Академический Документы

Профессиональный Документы

Культура Документы

ATTACH 3 LOG SHEET Updated

Загружено:

Hedi Ben MohamedОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ATTACH 3 LOG SHEET Updated

Загружено:

Hedi Ben MohamedАвторское право:

Доступные форматы

Section 1 – Maintenance Contacts List

Service / Repair Contacts

Organization or

Name & Position Telephone Cell Phone e-mail

Company

Water Testing Lab

Water Testing Lab

Pump Supplier

Equipment Vendor

Equipment Vendor

Equipment Vendor

Rental Equip

Chemical Supplier

Chlorine Supplier

Electrical Contractors

Safe Dig / One Call

Excavating

Contractors

Eng. Consultants

Page 1 of 12 O&M Manual and Preventative Maintenance Log Template

Section 2 - Bound and Indexed Equipment

Manufacturer Manuals

Source or Sources of Water (Unique ID #)

Types of Treatment (e.g., Chlorination, Filtration, etc.)

Chlorine Feed Equipment (Size, Mfr & Model)

Ammonia Feed Equipment (Size, Mfr & Model)

Ortho/Polyphosphate Feed Pumps (Size, Mfr & Model)

Other Chemical Feed Equipment (Size, Mfr & Model)

Treatment Equipment (Size, Mfr & Model)

Treatment Equipment (Size, Mfr & Model)

Treatment Equipment (Size, Mfr & Model)

Standby Power Equipment (Size, Mfr & Model)

Major Controls

Control Valves (Size, Mfr & Model)

Pump Controls (Type, Mfr & Model)

Other Controls (Type, Mfr & Model)

Storage & Distribution Features

High Service Pumps (Size, Mfr & Model)

High Service Pumps (Size, Mfr & Model)

High Service Pumps (Size, Mfr & Model)

Storage Tanks (Size, Mfr & Model)

Storage Tanks (Size, Mfr & Model)

Storage Tanks (Size, Mfr & Model)

Page 2 of 12 O&M Manual and Preventative Maintenance Log Template

Section 3 - Preventative Maintenance Log

Recommended Daily Operational Duties / Preventative Maintenance

Water Record Water Plant Meter Readings

Meter Readings Calculate Total Daily Production

Inspect Well Pumps & Controls

Check Chemical Solution Tanks & Record Amount Used

Pumps & Tank Check & Record Water Levels in Storage Tanks

Levels Inspect Chemical Feed Pumps

Inspect High Service Pumps & Controls

Record Pump Run Times & Start Cycles

Check & Record Chlorine Residual at Point of Application

Sampling & Check & Record Chlorine Residual at Nearest Customer

Readings Check & Record Chlorine Residual in Distribution System at Remote Points

Check Instrumentation for Proper Input / Output

Investigate Customer Complaints

Complete a Daily Security Check

Windows, Doors, Hatches, Vents, Screens for Evidence of Tampering or Vandalism

Security

Well Caps, Vents & Seals

Security Lighting, Locks & Alarms

Inspect Fences & Gates

Recommended Weekly Operational Duties / Preventative Maintenance

Inspect Chlorine & Fluoride Testing Equipment (Calibration & Reagents)

Inspections &

Check & Record Well Pumps Pumping Rate

Conditions

Check Membrane System Pressure Differential

Clean Pump House and/or Plant Operations Office

Cleaning

Clean Water System Grounds

Check ALL Station Alarms for Proper Operation

Security

Check Stand-By Power Source to Ensure Emergency Operation

Recommended Monthly Operational Duties / Preventative Maintenance

Check & Record Electric Meters

Take Appropriate Monthly Water Quality Samples

Check & Record Static & Draw-Down (Pumping) Levels in Wells

Confirm Submittal of Monthly Operation Reports (MORs)

