Академический Документы

Профессиональный Документы

Культура Документы

FCD SHEET P2-01, P6-01 &SRF MGB-SRF-027-CP:02-025-P-003 MS No. MGB-MS-001-PS-001 SECTION 15400 PW200 ITEM 3.3 ITP No. MGB-ITP-001-PC-001

Загружено:

Imho TepОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FCD SHEET P2-01, P6-01 &SRF MGB-SRF-027-CP:02-025-P-003 MS No. MGB-MS-001-PS-001 SECTION 15400 PW200 ITEM 3.3 ITP No. MGB-ITP-001-PC-001

Загружено:

Imho TepАвторское право:

Доступные форматы

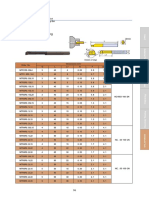

MARRIOTT GRAND BALLROOM PROJECT

INSTALLATION INSPECTION CHECKLIST FOR PVC PERFORATED PIPES & FITTINGS REV: A1

DRAWING REFERENCE: FCD SHEET P2-01, P6-01 &SRF MGB-SRF-027-CP:02-025-P-003 MS No. MGB-MS-001-PS-001

SPECIFICATION REFERENCE: SECTION 15400 PW200 ITEM 3.3 ITP No. MGB-ITP-001-PC-001

DISCIPLINE

LOCATION / AREA

ITEM REMARKS

ACTIVITIES / ITEMS TO BE INSPECTED STATUS

NO. NGCB EELHI

1 Check pipes, fittings & ancillary materials used conform to approved submittals

2 Check fabricated PVC pipe perforation holes & filter cloth are as per approved shop

drawings

3 Check pipe layout in the approved shop drawing

4 Check the spacing and adquacy of suppports

5 Check pipe slope / invert pipe levels

6 Check pipe bedding and backfill materials are acceptable

7 Check final connection to Sump pit

COMMENTS / DESCREPANCY (IF ANY)

NSC CQC ENGINEER GENCON QC ENGINEER EELHI INSPECTOR

SIGNATURE

NAME

DATE

MARRIOT GRAND BALLROOM PROJECT

INCOMING MATERIAL INSPECTION CHECKLIST FOR PVC PIPES REV: A1

DRAWING REFERENCE: FCD SHEET P2-01, P6-01 &SRF MGB-SRF-027-CP:02-025-P-003 Ms No. MGB-MS-001-PW-001

SPECIFICATION REFERENCE: SECTION 15400 PW200 ITEM 3.3 ITP No. MGB-ITP-001-PW-001

DISCIPLINE:

LOCATION / AREA

REMARKS

ITEM NO ACTIVITIES / ITEMS TO BE INSPECTED STATUS

NGCB EELHI

1 Check pipes and fittings conform to approve SRF

2 Check material brand is approved

3 Inspect all pipes, fittings and jointing materials are new and free from any

defects

4 Check required solvent cement and lubricant are available

5 Check the quantity / specification of pipes, en cap and fittings are according

to technical specification / codes

6 Check delivered quantity

7 Check all items are stored in orderly manner

COMMENTS / DESCREPANCY (IF ANY)

NSC CQC ENGINEER GENCON QC ENGINEER EELHI INSPECTOR

SIGNATURE

NAME

DATE

Вам также может понравиться

- Check List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Документ2 страницыCheck List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Imho TepОценок пока нет

- Checklist Mechanical Block-Outs and Pipe SleevesДокумент2 страницыChecklist Mechanical Block-Outs and Pipe SleevesImho Tep100% (1)

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalДокумент17 страницKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadОценок пока нет

- Itp & Material Inspection For Concrete RehabilitationДокумент3 страницыItp & Material Inspection For Concrete RehabilitationImho TepОценок пока нет

- Kok04200 Material TracabilityДокумент41 страницаKok04200 Material Tracabilityqamar qateebОценок пока нет

- MOS-0570-5685619-00 CombinedДокумент11 страницMOS-0570-5685619-00 Combinedarmsarabia01Оценок пока нет

