Академический Документы

Профессиональный Документы

Культура Документы

Positive Displacement Air Blowers - Sizes 3& 4: Based On Success

Загружено:

Robert R. TiinОригинальное название

Авторское право

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPositive Displacement Air Blowers - Sizes 3& 4: Based On Success

Загружено:

Robert R. TiinHR

ROTARY

BLOWERS

Positive Displacement

Air Blowers - Sizes 3& 4

Based on Success

HR Blowers are one of the world’s leading air blower

manufacturers and have a reputation for quality, innovation

and service.

Design Features pressed-in steel shafts (size 4). The shaft

The conservative load carrying capacity of diameter of machines in the HR Blowers

the larger diameter rolling element bearings range is larger than that of earlier designs,

ensures an extended operating life. enabling increased operating pressures to

be achieved without increasing blower size.

Timing gear life is also extended by

controlled lubrication systems. GEARS: The precision ground and hardened

steel spur gears are taper mounted onto

The computer calculated impeller profiles the impeller shafts. The timing of the

ensure maximum volumetric efficiency

with minimum absorbed power without

impellers relative to each other is accurately User Benefits

maintained at all times.

sacrificing torsional rigidity. The delivered air is guaranteed

BEARINGS: The bearings are of generous to be oil free because internal

The high rigidity of the impeller / shafts proportions to give long operational life.

permits a higher pressure rise to be lubrication is unnecessary, and

Grease lubricated double row ball bearings

obtained than with other machines of because all HR Blowers Positive

are used at the drive end of the blower. In

comparable size. addition to their normal duty of carrying Displacement Air Blowers are

The generous shaft diameter keeps drive radial loads associated with the differential constructed with air gaps which

stresses low. air pressure on the rotating impellers, the completely isolate bearing and gear

Gear and shaft strength is substantially ball bearings provide axial location of the lubrication from the compression

increased by the use of taper mounted gears impellers. Parallel roller bearings at the rear chamber.

which do not need keyways for location. end splash lubrication by oil from the gears.

Noise levels are kept to a minimum.

Setting of the gear wheels to obtain correct LUBRICATION: An advanced design of Mechanical noise levels have been

timing of the impellers is simplified, a controlled gear wheel lubrication enables reduced by the running accuracy of

feature that facilitates field maintenance. the gears to operate at a high pitch line the taper mounted gears. Air noise

Precision ground and hardened steel velocity without the need for an oil pump.

is reduced by carefully designed air

gears are used to ensure smooth, silent Simple, maintenance free oil throwers fitted

ports and the elimination of

running and accurate timing of the rotating behind each bearing in the gearcase prevent

leakage of oil. resonant unbraced surfaces.

impellers. A controlled lubrication system

is provided to ensure efficient operation DIRECTION OF ROTATION: Detachable

The blower can be installed for

without waste of energy in the gearcase. mounting feet enable the blower to be either vertical or horizontal air flow

Specially designed rotary oil seals are used positioned for either vertical or horizontal simply by repositioning the

in the gearcase. This feature eliminates air flow. Standard machines have a right mounting feet. Installation costs

maintenance associated with the use of hand drive shaft for vertical air flow, and a can be reduced by versatility of

lip seals. bottom drive shaft for horizontal air flow. mounting arrangement.

If machines are required with a left hand or

Design and manufacture is in accordance The generous diameter of the drive

top drive shaft, all that needs to be done is

with metric standards. shaft permits the use of V-belt drives

turn the gearcase and trough through 180º.

Use as an Exhauster Centre timing permits clockwise or anti- without the need for a double outer

clockwise drive shaft rotation. bearing.

If used as an exhauster and dust or liquids

could be drawn into the machine due to BLOWER PROTECTION SYSTEM: (optional All machines are performance

inadequate filtration, closed end rotors extra). A number of insulated probes tested under the most arduous

should be specified. This will minimise risk projecting into the cylinder which are design conditions before despatch.

of loss of dynamic balance due to material electrically connected to one another and Air blowers can also be used as air

inside the rotors. to a junction box mounted on the blower exhausters. Performance charts on

Specification can be fitted. To operate this system a

application.

control box is also required. The protection

CASING: The cylinder and headplates are

system (UK and foreign patents granted)

manufactured from cast iron. The gearcase detects excessive closure of the fine working

is manufactured from aluminium. clearances within the blower which might be

IMPELLERS AND SHAFTS: The impellers are caused by overload. Should this happen, the

made from SG iron, and cast with integral prime mover is shut down automatically to

shafts. (size 3) and from mehanite and have prevent seizure of the blower.

