Академический Документы

Профессиональный Документы

Культура Документы

Dormakaba: (Architectural Firm) Dormakaba MAGNEO (Project Name)

Загружено:

Sdferwste SrqreОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dormakaba: (Architectural Firm) Dormakaba MAGNEO (Project Name)

Загружено:

Sdferwste SrqreАвторское право:

Доступные форматы

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

SECTION 08 42 29 – SLIDING DOOR ENTRANCES

PART 1 GENERAL

1.1.1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

1.1.1.2 SUMMARY

A. This section includes the following types of automatic entrances:

1. Interior, single and bi-parting sliding interior automatic entrances.

B. Related Sections:

1. Division 7 Sections for caulking to the extent not specified in this section.

2. Division 08 Sections for “Aluminum-Framed Entrances and Storefronts” for entrances

furnished and installed separately in Division 8 Section.

3. Division 8 Section “Door Hardware” for hardware to the extent not specified in this

section.

4. Division 08 Section “Glazing” for materials and installation requirements of glazing for

automatic entrances.

5. Division 26 and 28 Sections for electrical connections including conduit and wiring for

automatic entrance operators and access-control devices.

1.1.1.3 REFERENCES

A. References: Refer to the version year adopted by the Authority Having Jurisdiction.

1. ANSI A117.1 - Accessible and Usable Buildings and Facilities.

2. ICC/IBC - International Building Code.

3. CUL – Approved for use in Canada.

4. NFPA 70 - National Electrical Code.

5. NFPA 101 - Life Safety Code.

B. American National Standards Institute (ANSI) / Builders Hardware Manufacturers Association

(BHMA).

1. ANSI/BHMA A156.10 American National Standard for Power Operated Pedestrian Doors.

2. ANSI/BHMA A156.38 American National Standard for Low Energy Power Operated

Sliding and Folding Doors

3. ANSI Z97.1 Standards for Safety Glazing Material Used in Buildings.

C. Underwriters Laboratories (UL).

1. UL 325 Standard for Safety for Door, Drapery, Gate, Louver and window Operators and

Systems.

D. American Association of Automatic Door Manufacturers (AAADM).

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 1 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

E. American Society for Testing and Materials (ASTM).

1. ASTM B221 Standard Specification for Aluminum and Aluminum Alloy Extruded Bars,

Rods, Wire, Profiles and Tubes.

2. ASTM B209 Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate.

F. American Architectural Manufacturers Association (AAMA).

1. AAMA 611 Voluntary Specification for Anodized Architectural Aluminum.

G. National Association of Architectural Metal Manufacturers (NAAMM).

1. Metal Finishes Manual for Architectural Metal Products.

H. International Building Code (IBC)

1. IBC: International Building Code.

1.1.1.4 DEFINITIONS

A. Activation device: Device that, when actuated, sends an electrical signal to the door operator to

initiate the door operation.

B. Monitored Safety Devices: A tested system that works in conjunction with the automatic door

control that detects the presence of a person or an object within a zone where contact could

occur and provides a signal to stop the movement of the door.

C. AAADM: American Association of Automatic Door Manufacturers.

D. For automatic door terminology, refer to BHMA A156.38 for definitions of terms.

1.1.1.5 PERFORMANCE REQUIREMENTS

A. General: Provide automatic doors that have been designed and fabricated to comply with

specified performance requirements, as demonstrated by testing manufacturers corresponding

systems.

B. Compliance:

1. ICC/IBC International Building Code

2. ANSI/BHMA A 156.38 American National Standard for Low Energy Power Operated

Sliding and Folding Doors.

3. UL 325 Listed

4. NFPA 70 National Electrical Code.

5. NFPA 101 Life Safety Code

6. CUL Approved for use in Canada

C. Automatic Door equipment accommodates light to medium pedestrian traffic.

D. Automatic Door equipment accommodates up to the following weights for active leaf door:

1. Single Slide Doors 175 lb.(80 kg) per active leaf.

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 2 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

E. Entrapment Force Requirements:

1. Power-Operated Sliding Doors: Not more than 15 lbf (67 N) required to prevent stopped

door from closing.

1.1.1.6 SUBMITTALS

A. Comply with Division 01 – Submittal Procedures.

B. Product Data: Manufacturer’s product data sheets including installation details, material

descriptions, dimensions of individual components and profiles fabrication, operational

descriptions and finishes.

C. Shop Drawings: For automatic entrances. Include plans, elevations, sections, details, hardware

mounting heights, additional accessories and attachments to other work.