- Daily QAQC Check SheetsДокумент1 страницаDaily QAQC Check Sheetsfhairuz.wahidОценок пока нет

- Technical Specification For Level Control ValvesДокумент13 страницTechnical Specification For Level Control ValvesAylaОценок пока нет

- NFE1 IR 21311 BUR 036 - FinalДокумент7 страницNFE1 IR 21311 BUR 036 - FinalДмитрий ИтигинОценок пока нет

- Subh (Pipe Inspection Procedure)Документ3 страницыSubh (Pipe Inspection Procedure)subhashaheer524Оценок пока нет

- QC PL 0006Документ1 страницаQC PL 0006AmeerОценок пока нет

- ITP For Pipeline Welding ProcedureДокумент15 страницITP For Pipeline Welding ProcedureNYO100% (2)

- Bolted Flange and Gasket Joints Assembly ProcedureДокумент9 страницBolted Flange and Gasket Joints Assembly ProceduremohdОценок пока нет

- Itp & Material Inspection For MasonryДокумент3 страницыItp & Material Inspection For MasonryImho TepОценок пока нет

- MGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031Документ9 страницMGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031velmurug_balaОценок пока нет

- A-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksДокумент25 страницA-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksUnna Malai50% (2)

- Mechanical WIP ChecklistsДокумент20 страницMechanical WIP ChecklistsJovani G. BallonОценок пока нет

- For Field Joint CoatingДокумент8 страницFor Field Joint Coatingrebbouche bilelОценок пока нет

- Itp Ralgo HssДокумент5 страницItp Ralgo Hssmark quijlvoОценок пока нет

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalДокумент11 страниц25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikОценок пока нет

- S-41-1224-001WR - Rev 1Документ38 страницS-41-1224-001WR - Rev 1heri_prasetyadiОценок пока нет

- Punch List For Fire Water Pump & Foam Pump PackageДокумент4 страницыPunch List For Fire Water Pump & Foam Pump PackageGomathyselviОценок пока нет

- TR Foam Tank Crude PumpДокумент3 страницыTR Foam Tank Crude PumpirfanlarikhotmailcomОценок пока нет

- Focus Assessment FAДокумент2 страницыFocus Assessment FAkousick sundararajanОценок пока нет

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Документ1 страницаCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumОценок пока нет

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingДокумент109 страниц60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimОценок пока нет

- Piping Inspection ProcedureДокумент9 страницPiping Inspection Proceduremohd as shahiddin jafriОценок пока нет

- KLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelДокумент5 страницKLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelRana AsifОценок пока нет

- Test Pack ProcedureДокумент10 страницTest Pack ProcedureDaengkulle Firmansyah PuteraОценок пока нет

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - B Re-Instatement Leak Test P04-B1Документ8 страницPetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - B Re-Instatement Leak Test P04-B1Wael ChouchaniОценок пока нет

- MR For FRP Pipe - Fittings & FlangesДокумент49 страницMR For FRP Pipe - Fittings & FlangeskasvikrajОценок пока нет

- CHK PH 0002Документ4 страницыCHK PH 0002jvfcvОценок пока нет

- CHK PH 0001Документ6 страницCHK PH 0001jvfcvОценок пока нет

- JXN ITR-A Piping PDFДокумент21 страницаJXN ITR-A Piping PDFAmyОценок пока нет

- TANK 06 Test PackДокумент12 страницTANK 06 Test PackGomathyselvi100% (2)

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFДокумент8 страницMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhОценок пока нет

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionДокумент10 страницProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiОценок пока нет

- Survey Works - Ras LaffanДокумент7 страницSurvey Works - Ras LaffanDindo QuintanОценок пока нет

- Pipe Hanger Support Inspection Checklist P055BZOR-0051-Q-677Документ1 страницаPipe Hanger Support Inspection Checklist P055BZOR-0051-Q-677Thomas SebastianОценок пока нет