Lubricate Pumps, Motors, Blowers & ALL Moving/Rotating Equipment

Inspect ALL Pumps House Water Lines, Gaskets & Fittings for Corrosion & Leaks

Inspections &

Inspect Pump, Seals, Water Lines & Fittings for Corrosion & Leaks

Conditions

Listen to Pump for Unusual Noises (or signs that Bearings are Wearing Out)

Inspect Scales, Analyzer / Alarm, Oxygen Breathing Apparatus, Cross Ventilation

Inspect Filter Head for Leaks

Inspect and Add Salt to Brine Tank (i.e. Ion Exchange Only)

Run Emergency Generator, Check ALL Fluid and Fuel Levels

Test Eye Wash & Emergency Shower

Clean & Inspect Wellheads

Cleaning

Inspect & Clean Chlorine Injection Points

Inspect Tank Overflow Vent Screens, Ensure Screen Intact, Check Manway Hatch & Ensure it

Security

is Secured

Page 3 of 12 O&M Manual and Preventative Maintenance Log Template

Recommended Quarterly Operational Duties / Preventative Maintenance

Flush Dead-End Lines (Feb, May, Aug & Nov)

Cleaning Lubricate Locks

Clean, Inspect & Disinfect Aerator / Degassifier Screens, Sprayheads & Gaskets

Preventative Maintenance (PM) Recommendations

January PM Recommendations

Flush Half Distribution System

Exercise Half Fire Hydrants

February PM Recommendations (Peak Month)

Flush Remaining Distribution System & Exercise Remaining Fire Hydrants (not completed in January)

Flush Dead-End Lines (Feb, May, Aug & Nov)

Inspect, Clean & Repair Control Panels in Water Treatment Plant

March PM Recommendations

Inspect Storage Tanks for Defects & Sanitary Deficiencies

Clean Storage Tanks as Needed

Structural Inspection of Tank & Coatings

Perform Tank Coating Repairs per Mfr Specifications & Recommendations

Clean, Inspect & Disinfect Aerator / Degassifier Screens, Sprayheads & Gaskets

April PM Recommendations

Clean & Inspect Chemical Feed Lines

Clean & Inspect Chemical Solution Tank

Calibrate Chemical Feed Pumps

May PM Recommendations

Flush Distribution System

Exercise ALL Fire Hydrants & Check FH Valves

Water Plant & Pump House Building Preventive Maintenance

Flush Dead-End Lines (Feb, May, Aug & Nov)

June PM Recommendations

Contact Electrician to Check Emergency Generator & Run on Load Bank

Contact Electrician to Check Running Amps on Pumps

Make Sure Unnecessary Equipment is Properly Decommissioned

Review Emergency Response Plan – Update as Necessary

Clean, Inspect & Disinfect Aerator / Degassifier Screens, Sprayheads & Gaskets

Prepare Water System for Summer Operation (Fuel, Generators, Shutters)

Page 4 of 12 O&M Manual and Preventative Maintenance Log Template

July PM Recommendations

Building Preventive Maintenance

August PM Recommendations

Operate ALL Valves Inside Treatment Plant & Pump House

Clean & Inspect ALL Safety Equipment

Flush Dead-End Lines (Feb, May, Aug & Nov)

September PM Recommendations

Clean RO Membranes

Overhaul or Replace Pressure Relief Valves on Hydropneumatic Tanks

Test Pressure Reducing Valves & RPZs

Clean, Inspect & Disinfect Aerator / Degassifier Screens, Sprayheads & Gaskets

October PM Recommendations

Overhaul Chemical Feed Pumps

Clean & Inspect Chemical Feed Lines

Clean & Inspect Chemical Solution Tanks

Calibrate Chemical Feed Pumps after Overhaul

Test Eye Wash & Emergency Shower

November PM Recommendations

Exercise HALF of ALL Mainline Valves

Check Water Meter For Accuracy

Change Media in Filter

Flush Dead-End Lines (Feb, May, Aug & Nov)

