Академический Документы

Профессиональный Документы

Культура Документы

Facts at Your Fingertips-200803-Membranes

Загружено:

onizuka-t2263Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Facts at Your Fingertips-200803-Membranes

Загружено:

onizuka-t2263Авторское право:

Доступные форматы

Membranes

Department Editor: Kate Torzewski

S

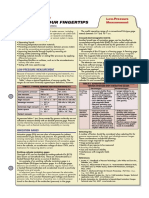

eparation by a membrane is achieved by Micrometers, 0.001 0.01 0.1 1.0 10

log scale

creating a boundary between different

bulk gas or liquid mixtures. As different

Scanning electron microscope Optical microscope

solvents and solutes flow through a membrane

at different rates, separation is achieved. Particle size

Here, we will focus on three filtration range Molecular Macromolecular Microparticle

techniques: microfiltration (MF), ultrafiltration Albumin protein Yeast cells

(UF) and nanofiltration (NF). These processes

are characterized by the size of the particle Aqueous salts Carbon black Paint pigment

that can be separated by the membrane, as Bacteria

Typical

illustrated in the figure. Each membrane type particles Sugar Virus A.C. fine test dust

is best suited for unique applications and is

Synthetic Tobacco smoke Milled flour

designed with the module and material that dye

will allow the best separation. Latex emulsion

Flow through a membrane is characterized Pesticide Colloidal silica Blue indigo dye Red

as either tangential flow filtration (TFF), where blood

Asbestos fibers cells

the feed stream flows at a velocity vector nor-

mal to the membrane surface, or normal flow Gelatin Coal dust

filtration (NFF), where the stream flows tangent

to the membrane surface. The flow pattern is Process for Ultrafiltration

filtration

dependent on the type of module utilized. NFF Nanofiltration Microfiltration

modules include: cartridges, stacked disks

and flat sheets. TFF modules include: plate-

and-frame (cassettes), hollow fibers, tubes, of crystallite orientation, fracture in such a way NANOFILTRATION

monoliths, spirals and vortex flow. that reproducible microchannels are made.

MICROFILTRATION Membrane modules NF, sometimes referred to as “loose RO

Many conventional designs are used in MF, (reverse osmosis),” utilizes a driving force

including cartridge-filter housing, plate-and- of 0.3 to 10.5 MPa to drive liquid solvents

MF separates particles from true solutions. This through the membrane while retaining small

frame-type devices, capillary bundles, tubular

technique is able to separate particles from solutes of about 10 to 100 nm in diameter.

membranes, spiral-wound modules and belt

about 0.1 to as high as 10 μm. As can be

filters. Ceramic MF membranes are available NF membranes are different from the mem-

seen from the figure, large, soluble macromol-

as flat sheet, single tubes, disc, and other forms, branes previously discussed, because they are

ecules, bacteria and other microorganisms can

primarily for lab use. Finally, cassettes are two usually charged, utilizing ion repulsion as a

be retained by MF membranes.

different cross-flow membrane devices. major method of charged-species rejection.

Membrane materials They have 20–80% NaCl retention and retain

MF membranes have the largest pore open- ULTRAFILTRATION > 200–1,000 Daltons of neutral organics,

ings of any other membrane. Typically, they with a low retention of dissolved gases.

can be classified as having tortuous or capil- UF membranes, with pore sizes ranging from Neutral or undissociated solutes have a lower

lary pores. about 1 to 100 nm in diameter, employ pres- retention than charged or dissociated solutes.

From solids. When membranes are made sure driving forces of 0.2–1.0 MPa. This tech- Membrane materials

by sintering or agglomeration of micropar- nique drives liquid solvents and small solutes Cellulose polymers. These are formed by

ticles, pores are formed by the interstices through the membrane, while retaining larger immersion casting of 30–40% polymer lac-

between solid particles. Common materi- particles, like large dissolved molecules, col- quers, which can include cellulose acetate,

als include: metal, metal oxide, graphite, loids and suspended solids. triacetate and acetate-butyrate, on a web

ceramic and polymer. immersed in water.