- ITP For Installation For PVC Perforated Pipes of Underdrain SystemДокумент3 страницыITP For Installation For PVC Perforated Pipes of Underdrain SystemImho Tep75% (4)

- For Construction: Reliance Bangladesh LNG & Power LimitedДокумент21 страницаFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaОценок пока нет

- Appendix - Propgress Report IДокумент406 страницAppendix - Propgress Report IFebri Ramdani NugrahaОценок пока нет

- Electrical Inspection ChecklistДокумент40 страницElectrical Inspection ChecklistMohamed100% (1)

- Holiday Test ProcedureДокумент8 страницHoliday Test Procedureraed waheeb100% (1)

- Material Take OffДокумент5 страницMaterial Take OffArindom KunduОценок пока нет

- Pipe Fabrication - ErectionДокумент18 страницPipe Fabrication - ErectionShrichand G. Bathv50% (2)

- Incoming Inspection ChecklistДокумент1 страницаIncoming Inspection ChecklistResearch GatewayОценок пока нет

- 038-Pro Welding Consumable Control Procedure PDFДокумент20 страниц038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- OCTG Stock InspectionДокумент6 страницOCTG Stock Inspectionamin peyvandОценок пока нет

- 2012A Functional Spec For 3LPP (3 Layer Poly Propelene) Corrosion Coating For Linepipes) (Rev. 0)Документ46 страниц2012A Functional Spec For 3LPP (3 Layer Poly Propelene) Corrosion Coating For Linepipes) (Rev. 0)Samuel John100% (1)

- SM 001 SRV SpecДокумент5 страницSM 001 SRV Specvardan_vardanОценок пока нет

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkДокумент38 страницMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTОценок пока нет

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - AДокумент3 страницыIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraОценок пока нет

- Mech FIR-006Документ2 страницыMech FIR-006Bibin Chacko MammenОценок пока нет

- Blowers Fans Supply Verification ITPДокумент7 страницBlowers Fans Supply Verification ITPgauravamberkarОценок пока нет

- Adobe Scan 25-Oct-2022Документ6 страницAdobe Scan 25-Oct-2022himanshu koleyОценок пока нет

- Section Subject: Shaybah CPF Expansion ProjectДокумент21 страницаSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- Itp FGP 2Документ21 страницаItp FGP 2fusionndtОценок пока нет

- Indra: Donggi Senoro LNG ProjectДокумент17 страницIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Millennium Erectors Corporation: 9445 Retiro ST., Guadalupe, Makati CityДокумент5 страницMillennium Erectors Corporation: 9445 Retiro ST., Guadalupe, Makati CityImho TepОценок пока нет

- MS For Installation of TilesДокумент6 страницMS For Installation of TilesImho TepОценок пока нет

- MS For Pre - CastДокумент14 страницMS For Pre - CastImho TepОценок пока нет

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Документ9 страницMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepОценок пока нет

- Itp & Material Inspection For MasonryДокумент3 страницыItp & Material Inspection For MasonryImho TepОценок пока нет

- List of Method Satement (MS)Документ7 страницList of Method Satement (MS)Imho Tep100% (1)

- MS For Installation of Pipe Sleeves For Fire Protection Works (Final Submission)Документ7 страницMS For Installation of Pipe Sleeves For Fire Protection Works (Final Submission)Imho TepОценок пока нет

- MS For Form - WorksДокумент8 страницMS For Form - WorksImho Tep100% (1)

- Itp For Installation of FormworksДокумент1 страницаItp For Installation of FormworksImho TepОценок пока нет

- Module 2: Labor Computation: MobilizationДокумент33 страницыModule 2: Labor Computation: Mobilizationapriljoy angelesОценок пока нет

- Grey Cast Iron CompositionДокумент6 страницGrey Cast Iron CompositionSatendra ThakurОценок пока нет

- RC Beam Design Using MCDXДокумент20 страницRC Beam Design Using MCDXChanthy RathedОценок пока нет

- WIKA Bridge ProductsДокумент3 страницыWIKA Bridge ProductsMadi Civil El-ClasicoОценок пока нет

