Академический Документы

Профессиональный Документы

Культура Документы

Micro Coriolis Flowmeter For Drug Infusion Monitoring: Flow Sensors

Загружено:

Parth Nakhale0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров2 страницыMEMS notes

Оригинальное название

mems

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMEMS notes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров2 страницыMicro Coriolis Flowmeter For Drug Infusion Monitoring: Flow Sensors

Загружено:

Parth NakhaleMEMS notes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

FLOW SENSORS

MEMS flow sensors have advantages such as high

repeatability, fast response, low power consumption, high

sensitivity, high resolution, and batch production.

MEMS flow sensors are classified either thermal or non thermal.

Most

of the MEMS flow sensors are thermal flow sensors which are

based on thermal measurement principle. These thermal

sensors are less expensive, more reliable, more accurate, and

smaller than competitive approaches.

MICRO CORIOLIS FLOWMETER

FOR DRUG INFUSION MONITORING

If the mass flow of the liquid or drug in

such a tube changes, the vibrating tube twists as a result of the

Coriolis force. This twisting motion is sensed capacitively by

the micro sensor. By measuring the true mass flow of a liquid

with respect to time, the dose volume and dose rate can be

monitored and occlusions detected

• Improving drug delivery accuracy.

• Monitoring the dose, dose rate and total infused

volume

.• Detecting air bubbles and occlusions.

• Offering controlled retrograde infusion capability

and a temperature measurement option

Micro coriolis mass flow sensor

Operating principle- A Coriolis type flow sensor consists of

a vibrating tube, by an externally imposed vibration moving

mass inside the tube is forced to change its velocity. Which

forms coriolis forces that can be detected [11]. That can be

expressed by

F = -2Lω×Φ (1)

Where F is coriolis force, L is length of the tube, ω is the

frequency of vibration, Φ is the mass flow.

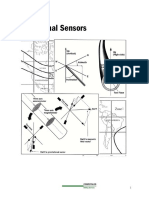

Working- As shown in figure-2 flow inters in inlet holes of

the chip and leaves from outlet hole. The sensor was

connected to electronics which deliver the actuation signal

and process the detection signal. These two signals are in

counter-phase to eliminate the influence of parasitic

capacitance to the substrate. The counter electrodes are kept at

virtual ground by two charge amplifiers. As coriolis form due

to flow, it affect comb position which generated and detected

by capacitors C1 and C2 at outside of the loop. These output

signals of the charge amplifiers are amplitude modulated

signals of 1.4 MHz, where the amplitude is proportional to the

sensor capacitance. Even smallest coriolis displace in the

comb structure which generate a signals. These signals are

demodulated using standard integrated analog multipliers and

an op-amp based second-order low pass filter at 3 kHz.

Summation of the two output signals gives a measure for the

difference in capacitance (C1-C2), i.e. the actuation amplitude.

The difference between the output signals is a measure

for the common variation in the capacitors due to the Coriolis

effect which is used to measure the flowrate.

Micro thermal flow sensor

Three sensing resistors that change its resistance

with temperature are located on the outside surface along the

flow channel, so these are non-wetted to the liquid to be

measured. The center resistor (H) heats the liquid, and the

resistors on both sides (Td and Tu) measure the temperature

of the fluid. H is controlled at constant temperature to make

temperature distribution around the heater. This temperature

distribution profile depends on flow velocity. Flow velocity

becomes faster, more heat transfers from upstream to

downstream and the temperature at downstream becomes

higher. Consequently, flow velocity can be determined from

the measured difference in temperature between Td and Tu.