D. Samples: color samples of exposed finish as required.

E. Informational Submittals: Manufacturers product information and applicable sustainability

program credits that are available towards a LEED rated product certification.

1. Credit MR 4.1 and 4.2: Manufacture’s or fabricator’s certificate indicating percentage of

post-consumer recycled content by weight and pre-consumer recycled content by weight

for each product specified under this section.

F. Manufacturers Field Reports: Submit manufacturer’s field reports from AAADM certified

technician of inspection and approval of doors for compliance with ANSI/BHMA A 156.38 after

completion of installation.

G. Operating and Maintenance Manuals: Provide manufacturers operating, owners and

maintenance manuals for each item specified as required in Division 01, Closeout Submittals.

1.1.1.7 QUALITY ASSURANCE

A. Manufacturer Qualifications: 10 years minimum of documented experience in manufacturing

door equipment similar to that indicated within this specification with a proven record of

successful service performance. A manufacturer with company certificate issued by AAADM.

B. Installer Qualifications: Installers, trained by the primary product manufacturers, with a minimum

5 years documented experience installing and maintenance of units similar in material, design,

and extent to that indicated in this specification and whose work has resulted in construction

with a record of successful in-service performance. Manufacturer's authorized representative

who is trained and approved for installation and maintenance of units by AAADM required for

this Project

C. Source Limitations for Automatic Entrances: Obtain automatic entrances from single source

from single manufacturer.

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 3 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

D. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70,

by a qualified testing agency, and marked for intended location and application.

E. Power-Operated Door Standard: ANSI/BHMA A156.38 Current year.

F. Emergency-Exit Door Requirements: Comply with requirements of authorities having jurisdiction

for automatic entrances serving as a required means of egress.

G. Pre-installation Conference: Conduct conference at site or a mutually agreed site if required.

1.1.1.8 PROJECT CONDITIONS

A. Field Measurements: Verify actual dimensions of openings to receive automatic entrances by

field measurements before fabrication.

1.1.1.9 COORDINATION

A. Coordinate hardware with doors, frames, and related work to ensure proper size, thickness,

hand, function, and finish. Coordinate hardware for automatic entrances with hardware required

for rest of project.

B. Electrical System Roughing-in: Coordinate layout and installation of automatic entrances with

connections to power supplies and access-control system.

1.1.1.10 WARRANTY

A. Automatic Entrance Doors shall be free of defects in material and workmanship for a period of

One (1) year from the date of substantial completion.

B. During the warranty period a factory trained technician shall preform service and affect repairs.

A safety inspection shall be performed after each adjustment or repair and a completed

inspection form submitted to the owner.

C. During the warranty period all warranty work shall be performed during normal working hours.

PART 2 - PRODUCTS

2.1.1.1 MANUFACTURER

A. dormakaba • Reamstown, PA • 1-844-SPEC-NOW (1-844-773-2669) • Website:

www.dormakaba.us • Email: specnow.us@dormakaba.com

Choose the substitution clause applicable for the project select item ‘B” or “C”

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 4 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

B. [Substitutions: Requests for substitution and product approval in compliance with the

specification must be submitted in writing and in accordance with the procedures

outlined in Division 1, Section “Substitution Procedures”. Approval of requests is at the

discretion of the architect, owner, and their designated consultants.]

C. [Substitutions: Not Permitted.]

Choose type or multiple type of door configurations for the project. This is a single slide system two

independent door systems would be connected together to achieve a Bi parting Slider.

2.1.1.2 SLIDING AUTOMATIC ENTRANCES

A. Model: dormakaba, MAGNEO Single Slide automatic door. (Basis of Design)

1. Sliding Automatic Door Configuration:

a. Single slide active leaf door system.

1) Configuration: Single slide one sliding leaf.

2) Traffic Pattern: Two –Way

3) Header Mounting: [On Wall] [In wall] [On Glass]

4) Sliding Panel Mounting: [Manet through Glass] [Clamp rail top edge of

Glass]

B. Model: dormakaba MAGNEO Bi Parting Automatic Doors (Basis of Design)

1. Sliding Automatic Door Configuration:

a. Bi-Parting, Two (2) independent Single Sliding active leaf door systems,

1) Configuration: Two sliding leaves. (two systems)

2) Traffic Pattern: Two –Way

3) Header Mounting: [On Wall] [In wall] [On Glass]

4) Sliding Panel Mounting: [Manet through Glass] [Clamp rail top edge of

Glass]

C. Dimensions: Confirm door package dimensions as indicated on architectural drawings.

2.1.1.3 DOOR OPERATORS

A. Drive System: Linear Magnetic Drive (LMD) - By using the attraction and repulsion of magnets,

a computer controlled set of coils pushes and pulls the door, open and closed. This Technique

allows the door to operate effortlessly without belts, pulleys gears or motors.