December PM Recommendations

Exercise Remaining HALF of ALL Mainline Valves

ALL Safety Equipment - Clean & Inspect

Clean, Inspect & Disinfect Aerator / Degassifier Screens, Sprayheads & Gaskets

Clean, Inspect & Disinfect Aerator / Degassifier

Page 5 of 12 O&M Manual and Preventative Maintenance Log Template

Suggested Preventative Maintenance Log

Last

Suggested Service Service Service

Category Service

Frequency (Date) (Date) (Date)

(Date)

Well / Source Water

Clean & Inspect Pump, Controls Seals, Vent

Monthly

& Screen

Check & Record Static & Draw-Down

Monthly

(Pumping)

Water Plant & Pump House

Inspect Water Lines, Gaskets & Fittings for

Monthly

Corrosion & Leaks

Lubricate Pumps, Motors, Blowers and ALL

Monthly

Moving / Rotating Equipment

Building Preventive Maintenance Annually - July

Exercise ALL Valves Inside Treatment

Annually - Aug

Plant & Pump House

Annually - Nov

Check Water Meter For Accuracy

(or per Mfr)

High Service Pumps

Inspect Pump, Seals, Water Lines & Fittings

Monthly

for Corrosion & Leaks

Listen to Pump for Unusual Noises Monthly

Safety & Security

ALL Safety Equipment - Clean & Inspect Annually - Dec

Emergency Response Plan Review/Update Annually - June

Chemical Feed Systems (Liquid)

Inspect Pump, Seals, Water Lines & Fittings

Monthly

for Corrosion & Leaks

Clean Chlorine Injection Points Monthly

Overhaul Chemical Feed Pumps (Feeder

Head Cleaned, O-Rings, Check Valves & Annually - Oct

Diaphragms, Worn-Out Parts Replaced)

Bi-annually

Test Eye Wash & Emergency Shower

Apr & Oct

Bi-annually

Chemical Feed Lines - Clean & Inspect

Apr & Oct

Bi-annually

Chemical Solution Tanks - Clean & Inspect

Apr & Oct

Bi-annually

Calibrate Chemical Feed Pumps

Apr & Oct

Chemical Feed Systems (Gas)

Inspect Scales, Analyzer / Alarm, Oxygen

Monthly

Breathing Apparatus, Cross Ventilation

Inspect & Clean Chlorine Injection Points Monthly

Page 6 of 12 O&M Manual and Preventative Maintenance Log Template

Last

Suggested Service Service Service

Category Service

Frequency (Date) (Date) (Date)

(Date)

Aerator / Degassifer

Inspect Screens, Sprayheads & Gasket Annually - Dec

Clean, Inspect & Disinfect Aerator /

Annually - Dec

Degassifer

Filter / Water Softener

Inspect Filter Head for Leaks Monthly

Inspect and Add Salt to Brine Tank Monthly

Change Media in Filter Per Mfr - Nov

Reverse Osmosis / Membrane Softening Unit

Check Pressure Differential Weekly

Annually – Sep

Clean Membranes

or per Mfr

Replace Membranes per Mfr

Storage Tanks

Inspect Overflow Vent Screens, Ensure

Screen Intact, Check Manway Hatch & Monthly

Ensure it is Secured

Inspect Storage Tanks for Defects, Leaks &

Annually - Mar

Sanitary Deficiencies

Clean Storage Tanks if Needed Annually – Mar

Structural Inspection of Tank & Coatings by Annually - Mar

Engineer (Clean Prior to Inspection)

Perform Coating Repairs per Mfr Specs Annually - Mar

Replace Pressure Relief Valves on Annually - Sep

Hydropneumatic Tanks (or per Mfr)

