Butt Weld Fitting B16.9 A.403Документ16 страницButt Weld Fitting B16.9 A.403Jimmy ChanОценок пока нет

- Procurement (MEP VENDERS)Документ4 страницыProcurement (MEP VENDERS)Skylink Estimation TeamОценок пока нет

- TT MultiV 5 AirSourceSystem Install TipsДокумент10 страницTT MultiV 5 AirSourceSystem Install TipsMatthewОценок пока нет

- QB78 CO2 Air Rifle TuningДокумент14 страницQB78 CO2 Air Rifle Tuningaakk75100% (7)

- Ece R 110 CNGДокумент179 страницEce R 110 CNGGoran KosticОценок пока нет

- Manual Operated Grader For Round Vegetables.1Документ58 страницManual Operated Grader For Round Vegetables.1Leena BisenОценок пока нет

- Site Erection Procedure For Piping InstallationДокумент10 страницSite Erection Procedure For Piping InstallationIrsan HaeruddinОценок пока нет

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsДокумент6 страницTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDОценок пока нет

- Plate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Документ16 страницPlate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Jacob PhilipОценок пока нет

- PVC Large-Diameter DWV Fittings: BR-LDFДокумент4 страницыPVC Large-Diameter DWV Fittings: BR-LDFBruce DoyaoenОценок пока нет

- Welder Testing Procedure 2014 2Документ3 страницыWelder Testing Procedure 2014 2Sandip JawalkarОценок пока нет

- G SM PPLT Pip 805Документ12 страницG SM PPLT Pip 805rokan123Оценок пока нет

- Astm d3262Документ9 страницAstm d3262pieremicheleОценок пока нет

- DVS 2207-13 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-CДокумент7 страницDVS 2207-13 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-CEugenioОценок пока нет

- Valve CatalogueДокумент68 страницValve CatalogueAbu___Abdullah100% (2)

- Weld Joints and Weld Types - Part2Документ1 страницаWeld Joints and Weld Types - Part2joshua_tan_31Оценок пока нет

- B 429 - 00 Qjqyos1sruqДокумент10 страницB 429 - 00 Qjqyos1sruqGalih PutraОценок пока нет

- ITEM 1.16 Blowers For Aeration TankДокумент491 страницаITEM 1.16 Blowers For Aeration TankChad HuntОценок пока нет

- Turbo RinglockДокумент11 страницTurbo RinglockarkedОценок пока нет

- Bedding & Back Filling SpecificationДокумент3 страницыBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- Greenlee BendingДокумент22 страницыGreenlee BendingSetyohdWОценок пока нет

- Mech Cat PDFДокумент169 страницMech Cat PDFardi_a0uОценок пока нет

- ANSI C80.1-2005 For Electrical Rigid Steel Conduit PDFДокумент11 страницANSI C80.1-2005 For Electrical Rigid Steel Conduit PDFErnestoОценок пока нет

- Waterco's Master Catalogue 2021-2022Документ184 страницыWaterco's Master Catalogue 2021-2022ethan8888Оценок пока нет

- Recommended Spares - AllДокумент14 страницRecommended Spares - AllAkshat RastogiОценок пока нет

- Pig SignalДокумент4 страницыPig SignalDenstar Ricardo SilalahiОценок пока нет

- Uponor PRO " Manifold - Technical Guideline: Uponor Underfloor Heating and CoolingДокумент6 страницUponor PRO " Manifold - Technical Guideline: Uponor Underfloor Heating and CoolingCristi CoroamaОценок пока нет

- Flow Control Chamber DdrawingДокумент1 страницаFlow Control Chamber DdrawingPranav KumarОценок пока нет