1. Operator Features:

a. Power opening and closing.

a. Adjustable opening and closing speeds.

b. Adjustable hold-open time between 0 and 30 seconds.

c. Obstruction recycle.

d. Intergraded access control capabilities.

2. Door Switches: Interior side mounted program switches consisting of:

a. Main Switch-Auto-Close-Open, operates door in automatic mode, turns door off, or

keeps it fully open.

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 5 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

B. Rollers: .75 inches (19 mm) diameter Delrin wheels with self-lubricating sealed ball bearing

cores. Sliding door(s) stabilized on the track by top and bottom captured wheels

Consult SPEC NOW for additional glazing options or solid panel options.

C. Glass: Glazing shall comply with ANSI Z97.1 thickness as indicated.

1. Glazing Active Door Panels [3/8” (10mm)] to [ 1/2” (13 mm)] tempered unless otherwise

specified.

2. Glazing Sidelite Door Panels [3/8” (10 mm)] to 1/2” (13 mm)] tempered unless

otherwise specified

3. Glazing Installation: Review Division 8 Section for glazing requirements.

D. Handle Types (optional):

1. [Recessed pull handle]

2. [1” Stainless Steel Back-to-Back vertical pull handles 13-3/4” overall (350mm)]

3. [1” Stainless Steel Back-to-Back vertical pull handles 28-3/8” overall (720mm)]

E. Solid Panel: Accommodates [1 ½” (38mm) to 1 ¾” (44 mm)] Solid Door.

1. [Solid panel furnished by others]

Choose appropriate door opening sizes

F. Field adjustable clear opening widths based on operator header length:

1. [Header and track size of 72” in length to obtain a clear door opening width of up

to 34”]

2. [Header and track size of 82” in length to obtain a clear door opening width of up

to 39”]

3. [Header and track size of 92” in length to obtain a clear door opening width of up

to 44”]

2.1.1.4 ACTIVATION AND SAFETY

A. Provide controls complying with cited BHMA standard for condition of exposure and for long-

term, maintenance-free operation under normal traffic load. Coordinate controls with door

operation and door operators.

Select additional activation devices for the sliding door operations.

B. Activation Device: [Push-plate switch] [wireless touch plate] [wireless touchless switch]

[on each side of door] [access control activator] to activate door operator.

When sensor activation is selected in lieu of “knowing act”, revise specification to meet requirements of

ANSI/BHMA A156.10

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 6 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

C. [Monitored Combination Motion/Presence Sensors: Self-contained units; consisting of

both motion and presence sensors in a single housing; adjustable to provide detection

field sizes and functions required by BHMA A156.38.

1. Motion Sensor: K-band-frequency, active infrared technology.

a. Provide capability for switching between bidirectional and unidirectional

detection.

b. For one-way-traffic entrances, sensor on egress side shall not be active

when doors are fully closed.]

2.1.1.5 ELECTRICAL

A. Electrical: 115VAC; 50/60 Hz.

2.1.1.6 HARDWARE

A. Automatic Locking for Sliding Door: Electrically controlled device mounted in header that

automatically locks door against sliding when in closed position. Use battery back up to insure

enhanced level of security.

B. Threshold: No Track is required adjacent to wall or sidelite panels. Only a 2 ½” (63mm) wide

guide bracket at the floor.

.

2.1.1.7 ALUMINUM FINISHES

A. Comply with NAAMM's "Metal Finishes Manual for Architectural and Metal Products" for

recommendations for applying and designating finishes.

B. Anodized Finish:

1. [Clear Anodic Finish: AAMA 611, AA-M12C22A31, Class II, 0.010 mm].

2. [Dark Bronze Anodic Finish: AAMA 611, AA-M12C22A44, Class I, 0.018 mm].

3. [Color Anodic Finish: AAMA 611, AA-M12C22A44, Class I, 0.018 mm]. [To match

architects sample]

C. Painted Finish:

1. [Powder coat painted to match architects sample] [Manufactures standard colors]

2. Kynar paint finish, [2 coat] [3 coat] [to match architects sample]

D. Clad Finish: Cladding shall be factory finished at manufacturers facility using .36 thick metal

cladding panel surface utilizing tesa® 4965 tape. Heat and humidity resistant, the specialized

adhesive tape is comprised of a polyester backing coated on both sides with a transparent

modified acrylic adhesive and a tensile strength of 20 N/cm. tesa® 4965 is recognized per UL

standard 969. UL file: MH 18055.