Controls, Electrical & Stand-By Power

Inspect, Clean & Repair Control Panels Annually - Feb

Prepare Water System Annually - July

Run Emerg Generator Monthly

Contact Electrician to Check Emergency

Annually - Jun

Generator & Run on Load Bank

Contact Electrician to Check Running Amps

Annually - Jun

on Pumps

Distribution System

Annually

Exercise ALL Mainline Valves

Jan & Feb

Flush Distribution System & Annually

Exercise ALL Fire Hydrants Nov & Dec

Quarterly - Feb,

Flush Dead-End Lines

May, Aug & Nov

Page 7 of 12 O&M Manual and Preventative Maintenance Log Template

Mainline Valves - Annually Jan & Feb

Last Service

Valve Service Service Service

Valve Location Service (D

ID # (Date) (Date (Date)

(Date) ate)

Page 8 of 12 O&M Manual and Preventative Maintenance Log Template

Fire Hydrants - Annually Nov & Dec

Last

FH ID Service Service Service Service

Fire Hydrant Location Service

# (Date) (Date) (Date (Date)

(Date)

Page 9 of 12 O&M Manual and Preventative Maintenance Log Template

Flush Distribution System - Annually Nov & Dec

Last

Pipe ID Service Service Service Service

Pipe Segment Location Service

# (Date) (Date) (Date (Date)

(Date)

Page 10 of 12 O&M Manual and Preventative Maintenance Log Template

VALVE RECORD

Location (street / address):

Type: Make: Size:

Opens: Left Right Other: # of Turns:

Date Installed:

Date Closes/Opens? # of Valve Status

Condition of Stem, Packing, Nut, Gearing, Etc.

Exercised (Y / N) Turns (Open or Closed)

Page 11 of 12 O&M Manual and Preventative Maintenance Log Template

DEAD-END WATER MAIN FLUSHING RECORD

Location (street):

Flushing Water Characteristics

Flushing Disinfectant Residual, mg/L

Duration (color, odor, etc.)

Date

(min.) Before Flushing After Flushing Before Flushing After Flushing

Page 12 of 12 O&M Manual and Preventative Maintenance Log Template

Вам также может понравиться

- Fire Fighting Equipment Monthly Inspection ReportДокумент2 страницыFire Fighting Equipment Monthly Inspection Reportnadeem mallickОценок пока нет

- Fire Water TankДокумент1 страницаFire Water TankAnonymous yCpjZF1rFОценок пока нет

- Workmen Camp Inspection FormДокумент3 страницыWorkmen Camp Inspection Formshamshad ahamed100% (1)

- Electrical Maintenance & Testing Hazard IdentificationДокумент10 страницElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaОценок пока нет

- Risk Ass - ProcessДокумент4 страницыRisk Ass - ProcessBalakrishnan Sivagnanam SОценок пока нет

- RISK ASSESSMENT FOR Ac Cleaning ServicesДокумент5 страницRISK ASSESSMENT FOR Ac Cleaning ServicesEGSC HSEОценок пока нет

- Firehydrant System ChecklistДокумент2 страницыFirehydrant System ChecklistbaryОценок пока нет

- Appendix - Fire Protection Preventive Maintenance ScheduleДокумент5 страницAppendix - Fire Protection Preventive Maintenance Schedulemohamed attiaОценок пока нет

- MSDS - Asada Threading Oiil Red - ENДокумент7 страницMSDS - Asada Threading Oiil Red - ENnghiaОценок пока нет

- Expectations and Deliverables HSE Excellence AwardДокумент4 страницыExpectations and Deliverables HSE Excellence AwardOki EriandiОценок пока нет

- Foam InductorДокумент6 страницFoam InductorDipanjan Chakrabarti100% (1)

- Maintenance Schedule For Fire Alarm Addressable SystemДокумент2 страницыMaintenance Schedule For Fire Alarm Addressable SystemRobert LuggardОценок пока нет

- Index: Cv. Dira Utama SejahteraДокумент12 страницIndex: Cv. Dira Utama SejahteraFreshop SurabayaОценок пока нет

- Niversity of Eicester: P W P R E & F M DДокумент27 страницNiversity of Eicester: P W P R E & F M DFOZCANОценок пока нет

- 10 Percent Acid Washing SOP TemplateДокумент5 страниц10 Percent Acid Washing SOP TemplatekofinyameОценок пока нет