Dimensions Horizontal Vertical

Flow Flow All dimensions in millimetres

Size A B C D E FH HH E FV HV G J K L M N P Q R S T U V W X Y

HR30

670 243 312 165 165 150 285 240

HR31

751 283 353 205 205 150 285 240

115 180 300 260 220 215 254 220 110 50.018/50.002 5.5/5.7 14.05/14.12 18 16 25 20 8 22

HR32

891 353 423 275 275 200 340 295

HR33

1005 410 480 333 333 200 340 295

HR40

833 293 396 200 200 200 340 8 295

HR41

954 353 456 260 260 200 340 8 295

145 220 355 315 260 255 310 250 140 65.030/65.011 7.0/7.2 17.957/18.00 18 16 26 20 22

HR42

1120 436 539

342.5 342.5 250 395 12 350

HR43

1275 513.5

616.5

420 420 300 440 12 395

Blower Performance

300 mbar 500 mbar 700 mbar 1000 mbar 300 mbar 500 mbar 700 mbar 1000 mbar

HR Speed m3/ kW m3/ kW m3/ kW m3/ kW HR Speed m3/ kW m3/ kW m3/ kW m3/ kW

Size rpm hour hour hour hour Size rpm hour hour hour hour

2720 1706 18.5 1648 29.3 1603 40.1 1548 56.2 2720 4367 42.8 4249 69.7

2500 1550 17.1 1491 26.9 1446 36.8 1390 51.7 2500 3976 39.4 3558 64.1

2300 1407 15.7 1349 24.8 1304 33.9 1247 47.5 2300 3621 36.2 3502 59.0 Maximum pressure rise for size

30 2100 1265 14.3 1208 22.7 1162 31.0 1106 43.4 33 2100 3265 33.1 3146 53.8 33 is 550 mbar See performance

1900 1123 12.9 1065 20.5 1019 28 963 39.3 1900 2909 29.9 2791 48.7 chart for details.

1700 980 11.6 923 18.3 877 25.1 821 35.1 1700 2553 26.8 2435 43.6

1500 838 10.2 780 16.2 735 22.1 678 31.0 1500 2198 23.6 2079 38.5

1300 696 8.9 638 14.0 593 19.2 1300 1842 20.5 1724 33.3

2720 2360 24.4 2291 39.1 2236 53.8 2168 75.8 2080 2951 31.5 2851 50.1 2773 68.7 2677 96.6

2500 2147 22.5 2078 35.9 2023 49.4 1955 69.6 1900 2662 28.8 2562 45.8 2484 62.8 2386 88.2

2300 1953 20.7 1884 33.1 1829 45.5 1761 64.1 1700 2340 25.7 2241 40.9 2162 56.1 2065 79.0

31 2100 1759 18.9 1690 30.2 1635 41.5 1567 58.5 40 1500 2018 22.7 1919 36.1 1840 49.5 1743 69.7

1300 1697 19.7 1597 31.3 1519 42.9 1421 60.4

1900 1566 17.0 1496 27.3 1441 37.6 1374 52.9

1100 1375 16.7 1276 26.5 1197 36.3 1100 51.1

1700 1372 15.3 1303 24.4 1248 33.6 1180 47.3

900 1058 13.6 954 21.7 875 29.7

1500 1178 13.5 1109 21.6 1054 29.6 986 41.8

1300 984 11.7 915 18.7 860 25.7 792 36.2 2080 4226 43 4100 69 4001 96 3878 135

1900 3817 39 3692 63 3592 87 3470 123

2720 3455 34.5 3356 55.9 3279 77.3

1700 3363 35 3238 57 3138 78 3016 110

2500 3144 31.7 3045 51.4 2968 71.1

41 1500 2909 31 2783 50 2684 69 2562 97

2300 2861 29.2 2763 47.3 2685 65.4

1300 2455 27 2329 43 2230 60 2107 84

32 2100 2578 26.7 2480 43.2 2402 59.7 1100 2001 23 1875 37 1776 51 1653 71

1900 2296 24.1 2197 39.1 2120 54.0 900 1546 19 1421 30 1322 41 1199 58

1700 2013 21.6 1915 35.0 1837 48.3

1500 1730 19.0 1632 30.8 1554 42.6 2080 5921 59 5750 95 5614 132

1900 5350 54 5179 87 5043 121

1300 1448 16.5 1350 26.7 1272 37.0

1700 4715 48 4544 78 4408 108

42 1500 4081 42 3909 69 3774 95

The volume of air delivered is measured at inlet conditions of 15°C and 1013 mbar absolute

