Академический Документы

Профессиональный Документы

Культура Документы

0037-0041 (3) Topical and Transdermal Drug Products-Product Quality Tests

Загружено:

Merrene Bright Divino JudanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

0037-0041 (3) Topical and Transdermal Drug Products-Product Quality Tests

Загружено:

Merrene Bright Divino JudanАвторское право:

Доступные форматы

Accessed from 128.83.63.

20 by nEwp0rt1 on Thu Dec 01 21:44:27 EST 2011

USP 35 General Requirements / 〈3〉 Topical and Transdermal Drug Products 37

time and in no case is more than sufficient to permit the ter in Injections 〈788〉, provided that scientific data are availa-

withdrawal and administration of 1 L. ble to justify this exemption.

Preparations intended for intraspinal, intracisternal, or per-

idural administration are packaged only in single-dose

containers. STERILITY

Unless otherwise specified in the individual monograph, a

multiple-dose container contains a volume of Injection suffi- Sterility Tests—Preparations for injection meet the re-

cient to permit the withdrawal of not more than 30 mL. quirements under Sterility Tests 〈71〉.

The following injections are exempt from the 1-L restric-

tion of the foregoing requirements relating to packaging:

1. Injections packaged for extravascular use as irrigation CONSTITUTED SOLUTIONS

solutions or peritoneal dialysis solutions

2. Injections packaged for intravascular use as parenteral Dry solids from which constituted solutions are prepared

nutrition or as replacement or substitution fluid to be for injection bear titles of the form [DRUG] for Injection. Be-

administered continuously during hemofiltration cause these dosage forms are constituted at the time of use

Injections packaged for intravascular use that may be used by the health-care practitioner, tests and standards pertain-

for intermittent, continuous, or bolus replacement fluid ad- ing to the solution as constituted for administration are not

ministration during hemodialysis or other procedures, unless included in the individual monographs on sterile dry solids

excepted above, must conform to the 1-L restriction. or liquid concentrates. However, in the interest of assuring

Injections labeled for veterinary use are exempt from the quality of injection preparations as they are actually ad-

packaging and storage requirements concerning the limita- ministered, the following nondestructive tests are provided

tion to single-dose containers and the limitation on the vol- for demonstrating the suitability of constituted solutions

ume of multiple-dose containers. when they are prepared just prior to use.

Completeness and Clarity of Solution—Constitute the

solution as directed in the labeling supplied by the manu-

FOREIGN AND PARTICULATE MATTER facturer for the sterile dry dosage form.

A: The solid dissolves completely, leaving no visible resi-

All articles intended for parenteral administration shall be due as undissolved matter.

prepared in a manner designed to exclude particulate mat-

ter as defined in Particulate Matter in Injections 〈788〉 and B: The constituted solution is not significantly less clear

other foreign matter. Each final container of all parenteral than an equal volume of the diluent or of Purified Water

preparations shall be inspected to the extent possible for the contained in a similar vessel and examined similarly.

presence of observable foreign and particulate matter (here- Particulate Matter—Constitute the solution as directed

after termed “visible particulates”) in its contents. The in- in the labeling supplied by the manufacturer for the sterile

spection process shall be designed and qualified to ensure dry dosage form: the solution is essentially free from parti-

that every lot of all parenteral preparations is essentially free cles of foreign matter that can be observed on visual

from visible particulates. Qualification of the inspection pro- inspection.

cess shall be performed with reference to particulates in the

visible range of a type that might emanate from the manu-

facturing or filling process. Every container which has con-

tents that show evidence of visible particulates shall be re-

jected. The inspection for visible particulates may take place

when inspecting for other critical defects, such as cracked or

defective containers or seals, or when characterizing the ap-

pearance of a lyophilized product. Add the following:

Where the nature of the contents or the container–closure

system permits only limited capability for the inspection of

the total contents, the 100% inspection of a lot shall be 〈3〉 TOPICAL AND

▲

supplemented with the inspection of constituted (e.g.,

dried) or withdrawn (e.g., dark amber container) contents TRANSDERMAL DRUG PRODUCTS

of a sample of containers from the lot.