Вам также может понравиться

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- A Practical Guide To Conductivity MeasurementДокумент3 страницыA Practical Guide To Conductivity MeasurementDheeraj YadavОценок пока нет

- Sensors: Lecture of Week No 12Документ21 страницаSensors: Lecture of Week No 12omniahagras78Оценок пока нет

- Mems Assignment TwoДокумент7 страницMems Assignment TwoDrey rap.dance.songwritingОценок пока нет

- Am 4Документ31 страницаAm 4FlameAssailant ADОценок пока нет

- Transducers and Sensors ReviewДокумент113 страницTransducers and Sensors ReviewSyedZameerОценок пока нет

- Energy Audit Instruments: DescriptionДокумент10 страницEnergy Audit Instruments: DescriptionVinayak ThakurОценок пока нет

- Sensors IA2Документ7 страницSensors IA2Pavan MОценок пока нет

- Definition of SensorsДокумент6 страницDefinition of SensorsMaela PlacidoОценок пока нет

- Sensors Used in Medical FieldДокумент15 страницSensors Used in Medical FieldVidhya Shankar100% (1)

- International Journal of Pure and Applied Mathematics Volume 119 No. 12 2018, 11921-11927Документ8 страницInternational Journal of Pure and Applied Mathematics Volume 119 No. 12 2018, 11921-11927prekshit patilОценок пока нет

- Principles of Microsystems: Prepared By: Kiran WaliaДокумент22 страницыPrinciples of Microsystems: Prepared By: Kiran WaliaAdityaОценок пока нет

- Assignment Transducers - PaulДокумент5 страницAssignment Transducers - PaulPaul Niño LagareОценок пока нет

- Selecting the Right Flowmeter for Your ProcessДокумент1 страницаSelecting the Right Flowmeter for Your ProcessortegaroberОценок пока нет

- Application of MemsДокумент7 страницApplication of MemsAnuja SuryanОценок пока нет

- MODERN INSTRUMENTATION APPLICATIONS IN PROCESS INDUSTRIESДокумент49 страницMODERN INSTRUMENTATION APPLICATIONS IN PROCESS INDUSTRIESAnjani KrishnaОценок пока нет

- أجهزه قياس برزنتيشنДокумент30 страницأجهزه قياس برزنتيشنmohmmedhatemali43Оценок пока нет

- All AssignmentДокумент12 страницAll AssignmentChala GetaОценок пока нет

- Conductivity Cells Types of Conductivity Cell 2 Electrode CellДокумент5 страницConductivity Cells Types of Conductivity Cell 2 Electrode CellRosalyn Ilagan SagunОценок пока нет

- Principle of Operation: Coriolis FlowmeterДокумент28 страницPrinciple of Operation: Coriolis FlowmeterRaul CageОценок пока нет

- Brewery Distance LearningДокумент3 страницыBrewery Distance LearningRomel AganОценок пока нет

- Unit Iii Sensors and Machine Vision: Prepared by B.Balasubramanian Ap/Mech CcetДокумент66 страницUnit Iii Sensors and Machine Vision: Prepared by B.Balasubramanian Ap/Mech CcetBala mechОценок пока нет

- Bioreactor Instrumentation MeasurementsДокумент12 страницBioreactor Instrumentation MeasurementsIrish Siaotong100% (1)

- SensorsДокумент2 страницыSensorsinagantimanojОценок пока нет

- CHE Facts 0709Документ1 страницаCHE Facts 0709Ivan Mario VillcaОценок пока нет

- MEMS Micro-electromechanical Systems OverviewДокумент10 страницMEMS Micro-electromechanical Systems Overviewabhi shekОценок пока нет

- Types of Sensors: ThermistorsДокумент16 страницTypes of Sensors: ThermistorsJinesh VinayachandranОценок пока нет

- Module-1-Senosrs and Energy Systems - CSE-GKP - Docx-13.08.2023Документ33 страницыModule-1-Senosrs and Energy Systems - CSE-GKP - Docx-13.08.2023Mohammed owaisОценок пока нет

- Control System InstrumentationДокумент88 страницControl System Instrumentationyeay_meОценок пока нет

- Sensor Classification and How To Choose A SensorДокумент7 страницSensor Classification and How To Choose A SensorAkhilesh Reddy KarraОценок пока нет

- Capacitive TransducerДокумент7 страницCapacitive TransducerDaksh Dagli100% (6)

- Lec Two SensorsДокумент37 страницLec Two SensorsBasma EltanekhyОценок пока нет

- Five-Part Hematology AnalyzerДокумент78 страницFive-Part Hematology Analyzerswaraj sharmaОценок пока нет

