Академический Документы

Профессиональный Документы

Культура Документы

Industrial Internship at RAYALASEEMA THERMAL POWER

Загружено:

Goutham Reddy0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаОригинальное название

Internship Poster_Template (1)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаIndustrial Internship at RAYALASEEMA THERMAL POWER

Загружено:

Goutham ReddyАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

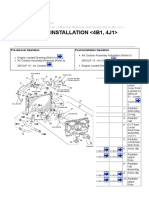

Industrial Internship at RAYALASEEMA THERMAL POWER PROJECT

Duration : 07/06/2019 to 07/07/2019

PALLI GOUTHAM REDDY| 17BME0720 | School of Mechanical

Organization Information Engineering

Rayalaseema Thermal Power Project is a 1050MW coal plant in Muddanur, Cuddapah, district, Andhra Pradesh, India, operated by

Andhra Pradesh Power Generation Corporation (APGENCO). It comprises 5 units, each 210 MW, built between 1994 and 2010.

Rayalaseema Thermal Power Plant was developed under 3 stages namely stages I, II and III. It stood first in-country during 98-99,

2002–03, 2003–04 and second during 99-2000, 2001-02. The station has received Meritorious productivity awards for six consecutive

years and an Incentive award for seven consecutive years. BHEL commissioned stage IV unit 1x600MW in March 2018 leading to a

total installed capacity of RTPP to 1650MW.

Day to Day Activities

Day Date Activity

1 07/06/2019 introduction to RTPP. Rules and regulations followed in RTPP and safety measures should be followed in RTPP. Hierarchy in RTPP.

2 08/06/2019 Brief overview about the essential inputs to the power project. Visited the workshop and the work done by the workers.

3 10/06/2019 Power plant overview. There are 5 stages in the thermal power plant.

4 11/06/2019 class about auxiliary systems of the Power plant which consists of cooling pond, condenser and the pumps.

5 12/06/2019 Class on the Carnot cycle. To calculate thee efficiency of Carnot cycle.

6 13/06/2019 Class on the Rankine cycle.

7 14/06/2019 Class on the importance and improving Rankine cycle efficiency.

8 15/06/2019 A group discussion and suggestions about improving Rankine cycle efficiency.

9 17/06/2019 Introduction to steam generators. The boilers used in RTPP are the Babcock and Wilcox boilers.

10 18/06/2019 Introduction about the components of the boiler. Furnace ,drum, soot blowers, coal piping burners and Igniters and oil burners.

11 19/06/2019 Classification of boilers. Boilers are classified in many ways based on their position, size, amount of steam generated and circulation

12 20/06/2019 Discussion about high pressure and low-pressure boilers and firetube and water tube boilers.

13 21/06/2019 Boiler mountings and accessories. Mountings are used for safety where as accessories are used to increase the boiler efficiency.

14 22/06/2019 Performance of boilers. The parameters are evaporative capacity, equivalent evaporation, factor f evaporation, boiler efficiency.

15 24/06/2019 Explanation about boiler draught cooling tower.

16 26/06/2019 Explanation about boiler drum and electrostatic precipitator.

17 27/06/2019 Class on economizer. Location of economizer in the boiler and the function of economizer.

18 28/06/2019 Class on super heaters. Location of super heater in the boiler and the function of super heater in the boiler.

19 29/06/2019 Class on air pre-heaters. Location of air pre-heaters and the function of air pre-heaters..

20 01/07/2019 Discussion on overall plant efficiency improvement.

21 02/07/2019 Combustion equipment and firing methods and pulverized coal firing.

22 03/07/2019 Coal handling and preparation and ash handling and preparation.

23 04/07/2019 Turbine overview and components of the turbine. Geometrical dimensions of the turbine.

24 05/07/2019 Took a day to visit the electrical department in the thermal power plant. Visited steam generators in other divisions.

25 06/07/2019 I passed my greetings to my guide and the managers, junior engineers, workers as they shared knowledge to me and took my

certificate.