1. [Stainless Steel with No. 4 Satin Finish]

2. [Stainless Steel with No. 8 Mirror Finish]

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 7 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

3. [Bronze with No. 4 Satin Finish]

4. [Bronze with No. 8 Mirror Finish]

Consult SPEC NOW Center for customized finish options.

EXECUTION

PART 3 - EXECUTION

2.1.1.1 EXAMINATION

A. Examine doors and frames with Installer present, for compliance with requirements for

installation tolerances, wall and floor construction and other conditions affecting performance of

automatic entrances.

B. Examine roughing in for electrical source power to verify actual locations of wiring connections.

C. Proceed with installation only after unsatisfactory conditions have been corrected.

3.1.1.1 INSTALLATION

A. General: Do not install damaged components. Fit frame joints to produce hairline joints free of

burrs and distortion. Rigidly secure non-movement joints.

B. Entrances: Install automatic entrances plumb and true in alignment with established lines and

grades without warp or rack of framing members and doors. Anchor securely in place.

1. Install surface-mounted hardware using concealed fasteners to greatest extent possible.

2. Set headers, carrier assemblies, tracks, operating brackets, and guides level and true to

location with anchorage for permanent support.

C. Door Operators: Connect door operators to electrical power distribution system as specified in

Division 26 Sections.

D. Glazing: Install glazing as specified in Division 08 Section Glazing according to automatic door

manufactures instructions.

E. Signage: Apply signage on both sides of each door and each sidelight as required by

BHMA/ANSI A 156.38.

3.1.1.2 FIELD QUALITY CONTROL

A. Manufacturer’s representative shall provide technical assistance and guidance for installation of

automatic doors.

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 8 of 9

dormakaba

1-844-SPEC-NOW

specnow@dorma.com

[ARCHITECTURAL FIRM] dormakaba MAGNEO

[PROJECT NAME] LOW ENERGY POWER OPERATED SLIDING DOORS

1. Factory trained and AADM certified representative shall test and inspect each automatic

door to determine compliance of the installed system to BHMA/ANSI 156.38

3.1.1.3 ADJUSTING

A. Adjust door operators, controls, and hardware for smooth and safe operation.

3.1.1.4 CLEANING AND PROTECTION

A. Clean glass and metal surfaces promptly after installation. Remove excess glazing and sealant

compounds, dirt, and other substances. Repair damaged finish to match original finish.

1. Comply with requirements in Division 08 Section "Glazing" for cleaning and maintaining

glass.

3.1.1.5 DEMONSTRATION

A. Engage a factory authorized representative to train Owner's maintenance personnel to adjust,

operate, and maintain safe operation of automatic entrances.

END OF SECTION

dormakaba 08 42 29 SLIDING DOOR ENTRANCES

MAGNEO Page 9 of 9

Вам также может понравиться

- Template 084229 Esa 500 All Glass Automatic Sliding Doors Rev20230406Документ9 страницTemplate 084229 Esa 500 All Glass Automatic Sliding Doors Rev20230406Royal LockОценок пока нет

- Template 084229 Esa Fine Frame 400t Automatic Sliding Doors Rev20230406Документ9 страницTemplate 084229 Esa Fine Frame 400t Automatic Sliding Doors Rev20230406Royal LockОценок пока нет

- Template 084229 Esa 100t Automatic Sliding Doors Rev20230406Документ10 страницTemplate 084229 Esa 100t Automatic Sliding Doors Rev20230406Royal LockОценок пока нет

- Template 084229 Esa 200 300 Series Automatic Sliding Doors v1Документ11 страницTemplate 084229 Esa 200 300 Series Automatic Sliding Doors v1Akmal MaulanaОценок пока нет

- Ficha Técnica Automatizada STANLEY Dura-GlideBrochure2 PDFДокумент12 страницFicha Técnica Automatizada STANLEY Dura-GlideBrochure2 PDFRene JaquezОценок пока нет

- 087100-Door HardwareДокумент7 страниц087100-Door HardwareAmogh SwamyОценок пока нет

- SECTION 08 71 13 Automatic Door OperatorsДокумент9 страницSECTION 08 71 13 Automatic Door OperatorsJuanPaoloYbañezОценок пока нет