1300 3446 37 3275 60 3139 83

1100 2811 31 2640 50 2504 70

Net Weight Size 30: 219kg Size 40: 466kg 900 2177 25 2006 41 1870 57

Size 31: 236kg Size 41: 500kg

2080 7530 73 7319 120

Size 32: 282kg Size 42: 600kg

1900 6806 67 6595 110

Size 33: 306kg Size 43: 680kg Maximum pressure rise for size

1700 6002 60 5791 98

43 is 550 mbar See performance

43 1500 5197 53 4987 87

chart for details.

1300 4393 46 4183 75

1100 3589 39 3378 63

900 2785 3 2574 52

Bridge Mills, Huddersfield Road, Holmfirth, West Yorkshire HD9 3TW

Tel: 01484 691858 Fax: 01484 680467 Following the Company’s policy of constant development, we reserve the right to alter any detail

specified or illustrated in this publication without notice and without incurring any obligation to

Email: sales@hrblowers.co.uk provide such modifications on machines previously delivered.

Вам также может понравиться

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallОт EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallРейтинг: 4 из 5 звезд4/5 (8)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionОт EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionРейтинг: 4 из 5 звезд4/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- DG Synchronizing PanelДокумент33 страницыDG Synchronizing PanelArvind KumarОценок пока нет

- 2 Way Switch (3 Wire System, New Harmonised Cable Colours) - Light WiringДокумент3 страницы2 Way Switch (3 Wire System, New Harmonised Cable Colours) - Light WiringamithkmОценок пока нет

- SPX-Plenty Mixer PDFДокумент24 страницыSPX-Plenty Mixer PDFkingathur26681100% (1)

- Tilting Pad Thrust BearingДокумент6 страницTilting Pad Thrust BearingChristopher GarciaОценок пока нет

- Premium Transmission Gear BoxДокумент80 страницPremium Transmission Gear BoxShipra Shalini83% (6)

- 01 Chemical ProcessДокумент333 страницы01 Chemical ProcessDavid ValladaresОценок пока нет

- Cce WL B Series 821b 921b Brochure 06-09-2009Документ28 страницCce WL B Series 821b 921b Brochure 06-09-2009Renato Evangelista100% (1)

- Cameron CCДокумент6 страницCameron CCYogesh Badhe100% (1)

- RH 120eДокумент8 страницRH 120eSawadogo Gustave NapinguebsonОценок пока нет

- Hitachi Excavator ZX200-3G & ZX200-3GДокумент11 страницHitachi Excavator ZX200-3G & ZX200-3GJi Uvex83% (6)

- Sany Excavators SY135 Tier 3Документ9 страницSany Excavators SY135 Tier 3csbersama100% (2)

- Volvo Crawler Excavators: More Care. Built inДокумент12 страницVolvo Crawler Excavators: More Care. Built inAnonymous 0PuvmpoОценок пока нет

- 6991 5066 62j DIAMEC U4 PHCДокумент132 страницы6991 5066 62j DIAMEC U4 PHCMoises Fernando Quijada ContrerasОценок пока нет

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsОт EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsРейтинг: 4 из 5 звезд4/5 (1)

- Air Changes Per HourДокумент28 страницAir Changes Per Hourkunanto kunantoОценок пока нет

- GeislingerДокумент5 страницGeislingerSameh Jeep100% (1)

- Agitator Shaft DeflectionДокумент9 страницAgitator Shaft DeflectionTan Chee MingОценок пока нет

- An-PP-001 Turboexpander Design FeaturesДокумент5 страницAn-PP-001 Turboexpander Design FeaturesSobhy GendykhelaОценок пока нет

- Sany Excavators SY135CДокумент9 страницSany Excavators SY135Ccsbersama100% (4)

- SM - Volvo g976 Motor GraderДокумент21 страницаSM - Volvo g976 Motor GraderLuan Max100% (2)

- Durotech Air System Company ProfileДокумент7 страницDurotech Air System Company ProfilejhpatelОценок пока нет

- CP PetДокумент4 страницыCP PetjayeshОценок пока нет

- RH 120e HandbookДокумент8 страницRH 120e HandbookEgyiri Frederick100% (1)