All large-volume Injections for single-dose infusion and —PRODUCT QUALITY TESTS

small-volume Injections are subject to the light obscuration

or microscopic procedures and limits for subvisible particu-

late matter set forth in Particulate Matter In Injections 〈788〉,

unless otherwise specified in the individual monograph. An

article packaged as both a large-volume and a small-volume INTRODUCTION

Injection meets the requirements set forth for small-volume

Injections where the container is labeled as containing 100 Topically applied drug products fall into two general cate-

mL or less, if the individual monograph states a test for gories: those applied to achieve local action and those ap-

Particulate Matter in Injections 〈788〉; it meets the require- plied to achieve systemic effects after absorption through

ments set forth for large-volume Injections for single-dose the skin into the blood circulation. Local action can occur at

infusion where the container is labeled as containing more or on the surface of the application site (e.g., stratum

than 100 mL. corneum, ocular epithelium), in the underlying tissues (e.g.,

Solutions for injection administered by the intramuscular epidermis and/or dermis) and on subcutaneous tissues (e.g.,

or subcutaneous route must meet the requirements of Par- muscle or joint).

ticulate Matter in Injections 〈788〉. Topically applied drug products include, but are not re-

Parenterals packaged and labeled exclusively for use as stricted to creams, gels, ointments, pastes, suspensions, lo-

irrigating solutions are exempt from the requirements of tions, foams, sprays, aerosols, solutions, and transdermal de-

Particulate Matter in Injections 〈788〉. Radiopharmaceutical livery systems (TDS, also known as patches). The definitions

preparations are exempt from the requirements of Particu- and descriptions of these dosage forms, and brief informa-

late Matter in Injections 〈788〉. Parenteral products for which tion on their composition and/or manufacturing process can

the labeling specifies the use of a final filter prior to adminis- be found in Pharmaceutical Dosage Forms 〈1151〉.

tration are exempt from the requirements of Particulate Mat- Procedures and acceptable criteria for testing topically ap-

plied drug products can be divided into those that assess

Official from May 1, 2012

Copyright (c) 2011 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 128.83.63.20 by nEwp0rt1 on Thu Dec 01 21:44:27 EST 2011

38 〈3〉 Topical and Transdermal Drug Products / General Requirements USP 35

general product quality attributes and those that assess Uniformity of Dosage Units: This test is applicable for

product performance. The product quality attributes include TDS and for dosage forms packaged in single-unit contain-

the following: description, identification, assay (strength), ers (see Uniformity of Dosage Units 〈905〉).

impurities, physicochemical properties, uniformity of dosage Water Content: A test for water content should be in-

units, water content, pH, apparent viscosity, microbial limits, cluded when appropriate (see Water Determination 〈921〉).

antimicrobial preservative content, antioxidant content, ste- This test is generally formulation dependent. Therefore, it is

rility, if applicable, and other tests that may be product spe- not included in the compendial drug product monograph

cific. Product performance testing assesses drug release and but is part of the manufacturer’s specification for the drug

other attributes that affect drug release from the finished product.

dosage form. Microbial Limits: Microbial examination of nonsterile

Although most topically applied drug products are semis- drug products is performed according to the methods given

olids, liquids, or suspensions, TDS are physical devices that in general chapters Microbiological Examination of Nonsterile

are applied to the skin and vary in their composition and Products: Microbial Enumeration Tests 〈61〉 and Microbiologi-

method of fabrication. TDS release their active ingredients cal Examination of Nonsterile Products: Tests for Specified Mi-

by different mechanisms. They can be passive or active. This croorganisms 〈62〉, unless the formulation itself is demon-

chapter covers only the tests related to passive TDS. strated to have antimicrobial properties. Acceptance criteria

for nonsterile pharmaceutical products based on total aero-

PRODUCT QUALITY TESTS FOR TOPICALLY bic microbial count (TAMC) and total combined yeasts and

molds count (TYMC) are given in Microbiological Examination

APPLIED DRUG PRODUCTS of Nonsterile Products: Acceptance Criteria for Pharmaceutical

Preparations and Substances for Pharmaceutical Use 〈1111〉.

Antimicrobial Preservative Content: Acceptance crite-

Universal Tests ria for antimicrobial preservative content in multidose prod-

ucts should be established. They should be based on levels

Universal tests (see ICH Guidance Q6A—Specifications: Test of antimicrobial preservative necessary to maintain the prod-

Procedures and Acceptance Criteria for New Drug Substances uct’s microbiological quality at all stages throughout its pro-

and New Drug Products: Chemical Substances, available at posed usage and shelf life (see Antimicrobial Effectiveness

www.ich.org) are listed below and are applicable to all topi- Testing 〈51〉).

cally applied drug products. Antioxidant Content: If antioxidants are present in the

Description: A qualitative description of the drug prod- drug product, tests of their content should be established

uct should be provided. The acceptance criteria should in- unless oxidative degradation can be detected by another

clude the final acceptable appearance of the finished dosage test method such as impurity testing. Acceptance criteria for

form and packaging. A visual examination should identify antioxidant content should be established. They should be

changes in color, adhesive migration (i.e., cold flow) for based on the levels of antioxidant necessary to maintain the

TDS, separations, crystallization, etc., that are specific to the product’s stability at all stages throughout its proposed us-

drug product. The description should specify the content or age and shelf life.