- EHS-2035.Safety Management Procedure - 582020Документ11 страницEHS-2035.Safety Management Procedure - 582020hoangmtbОценок пока нет

- Nitoproof 230Документ2 страницыNitoproof 230Balasubramanian Ananth50% (2)

- Construction Assessment Checklist: Green TagДокумент2 страницыConstruction Assessment Checklist: Green TagRyan GillespieОценок пока нет

- Mobile Scaffold Inspection ChecklistДокумент3 страницыMobile Scaffold Inspection Checklistanthony murphyОценок пока нет

- Checklist For Equipment Inspection Fire ExtinguisherДокумент1 страницаChecklist For Equipment Inspection Fire ExtinguisherIdada EzekielОценок пока нет

- SWP 013 Oxy Acetylene WeldingДокумент4 страницыSWP 013 Oxy Acetylene WeldingBajaj NitinОценок пока нет

- Cleaning Chlorination Water Tank Risk AnalysisДокумент2 страницыCleaning Chlorination Water Tank Risk AnalysisRamyОценок пока нет

- PPE Disposal SOPДокумент2 страницыPPE Disposal SOPAmit MakwanaОценок пока нет

- Fire Alarm MaintenanceДокумент2 страницыFire Alarm Maintenancesamantha1966Оценок пока нет

- Air Receiver Tank Hazard ChecklistДокумент2 страницыAir Receiver Tank Hazard ChecklistJade JavierОценок пока нет

- HSE 16 Incident Near Miss ReportДокумент1 страницаHSE 16 Incident Near Miss ReportBa N NhimОценок пока нет

- RA013-C Panel Electrical Work-8766Документ4 страницыRA013-C Panel Electrical Work-8766anisaanОценок пока нет

- 4 Safe Practices For ElecДокумент8 страниц4 Safe Practices For ElecSandeep GuptaОценок пока нет

- Stacker Preventive Maintenance Weekly: Clean and InspectДокумент1 страницаStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- Tripod Inspection Form - FillableДокумент1 страницаTripod Inspection Form - FillablehienleeОценок пока нет

- Compress Air Commissioning ProcedureДокумент6 страницCompress Air Commissioning Procedurevishwas salunkheОценок пока нет

- Earth Pit Maintenance Instructions MBCДокумент2 страницыEarth Pit Maintenance Instructions MBCdilipgmОценок пока нет

- Nirali H. Patel, MD Pediatric Emergency Medicine Children's Hospital Medical Center of AkronДокумент31 страницаNirali H. Patel, MD Pediatric Emergency Medicine Children's Hospital Medical Center of Akronmarsan12Оценок пока нет

- Checklist For Fire ExtinguisherДокумент1 страницаChecklist For Fire ExtinguisherJr FaizalОценок пока нет

- Jsa For PCCДокумент6 страницJsa For PCCCICON EngineersОценок пока нет

- Manual Handling ChartДокумент20 страницManual Handling ChartTatak Bay Ahmed100% (1)

- MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and PurposeДокумент2 страницыMSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purposesarge18100% (1)

- Hvac CVДокумент2 страницыHvac CVsarfaraz055Оценок пока нет

- Earth Compactor Daily Check ListДокумент2 страницыEarth Compactor Daily Check ListpjosesmОценок пока нет

- Example Risk Assessment For Food Preparation, Cooking and ServiceДокумент5 страницExample Risk Assessment For Food Preparation, Cooking and ServiceSiva Prasad100% (1)

- Form 13Документ4 страницыForm 13Jayendra NaiduОценок пока нет

- Welding Checklist 9195Документ3 страницыWelding Checklist 9195Michael PenaОценок пока нет

- 07 - TDS - Masterflow 520Документ3 страницы07 - TDS - Masterflow 520Alexi ALfred H. TagoОценок пока нет

- Working at Heights: Dr.P.MuralidharДокумент48 страницWorking at Heights: Dr.P.MuralidharRituraj SinghОценок пока нет