Membrane materials

Ceramic. These membranes are typically Thin film composites. Formed by interfacial

UF membranes are typically made of polymeric

created by the sol-gel process, which is the polymerization, TFCs involve coating a

structures, such as polyethersulfone, regener-

successive deposition of smaller ceramic microporous membrane substrate with an

ated cellulose, polysulfone, polyamide, poly-

precursor spheres, followed by firing to form aqueous prepolymer solution, then immers-

acrylonitrile or various fluropolymers. They are

multitube monoliths. ing it in a water-immiscible solvent contain-

formed by immersion casting on a web or as a

Track etched. A polymer film is exposed to composite on an MF membrane. Membrane se- ing a reactant.

a collimated beam of radiation that breaks lection is based on molecular-weight rating for Crosslinked polyetherurea. Some of these

chemical bonds in the polymer chains. The high yields, chemical and mechanical robust- membranes feature NaCl retention and

film is then etched in a bath that selectively at- ness during product processing and Clean In water permeability.

tacks the damaged polymer, a technique that Place, and process flux for sizing and costing.

produces a film with photogenic pores. Membrane modules

Chemical phase inversion. A solution of a Membrane modules NF membrane modules are available in

concentrated polymer in solvent is spread into a Modules include cassettes, spirals, hollow spiral, hollow fiber, tubular, and plate-and-

thin film, then precipitated through the slow ad- fibers, tubes, flat sheets, and inorganic mono- frame formats. Spirals are most common,

dition of a nonsolvent to produce tortuous pores. liths. These primarily operate in TFF to increase as they have low feed-side pressure props,

Thermal phase inversion. A solution of flux by reducing plugging. For virus removal are less prone to clogging, are easily

polymer in a poor solvent is prepared at an and water treatment, however, NFF operation cleaned, are mechanically robust, and are

elevated temperature. After being formed into is run with cartridge and hollow fiber modules. most economical.

its final shaped, the temperature is dropped

and the polymer precipitates, and the solvent References

is washed out. 1.“Perry’s Chemical Engineers’ Handbook,” 8th ed. McGraw Hill, New York, 2008.

Streched polymers. Semicrystalline polymers, 2.Seidel, A., ed. in chief, “Separation Technology,” second edition, John Wiley and Sons, Inc., New

which are stretched perpendicular to the axis Jersey, 2008.

FACTS AT YOUR FINGERTIPS Sponsored by:

Вам также может понравиться

- Module 1 Property Relationship PDFДокумент32 страницыModule 1 Property Relationship PDFManideep DuggiОценок пока нет

- Craters Produced by Explosions On The Soil SurfaceДокумент15 страницCraters Produced by Explosions On The Soil SurfacegpdufОценок пока нет

- Membrane Filtration Reverse Osmosis and NanofiltrationДокумент61 страницаMembrane Filtration Reverse Osmosis and NanofiltrationJanice Omadto100% (1)

- Membrane Separation Processes - Technology and Business OpportunitiesДокумент41 страницаMembrane Separation Processes - Technology and Business OpportunitiesMashiro Hikari0% (1)

- Water Treatment Membrane Processes PDFДокумент80 страницWater Treatment Membrane Processes PDFmehdi hennousОценок пока нет

- MSDS r407cДокумент16 страницMSDS r407cHardiman ArbiОценок пока нет

- Water Treatment - Reverse OsmosisДокумент217 страницWater Treatment - Reverse OsmosisDangolОценок пока нет

- Selecting Systems: Membrane FiltrationДокумент4 страницыSelecting Systems: Membrane FiltrationRaul TejedaОценок пока нет

- Membrane SeparationДокумент83 страницыMembrane SeparationKitty LastОценок пока нет

- Membrane Filtration TechniquesДокумент53 страницыMembrane Filtration TechniquesSreejesh P C100% (1)

- Membrane Separation ProcessesДокумент93 страницыMembrane Separation ProcessesMohammad ShafiОценок пока нет

- Membrane Technology Overview for Water TreatmentДокумент39 страницMembrane Technology Overview for Water Treatmentarun kumar100% (1)

- Advanced Topics in Membrane Separation and Electrophoresis: Class 1 To 4Документ18 страницAdvanced Topics in Membrane Separation and Electrophoresis: Class 1 To 4Mugdha Dabir-PathakОценок пока нет

- Bubble Column ReactorsДокумент34 страницыBubble Column ReactorsGhaya Bani Rushaid100% (2)

- Chapter 2. Membrane Technologies For Industrial Wastewaters TreatmentДокумент40 страницChapter 2. Membrane Technologies For Industrial Wastewaters TreatmentSophie LvОценок пока нет

- Membrane Processes OverviewДокумент58 страницMembrane Processes OverviewWazif ZakwanОценок пока нет

- 20130503132937Документ19 страниц20130503132937Wendy0% (1)

- 13 Chapter 1Документ35 страниц13 Chapter 1Koteswari MandavalliОценок пока нет

- 07 Membrane SeparationДокумент36 страниц07 Membrane SeparationRalph EvidenteОценок пока нет

- Passivation GMPДокумент51 страницаPassivation GMPAlexander AvdeiОценок пока нет