the label claim of the article. This is not a compendial test Sterility: Depending on the use of the dosage form

but is part of the manufacturer’s specification for the drug (e.g. ophthalmic preparations, products that will be applied

product. to open wounds or burned areas), sterility of the product

Identification: Identification tests are discussed in Gen- should be demonstrated as appropriate (see Sterilty Tests

eral Notices and Requirements, 5.40. Identification tests 〈71〉).

should establish the identity of the drug or drugs present in pH: When applicable, topically applied drug products

the article and should discriminate between compounds of should be tested for pH at the time of batch release and at

closely related structures that are likely to be present. Iden- designated stability time points for batch-to-batch monitor-

tity tests should be specific for the drug substance(s) (e.g., ing. Because some topically applied drug products contain

infrared spectroscopy). Near infrared (NIR) or Raman spec- very limited quantities of water or aqueous phase, pH meas-

trophotometric methods also could be acceptable for the urements may not always be warranted.

identification of the drug product (see Near-Infrared Spectro- This test is generally formulation dependent. Therefore, it

photometry 〈1119〉 and Raman Spectroscopy 〈1120〉). Identifi- is not included in the compendial drug product monograph

cation solely by a single chromatographic retention time is but is part of the manufacturer’s specification for the drug

not specific. product.

Assay: A specific and stability-indicating test should be Particle Size: The particle size of the active drug sub-

used to determine the strength (content) of the drug prod- stance(s) in topically applied drug products is usually deter-

uct. In cases when the use of a nonspecific assay (e.g., Ti- mined and controlled at the formulation development stage.

trimetry 〈541〉) is justified, other supporting analytical proce- However, topically applied drug products should be ex-

dures should be used to achieve overall specificity. amined for evidence of particle size alteration (i.e., appear-

Impurities: Process impurities, synthetic by-products, ance of particles, changes in particle form, size, shape,

impurities associated with the adhesive (e.g., residual mono- habit, or aggregation) of the active drug substance that

mers), residual solvents (see Residual Solvents 〈467〉), heavy may occur during the course of product processing and

metals (see Heavy Metals 〈231〉), and other inorganic and storage. Such examinations should be conducted at the

organic impurities may be present in the drug substance time of batch release and at designated stability test time

and excipients used in the manufacture of the drug product points for batch-to-batch monitoring because changes that

and should be assessed and controlled. Impurities arising are visually (macro- and microscopically) observable would

from the degradation of the drug substance and those aris- likely compromise the integrity and/or performance of the

ing during the manufacturing process of the drug product drug product. These types of testing are generally formula-

should also be assessed and controlled. tion dependent. Therefore, such tests are not included in

compendial monographs but are part of the manufacturer

specification for the drug product.

Specific Tests

In addition to the universal tests listed above, the follow-

ing specific tests should be considered on a case-by-case

basis.

Official from May 1, 2012

Copyright (c) 2011 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 128.83.63.20 by nEwp0rt1 on Thu Dec 01 21:44:27 EST 2011

USP 35 General Requirements / 〈3〉 Topical and Transdermal Drug Products 39

SPECIFIC TESTS FOR OPHTHALMIC DRUG Uniformity in Containers

PRODUCTS

Topically applied semisolid drug products may show phys-

Ophthalmic dosage forms must meet the requirements of ical separation during manufacturing processes and during

Sterility Tests 〈71〉. If the specific ingredients used in the for- their shelf life. To ensure the integrity of the drug product,

mulation do not lend themselves to routine sterilization it is essential to evaluate the uniformity of the finished prod-

techniques, ingredients that meet the sterility requirements uct at the time of batch release and throughout its assigned

described under Sterility Tests 〈71〉, along with aseptic manu- shelf life.

facture, may be used. Multiple-use ophthalmic preparations

must contain a suitable substance or mixture of substances

to prevent growth of, or to destroy, microorganisms acci- PRODUCTS PACKAGED IN TUBES

dentally introduced during the use of the product (see

Added Substances under Ophthalmic Ointments 〈771〉), unless Within-tube content uniformity can be assessed in the fol-

otherwise directed in the individual monograph or unless lowing manner.

the formula itself is bacteriostatic and/or the delivery system Carefully remove or cut off the bottom tube seal and

promotes bacteriostasis. The finished ophthalmic prepara- make a vertical cut from the bottom to the top of the tube.

tion must be free from large particles and must meet the Carefully cut the tube around the upper rim, open the two

requirements for Leakage and for Metal Particles under flaps and lay the flaps open to expose the product.