- 08 33 23 Overhead Coiling DoorsДокумент14 страниц08 33 23 Overhead Coiling Doorsomar shadyОценок пока нет

- SECTION 08 42 33 Revolving Door EntrancesДокумент14 страницSECTION 08 42 33 Revolving Door EntrancesJuanPaoloYbañezОценок пока нет

- Overhead Coiling Doors SpecsДокумент10 страницOverhead Coiling Doors SpecsAHMAD SHОценок пока нет

- Spek AluminiumWindows PDFДокумент13 страницSpek AluminiumWindows PDFSantoso Simanjuntak100% (1)

- Prescriptive SpecificationДокумент10 страницPrescriptive SpecificationDebbie Jhem DicamОценок пока нет

- SECTION 08 41 13 Aluminum-Framed Entrances and StorefrontsДокумент13 страницSECTION 08 41 13 Aluminum-Framed Entrances and StorefrontsJuanPaoloYbañezОценок пока нет

- 32 31 00safДокумент13 страниц32 31 00safbrian walter abarintosОценок пока нет

- Aluminum WindowsДокумент14 страницAluminum Windowshayat49000Оценок пока нет

- Acousti-Seal Premier Electric (933E) Technical DataДокумент18 страницAcousti-Seal Premier Electric (933E) Technical Datamohammed yousufОценок пока нет

- Air CurtainsДокумент5 страницAir Curtainsadel rihanaОценок пока нет

- Aluminum SpecsДокумент8 страницAluminum SpecsDinesh RathorОценок пока нет

- SP-008 Doors and WindowsДокумент100 страницSP-008 Doors and WindowsmcbluedОценок пока нет

- FL - Aluminum Doors and WindowsДокумент9 страницFL - Aluminum Doors and WindowsAmro Ahmad AliОценок пока нет

- Glazed Aluminum Curtain WallsДокумент22 страницыGlazed Aluminum Curtain Wallsnvdinh511Оценок пока нет

- SECTION 08 56 53 Blast Resistant WindowsДокумент10 страницSECTION 08 56 53 Blast Resistant WindowsJuanPaoloYbañezОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsДокумент16 страницITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsuddinnadeemОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300: 08520-1 Aluminum WindowsДокумент7 страницITCC in Riyadh Residential Complex J10-13300: 08520-1 Aluminum WindowsuddinnadeemОценок пока нет

- OpeningsДокумент159 страницOpeningssadoonОценок пока нет

- Section 12494 Roller ShadesДокумент5 страницSection 12494 Roller ShadesMØhãmmed ØwięsОценок пока нет

- Division 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralДокумент10 страницDivision 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralOrin Orang InsyafОценок пока нет

- FL - Sliding Aluminum Framed Glass Doors - AvantiДокумент6 страницFL - Sliding Aluminum Framed Glass Doors - AvantiMichelle GozonОценок пока нет

- Fall Protection Equipment Systems: Section 07700 Roof Specialties and AccessoriesДокумент14 страницFall Protection Equipment Systems: Section 07700 Roof Specialties and AccessoriesDeana WhiteОценок пока нет

- 3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageДокумент9 страниц3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageRОценок пока нет

- 2d Contoh SPEC ACP - InternasionalДокумент16 страниц2d Contoh SPEC ACP - InternasionalLukas SuryanataОценок пока нет

- University of Houston Master Construction SpecificationsДокумент9 страницUniversity of Houston Master Construction SpecificationsParvez Syed RafiОценок пока нет

- Aluflam Fire-Rated Aluminum Full Vision Doors and Frames - 3-Part SpecificationДокумент7 страницAluflam Fire-Rated Aluminum Full Vision Doors and Frames - 3-Part Specificationlink4biz1974Оценок пока нет

- Aluminum Doors Product Guide SpecificationДокумент6 страницAluminum Doors Product Guide SpecificationAddis FikreОценок пока нет

- 09 69 33fazДокумент11 страниц09 69 33fazbrian walter abarintosОценок пока нет

- SECTION 08 17 10 Integrated Door AssembliesДокумент13 страницSECTION 08 17 10 Integrated Door AssembliesJuanPaoloYbañezОценок пока нет

- Specification Guide 20Документ14 страницSpecification Guide 20Jeppoy PaladoОценок пока нет

- SECTION 11 12 00 Parking Control EquipmentДокумент10 страницSECTION 11 12 00 Parking Control EquipmentRima Baz FadousОценок пока нет