- Mechatronics Sensor Communication DesignДокумент52 страницыMechatronics Sensor Communication DesignNahomОценок пока нет

- Different Types of Sensors ExplainedДокумент14 страницDifferent Types of Sensors ExplainedTrency FernandesОценок пока нет

- Wideband Multiprobe Microwave MultimeterДокумент3 страницыWideband Multiprobe Microwave MultimeterArif HurairahОценок пока нет

- Automation in Water Distribution SystemДокумент27 страницAutomation in Water Distribution SystemKunal DeshmukhОценок пока нет

- 2-Sensors and TransducersДокумент68 страниц2-Sensors and Transducersteklaykibrom3Оценок пока нет

- Chapter 5a - SensorsДокумент44 страницыChapter 5a - SensorsMinh Tiến NguyễnОценок пока нет

- Process Control 128Документ60 страницProcess Control 128Gagan SharmaОценок пока нет

- BT505 BIOSENSORS - HandoutsДокумент66 страницBT505 BIOSENSORS - HandoutsMehru NisaОценок пока нет

- Sensor (Compatibility Mode)Документ49 страницSensor (Compatibility Mode)JuprayОценок пока нет

- 1a MWD Survey MeasurementsДокумент22 страницы1a MWD Survey MeasurementsAli AhmedОценок пока нет

- Flow Measurements: Prepared By: Mirroyal Ismayilov (R6KX99) Pu Ruijie (D13L6M) Kashif Ali (DL0YNX) Tobi Eso (DBZIC5)Документ39 страницFlow Measurements: Prepared By: Mirroyal Ismayilov (R6KX99) Pu Ruijie (D13L6M) Kashif Ali (DL0YNX) Tobi Eso (DBZIC5)Mahmoud Abo ElnasrОценок пока нет

- Lecure-2 Sensors For Biomedical ApplicationsДокумент98 страницLecure-2 Sensors For Biomedical ApplicationsDivya Aseeja0% (1)

- Waters LC-MS PrimerДокумент44 страницыWaters LC-MS PrimerKiran ChokshiОценок пока нет

- Introduction To Robotics M3 L1Документ28 страницIntroduction To Robotics M3 L1Nithya ShreeОценок пока нет

- SensorДокумент15 страницSensorsultansingh007Оценок пока нет

- Unit Iv - SensorsДокумент10 страницUnit Iv - SensorsPG ChemistryОценок пока нет

- 66 - 15575 - EC 732 - 2014 - 1 - 1 - 2 - Chapter 1Документ11 страниц66 - 15575 - EC 732 - 2014 - 1 - 1 - 2 - Chapter 1ዘረአዳም ዘመንቆረርОценок пока нет

- Ultrasonic Flowmeter and Hot Wire AnemometerДокумент32 страницыUltrasonic Flowmeter and Hot Wire AnemometerManzari AnandОценок пока нет

- Chapter 5Документ48 страницChapter 5Endalk SimegnОценок пока нет

- Hot Wire AnemometerДокумент16 страницHot Wire AnemometerjennybunnyomgОценок пока нет

- Transducer Notes Vtu (Electrical and Electronics Measurement and Instrumentation)Документ50 страницTransducer Notes Vtu (Electrical and Electronics Measurement and Instrumentation)Narayan S. Burbure50% (4)

- Digital Flow Meter For GasДокумент2 страницыDigital Flow Meter For GasMASSFLOWMEASUREMENTSОценок пока нет

- Flow Transmitters PDFДокумент6 страницFlow Transmitters PDFMurugeshОценок пока нет

- Sensors and Transducers Overview by Dr. Tarek A. TutunjiДокумент77 страницSensors and Transducers Overview by Dr. Tarek A. TutunjiVarunОценок пока нет

- C8: Sensor and Sensor TechnologyДокумент72 страницыC8: Sensor and Sensor TechnologyOladokun Sulaiman Olanrewaju100% (4)

- Types of Flow Measuring DevicesДокумент19 страницTypes of Flow Measuring DevicesRafat ShaikhОценок пока нет