Ophthalmic Ointments 〈771〉. The immediate containers for Inspect the product visually for the presence of phase sep-

ophthalmic preparations shall be sterile at the time of filling aration, change in physical appearance and texture, and

and closing. It is mandatory that the immediate containers other properties described in the product test for Descrip-

for ophthalmic preparations be sealed and tamper-proof so tion. If there is no observable phase separation or change in

that sterility is ensured at the time of first use. physical appearance and texture, and if the product meets

the Description acceptance criteria, proceed as described be-

low. If the product exhibits phase separation and/or change

SPECIFIC TESTS FOR TOPICALLY APPLIED in physical appearance or texture, the product fails the tube

SEMISOLID DRUG PRODUCTS content uniformity test.

The procedures describe below can be modified depend-

ing on the sensitivity of the quantitative procedure used to

assay the drug substance(s) present in the formulation.

Apparent Viscosity For Multiple-Dose Products That Contain 5 g or More:

Procedure 1—

Viscosity is a measure of a formulation’s resistance to flow 1. Using a single tube, after visually inspecting the prod-

and is an assessment of the rheological properties of the uct remove an appropriate amount of product from

dosage form (e.g., semisolid dosage form). Because only the top, middle, and bottom portions of the tube.

Newtonian fluids possess a measurable viscosity that is inde- The sample size should be sufficient for at least one

pendent of shear rate, semisolid pharmaceutical dosage assay determination of the active ingredient(s). Carry

forms which are non-Newtonian products exhibit an appar- out the assay test for the active ingredient(s) in each

ent viscosity. portion of the product, and evaluate the test results

The apparent viscosity of semisolid drug products should using Acceptance Criteria A.

be tested at the time of batch release and initially at desig- 2. If the product fails Acceptance Criteria A, test 3 addi-

nated stability test time-points to set specifications for tional tubes from the same batch following step 1

batch-to-batch and shelf life monitoring. Measurement pro- described above, and evaluate all 12 test results using

cedures should be developed as outlined in Viscosity 〈911〉. Acceptance Criteria B.

For semisolids that show thixotropy and/or irreversible Procedure 2—

changes in viscosity after shearing, specific attention should 1. Using two tubes, after visually inspecting the product,

be given to sample preparation procedures to minimize vari- remove an appropriate amount of product from the

ability in the measurement of apparent viscosity caused by top, middle, and bottom portions of each tube. The

variable shear histories (e.g., mixing speed and temperature, sample size should be sufficient for at least one assay

filling operation, sample handling). Furthermore, for some determination of the active ingredient(s). Carry out

products, it may be warranted to have apparent viscosity the assay test for the active ingredient(s) in each por-

specifications at more than one set of conditions (e.g., bulk tion of the tube, and evaluate the test results using

in-process stage, final packaged product, high and low Acceptance Criteria A.

shear rates, different temperatures). 2. If the product fails Acceptance Criteria A, test 2 addi-

Apparent viscosity specifications based on data obtained tional tubes from the same batch following step 1

during product development and shelf life testing should be described above, and evaluate all 12 test results using

established for batch release and throughout their proposed Acceptance Criteria B.

shelf life.

The apparent viscosity test is formulation and/or process For Multiple-Dose Products That Contain Less Than

dependent. Therefore, it is not included in compendial drug 5 g of Product:

product monographs but is part of the manufacturer’s spec- 1. Test the top and bottom portions of 2 tubes using

ification for the drug product. Furthermore, the specifica- Procedure 1 or Procedure 2 as described above. Evalu-

tions for apparent viscosity of semisolid dosage forms at ate the test results using Acceptance Criteria A.

batch release and during stability testing may be different. 2. If the product fails Acceptance Criteria A, test 2 addi-

Although the apparent viscosity of the finished drug product tional tubes from the same batch following step 1

at the time of batch release must conform to the product described above, and evaluate all 8 test results using

development specifications, for stability testing, the appar- Acceptance Criteria B.

ent viscosity specifications for the drug product should be Tube (Container) Content Uniformity Test Acceptance

based on statistical assessment of the product over its shelf Criteria: In determining the relative standard deviation

life. (RSD) from multiple tubes, first determine the variance from

the three measurements for each tube and average across

the tubes. The RSD is calculated using this average variance.

Acceptance Criteria A—All assay results are within the

range of 90%–110% of the product label claim and the RSD

Official from May 1, 2012

Copyright (c) 2011 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 128.83.63.20 by nEwp0rt1 on Thu Dec 01 21:44:27 EST 2011

40 〈3〉 Topical and Transdermal Drug Products / General Requirements USP 35

is NMT 6% or as specified in the product specification or in Acceptance criteria are product specific and defined to as-

the compendial monograph. If the RSD is greater than 6%, sure that adhesion of each batch of TDS are within the

use Acceptance Criteria B. range defined by the product design and are consistent be-

Acceptance Criteria B—No assay result is outside the range tween batches based on the product development specifica-

of 90%–110% of the product label claim and the RSD of tions or statistical assessment of multiple product batches

the 12 assay results is NMT 6% or as specified in the prod- over the product’s shelf life.

uct specification or in the compendial monograph.