- Multi-Stage Steam Turbines: Proven Reliability and EfficiencyДокумент8 страницMulti-Stage Steam Turbines: Proven Reliability and EfficiencyAlfredo Velasquez100% (1)

- Steam TurbinesДокумент8 страницSteam TurbinesFachri Ramadhan100% (1)

- Piping Specification SheetДокумент63 страницыPiping Specification SheetNilesh Gohel100% (1)

- Mhi Integrally Geared CompressorsДокумент6 страницMhi Integrally Geared CompressorscandhareОценок пока нет

- Positive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessДокумент2 страницыPositive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessRobert R. TiinОценок пока нет

- HR Blowers Data SheetДокумент2 страницыHR Blowers Data Sheetrelli10Оценок пока нет

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileДокумент2 страницыHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94Оценок пока нет

- Compressor FS604 Data SheetДокумент4 страницыCompressor FS604 Data SheetprimmughalОценок пока нет

- Bronchure Power Plants H029 1310 E CHRIS MARINEДокумент12 страницBronchure Power Plants H029 1310 E CHRIS MARINEjennybelenОценок пока нет

- Generator Design, Frame Size 710-1250: ABB Contact For India LinksДокумент1 страницаGenerator Design, Frame Size 710-1250: ABB Contact For India Linksgurunathan14Оценок пока нет

- HPH BrochureДокумент12 страницHPH BrochureCristhian Vilca SilvestreОценок пока нет

- Abanicos para Flujo MezcladoДокумент52 страницыAbanicos para Flujo MezcladojhossielmartineauОценок пока нет

- GD NG Rotary Screws PDFДокумент8 страницGD NG Rotary Screws PDFgilar herliana putraОценок пока нет

- Compresor CentrifugoДокумент6 страницCompresor Centrifugoalegria_systemsОценок пока нет

- AG 3.1 End Suction DS Series 3422 Sterling SPA034 HR2Документ12 страницAG 3.1 End Suction DS Series 3422 Sterling SPA034 HR2KhalidОценок пока нет

- Detailed DescriptionM75 M3502SДокумент9 страницDetailed DescriptionM75 M3502SbiberiusОценок пока нет

- Fenner GearsДокумент28 страницFenner Gearsmanoj983@gmail.comОценок пока нет

- Blowers TS R: Everest Twin Lobe Rotary Air BlowersДокумент1 страницаBlowers TS R: Everest Twin Lobe Rotary Air Blowersankitsaxena123Оценок пока нет

- Wärtsilä Seals and Bearings Linesafe DatasheetДокумент4 страницыWärtsilä Seals and Bearings Linesafe DatasheetFERMIN ARTEAGAОценок пока нет

- AEROMIX Twister BrochureДокумент2 страницыAEROMIX Twister BrochureViorel HarceagОценок пока нет

- Compresores Centrifugos HДокумент14 страницCompresores Centrifugos HEduardo Ledezma100% (1)

- Pcr200 200dth BroДокумент9 страницPcr200 200dth BrojiaozhongxingОценок пока нет

- The Maximizer Pumping UnitДокумент16 страницThe Maximizer Pumping UnitJORGE ELIECER RUEDA PINZONОценок пока нет

- Case CX350B Specifications - 5 - 1Документ20 страницCase CX350B Specifications - 5 - 1Ulises Erica Mendez DufourОценок пока нет

- Turbine Meter: Above All - Accuracy and ReliabilityДокумент8 страницTurbine Meter: Above All - Accuracy and ReliabilityTITOОценок пока нет

- Heavy Equipment - Spek RH120EДокумент12 страницHeavy Equipment - Spek RH120EDavid HalomoanОценок пока нет

- Pöttinger Top / Top CДокумент20 страницPöttinger Top / Top CdividoОценок пока нет

- Screw BlowersДокумент20 страницScrew BlowersAhmed NahrawyОценок пока нет

- Hydraulic Excavator: Engine WeightsДокумент36 страницHydraulic Excavator: Engine WeightsdongОценок пока нет

- CAT - Excavadora - Orugas - 320D-320D L With C6.6 Engine - English - 2012 PDFДокумент24 страницыCAT - Excavadora - Orugas - 320D-320D L With C6.6 Engine - English - 2012 PDFTcristomoradoОценок пока нет

- Motor Grader Terex DimensionДокумент16 страницMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- GGGДокумент9 страницGGGTech RunnerОценок пока нет

- Compresor ElliotДокумент12 страницCompresor ElliotMARTINA FERRARIОценок пока нет