- TvfteamДокумент1 страницаTvfteamParth NakhaleОценок пока нет

- Bitcoin: - Parth Nakhale - Atif AhmedДокумент8 страницBitcoin: - Parth Nakhale - Atif AhmedParth NakhaleОценок пока нет

- MNNIT Allahabad Bags The All India Inter NIT Table Tennis Championship Title For The Second Time in Two YearsДокумент2 страницыMNNIT Allahabad Bags The All India Inter NIT Table Tennis Championship Title For The Second Time in Two YearsParth NakhaleОценок пока нет

- StarДокумент4 страницыStarParth NakhaleОценок пока нет

- Affidavit ParentДокумент1 страницаAffidavit ParentPRASENJIT MANDALОценок пока нет

- Understanding The Refugee Crisis in Middle EastДокумент6 страницUnderstanding The Refugee Crisis in Middle EastParth NakhaleОценок пока нет

- Chegg FinalДокумент2 страницыChegg FinalParth NakhaleОценок пока нет

- How to become a tutor and earn money on Chegg: Ashu Pant shares his experienceДокумент3 страницыHow to become a tutor and earn money on Chegg: Ashu Pant shares his experienceParth NakhaleОценок пока нет

- RefДокумент1 страницаRefParth NakhaleОценок пока нет

- Scale: It Is Common To Make A Distinction Between Thematic and Topographic MapsДокумент4 страницыScale: It Is Common To Make A Distinction Between Thematic and Topographic MapsParth NakhaleОценок пока нет

- Marking Scheme PPДокумент1 страницаMarking Scheme PPParth NakhaleОценок пока нет

- Indian School Al Ghobra Assessment I C++ Program OutputДокумент12 страницIndian School Al Ghobra Assessment I C++ Program OutputParth NakhaleОценок пока нет

- MITMUNC 2015 Position PaperДокумент2 страницыMITMUNC 2015 Position PaperParth NakhaleОценок пока нет

- How To Write A ResolutionДокумент1 страницаHow To Write A ResolutionParth NakhaleОценок пока нет

- Water Resource Management Notes For MNNITДокумент6 страницWater Resource Management Notes For MNNITParth NakhaleОценок пока нет

- Coursera Financial AidДокумент1 страницаCoursera Financial AidParth NakhaleОценок пока нет

- MEMS Accelerometers-KoncnaДокумент17 страницMEMS Accelerometers-KoncnaaryakushalОценок пока нет

- Unit4 1 PDFДокумент16 страницUnit4 1 PDFParth NakhaleОценок пока нет

- MemsДокумент4 страницыMemsParth NakhaleОценок пока нет

- 2015 BFnature15750 MOESM58 ESMДокумент9 страниц2015 BFnature15750 MOESM58 ESMmacheng yangОценок пока нет

- SV Is5Документ205 страницSV Is5weiya100% (1)

- Vortex-Induced Oscillation-A Selective ReviewДокумент18 страницVortex-Induced Oscillation-A Selective ReviewWade ZhouОценок пока нет

- At The Completion of The CourseДокумент2 страницыAt The Completion of The Courseoday albuthbahakОценок пока нет

- Parallel Circuit PDFДокумент6 страницParallel Circuit PDFRajdeep DasОценок пока нет

- Moisture and Total Solids AnalysisДокумент44 страницыMoisture and Total Solids AnalysisNicholas BoampongОценок пока нет

- Vesic 1975 Bearing Capacity of Shallow FoundationsДокумент27 страницVesic 1975 Bearing Capacity of Shallow Foundationst.w.c.100% (2)

- Homework Helpers - Chemistry PDFДокумент311 страницHomework Helpers - Chemistry PDFTamby100% (1)

- Generator DataДокумент8 страницGenerator DataMohammad Ibnul HossainОценок пока нет

- Assignment 1 (ELE8306 - 21)Документ5 страницAssignment 1 (ELE8306 - 21)umarsaboОценок пока нет

- Forane 22 Saturation Pressure Temperature DataДокумент1 страницаForane 22 Saturation Pressure Temperature Datavineeth100% (1)