Peel Adhesion Test

PRODUCTS PACKAGED IN CONTAINERS OTHER THAN TUBES

This test measures the force required to remove (peel

For semisolid products packaged in a container other than away) a TDS attached to a standard substrate surface (e.g.,

a tube when the sampling method presented above cannot polished stainless steel). The TDS is applied to the substrate

be used, other sampling methods are acceptable, such as using specified techniques for application and is conditioned

the one described below for a jar. at a specified temperature and time. Then, the TDS is

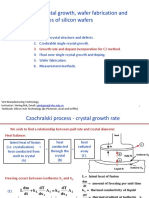

1. Select a suitable syringe of sufficient length to extend peeled away from the substrate with an instrument that al-

to the bottom of the container. lows control of peel angle (e.g., 90 or 180 degrees) and

2. Remove and set aside the syringe plunger and cut off peel rate (e.g., 300 mm/min), and the peel force is re-

the bottom of the syringe barrel. Sampling should corded. This procedure is repeated using a minimum of five

take place from a location to the left/right of the independent samples. The product fails the test if the

mid-line of the jar surface to preserve an undisturbed mean peel force is outside the acceptable range determined

region on the other side for any additional investiga- during product development and/or based on statistical as-

tion (See Figure 1). sessment of multiple product batches over the product’s

shelf life.

Release Liner Peel Test

This test measures the force required to separate the re-

lease liner from the adhesive layer of the TDS. The test is

performed with a finished product sample. The test sample

is conditioned using specific procedures (temperature and

time). Then the release liner is pulled away from the TDS

with an instrument that allows for control of peel angle

(e.g., 90 or 180 degrees) and peel rate, and the peel force

is recorded. This procedure is repeated using a minimum of

five independent samples. The product fails the test if the

mean peel force is outside the acceptable range determined

during product development and/or based on statistical as-

Figure 1. Sampling from a jar container. sessment of multiple product batches over the product’s

shelf life.

3. Slowly push the syringe barrel into the container until

it reaches the bottom. Then, twist the syringe barrel Tack Test

containing the sample core, and remove the syringe

from the container. Several methods of tack tests have been developed. Ex-

4. Insert the syringe plunger into the barrel and carefully amples include the probe tack method and the rolling ball

extrude the sample core onto a clean surface in three method. It is up to the TDS manufacturer to decide which

equal portions to represent the top, middle, and bot- one is more appropriate for each drug product.

tom portions of the container.

5. Remove an appropriate sample representative of the

middle section of the top, middle, and bottom por- PROBE TACK METHOD

tions of the container samples, and test according to

the instructions outlined in Products Packaged in This test measures the force required to separate the tip

Tubes. of the test probe from the adhesive layer of the TDS. This

test uses an instrument designed to create a bond between

the tip of the stainless steel test probe of defined geometry

SPECIFIC TESTS FOR TRANSDERMAL and the TDS using a controlled force (light pressure) and

DELIVERY SYSTEMS specified test conditions (i.e., rate, contact time, contact

pressure, temperature). Then, while controlling the rate of

TDS or patches are formulated with an adhesive layer to probe removal, the test measures the profile of force re-

ensure intimate contact with the skin to allow the delivery quired to separate the probe tip from the TDS and the max-

of the desired dose of drug. Adhesives in TDS must permit imum force required to break the bond (tack). This proce-

easy removal of the release liner before use, must adhere dure is repeated using a minimum of five independent

properly to human skin upon application, must maintain ad- samples. The product fails the test if the mean test result

hesion to the skin during the prescribed period of use, and [force profile(s) and/or tack] is outside the acceptable range

must permit easy removal of the TDS at the end of use determined during product development and/or based on

without leaving a residue or causing damage to the skin or statistical assessment of multiple product batches over the

other undesirable effect(s). Additionally, adhesives must be product’s shelf life.

able to maintain the performance of the TDS throughout

the shelf life of the drug product. ROLLING BALL METHOD

Three types of TDS adhesion tests are generally used: peel

adhesion test (from a standard substrate), release liner peel This test measures the distance travelled by a defined ball

test, and tack test. on the adhesive layer of the TDS under defined conditions,

as a parameter dependent on the tack properties of the ad-

Official from May 1, 2012

Copyright (c) 2011 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 128.83.63.20 by nEwp0rt1 on Thu Dec 01 21:44:27 EST 2011

USP 35 General Requirements / 〈11〉 USP Reference Standards 41

hesive layer. This test uses a setup designed to roll a ball wiped. The inside surface of the pouch should also be

(with defined material, weight, size, and surface) from a wiped. The swab(s) is (are) then extracted and as-

ramp (with defined angle and length) onto the adhesive sayed for the drug.

layer (with defined orientation) under specified test condi- 4. The product fails if the total amount of drug from the

tions (temperature) (see ASTM D3121 for more details). The TDS, and the corresponding pouch, exceed the ac-

distance traveled by the ball on the adhesive layer is meas- ceptable limit established by the manufacturer.

ured using a suitable measuring device. This procedure is ▲USP35

repeated using a minimum of five independent samples.