- Tds-Fevicol Ac Duct King Lag Coating Af 5590 LatestДокумент2 страницыTds-Fevicol Ac Duct King Lag Coating Af 5590 LatestRamakrishnan SitaramanОценок пока нет

- Contractor Ehs Risk Assessment For NDT TestingДокумент6 страницContractor Ehs Risk Assessment For NDT TestingBernard PenuliarОценок пока нет

- Jsa CompressorДокумент9 страницJsa CompressorRavi thokalОценок пока нет

- The University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Документ1 страницаThe University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Rao UmarОценок пока нет

- Catalogo Chaglin YZ12HDДокумент4 страницыCatalogo Chaglin YZ12HDIwa RizaОценок пока нет

- Safety Questions For ExaminationДокумент1 страницаSafety Questions For ExaminationAkeem Dwayne Ralph NoelОценок пока нет

- Basic Interview Related Question and Answers For Fire Pump InstallerДокумент9 страницBasic Interview Related Question and Answers For Fire Pump InstallerMuhammad AhmadОценок пока нет

- Chemical Manifest and Hazardous Chemical Substance List KathuДокумент13 страницChemical Manifest and Hazardous Chemical Substance List KathuVictorОценок пока нет

- Eyewashinspection Checklist 2012 - 0Документ1 страницаEyewashinspection Checklist 2012 - 0perezismaelОценок пока нет

- Cable Installation For - SWMSДокумент6 страницCable Installation For - SWMSthanitoОценок пока нет

- Risk Assessment and Method StatementДокумент18 страницRisk Assessment and Method StatementTijana LalovićОценок пока нет

- Safety InductionДокумент57 страницSafety Inductionlahmar asmaОценок пока нет

- Hotel Maintenance Checklist InfraspeakДокумент19 страницHotel Maintenance Checklist InfraspeakWahjuda SaputraОценок пока нет

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USДокумент9 страницPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardeОценок пока нет

- Ammonia Plant Maint.Документ11 страницAmmonia Plant Maint.mahmadwasiОценок пока нет

- Premium-Content iSOLUTIONSWaterTreatment EN INT Article-LearningДокумент4 страницыPremium-Content iSOLUTIONSWaterTreatment EN INT Article-Learningkesavaganesan58Оценок пока нет

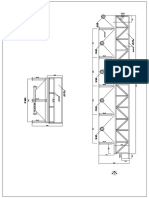

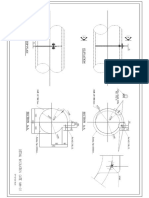

- Section Aa Section BB Fire Fighting TankДокумент1 страницаSection Aa Section BB Fire Fighting TankHedi Ben MohamedОценок пока нет

- Petroleum Development Oman L.L.C.: Document Title: H Sandso Management The Basics, Classification & Sour ContractsДокумент31 страницаPetroleum Development Oman L.L.C.: Document Title: H Sandso Management The Basics, Classification & Sour Contractsxu zhaoОценок пока нет

- Hazardous Area Hazardous Area ClassificaДокумент106 страницHazardous Area Hazardous Area ClassificaHedi Ben MohamedОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Oisd GDN 178Документ21 страницаOisd GDN 178Hedi Ben MohamedОценок пока нет

- Guidances For Single Point MooringДокумент53 страницыGuidances For Single Point Mooringgenesis L. OrtizОценок пока нет

- Decanteur Ver1Документ1 страницаDecanteur Ver1Hedi Ben MohamedОценок пока нет

- NETZSCH NEMO® Progressing Cavity Pumps ENДокумент28 страницNETZSCH NEMO® Progressing Cavity Pumps ENEduuОценок пока нет

- FG Od en V2.0Документ2 страницыFG Od en V2.0Hedi Ben MohamedОценок пока нет

- Butterfly Valve K4 PVC-U - PP - PVDF Actuator ERДокумент6 страницButterfly Valve K4 PVC-U - PP - PVDF Actuator ERHedi Ben MohamedОценок пока нет