- NASA CR-1785, Radiation Effects Design HDBKДокумент475 страницNASA CR-1785, Radiation Effects Design HDBKRGK77Оценок пока нет

- Your Past Lives Michael TalbotДокумент165 страницYour Past Lives Michael TalbotLester Lim86% (7)

- Test Planner-Repeater Course - 2023-2024 - (Phase-03)Документ2 страницыTest Planner-Repeater Course - 2023-2024 - (Phase-03)SbjОценок пока нет

- QUIZ 2 RIGID MOTION Master 9 THДокумент3 страницыQUIZ 2 RIGID MOTION Master 9 THBombasticОценок пока нет

- Chemical Thermodynamics: Module - 4Документ25 страницChemical Thermodynamics: Module - 4TeachingTrainingCoaching KnowledgeSharingSessionОценок пока нет

- D Shirmohammadi - A Compensation-Based Power Flo Method - IEEE TPS - 1998 - ConsultДокумент10 страницD Shirmohammadi - A Compensation-Based Power Flo Method - IEEE TPS - 1998 - ConsultJorge Luis Vega HerreraОценок пока нет

- Robot DynamicsДокумент52 страницыRobot Dynamicssilviocus88Оценок пока нет

- Work and EnergyДокумент32 страницыWork and Energycreative dudeОценок пока нет

- Beams - Determinate: Using Area Moment MethodДокумент16 страницBeams - Determinate: Using Area Moment MethodOmen JettОценок пока нет

- Experiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inДокумент5 страницExperiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inSanab KumarОценок пока нет

- Paul FrictionДокумент5 страницPaul FrictionPaul Aldrin OlvezОценок пока нет

- IEEE 4 Node Test Feeder Revised Sept. 19, 2006Документ9 страницIEEE 4 Node Test Feeder Revised Sept. 19, 2006Town Obio EteteОценок пока нет

- Analysis AssigmentДокумент50 страницAnalysis AssigmentAliyi MuktarОценок пока нет

- Large Deflections of Cantilever BeamsДокумент4 страницыLarge Deflections of Cantilever BeamsHasan Ayouby100% (1)

- Application of Tomography Inversion Methods To Determine The Seismic Wave Velocity Structure (VP, VS, VPVS) of The MEQ Data On ALPHA Geothermal FielДокумент5 страницApplication of Tomography Inversion Methods To Determine The Seismic Wave Velocity Structure (VP, VS, VPVS) of The MEQ Data On ALPHA Geothermal FielWegiDwiSaptoОценок пока нет

- Can CrusherДокумент11 страницCan CrusherElakkiya KarthicОценок пока нет

- Chapter 1Документ55 страницChapter 1nur izzah fatiniОценок пока нет

- Review Questions: 3. The Cyclist Has A Mass of 50 KG and Is Accelerating at 0.9 M/sДокумент8 страницReview Questions: 3. The Cyclist Has A Mass of 50 KG and Is Accelerating at 0.9 M/sMohamedОценок пока нет

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОт EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОценок пока нет

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionОт EverandBuild Your Own Electric Vehicle, Third EditionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Implementing an Integrated Management System (IMS): The strategic approachОт EverandImplementing an Integrated Management System (IMS): The strategic approachРейтинг: 5 из 5 звезд5/5 (2)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureОт EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureРейтинг: 3.5 из 5 звезд3.5/5 (48)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeОт EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeРейтинг: 4 из 5 звезд4/5 (130)

- The Rare Metals War: the dark side of clean energy and digital technologiesОт EverandThe Rare Metals War: the dark side of clean energy and digital technologiesРейтинг: 5 из 5 звезд5/5 (2)

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- ISO 50001: A strategic guide to establishing an energy management systemОт EverandISO 50001: A strategic guide to establishing an energy management systemОценок пока нет

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksОт EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksОценок пока нет

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesОт EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertРейтинг: 3 из 5 звезд3/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyОт EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyРейтинг: 5 из 5 звезд5/5 (3)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)