Key Learning Experience/Skills Acquired Certificate

• Understood the process flow involved in the power plant.

• Understood the organization structure and hierarchy of the organization.

• Concepts of Total Quality Management and Implementation.

• Gained hands on experience in assembly or tooling .

• Gained knowledge about the boiler and turbine and efficiency of the

rankine cycle.

• Understood various machining and fabrication process.

• Understood the work environment.

Provide the necessary proof for the key learning experiences you have

mentioned .

Supervisor of the Organization

Mr. G Sree Ramulu

Organization Name :RAYALASEEMA THERMAL POWER PROJECT

Contact Details including mail ID and Phone Number

9440907113, rtpp.ce@apgenco.gov.in

Вам также может понравиться

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsОт EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsРейтинг: 4 из 5 звезд4/5 (9)

- Practical Training Report on Power Plant FamiliarizationДокумент67 страницPractical Training Report on Power Plant FamiliarizationAnaytullah AnsariОценок пока нет

- Industrial Training Seminar 2019Документ31 страницаIndustrial Training Seminar 2019Siddhant GoswamiОценок пока нет

- Industrial Training Report-IPGCL& PPCLДокумент49 страницIndustrial Training Report-IPGCL& PPCLBrajesh YadavОценок пока нет

- Training ReportДокумент21 страницаTraining ReportPiyush Khandait0% (1)

- Amarjeet KumarДокумент3 страницыAmarjeet Kumaramarjeet kumarОценок пока нет

- JPCL - TaqiДокумент22 страницыJPCL - TaqiAsad UllahОценок пока нет

- Oup Accepted Manuscript 2018Документ13 страницOup Accepted Manuscript 2018KARTIKEY SRIVASTAVAОценок пока нет

- A Project Report On Power Factor Improvement in SPRS (Slip Power Recovery Systems) byДокумент46 страницA Project Report On Power Factor Improvement in SPRS (Slip Power Recovery Systems) bysiddu_27Оценок пока нет

- Internship ReportДокумент11 страницInternship ReportMubarak KazminОценок пока нет

- Industrial Training Report-IPGCL& PPCLДокумент92 страницыIndustrial Training Report-IPGCL& PPCLSaurav Kumar100% (2)

- Report on Vocational Training at Budge Budge Power PlantДокумент42 страницыReport on Vocational Training at Budge Budge Power PlantAnonymous kXXKxxbCSf100% (1)

- HPC Technical Services: BoilerДокумент18 страницHPC Technical Services: BoilerRichard Andrianjaka LuckyОценок пока нет

- Engenius Erectors Private Limited: A Brief Outline of a Leading Power Plant Construction CompanyДокумент61 страницаEngenius Erectors Private Limited: A Brief Outline of a Leading Power Plant Construction CompanyManjesh BnОценок пока нет

- Power Plant Manual: A Guide to Thermal Power Station Operations and MaintenanceДокумент151 страницаPower Plant Manual: A Guide to Thermal Power Station Operations and MaintenanceYogendra100% (1)

- Summer Training Report: Badarpur Thermal Power Station (A Unit of NTPC)Документ72 страницыSummer Training Report: Badarpur Thermal Power Station (A Unit of NTPC)mansi_angel100% (1)

- Design and Fabrication of Electricity Production System From Industrial Heat or Waste Material ReportДокумент20 страницDesign and Fabrication of Electricity Production System From Industrial Heat or Waste Material ReportErole Technologies Pvt ltd Homemade EngineerОценок пока нет

- A Study On Labour UnrestДокумент169 страницA Study On Labour UnrestShanmuka SreenivasОценок пока нет

- Heg Minor Training ReportДокумент23 страницыHeg Minor Training ReportSourabh SenОценок пока нет

- WHR 1Документ4 страницыWHR 1Ashok KumarОценок пока нет

- Amarendra Kancharla - 17BME0828 - School of Mechanical EngineeringДокумент1 страницаAmarendra Kancharla - 17BME0828 - School of Mechanical EngineeringGoutham ReddyОценок пока нет