- SECTION 08 71 00 Door HardwareДокумент113 страницSECTION 08 71 00 Door HardwareJuanPaoloYbañezОценок пока нет

- SECTION 08 33 13 Coiling Counter DoorsДокумент10 страницSECTION 08 33 13 Coiling Counter DoorsJuanPaoloYbañezОценок пока нет

- Specifications Milgard Standard Aluminum Windows - 5Документ12 страницSpecifications Milgard Standard Aluminum Windows - 5mansiОценок пока нет

- 2900 Series: 2 " Architectural Fixed, Projected & Casement WindowДокумент6 страниц2900 Series: 2 " Architectural Fixed, Projected & Casement WindowJhun Marticio UapОценок пока нет

- Section 8 Specs - PremierДокумент5 страницSection 8 Specs - Premiersoncoi18122222Оценок пока нет

- Section 077129 - Manufactured Roof Expansion JointsДокумент6 страницSection 077129 - Manufactured Roof Expansion JointsWENDING HUОценок пока нет

- Eme745 Csi 3 Part Guide Specification RTF 2577Документ8 страницEme745 Csi 3 Part Guide Specification RTF 2577Eldhose VargheseОценок пока нет

- Prefabricated Metal BuildingДокумент25 страницPrefabricated Metal Building3486428Оценок пока нет

- SECTION 08 51 13 Aluminum WindowsДокумент12 страницSECTION 08 51 13 Aluminum WindowsEdzel QuijanoОценок пока нет

- 04 3023 01Документ5 страниц04 3023 01U MariappanОценок пока нет

- SECTION 08 51 23 Steel WindowsДокумент11 страницSECTION 08 51 23 Steel WindowsJuanPaoloYbañezОценок пока нет

- Wood DoorsДокумент8 страницWood DoorsJad Antonios JelwanОценок пока нет

- SECTION 081700 Synterga Door SpecificationДокумент8 страницSECTION 081700 Synterga Door SpecificationMimi AkiОценок пока нет

- SECTION 08 11 13 Hollow Metal Doors and FramesДокумент16 страницSECTION 08 11 13 Hollow Metal Doors and FramesJuanPaoloYbañezОценок пока нет

- Section 10 2239Документ4 страницыSection 10 2239Reyn Ma G.Оценок пока нет

- 26 - 29 - 13 Enclosed Motor ControllersДокумент2 страницы26 - 29 - 13 Enclosed Motor Controllersxdbxbg4fptОценок пока нет

- SECTION 08 36 13 Sectional DoorsДокумент9 страницSECTION 08 36 13 Sectional DoorsJuanPaoloYbañezОценок пока нет

- Product DescriptionДокумент6 страницProduct DescriptionPatrisha SantosОценок пока нет

- Architectural Specifications: Profiler Series 2000-IDS-2Документ5 страницArchitectural Specifications: Profiler Series 2000-IDS-2civilISMAEELОценок пока нет

- VA NCA 08 51 13 - Window SpecificationsДокумент7 страницVA NCA 08 51 13 - Window SpecificationsRichard OchotorenaОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Cannabis/Hemp Extract Vaporizers: Standard Classification ForДокумент9 страницCannabis/Hemp Extract Vaporizers: Standard Classification ForSdferwste SrqreОценок пока нет

- Rubber-Stress Relaxation in Tension Under Non-Isothermal ConditionsДокумент4 страницыRubber-Stress Relaxation in Tension Under Non-Isothermal ConditionsSdferwste SrqreОценок пока нет

- Detailed Hydrocarbon Analysis by High Resolution Gas Chromatography With Vacuum Ultraviolet Absorption Spectroscopy (GC-VUV)Документ45 страницDetailed Hydrocarbon Analysis by High Resolution Gas Chromatography With Vacuum Ultraviolet Absorption Spectroscopy (GC-VUV)Sdferwste SrqreОценок пока нет

- Domestic Cannabis/Hemp Plant Indoor Growing Appliances: Standard Classification ForДокумент6 страницDomestic Cannabis/Hemp Plant Indoor Growing Appliances: Standard Classification ForSdferwste SrqreОценок пока нет

- Potential Expansion of Steel Slag From Hydration Reactions by AutoclaveДокумент5 страницPotential Expansion of Steel Slag From Hydration Reactions by AutoclaveSdferwste SrqreОценок пока нет

- Cannabis/Hemp Flower Vaporizers: Standard Guide ForДокумент4 страницыCannabis/Hemp Flower Vaporizers: Standard Guide ForSdferwste SrqreОценок пока нет