The product fails the test if the mean distance travelled is

outside the acceptable range determined during product

development and/or based on statistical assessment of mul-

tiple product batches over the product’s shelf life.

Leak Test 〈11〉 USP REFERENCE STANDARDS

This test is applicable only to form-fill-seal (reservoir or

pouched)-type TDS. Form-fill-seal TDS must be manufac- Reference Standards provided by the United States Phar-

tured with zero tolerance for leaks because of their potential macopeial Convention (USP Reference Standards, or RS) are

for dose dumping if leaking occurs. highly characterized specimens reflective of specified drugs

In-process control methods to examine TDS for leakers or and foods (drug substances, biologics, excipients, dietary

potential leakers are needed and require considerable devel- supplements, food ingredients, impurities, degradation

opment on the part of TDS manufacturers. products, reagents, and performance verification standards).

When approved as suitable for use as comparison standards

for documentary tests or assays (i.e., as a monograph com-

IN-PROCESS TESTING ponent) in the United States Pharmacopeia (USP) or National

Formulary (NF), USP RS also assume official status and legal

During the manufacturing process, the presence of leak- recognition in the United States. Assessment of the suitabil-

age, or potential for leakage, because of TDS perforation, ity for use in other applications rests with the user. Official

cuts, and faulty seals resulting from failures such as air bub- USP RS are primary standards in jurisdictions that so recog-

bles, gel splash, or misalignment of a TDS’s backing and nize them as such and, when appropriate, are calibrated

release liner layers, must be examined. Unless automated relative to international reference materials such as those

process analytical technology is implemented, in-process provided by the World Health Organization. USP RS are

testing to identify these defects should be performed using never intended for therapeutic use. USP’s RS are provided

the following test procedures: for legal metrology purposes and can help ensure compara-

Visual Inspection: bility of results and traceability to Système International

1. A specified number of TDS, defined based on the d’Unités (SI) units whether certified or not. USP RS are

batch size, should be randomly examined. Reference Materials as defined in the International Vocabulary

2. Each sampled TDS should be thoroughly visually in- of Metrology—Basic and General Concepts and Associated

spected for leakage. Terms (VIM): 3rd Edition 2007.

3. The product fails if any of the TDS examined is de-

tected with a leak.

Seal Integrity: TYPES OF REFERENCE STANDARDS

Transdermal system seals should be stress tested to en-

sure that the application of pressure does not force seals to

open, thereby leading to leakage. Reference Standards for USP or NF Articles

1. A specified number of TDS, defined based on the

batch size, should be randomly examined. Reference Standards for official articles in USP or NF are

2. Each sampled TDS should be thoroughly visually in- provided as pure materials or as mixtures of chemicals re-

spected for leakage. flective of the corresponding drug substances or excipients.

3. Each sampled TDS is placed on a hard, flat surface The use of these materials is specified in the article’s mono-

and overlaid with a weight so that it is subjected to graph, and these materials generally are necessary for use in

13.6 kg. The weight should be left in place for 2 the Assay and/or the Identification tests. The suitability of a

minutes. Upon removal of the weight, the TDS USP RS for uses outside those specified in a monograph is

should be visually inspected for leakage. the responsibility of the user. The property value or calcula-

4. The product fails if the number of TDS detected with tion value of the Reference Standard is stated on the label

a leak is greater than the acceptable limit established and should be included in calculations used in the mono-

by the manufacturer. graph and applicable general chapters. For Reference Stan-

Packaged Product Testing: dards that do not bear a property value or calculation value

TDS may leak after they have been individually placed in on the label or in accompanying documentation, assume

the primary packaging material as a result of the packaging the Reference Standard is 100.0% pure for compendial

operation itself or by user opening of the packaging. There- quantitative applications.

fore, TDS should be tested for leakage after they have been

manufactured and packaged in their primary packaging

material. Impurity Reference Standards

1. A specified number of TDS, defined based on the

batch size, should be randomly tested after they have Reference Standards for impurities may include the

been placed in their primary packaging material. following:

2. The sampled TDS should be removed from their • Organic impurities that may arise either during the

packaging and thoroughly visually inspected for manufacturing process or during the shelf-life storage of

leakage. an article and may include starting materials, in-

3. Each sampled TDS should then be uniformly wiped termediates, by-products, reagents, catalysts, and/or

with a solvent-moistened swab. Both the backing side degradation products.