- Vulnerability Assessment of An Existing Jetty at Chittagong DockyardДокумент5 страницVulnerability Assessment of An Existing Jetty at Chittagong DockyardHazairin As-Shiddiq RahmanОценок пока нет

- Assignment 2 TosДокумент3 страницыAssignment 2 TosAjay YadavОценок пока нет

- Ethiopian Construction Works Corporation (ECWC) Summary Guard HouseДокумент6 страницEthiopian Construction Works Corporation (ECWC) Summary Guard Housegetnet100% (3)

- Deep Soil MixingДокумент14 страницDeep Soil MixingBudi ManОценок пока нет

- 096723-Resinous Floor SpecsДокумент7 страниц096723-Resinous Floor SpecsGhayas JawedОценок пока нет

- Development of Resilient Reinforced Concrete Public Apartment Buildings by Using Wall Elements Including Non-Structural Walls For Damage Reduction in El SalvadorДокумент6 страницDevelopment of Resilient Reinforced Concrete Public Apartment Buildings by Using Wall Elements Including Non-Structural Walls For Damage Reduction in El SalvadorWilliam GuzmánОценок пока нет

- Suspended Wood Ceiling SystemsДокумент9 страницSuspended Wood Ceiling SystemsSimran DeepОценок пока нет

- Ctoe Case Study: New Balance Athletic Shoe IncДокумент12 страницCtoe Case Study: New Balance Athletic Shoe IncSakshi ShardaОценок пока нет

- Turning TOTIME Miniature Tools PDFДокумент14 страницTurning TOTIME Miniature Tools PDFvedrenne92Оценок пока нет

- BS 5950 Part 4 1994 - Code of Practice For Design of Composite Slabs With Profiled Steel SheetingДокумент39 страницBS 5950 Part 4 1994 - Code of Practice For Design of Composite Slabs With Profiled Steel Sheeting111111100% (2)

- CompositesДокумент55 страницCompositesali mohammed100% (1)

- Saudi Aramco Inspection ChecklistДокумент1 страницаSaudi Aramco Inspection ChecklistjunaidОценок пока нет

- Precast Book in TДокумент6 страницPrecast Book in TVinay JaiswalОценок пока нет

- Famous Foreign ArchitectsДокумент21 страницаFamous Foreign ArchitectsCrisostomo Andiong BaltazarОценок пока нет

- Welding SymbolsДокумент60 страницWelding Symbolskimboon_ngОценок пока нет

- Construction Thermal Insulation Weather Resistance: An Example of CladdingДокумент10 страницConstruction Thermal Insulation Weather Resistance: An Example of CladdingVarunОценок пока нет

- Resume Titian Damai Mandiri PDFДокумент8 страницResume Titian Damai Mandiri PDFBernard RiaulanОценок пока нет

- Data Sheet - HCU603 PDFДокумент1 страницаData Sheet - HCU603 PDFlaxmi29Оценок пока нет

- DATABASE - OragadamДокумент2 страницыDATABASE - OragadamJiyoPaulОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент33 страницыNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORОценок пока нет

- Guide To Good Factory Planning EbookДокумент15 страницGuide To Good Factory Planning EbookWeb Spring100% (1)

- Typical Second and Third Floor Plan: Four (4) Storey, Twenty (20) Classroom School BuildingДокумент1 страницаTypical Second and Third Floor Plan: Four (4) Storey, Twenty (20) Classroom School BuildingJuan Istil100% (1)

- Stas 1242-4-85 RДокумент9 страницStas 1242-4-85 RSzabolcs KovacsОценок пока нет

- Cylinder Test ReportДокумент1 страницаCylinder Test Reportraju_420034520Оценок пока нет

- History of Architecture 2 History of Architecture 2 Ar. Diane A. Jose Ar. Diane A. JoseДокумент28 страницHistory of Architecture 2 History of Architecture 2 Ar. Diane A. Jose Ar. Diane A. JoseJohn Roldan BuhayОценок пока нет