- Urinary Intermittent Catheters: Standard Performance Specification ForДокумент6 страницUrinary Intermittent Catheters: Standard Performance Specification ForSdferwste SrqreОценок пока нет

- D 8356 - 20Документ8 страницD 8356 - 20Sdferwste SrqreОценок пока нет

- Methyl Hydrogen Content of Hydrocarbon Oils by High Resolution Nuclear Magnetic Resonance SpectrosДокумент6 страницMethyl Hydrogen Content of Hydrocarbon Oils by High Resolution Nuclear Magnetic Resonance SpectrosSdferwste SrqreОценок пока нет

- Cannabis/Hemp Extract Vaporizers: Standard Guide ForДокумент4 страницыCannabis/Hemp Extract Vaporizers: Standard Guide ForSdferwste SrqreОценок пока нет

- Personal Cannabis/Hemp Plant Growing Appliances: Standard Guide ForДокумент6 страницPersonal Cannabis/Hemp Plant Growing Appliances: Standard Guide ForSdferwste SrqreОценок пока нет

- Determining Enhanced Filter Blocking Tendency (EFBT) : Standard Test Method ForДокумент8 страницDetermining Enhanced Filter Blocking Tendency (EFBT) : Standard Test Method ForSdferwste SrqreОценок пока нет

- Basic Carbonate White Lead Pigment: Standard Specification ForДокумент2 страницыBasic Carbonate White Lead Pigment: Standard Specification ForSdferwste SrqreОценок пока нет

- Trace Metal Content Analysis in Carbon Black: Standard Test Method ForДокумент4 страницыTrace Metal Content Analysis in Carbon Black: Standard Test Method ForSdferwste SrqreОценок пока нет

- Cannabis/Hemp Flower Vaporizers: Standard Classification ForДокумент6 страницCannabis/Hemp Flower Vaporizers: Standard Classification ForSdferwste SrqreОценок пока нет

- Assessment and Inclusion of Wall Deposits in The Analysis of Single-Stage Samplers For Airborne Particulate MatterДокумент9 страницAssessment and Inclusion of Wall Deposits in The Analysis of Single-Stage Samplers For Airborne Particulate MatterSdferwste SrqreОценок пока нет

- Flammability of Electrical Insulating Materials Intended For Wires or Cables When Burning in A Vertical ConfigurationДокумент5 страницFlammability of Electrical Insulating Materials Intended For Wires or Cables When Burning in A Vertical ConfigurationSdferwste SrqreОценок пока нет

- Standard Test Method For: Designation: D8368 21Документ16 страницStandard Test Method For: Designation: D8368 21Sdferwste SrqreОценок пока нет

- High Bypass - Low Bearing Interaction Response of Polymer Matrix Composite LaminatesДокумент29 страницHigh Bypass - Low Bearing Interaction Response of Polymer Matrix Composite LaminatesSdferwste SrqreОценок пока нет

- Corrosion of Metal Produced by Contact With Leather: Standard Test Method ForДокумент3 страницыCorrosion of Metal Produced by Contact With Leather: Standard Test Method ForSdferwste SrqreОценок пока нет

- Determination of Individual Particle Strength of Low Surface Area Catalysts and Catalyst Carriers by Drop Test Onto A Steel PlateДокумент4 страницыDetermination of Individual Particle Strength of Low Surface Area Catalysts and Catalyst Carriers by Drop Test Onto A Steel PlateSdferwste SrqreОценок пока нет

- Geosynthetic Cementitious Composite Mat (GCCM) Materials: Standard Specification ForДокумент4 страницыGeosynthetic Cementitious Composite Mat (GCCM) Materials: Standard Specification ForSdferwste SrqreОценок пока нет

- Softening Point of Pitches (Cube-in-Water Method) : Standard Test Method ForДокумент4 страницыSoftening Point of Pitches (Cube-in-Water Method) : Standard Test Method ForSdferwste SrqreОценок пока нет

- Alaska Product Overview 2021.11.2Документ52 страницыAlaska Product Overview 2021.11.2Sdferwste SrqreОценок пока нет

- Materials For Roads and Pavements: Standard Terminology Relating ToДокумент5 страницMaterials For Roads and Pavements: Standard Terminology Relating ToSdferwste SrqreОценок пока нет

- Ce 5 - Highway and Railroad EngineeringДокумент2 страницыCe 5 - Highway and Railroad EngineeringJino MancaoОценок пока нет