- Combined Cycle Power PerformanceДокумент4 страницыCombined Cycle Power PerformanceSyedNadeemAhmedОценок пока нет

- Field Engineer with 7+ years experienceДокумент5 страницField Engineer with 7+ years experienceRaj PalatiОценок пока нет

- About The Company1Документ34 страницыAbout The Company1AHMET ÇELİKОценок пока нет

- Project Report On TurbineДокумент45 страницProject Report On TurbineDeepak KumarОценок пока нет

- Devandra - Godara - Resume (1) - 3Документ1 страницаDevandra - Godara - Resume (1) - 3Devandra GodaraОценок пока нет

- Final Report 2 PsДокумент27 страницFinal Report 2 PsNishant AsharОценок пока нет

- Energy Storage System Using Regenerative Braking in An Electric Car Final Year Project ProposalДокумент25 страницEnergy Storage System Using Regenerative Braking in An Electric Car Final Year Project ProposalShah ZamanОценок пока нет

- Project Study Report: "Centrifugal Pump, Gas Turbine & Mechanical Seal"Документ28 страницProject Study Report: "Centrifugal Pump, Gas Turbine & Mechanical Seal"Shivam AgrawalОценок пока нет

- Bagaimana Industri BerperanДокумент45 страницBagaimana Industri BerperanYusnia HamidahОценок пока нет

- Gas Industy Training ReportДокумент23 страницыGas Industy Training ReportshivangОценок пока нет

- Aravali Power Corporation Internship Report (1) (Thermal Power Plant)Документ58 страницAravali Power Corporation Internship Report (1) (Thermal Power Plant)Vijay Chhillar100% (2)

- Industrial Visit TO Kothagudem Thermal Power PlantДокумент23 страницыIndustrial Visit TO Kothagudem Thermal Power PlantAbhishek NarayanaОценок пока нет

- Mini ProjectДокумент44 страницыMini ProjectVenkata Sai M60% (5)

- Boiler Tube CoatingsДокумент61 страницаBoiler Tube CoatingsRahul DeshmukhОценок пока нет

- Guide to Developing a Biomass ProjectДокумент16 страницGuide to Developing a Biomass ProjectHeb RuОценок пока нет

- Industrial Training Report: Indian Oil, Barauni RefineryДокумент39 страницIndustrial Training Report: Indian Oil, Barauni RefineryPriyanshu PrakashОценок пока нет

- Ramunaik Resume 2023Документ5 страницRamunaik Resume 2023ramu naik malothОценок пока нет

- Captive Thermal Power Plant Seminar ReportДокумент27 страницCaptive Thermal Power Plant Seminar ReportSubham100% (1)

- My Final Project (ARJUN)Документ86 страницMy Final Project (ARJUN)Brijesh PatelОценок пока нет

- Power Palnt Performance PDFДокумент161 страницаPower Palnt Performance PDFrafik1995100% (1)

- Powerplant PerformanceДокумент161 страницаPowerplant PerformancePhanindra Kumar J100% (1)

- PPE Microproject 3504Документ10 страницPPE Microproject 3504SohamОценок пока нет

- Final Project CorrectedДокумент32 страницыFinal Project CorrectedabebeОценок пока нет

- Power Plant Performance PDFДокумент161 страницаPower Plant Performance PDFvamsikl100% (2)

- Thermal Power PlantДокумент70 страницThermal Power PlantLovelesh MalavОценок пока нет

- Industrial Internship Training at Crisp, Bhopal: Submitted By:-Ashutosh YadavДокумент15 страницIndustrial Internship Training at Crisp, Bhopal: Submitted By:-Ashutosh YadavAshutosh yadavОценок пока нет

- Project NTPCДокумент43 страницыProject NTPCShubham CronosОценок пока нет

- Resume Vickram PДокумент2 страницыResume Vickram PMd AkhtarОценок пока нет

- Report on Industrial Training at NTPC Thermal Power StationДокумент32 страницыReport on Industrial Training at NTPC Thermal Power Stationqwerty singhОценок пока нет