- 17.0 Lec 8membran BioseprationДокумент19 страниц17.0 Lec 8membran BioseprationChan Chun ChenОценок пока нет

- Membranes FactsДокумент1 страницаMembranes FactsLisbeth Roos RoosОценок пока нет

- Che Facts 0308 MembranesДокумент1 страницаChe Facts 0308 MembranesLizzita CruzОценок пока нет

- Membrane Characteristics and Applications in Separation ProcessesДокумент4 страницыMembrane Characteristics and Applications in Separation Processesعبدالله البافاريОценок пока нет

- Membrane ProcessesДокумент49 страницMembrane ProcessesNur AmaninaОценок пока нет

- Membranes and ModulesДокумент6 страницMembranes and ModulesmadhujayarajОценок пока нет

- Lapres Membran Lom FixxДокумент36 страницLapres Membran Lom FixxZhОценок пока нет

- Membrane Separation ProcessesДокумент38 страницMembrane Separation ProcessesAbdul AzizОценок пока нет

- Membrane Separation UpdatedДокумент59 страницMembrane Separation Updatedbbfe89f31eОценок пока нет

- Membrane Separations: Microfiltration ReviewДокумент69 страницMembrane Separations: Microfiltration ReviewCristina SilvaОценок пока нет

- Membrane Transport Mechanism: Models and Equations for Water FlowДокумент42 страницыMembrane Transport Mechanism: Models and Equations for Water FlowJawahir IlmОценок пока нет

- CHE449 - MergedДокумент246 страницCHE449 - MergedmuffinОценок пока нет

- Seminar ReportДокумент13 страницSeminar ReportShohitaa Choudhry67% (3)

- 2-1 Preparation of Membranes-Polymeric MembranesДокумент46 страниц2-1 Preparation of Membranes-Polymeric MembranesHM SE100% (1)

- Edit Edit: MembraneДокумент8 страницEdit Edit: MembraneAcatrinei Alexandra AndreeaОценок пока нет

- 05 Chapter 5 MicrofiltrationДокумент19 страниц05 Chapter 5 MicrofiltrationPRITHASHNI LETCHUMANANОценок пока нет

- CE 480 - Membrane Processes - 01Документ31 страницаCE 480 - Membrane Processes - 01NTEYE CHITONGEОценок пока нет

- Keratinization - Dr. PriyaДокумент37 страницKeratinization - Dr. PriyaDr. Priya Patel75% (4)

- Membrane - Deepika PDFДокумент52 страницыMembrane - Deepika PDFDIPSОценок пока нет

- AP Biology Unit 2: CellsДокумент67 страницAP Biology Unit 2: Cellsapi-292966101Оценок пока нет

- Basic Principles of Ultrafiltration MembranesДокумент6 страницBasic Principles of Ultrafiltration Membranesmadhujayaraj100% (2)

- Membrane Types and Classification GuideДокумент17 страницMembrane Types and Classification GuideAMOL RASTOGI 19BCM0012Оценок пока нет

- Reverse Osmosis Principle & ExperimentДокумент17 страницReverse Osmosis Principle & ExperimentEtikОценок пока нет

- Make and Test Polysulfone MembraneДокумент9 страницMake and Test Polysulfone MembraneRizki AuОценок пока нет

- PHILOS CatalogДокумент8 страницPHILOS CatalogVo Ngoc HoangОценок пока нет

- Polymers in Separation ProcessesДокумент32 страницыPolymers in Separation ProcessesP.A. Gonzales CortesОценок пока нет

- Caderno UC1 HistologyДокумент15 страницCaderno UC1 HistologyantonietohОценок пока нет

- Membrane Separations Explained: Microfiltration, Materials, and Fouling ReductionДокумент69 страницMembrane Separations Explained: Microfiltration, Materials, and Fouling ReductionShikha JaiswalОценок пока нет

- Journal of Colloid and Interface Science: Garry Nathaniel B. Baroña, Mijin Choi, Bumsuk JungДокумент9 страницJournal of Colloid and Interface Science: Garry Nathaniel B. Baroña, Mijin Choi, Bumsuk JungNuraini RahmaОценок пока нет

- Tiraferri A Et Al DX - Doi.org:10.1021:am200536p - ACS Appl. Mater. Interfaces 2011, 3, 2869-2877Документ9 страницTiraferri A Et Al DX - Doi.org:10.1021:am200536p - ACS Appl. Mater. Interfaces 2011, 3, 2869-2877parnaz88Оценок пока нет

- Intercellular Junctions in Animals and PlantsДокумент22 страницыIntercellular Junctions in Animals and PlantsBrillian AlfiОценок пока нет