- Module 0 - Topics in Principles of Steel Design & Timber DesignДокумент2 страницыModule 0 - Topics in Principles of Steel Design & Timber DesignSte FunnyОценок пока нет

- Counterweight Rigging ManualДокумент34 страницыCounterweight Rigging ManualGustavo ArancibiaОценок пока нет

- Kubota Tractor B219 Loader - Model 25 Maximum Payload - 500 Pounds Figure: 1 - Safety PrecautionsДокумент17 страницKubota Tractor B219 Loader - Model 25 Maximum Payload - 500 Pounds Figure: 1 - Safety PrecautionsCameron MortimerОценок пока нет

- Technical Specification For 20 MVA Transformer PDFДокумент21 страницаTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Joint Less Pavements For Heavy-Duty Airport Application: The Semi-Flexible Approach Jean Mayer I & Mikael Thau 2Документ14 страницJoint Less Pavements For Heavy-Duty Airport Application: The Semi-Flexible Approach Jean Mayer I & Mikael Thau 2Dr Rajiv KumarОценок пока нет

- Pte TingoДокумент17 страницPte TingoGerson Jairo Santos AdanОценок пока нет

- Appendix 1 - Scope of WorkДокумент13 страницAppendix 1 - Scope of WorkNimra NaveedОценок пока нет

- 958101tender PDFДокумент120 страниц958101tender PDFSandeep Saini100% (1)

- LAIOДокумент2 страницыLAIOKenar PatelОценок пока нет

- Construction of One Storey Residential BuildingДокумент9 страницConstruction of One Storey Residential Buildingwdy2ysq8d7Оценок пока нет

- Dairy Building PlanningДокумент4 страницыDairy Building PlanningMonty KushwahaОценок пока нет

- NAPA PCR AsphaltMixtures v2Документ67 страницNAPA PCR AsphaltMixtures v2Fernando MolinasОценок пока нет

- Suresh Sir Presentation ReportДокумент28 страницSuresh Sir Presentation ReportRahul Kasaudhan100% (1)

- Mobile Load Chart Link Belt TLL - Web 0114Документ17 страницMobile Load Chart Link Belt TLL - Web 0114Patrick SmithОценок пока нет

- Exercises 3Документ2 страницыExercises 3Nguyen Anh ThaoОценок пока нет

- Foundation Plan Roof Beam Plan 1 2: A B A BДокумент1 страницаFoundation Plan Roof Beam Plan 1 2: A B A Bjay-ar barangayОценок пока нет

- Frank Ford-Guitar NutsДокумент29 страницFrank Ford-Guitar NutsoОценок пока нет

- B-0018-1-Al Khayal Gen. Cont. (Hordi Block) (Comp. Strength)Документ1 страницаB-0018-1-Al Khayal Gen. Cont. (Hordi Block) (Comp. Strength)Matrix LaboratoryОценок пока нет

- Perhitungan Mix Design Beton (ACI 211.4R-93)Документ14 страницPerhitungan Mix Design Beton (ACI 211.4R-93)Silvester Hadiaman ZalukhuОценок пока нет

- Concrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionДокумент2 страницыConcrete Construction Article PDF - Precast Stairs Speed Concrete Building ConstructionPhara LuckyОценок пока нет

- Sunidhi Rathore: Building Construction-VДокумент20 страницSunidhi Rathore: Building Construction-VSunidhi rathore100% (1)

- Arcg 213: Architectural Construction - IДокумент23 страницыArcg 213: Architectural Construction - Idhai xОценок пока нет

- Contract Doc AnalysisДокумент47 страницContract Doc AnalysisHazirah ZieraОценок пока нет

- Compressive GraphДокумент8 страницCompressive GraphResearcherОценок пока нет

- INFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingДокумент25 страницINFRA-TES-MST-CCC-CIV-00023 Rev. 0 - Excavation and BackfillingTaiwo OshinОценок пока нет

- Siemens SWMS SATURДокумент49 страницSiemens SWMS SATURsrinidhiОценок пока нет

- Inspection and Test PlanДокумент2 страницыInspection and Test PlanAmeei Emran Al-HajОценок пока нет

- Type VBL 153 IndustrialДокумент2 страницыType VBL 153 Industrialpouya alizadehОценок пока нет

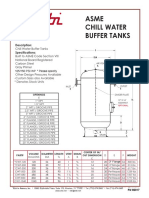

- Asme Chill Water Buffer Tanks: Description: SpecificationsДокумент1 страницаAsme Chill Water Buffer Tanks: Description: SpecificationsRan NОценок пока нет