- Energy Expert with 24 Years ExperienceДокумент5 страницEnergy Expert with 24 Years ExperiencesayedmhОценок пока нет

- Project ReportДокумент89 страницProject ReportgoyalzОценок пока нет

- Combined Cycle Power Plant Fundamentals: CourseДокумент7 страницCombined Cycle Power Plant Fundamentals: CourseArun KumarОценок пока нет

- Aruna Biomass-Company-ProfileДокумент8 страницAruna Biomass-Company-ProfileAdhavan ThamizhanОценок пока нет

- Aruna Biomass-Company-ProfileДокумент8 страницAruna Biomass-Company-ProfileAdhavan ThamizhanОценок пока нет

- Gist of Energy Audit in The Dairy IndustryДокумент3 страницыGist of Energy Audit in The Dairy Industrykeya2020Оценок пока нет

- HPE Final PDFДокумент19 страницHPE Final PDFZaroon KhanОценок пока нет

- Industrial Training - Report BookДокумент19 страницIndustrial Training - Report BookJason KОценок пока нет

- Pulp and Paper Industry: Energy ConservationОт EverandPulp and Paper Industry: Energy ConservationРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Palli Goutham Reddy 17BME0720: Hydraulic BrakesДокумент2 страницыPalli Goutham Reddy 17BME0720: Hydraulic BrakesGoutham ReddyОценок пока нет

- WINSEM2017-18 - CHY1002 - TH - SJT422 - VL2017185004961 - Reference Material II - EnvironmentДокумент16 страницWINSEM2017-18 - CHY1002 - TH - SJT422 - VL2017185004961 - Reference Material II - EnvironmentGoutham ReddyОценок пока нет

- Palli Goutham Reddy 17BME0720: Hydraulic BrakesДокумент3 страницыPalli Goutham Reddy 17BME0720: Hydraulic BrakesGoutham ReddyОценок пока нет

- Propeller Shaft Univ JointДокумент7 страницPropeller Shaft Univ JointGoutham ReddyОценок пока нет

- Chy1002 Environmental-Sciences TH 1.1 46 Chy1002 PDFДокумент2 страницыChy1002 Environmental-Sciences TH 1.1 46 Chy1002 PDFSai deepakОценок пока нет

- Prashanth Reddy M Resume UpdatedДокумент1 страницаPrashanth Reddy M Resume UpdatedGoutham ReddyОценок пока нет

- Graphical Method to Find Optimal SolutionsДокумент8 страницGraphical Method to Find Optimal SolutionsGoutham ReddyОценок пока нет

- Assembly and Disassembly of Air Brake System.: Mee3006 Automobile Engineering Experiment - 9Документ3 страницыAssembly and Disassembly of Air Brake System.: Mee3006 Automobile Engineering Experiment - 9Goutham ReddyОценок пока нет

- Experiment - 10 Sai Teja P 15bme0929Документ19 страницExperiment - 10 Sai Teja P 15bme0929Goutham ReddyОценок пока нет

- Personal Details Experience: Peram Venkata Siva Rami ReddyДокумент1 страницаPersonal Details Experience: Peram Venkata Siva Rami ReddyGoutham ReddyОценок пока нет

- Amarendra Kancharla - 17BME0828 - School of Mechanical EngineeringДокумент1 страницаAmarendra Kancharla - 17BME0828 - School of Mechanical EngineeringGoutham ReddyОценок пока нет

- WINSEM2017-18 - CHY1002 - TH - SJT422 - VL2017185004961 - Reference Material I - Environmental Problems, Causes, EffectsДокумент15 страницWINSEM2017-18 - CHY1002 - TH - SJT422 - VL2017185004961 - Reference Material I - Environmental Problems, Causes, EffectsGoutham ReddyОценок пока нет

- F10Документ3 страницыF10Akansha GuptaОценок пока нет

- Industrial Internship at RAYALASEEMA THERMAL POWERДокумент1 страницаIndustrial Internship at RAYALASEEMA THERMAL POWERGoutham ReddyОценок пока нет