- Avanti Brochure 09 MiniExtruder UltrasonicДокумент2 страницыAvanti Brochure 09 MiniExtruder UltrasonicVadimESPОценок пока нет

- Acsmacrolett 8b00173Документ5 страницAcsmacrolett 8b00173Linus hongОценок пока нет

- 1ee6308b-21ba-4652-a976-e3f41dbd5fa9Документ20 страниц1ee6308b-21ba-4652-a976-e3f41dbd5fa9BanОценок пока нет

- Ultra Filteration of MilkДокумент36 страницUltra Filteration of MilkMonty KushwahaОценок пока нет

- Membrane Separation Technology For Wastewater Treatment and Its Study Progress and Development TrendДокумент4 страницыMembrane Separation Technology For Wastewater Treatment and Its Study Progress and Development TrendEnrique MartinezОценок пока нет

- Fileseducationcyberlectured201501d201501 1001 PDFДокумент16 страницFileseducationcyberlectured201501d201501 1001 PDFSehaj MannОценок пока нет

- H2 Biology Notes On Cell Structure Cell Organelles PDFДокумент5 страницH2 Biology Notes On Cell Structure Cell Organelles PDFAnonymous 0iTAS7Оценок пока нет

- Mass Transfer in Membrane ProcessesДокумент16 страницMass Transfer in Membrane Processestatchanok1525Оценок пока нет

- General Biology 1: The Scientific Study of LifeДокумент69 страницGeneral Biology 1: The Scientific Study of Lifesweetygaming PHОценок пока нет

- Advances in Polymeric Nanofiltration Membrane - A ReviewДокумент56 страницAdvances in Polymeric Nanofiltration Membrane - A ReviewPolanqОценок пока нет

- Membrane Water Treatment Technologies for Clean Water ProductionДокумент22 страницыMembrane Water Treatment Technologies for Clean Water ProductionSnehal Dawkhar patilОценок пока нет

- 2008 NninreuleandreДокумент2 страницы2008 Nninreuleandreapi-413626812Оценок пока нет

- Polymers 14 05439Документ50 страницPolymers 14 05439Lidya HutaurukОценок пока нет

- Active Plasmonics and Tuneable Plasmonic MetamaterialsОт EverandActive Plasmonics and Tuneable Plasmonic MetamaterialsAnatoly V. ZayatsОценок пока нет

- Facts at Your Fingertips-201103-Infrared Temperature MeasurementДокумент1 страницаFacts at Your Fingertips-201103-Infrared Temperature Measurementonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowДокумент1 страницаFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)Документ1 страницаFacts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)onizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201105-Pressure Measurement ConsiderationsДокумент1 страницаFacts at Your Fingertips-201105-Pressure Measurement Considerationsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201011-Viscosity MeasurementДокумент1 страницаFacts at Your Fingertips-201011-Viscosity Measurementonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201006-Fluid MechanicsДокумент1 страницаFacts at Your Fingertips-201006-Fluid Mechanicsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201012-Project Design Decision-Making Option ListsДокумент1 страницаFacts at Your Fingertips-201012-Project Design Decision-Making Option Listsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201010-MSMPR Crystallization EquipmentДокумент1 страницаFacts at Your Fingertips-201010-MSMPR Crystallization Equipmentonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201007-Conservation Economics Carbon Pricing ImpactsДокумент1 страницаFacts at Your Fingertips-201007-Conservation Economics Carbon Pricing Impactsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201102-Control Valve Position SensorsДокумент1 страницаFacts at Your Fingertips-201102-Control Valve Position Sensorsonizuka-t2263Оценок пока нет

- Heat Transfer Fluids: System FiltrationДокумент1 страницаHeat Transfer Fluids: System Filtrationonizuka-t2263Оценок пока нет

- Controlling membrane foulingДокумент1 страницаControlling membrane foulingonizuka-t2263Оценок пока нет

- CHE Facts 0410Документ1 страницаCHE Facts 0410gwinnruОценок пока нет

- Facts at Your Fingertips-201001-Low-Pressure MeasurementДокумент1 страницаFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Оценок пока нет

- Steam Tracer Lines and Traps GuideДокумент1 страницаSteam Tracer Lines and Traps Guideonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201002-Positive Displacement PumpsДокумент1 страницаFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200909-Heat Transfer System Design IIДокумент1 страницаFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFДокумент1 страницаFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Оценок пока нет

- Steam Tracer Lines and Traps GuideДокумент1 страницаSteam Tracer Lines and Traps Guideonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFДокумент1 страницаFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201002-Positive Displacement PumpsДокумент1 страницаFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200912-Creating Installed Gain GraphsДокумент1 страницаFacts at Your Fingertips-200912-Creating Installed Gain Graphsonizuka-t2263Оценок пока нет