- Cross VentilationДокумент1 страницаCross VentilationHedi Ben MohamedОценок пока нет

- Operating and Maintenance Instructions: Nemo PumpДокумент60 страницOperating and Maintenance Instructions: Nemo PumpLuis GutiérrezОценок пока нет

- Politecnico Di Torino Porto Institutional RepositoryДокумент8 страницPolitecnico Di Torino Porto Institutional RepositoryHedi Ben MohamedОценок пока нет

- Biological Odour Control System Specification - R1Документ24 страницыBiological Odour Control System Specification - R1Hedi Ben MohamedОценок пока нет

- Case Study - Fire Incident On MV of SPMДокумент4 страницыCase Study - Fire Incident On MV of SPMHedi Ben MohamedОценок пока нет

- SPM Rules June 2014 PDFДокумент55 страницSPM Rules June 2014 PDFNorman SasongkoОценок пока нет

- FG Od en V2.0Документ2 страницыFG Od en V2.0Hedi Ben MohamedОценок пока нет

- PE Fluid CompatibilityДокумент6 страницPE Fluid CompatibilityGerryОценок пока нет

- Product Technical CatalogueДокумент4 страницыProduct Technical CatalogueHedi Ben MohamedОценок пока нет

- 9434-Sfe - Sequential Functional ExtractionДокумент3 страницы9434-Sfe - Sequential Functional ExtractionHedi Ben MohamedОценок пока нет

- Multimedia Filter and Activated Carbon Filter Pilot Test StudyДокумент10 страницMultimedia Filter and Activated Carbon Filter Pilot Test StudyHedi Ben MohamedОценок пока нет

- Decanteur Ver1Документ1 страницаDecanteur Ver1Hedi Ben MohamedОценок пока нет

- Tank Pics-Filament Wound TanksДокумент3 страницыTank Pics-Filament Wound TanksHedi Ben MohamedОценок пока нет

- Amine Plant Troubleshooting and OptimizaДокумент26 страницAmine Plant Troubleshooting and OptimizaHedi Ben MohamedОценок пока нет

- Remember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Документ2 страницыRemember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Hedi Ben MohamedОценок пока нет

- Detail Isolating Gate Mh-01Документ1 страницаDetail Isolating Gate Mh-01Hedi Ben MohamedОценок пока нет

- Centrifugal Pumps - Engineering LibraryДокумент9 страницCentrifugal Pumps - Engineering LibraryHedi Ben MohamedОценок пока нет

- Remember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Документ2 страницыRemember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Hedi Ben MohamedОценок пока нет

- Remember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Документ2 страницыRemember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Hedi Ben MohamedОценок пока нет

- 47 Vocabulary Worksheets, Answers at End - Higher GradesДокумент51 страница47 Vocabulary Worksheets, Answers at End - Higher GradesAya Osman 7KОценок пока нет

- All-India rWnMYexДокумент89 страницAll-India rWnMYexketan kanameОценок пока нет

- SyerynДокумент2 страницыSyerynHzlannОценок пока нет

- Women in IslamДокумент22 страницыWomen in Islamsayed Tamir janОценок пока нет

- Spaces For Conflict and ControversiesДокумент5 страницSpaces For Conflict and ControversiesVistalОценок пока нет

- Life Without A Centre by Jeff FosterДокумент160 страницLife Without A Centre by Jeff Fosterdwhiteutopia100% (5)

- Reason and ImpartialityДокумент21 страницаReason and ImpartialityAdriel MarasiganОценок пока нет

- Discuss The Following Questions With Your Family Members Casually and Write The AnswersДокумент2 страницыDiscuss The Following Questions With Your Family Members Casually and Write The AnswersVincent Stephen AmalrajОценок пока нет

- Lae 3333 2 Week Lesson PlanДокумент37 страницLae 3333 2 Week Lesson Planapi-242598382Оценок пока нет