- Goutham Reddy Mechanical Engineer ProfileДокумент1 страницаGoutham Reddy Mechanical Engineer ProfileGoutham ReddyОценок пока нет

- WINSEM2017-18 - MAT2001 - ETH - SJT124 - VL2017185000400 - Reference Material III - Link To Download MAT2001 NotesДокумент1 страницаWINSEM2017-18 - MAT2001 - ETH - SJT124 - VL2017185000400 - Reference Material III - Link To Download MAT2001 NotesGoutham ReddyОценок пока нет

- Heat TreatmentДокумент20 страницHeat Treatmentshanu100% (1)

- WINSEM2017-18 - MAT2001 - ETH - GDNG08 - VL2017185000512 - Reference Material I - Design of Experriments-One Way ClassificationДокумент4 страницыWINSEM2017-18 - MAT2001 - ETH - GDNG08 - VL2017185000512 - Reference Material I - Design of Experriments-One Way ClassificationGoutham ReddyОценок пока нет

- TALAT Lecture 3205: The Fluidity of Molten MetalsДокумент19 страницTALAT Lecture 3205: The Fluidity of Molten MetalsCORE MaterialsОценок пока нет

- Module 5 - Principles of Gating and RiseringДокумент14 страницModule 5 - Principles of Gating and RiseringGoutham ReddyОценок пока нет

- Course Code: MEE2014 Deadline Course Name: Metal Casting Technology Max. Marks: 10 Faculty-In-Charge: Dr. Srinivasan Narayanan Slot: F1Документ1 страницаCourse Code: MEE2014 Deadline Course Name: Metal Casting Technology Max. Marks: 10 Faculty-In-Charge: Dr. Srinivasan Narayanan Slot: F1Kunaljeet ChakrabortyОценок пока нет

- L13 15Документ32 страницыL13 15saireddy4b1Оценок пока нет

- METAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGДокумент13 страницMETAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGGoutham ReddyОценок пока нет

- Module 3 - Casting Processes OverviewДокумент18 страницModule 3 - Casting Processes OverviewGoutham ReddyОценок пока нет

- Module 3: Taylor SeriesДокумент3 страницыModule 3: Taylor SeriesGoutham ReddyОценок пока нет

- Module 3: Laurent Series: Dr. T. PhaneendraДокумент4 страницыModule 3: Laurent Series: Dr. T. PhaneendraGoutham ReddyОценок пока нет

- Module 2: Conformal Mapping: Dr. T. Phaneendra January 3, 2019Документ13 страницModule 2: Conformal Mapping: Dr. T. Phaneendra January 3, 2019Goutham ReddyОценок пока нет

- "Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Документ27 страниц"Flexible Manufacturing System": K.AMARENDRA (17BME0828) P.GOUTHAM REDDY (17BME0720) Y.V.SIVS PRASANTH (17BME0457)Goutham ReddyОценок пока нет

- "Flexible Manufacturing System": Department of Mechanical EngineeringДокумент32 страницы"Flexible Manufacturing System": Department of Mechanical EngineeringGoutham ReddyОценок пока нет

- Provisional Grade History: Register No. Name Program SchoolДокумент3 страницыProvisional Grade History: Register No. Name Program SchoolGoutham ReddyОценок пока нет

- 41a JAQWLM : Induction SoilДокумент3 страницы41a JAQWLM : Induction SoilTomislav JovanovicОценок пока нет

- PICO CMS How To InstallДокумент5 страницPICO CMS How To InstallrakeshОценок пока нет

- Data Sheet NPNB HN22PA3Документ2 страницыData Sheet NPNB HN22PA3Liliana ZamoraОценок пока нет

- IoT-Based Agriculture: Monitoring Crops and Soil ConditionsДокумент21 страницаIoT-Based Agriculture: Monitoring Crops and Soil ConditionsAurangzaibОценок пока нет