- Adsorption PDFДокумент1 страницаAdsorption PDFrasik.kiraneОценок пока нет

- CHE Facts 0410Документ1 страницаCHE Facts 0410gwinnruОценок пока нет

- Facts at Your Fingertips-201001-Low-Pressure MeasurementДокумент1 страницаFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Оценок пока нет

- Above and Underground Storage Tanks PDFДокумент1 страницаAbove and Underground Storage Tanks PDFrasik.kiraneОценок пока нет

- Facts at Your Fingertips-200910-Chemical Resistance of ThermoplasticsДокумент1 страницаFacts at Your Fingertips-200910-Chemical Resistance of Thermoplasticsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200907-Flowmeter SelectionДокумент2 страницыFacts at Your Fingertips-200907-Flowmeter Selectiononizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200905-Choosing A Control SystemДокумент1 страницаFacts at Your Fingertips-200905-Choosing A Control Systemonizuka-t2263Оценок пока нет

- Specialty metals guide corrosion resistance and propertiesДокумент1 страницаSpecialty metals guide corrosion resistance and propertiesonizuka-t2263Оценок пока нет

- Military Polyurethane Adhesive StudyДокумент5 страницMilitary Polyurethane Adhesive StudyAsim MansoorОценок пока нет

- Bonite Bonite LDДокумент2 страницыBonite Bonite LDManoj ChitreОценок пока нет

- Chapter 5Документ9 страницChapter 5abdel83Оценок пока нет

- Octanium EU SDSДокумент13 страницOctanium EU SDSTudor RatiuОценок пока нет

- Bioorganic & Medicinal Chemistry LettersДокумент3 страницыBioorganic & Medicinal Chemistry LetterschemikanthОценок пока нет

- Chapter Three Working Fluids (A) Ideal Gas (Perfect Gas) :: Statement No. (1)Документ16 страницChapter Three Working Fluids (A) Ideal Gas (Perfect Gas) :: Statement No. (1)Bonifacio MifañaОценок пока нет

- Revised GCL I Lab ManualДокумент95 страницRevised GCL I Lab ManualomskirtОценок пока нет

- Salt Recovery EvaporationДокумент2 страницыSalt Recovery EvaporationKapwell LimitedОценок пока нет

- Enzyme Part 1-5 Vikneswaran 260110132004Документ7 страницEnzyme Part 1-5 Vikneswaran 260110132004Vikneswaran VîçkýОценок пока нет

- SARA PEREZ TRUJILLO - Molecules and Bonds 7BДокумент4 страницыSARA PEREZ TRUJILLO - Molecules and Bonds 7BApuestas JulanoОценок пока нет

- Sudarshan PigmentsДокумент20 страницSudarshan Pigments44gurpreetОценок пока нет

- Nuclear Tech English - PDFДокумент20 страницNuclear Tech English - PDFShivang BhardwajОценок пока нет

- Determination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationДокумент16 страницDetermination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationpeterОценок пока нет

- CPK Method Report with Ranges and ParametersДокумент1 страницаCPK Method Report with Ranges and ParametersHussein N. FarhatОценок пока нет

- Fluid Mechanics FundamentalsДокумент11 страницFluid Mechanics FundamentalsDeeptanshu ShuklaОценок пока нет

- Lab Report No 8Документ11 страницLab Report No 8Mansoob BukhariОценок пока нет

- Test 1 September 2020 SemesterДокумент3 страницыTest 1 September 2020 SemesterAhmed AlwaqediОценок пока нет

- Tribolube 64Документ2 страницыTribolube 64JasonОценок пока нет

- PhotosynthesisДокумент35 страницPhotosynthesisChristopher MullenОценок пока нет

- Hollosep Trial in SpainДокумент10 страницHollosep Trial in SpainGandrig F VendrisОценок пока нет

- Service - FL - en Cranex Tome SoredexДокумент432 страницыService - FL - en Cranex Tome Soredexdr.sherifbisharaОценок пока нет

- ASETAZOLAMIDДокумент9 страницASETAZOLAMIDfarmasiОценок пока нет

- 5070 w17 Ms 41 PDFДокумент6 страниц5070 w17 Ms 41 PDFSaad ArsalanОценок пока нет

- Materials Challenges in Hydrogen-Fuelled Gas TurbinesДокумент27 страницMaterials Challenges in Hydrogen-Fuelled Gas TurbinesSaiful ShokriОценок пока нет

- Horizontal Vessel Foundation Design FounДокумент22 страницыHorizontal Vessel Foundation Design FounAllanОценок пока нет