and the release liner side of the TDS should be

Official from May 1, 2012

Copyright (c) 2011 The United States Pharmacopeial Convention. All rights reserved.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 0052-0052 (41) Weights and BalancesДокумент1 страница0052-0052 (41) Weights and BalancesMerrene Bright Divino JudanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Metro Manila Rates: One To Three Pieces TEN TO FIFTEEN PIECES (Around An Hour)Документ1 страницаMetro Manila Rates: One To Three Pieces TEN TO FIFTEEN PIECES (Around An Hour)Merrene Bright Divino JudanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 0054-0056 (55) Biological Indicators-Resistance Performance TestsДокумент3 страницы0054-0056 (55) Biological Indicators-Resistance Performance TestsMerrene Bright Divino JudanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 0056-0060 (61) Microbiological Examination of Nonsterile Products - Microbial Enumeration TestsДокумент5 страниц0056-0060 (61) Microbiological Examination of Nonsterile Products - Microbial Enumeration TestsMerrene Bright Divino JudanОценок пока нет

- 0060-0065 (62) Microbiological Examination of Nonsterile Products - Tests For Specified MicroorganismsДокумент6 страниц0060-0065 (62) Microbiological Examination of Nonsterile Products - Tests For Specified MicroorganismsMerrene Bright Divino JudanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- UP Manila Classical Ensemble Orientation I. Organizational ChartДокумент2 страницыUP Manila Classical Ensemble Orientation I. Organizational ChartMerrene Bright Divino JudanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- UPMCE Flyer ContentДокумент1 страницаUPMCE Flyer ContentMerrene Bright Divino JudanОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Do You Hear The People Sing StringsДокумент1 страницаDo You Hear The People Sing StringsMerrene Bright Divino JudanОценок пока нет

- UP Manila Classical Ensemble Orientation I. Organizational ChartДокумент2 страницыUP Manila Classical Ensemble Orientation I. Organizational ChartMerrene Bright Divino JudanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Ip 190 Laboratory Ay 2019-2020 Class Schedule Schedule Section 1 (MTH 1-4) Section 2 (TF 1-4)Документ1 страницаIp 190 Laboratory Ay 2019-2020 Class Schedule Schedule Section 1 (MTH 1-4) Section 2 (TF 1-4)Merrene Bright Divino JudanОценок пока нет

- Phar - 174 - Course Syllabus 2019-2020Документ3 страницыPhar - 174 - Course Syllabus 2019-2020Merrene Bright Divino JudanОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Lipids and Paper ChromatographyДокумент24 страницыLipids and Paper ChromatographyMerrene Bright Divino JudanОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- List of Common Medicinal Plants in The Philippines With Their Scientific NamesДокумент4 страницыList of Common Medicinal Plants in The Philippines With Their Scientific NamesMerrene Bright Divino JudanОценок пока нет

- Worksheet No. 7 Checklist Leaf Type Leaf ApexДокумент2 страницыWorksheet No. 7 Checklist Leaf Type Leaf ApexMerrene Bright Divino JudanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Secondary Products of MetabolismДокумент36 страницSecondary Products of MetabolismMerrene Bright Divino JudanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Illustrative List of Cosmetic Products by Categories: Appendix IДокумент2 страницыIllustrative List of Cosmetic Products by Categories: Appendix IMerrene Bright Divino JudanОценок пока нет

- Ex. 4C-1 Lipids and Fatty AcidsДокумент27 страницEx. 4C-1 Lipids and Fatty AcidsMerrene Bright Divino JudanОценок пока нет

- Exercise 6C (Oxidases and Peroxidases)Документ30 страницExercise 6C (Oxidases and Peroxidases)Merrene Bright Divino JudanОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Primary Products of PhotosynthesisДокумент32 страницыPrimary Products of PhotosynthesisMerrene Bright Divino JudanОценок пока нет

- 04 - Organic SynthesisДокумент45 страниц04 - Organic SynthesisMerrene Bright Divino JudanОценок пока нет

- 09.2 - Nucleic Acids As Drug Targets PDFДокумент33 страницы09.2 - Nucleic Acids As Drug Targets PDFMerrene Bright Divino JudanОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 12.3 - Molecular Formula DeterminationДокумент12 страниц12.3 - Molecular Formula DeterminationMerrene Bright Divino JudanОценок пока нет

- 01 - Enolates-and-Other-Carbon-NucleophilesДокумент45 страниц01 - Enolates-and-Other-Carbon-NucleophilesMerrene Bright Divino JudanОценок пока нет

- 02 - Redox ReactionsДокумент69 страниц02 - Redox ReactionsMerrene Bright Divino JudanОценок пока нет

- Quiz 1 On Cosmetic Product DevelopmentДокумент22 страницыQuiz 1 On Cosmetic Product DevelopmentMerrene Bright Divino JudanОценок пока нет