- Asian Parliamentary DebateДокумент10 страницAsian Parliamentary Debateryn hanakuroОценок пока нет

- Presbuteroi (Elders) and Episkopoi (Overseers) and Are Described in 1 Tim 3 and TitusДокумент15 страницPresbuteroi (Elders) and Episkopoi (Overseers) and Are Described in 1 Tim 3 and TitusNimaro Brenda100% (1)

- Child Health Services-1Документ44 страницыChild Health Services-1francisОценок пока нет

- Burton 1998 Eco Neighbourhoods A Review of ProjectsДокумент20 страницBurton 1998 Eco Neighbourhoods A Review of ProjectsAthenaMorОценок пока нет

- NR Serial Surname Given Name Middlename: Republic of The Philippines National Police CommissionДокумент49 страницNR Serial Surname Given Name Middlename: Republic of The Philippines National Police CommissionKent GallardoОценок пока нет

- Diffusion Osmosis Enzymes Maths and Write Up Exam QuestionsДокумент9 страницDiffusion Osmosis Enzymes Maths and Write Up Exam QuestionsArooj AbidОценок пока нет

- Case Study GingerДокумент2 страницыCase Study Gingersohagdas0% (1)

- Ag Advace Check 8-30Документ1 страницаAg Advace Check 8-30AceОценок пока нет

- Principles of Marketing: Quarter 1 - Module 6: Marketing ResearchДокумент17 страницPrinciples of Marketing: Quarter 1 - Module 6: Marketing ResearchAmber Dela Cruz100% (1)

- Ips Rev 9.8 (Arabic)Документ73 страницыIps Rev 9.8 (Arabic)ahmed morsyОценок пока нет

- Basic OmДокумент242 страницыBasic OmRAMESH KUMARОценок пока нет

- Ppivspiandpi G.R. No. 167715 November 17, 2010 Petitioner Respondents: Pfizer, Inc. and Pfizer (Phil.) Inc., TopicДокумент26 страницPpivspiandpi G.R. No. 167715 November 17, 2010 Petitioner Respondents: Pfizer, Inc. and Pfizer (Phil.) Inc., TopicMc Whin CobainОценок пока нет

- Multiple ChoiceДокумент3 страницыMultiple ChoiceEfrelyn CasumpangОценок пока нет

- Algebra Lineal Septima Edicion Stanley I. Grossman S. Mcgraw-Hilliinteramericana Editores S.A. de C.V Mexico, DFДокумент1 страницаAlgebra Lineal Septima Edicion Stanley I. Grossman S. Mcgraw-Hilliinteramericana Editores S.A. de C.V Mexico, DFJOSE JULIAN RAMIREZ ROJASОценок пока нет

- SBMPTN 2016 Kode 333Документ6 страницSBMPTN 2016 Kode 333Allisa MasithaОценок пока нет

- Basic Elements of Rural DevelopmentДокумент7 страницBasic Elements of Rural DevelopmentShivam KumarОценок пока нет

- Chapters Name in Sanskrit and English Setting The SceneДокумент3 страницыChapters Name in Sanskrit and English Setting The Sceneishvarchandra dasОценок пока нет

- Minimalist Aesthetics Business Plan by SlidesgoДокумент63 страницыMinimalist Aesthetics Business Plan by Slidesgorandom potatoОценок пока нет

- Posterior Cranial Fossa Anesthetic ManagementДокумент48 страницPosterior Cranial Fossa Anesthetic ManagementDivya Rekha KolliОценок пока нет

- Jao Vs Court of Appeals G.R. No. 128314 May 29, 2002Документ3 страницыJao Vs Court of Appeals G.R. No. 128314 May 29, 2002Ma Gabriellen Quijada-TabuñagОценок пока нет

- CDS11412 M142 Toyota GR Yaris Plug-In ECU KitДокумент19 страницCDS11412 M142 Toyota GR Yaris Plug-In ECU KitVitor SegniniОценок пока нет