- Airmotor CatalogДокумент33 страницыAirmotor CataloghawyegОценок пока нет

- Study of Shaft Position in Gas Turbine Journal BearingДокумент7 страницStudy of Shaft Position in Gas Turbine Journal Bearingarindam misraОценок пока нет

- CX350B 370BДокумент20 страницCX350B 370Bfaiz aliОценок пока нет

- Cabezotes Gardner DenverДокумент8 страницCabezotes Gardner DenverChristian CardenasОценок пока нет

- BW213 40 Specs PDFДокумент4 страницыBW213 40 Specs PDFMahmoud EmamОценок пока нет

- 370lc en KatalogДокумент16 страниц370lc en KatalogI am a Celtic100% (1)

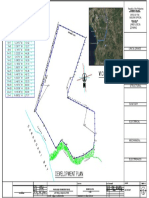

- Boundary Line 1: Service AreaДокумент1 страницаBoundary Line 1: Service AreaRobert R. TiinОценок пока нет

- Terminal Lugs. PinnionДокумент2 страницыTerminal Lugs. PinnionRobert R. TiinОценок пока нет

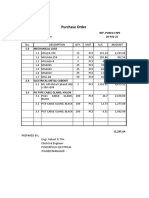

- Purchase Order: Lun Masla AquacultureДокумент2 страницыPurchase Order: Lun Masla AquacultureRobert R. TiinОценок пока нет

- Mechnical LuggsДокумент1 страницаMechnical LuggsRobert R. TiinОценок пока нет

- Vicinity Map: Land Use & ZoningДокумент1 страницаVicinity Map: Land Use & ZoningRobert R. TiinОценок пока нет

- Powerplug Electrical Goods TradingДокумент1 страницаPowerplug Electrical Goods TradingRobert R. TiinОценок пока нет

- Glamox DALI: You Define. We ConnectДокумент11 страницGlamox DALI: You Define. We ConnectRobert R. TiinОценок пока нет

- WQ Submersible Sewage Pump CH enДокумент40 страницWQ Submersible Sewage Pump CH enRobert R. TiinОценок пока нет

- Puhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryДокумент12 страницPuhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryRobert R. TiinОценок пока нет

- Ventilating Fan Specifications: Model 40KQTДокумент3 страницыVentilating Fan Specifications: Model 40KQTRobert R. TiinОценок пока нет

- EasyLogic PM2000 Series - METSEPM2110 PDFДокумент3 страницыEasyLogic PM2000 Series - METSEPM2110 PDFArabian controls switchgearОценок пока нет

- Condensing Unit Manual InstructionДокумент11 страницCondensing Unit Manual InstructionRobert R. TiinОценок пока нет

- Bahay Ni Iking - Rev04 - FLOOR PLANSДокумент1 страницаBahay Ni Iking - Rev04 - FLOOR PLANSRobert R. TiinОценок пока нет

- Cold Room Panel Specification and DataДокумент9 страницCold Room Panel Specification and DataRobert R. TiinОценок пока нет

- ABS-Encapsulated Low-Voltage Current Transformers For Indoor Use (Window-Type) - 1Документ1 страницаABS-Encapsulated Low-Voltage Current Transformers For Indoor Use (Window-Type) - 1Robert R. TiinОценок пока нет

- 65 Tons Horizontal Cement Silo Quotation 20210210Документ4 страницы65 Tons Horizontal Cement Silo Quotation 20210210Robert R. TiinОценок пока нет

- Robert Tiin LED Vapor Tight Sales QuoteДокумент1 страницаRobert Tiin LED Vapor Tight Sales QuoteRobert R. TiinОценок пока нет

- Shanghai Tongke Flow Technology Co.,Ltd Quotation List: Client: Lun Masla Aquaculture Attn: Mr. Robert R. TiinДокумент1 страницаShanghai Tongke Flow Technology Co.,Ltd Quotation List: Client: Lun Masla Aquaculture Attn: Mr. Robert R. TiinRobert R. TiinОценок пока нет

- 2-Page Product Description Amarex KRT WiДокумент2 страницы2-Page Product Description Amarex KRT WiRobert R. TiinОценок пока нет

- AQUI S AirstoneДокумент1 страницаAQUI S AirstoneRobert R. TiinОценок пока нет

- Puhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryДокумент12 страницPuhui Industry Part Project Cases in The Philippines - Suki From Puhui IndustryRobert R. TiinОценок пока нет