- Directors Note TGWDLMДокумент1 страницаDirectors Note TGWDLMMerrene Bright Divino JudanОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ausmetics Daily Chemicals FDA 483 2017Документ3 страницыAusmetics Daily Chemicals FDA 483 2017vijay narayanОценок пока нет

- Chapter - 6: Life ProcessesДокумент39 страницChapter - 6: Life Processessuneel kumar rathoreОценок пока нет

- Webpage List of Chemical Industry Companies CEFICДокумент11 страницWebpage List of Chemical Industry Companies CEFICkerasusОценок пока нет

- Energetics QuestionsДокумент22 страницыEnergetics Questionsmiyu kanzakiОценок пока нет

- Distinction Between Igneous, Sedimentary and Metamorphic RocksДокумент13 страницDistinction Between Igneous, Sedimentary and Metamorphic RocksFelipePacuanBagasbas-CafeIIIОценок пока нет

- Lec 13Документ44 страницыLec 1320-c-859Оценок пока нет

- Levoshin 100 MLДокумент1 страницаLevoshin 100 MLSharfina Akter BithiОценок пока нет

- F T. Topolimero. 24022020Документ2 страницыF T. Topolimero. 24022020FedericoОценок пока нет

- Review of Literature: Phyto Pharmacological Studies On Pithecellobium DulceДокумент12 страницReview of Literature: Phyto Pharmacological Studies On Pithecellobium DulceDr. Ramadevi DevarakondaОценок пока нет

- Steel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessДокумент9 страницSteel, Sheet, Hot Rolled, Carbon, Commercial, Structural, and High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessDarwin DarmawanОценок пока нет

- GASES Free Response WorksheetДокумент4 страницыGASES Free Response WorksheetJJОценок пока нет

- A Survey of Cleaning Validation General Principles and Best Practices 2013Документ35 страницA Survey of Cleaning Validation General Principles and Best Practices 2013edgar palominoОценок пока нет

- TMR2001A - TMH2001B Rev102013 enДокумент20 страницTMR2001A - TMH2001B Rev102013 enstefanovicana1Оценок пока нет

- Chapter 3 Wafer Fabr PDFДокумент31 страницаChapter 3 Wafer Fabr PDFheОценок пока нет

- Conduits Electrical LatviaДокумент13 страницConduits Electrical LatviaÖmer Faruk GÜLОценок пока нет

- Nervous System 1 (Viva)Документ53 страницыNervous System 1 (Viva)Mohammed shabekОценок пока нет

- Neet Mock 3Документ3 страницыNeet Mock 3mandaltitash2002Оценок пока нет

- Determination of GABA Content in Thai Brown Rice by An Optimized Enzyme Based MethodДокумент12 страницDetermination of GABA Content in Thai Brown Rice by An Optimized Enzyme Based MethodNgà ThúyОценок пока нет

- Org Chem Module AДокумент21 страницаOrg Chem Module ATootsie YeollieОценок пока нет

- 5070 - w14 - QP - 22 SolvedДокумент20 страниц5070 - w14 - QP - 22 SolvedMuhammad Bin RehanОценок пока нет

- Steam Distillation Lab Chemistry 11Документ3 страницыSteam Distillation Lab Chemistry 11tashy richardsОценок пока нет

- SYN Pharma-Solid Brochure EN-DPДокумент11 страницSYN Pharma-Solid Brochure EN-DPRita HenriquesОценок пока нет

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289Оценок пока нет

- Unit 3.2 - Covalent BondingДокумент11 страницUnit 3.2 - Covalent BondingAylin KasaОценок пока нет

- Product CatalogДокумент44 страницыProduct CatalogLeonardoDeiróОценок пока нет

- Properties of Minerals How Minerals Form Using Mineral ResourcesДокумент28 страницProperties of Minerals How Minerals Form Using Mineral ResourcesndОценок пока нет

- BLR - Operation & Maintenance Q&A - 2017Документ50 страницBLR - Operation & Maintenance Q&A - 2017RAJKUMARОценок пока нет

- Utilization of Fermented Mucuna Pruriens Leaf Meal As A Replacement For Soyabean Meal in Clarias Gariepinus (Burchell, 1822) Fingerlings DietsДокумент91 страницаUtilization of Fermented Mucuna Pruriens Leaf Meal As A Replacement For Soyabean Meal in Clarias Gariepinus (Burchell, 1822) Fingerlings DietsnierzaОценок пока нет

- Carbocations & CarbanionДокумент41 страницаCarbocations & CarbanionMuttu MОценок пока нет

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesОт EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesРейтинг: 4 из 5 звезд4/5 (2)

- Advanced Production Decline Analysis and ApplicationОт EverandAdvanced Production Decline Analysis and ApplicationРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)