- Oopm MiniДокумент20 страницOopm MiniAjit SargarОценок пока нет

- SEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualДокумент5 страницSEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualAz Zahra AzmanОценок пока нет

- EWA Renewable Resource Eligibility RequirementsДокумент36 страницEWA Renewable Resource Eligibility RequirementshanyalramadyОценок пока нет

- SBNHH-1D45C Product SpecificationsДокумент4 страницыSBNHH-1D45C Product SpecificationsMauricioОценок пока нет

- UntitledДокумент28 страницUntitledRakibul IslamОценок пока нет

- Aiml Virtual InternshipДокумент21 страницаAiml Virtual InternshipPainampuram JuhithaОценок пока нет

- Necessary Documents For Passport or E-Passport ApplicationДокумент1 страницаNecessary Documents For Passport or E-Passport ApplicationMizanul HoqueОценок пока нет

- 3D Instruments Accu-Cal Plus Instruction ManualДокумент20 страниц3D Instruments Accu-Cal Plus Instruction ManualGregОценок пока нет

- Private Fire Hydrant (PFH) Inspection and Testing FormДокумент2 страницыPrivate Fire Hydrant (PFH) Inspection and Testing Formarnab_8Оценок пока нет

- Major Front RKDFДокумент7 страницMajor Front RKDFsai projectОценок пока нет

- Subsea Xmas TreeДокумент8 страницSubsea Xmas Treemadonnite3781100% (1)

- Hikvision Smart Functions and Applications: Hikvision Certified Security AssociateДокумент48 страницHikvision Smart Functions and Applications: Hikvision Certified Security AssociateMiri HasanovОценок пока нет

- 1 BR LLamasoft Supply Chain Guru USДокумент6 страниц1 BR LLamasoft Supply Chain Guru USXiaozhen LiuОценок пока нет

- Missing Homework TemplateДокумент7 страницMissing Homework Templateafnangetppyqes100% (1)

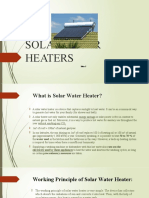

- Solar Water HeatersДокумент16 страницSolar Water HeatersKRUPA.SОценок пока нет

- CQI and IRCA Certified ISO/IEC 27001:2013 Lead Auditor Training CourseДокумент6 страницCQI and IRCA Certified ISO/IEC 27001:2013 Lead Auditor Training Coursedigi devaОценок пока нет

- Research Manuscript: Challenges of Home-Learning Through The Eyes of A StudentДокумент26 страницResearch Manuscript: Challenges of Home-Learning Through The Eyes of A StudentSai WatanabeОценок пока нет

- A Single Stage Integrated Bidirectional AC/DC and DC/DC Converter For Plug-In Hybrid Electric VehiclesДокумент6 страницA Single Stage Integrated Bidirectional AC/DC and DC/DC Converter For Plug-In Hybrid Electric VehiclesAli HussienОценок пока нет

- Course 1 Anchor Instalation inДокумент39 страницCourse 1 Anchor Instalation inViktorMarkuletsОценок пока нет

- overview of Possible Uses of SawdustДокумент194 страницыoverview of Possible Uses of SawdustMoreMoseySpeedОценок пока нет

- TECHNIC BROCHURE HiabДокумент10 страницTECHNIC BROCHURE HiabSANTIAGO HERNANDEZ RODRIGUEZОценок пока нет

- Mcse 0041Документ5 страницMcse 0041Rajat ManchandaОценок пока нет

- AJ&Smart Design Sprint ChecklistДокумент22 страницыAJ&Smart Design Sprint ChecklistTemo GiorgadzeОценок пока нет

- 64148069036e353d2c4d1930 - Weekly Timesheet Template - My HoursДокумент9 страниц64148069036e353d2c4d1930 - Weekly Timesheet Template - My Hoursoces1551Оценок пока нет

- The European Business Review - July August 2023Документ98 страницThe European Business Review - July August 2023bambiemily tanОценок пока нет

- Role of LibrarianДокумент19 страницRole of LibrarianVivekananda RaoОценок пока нет