- Estimate FenceДокумент2 страницыEstimate FenceRobert R. Tiin100% (1)

- Solar Guide Resistance TestДокумент1 страницаSolar Guide Resistance TestRobert R. TiinОценок пока нет

- SF SummaryДокумент1 страницаSF SummaryRobert R. TiinОценок пока нет

- 8 Verti Crete Spec SheetДокумент6 страниц8 Verti Crete Spec SheetRobert R. TiinОценок пока нет

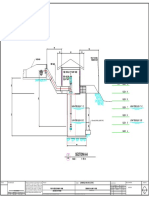

- PUMP r2Документ1 страницаPUMP r2Robert R. TiinОценок пока нет

- Finish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetДокумент5 страницFinish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetRobert R. TiinОценок пока нет

- 1.0 Building Grounding: Cost Estimate: Retrofit and RoofingДокумент2 страницы1.0 Building Grounding: Cost Estimate: Retrofit and RoofingRobert R. TiinОценок пока нет

- CPKN Complementary SizesДокумент68 страницCPKN Complementary SizesRobert R. TiinОценок пока нет

- Fig.17. Gasket Set: 3TNV80F-SPSUДокумент1 страницаFig.17. Gasket Set: 3TNV80F-SPSUliuzj7254Оценок пока нет

- 2951 0234 02 - No LoadДокумент2 страницы2951 0234 02 - No LoadAhmed DjemaiОценок пока нет

- Works Executed & Approved by JLL BhaskarДокумент15 страницWorks Executed & Approved by JLL BhaskarPraveen S JОценок пока нет

- Box 1290 060 005 (6S890 XML6925J13CN)Документ33 страницыBox 1290 060 005 (6S890 XML6925J13CN)Renner Tabraj EspinozaОценок пока нет

- OBJ01194Документ4 страницыOBJ01194cheikh ahmedОценок пока нет

- ABA-Constant-Torque Standard-DatasheetДокумент1 страницаABA-Constant-Torque Standard-DatasheetgauravОценок пока нет

- BC 1250 S - Gear Case Ass' y Exploded Parts ListДокумент9 страницBC 1250 S - Gear Case Ass' y Exploded Parts ListGoran Ristic-RileОценок пока нет

- Ezg 21Документ296 страницEzg 21Dalton WiseОценок пока нет

- DWD G1081TCДокумент36 страницDWD G1081TCAbo AhmedОценок пока нет

- SEKO Peristaltic PumpДокумент4 страницыSEKO Peristaltic PumpGovi SubramanianОценок пока нет

- Schematic DesignДокумент182 страницыSchematic DesignHendri AskoroОценок пока нет

- Speed TransДокумент5 страницSpeed Transarturo91Оценок пока нет

- AQV12VBCN - AQV12VBCN Service Manual PDFДокумент100 страницAQV12VBCN - AQV12VBCN Service Manual PDFnovyОценок пока нет

- Dealer Price List - 2023Документ10 страницDealer Price List - 2023yousufiacsОценок пока нет

- Is SEM4 Air ConditionerДокумент11 страницIs SEM4 Air ConditionerKhushi ChauhanОценок пока нет

- Electronic Devices: (Vocabulary)Документ2 страницыElectronic Devices: (Vocabulary)Avram Paula-roxanaОценок пока нет

- Winner Hydraulics - Price List: Index and Part Number Interchange ListДокумент23 страницыWinner Hydraulics - Price List: Index and Part Number Interchange ListSHANEОценок пока нет

- Schramm Chain AdjustmentДокумент4 страницыSchramm Chain AdjustmentRafaelОценок пока нет

- Pumpa Za BusilicuДокумент25 страницPumpa Za BusilicuRade ČikarićОценок пока нет

- REVIEWERДокумент5 страницREVIEWERVincent Jay MalvasОценок пока нет

- 909Документ22 страницы909S SanchitОценок пока нет

- Armado Transfer Toyota Land Cruiser J15Документ21 страницаArmado Transfer Toyota Land Cruiser J15Juan Carlos GlauserОценок пока нет

- LG SP122CNДокумент41 страницаLG SP122CNHenrry LingОценок пока нет

- My Laptop: Port, Power Jack, Projector Port, Ventilation System, Land Line Port, and Also HDMI Port Just inДокумент2 страницыMy Laptop: Port, Power Jack, Projector Port, Ventilation System, Land Line Port, and Also HDMI Port Just inherraОценок пока нет