Академический Документы

Профессиональный Документы

Культура Документы

Boletin Principios de Limpieza

Загружено:

Saul CerveraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boletin Principios de Limpieza

Загружено:

Saul CerveraАвторское право:

Доступные форматы

Application Engineering

B U L L E T I N

AE24-1105 R5 July 2008

Reformatted November 2010

Principles of Cleaning Refrigeration Systems

Emerson strongly supports refrigerant recovery and very detrimental to refrigeration systems and must be

recycling as part of the solution to the CFC/ozone removed before start up and after field service. Blowing

depletion problem. Only the latest techniques should out lines with dry nitrogen may remove a major part

be used when servicing equipment containing CFCs. of the air from a system, but if air is trapped in the

compressor during installation it is practically impossible

Examination of compressors returned to the factory for to remove from the compressor crankcase by purging

replacement indicates that many such replacements with nitrogen.

could have been prevented if all contaminants had

been removed from the refrigeration system at the time New and replacement compressors are shipped from

of field installation. Returned compressors are at times the factory with a dry air holding charge, and must be

reported as motor failures, but in reality the return is due evacuated before being put in service.

to damaged bearings, valve reeds, or connecting rods

caused by contaminants, which in turn caused motor Triple evacuation of the system or compressor, as

damage as a secondary effect. required, is strongly recommended (twice to 1,500

microns and finally to 500 microns,) breaking the

It is essential that all foreign materials be removed from vacuum each time with dry nitrogen. The vacuum pump

the system at the time of the original installation. Filings, must be connected to both the high and low sides of

shavings, dirt, solder, flux, metal chips, bits of steel wool, the system through properly sized connections, since

sand from sandpaper, and wire from cleaning brushes restrictive service connections may make the process

have all been found in systems and frequently end up so slow as to be unacceptable, or may lead to false

in the compressor. Many of these contaminants are readings because of pressure drop through the fittings.

so small they will pass through a fine mesh screen. In

addition, the metal fragments may be rotating because System Cleaning Procedure After Hermetic Motor

of gas velocity and cut or break the usual compressor Burn-out

suction screen. When a motor burnout occurs in the compressor, the

resulting high temperature arc causes a portion of the

Suction Line Filter and Filter-Driers refrigerant/oil mixture to break down into carbonaceous

As a result of the above types of contamination, a heavy sludge, corrosive acid, and water.

duty suction line filter or filter-drier is recommended

for every field installation. These are available with It has long been recognized that such contamination

reasonable pressure drop, and will provide maximum resulting from a burnout can result in repeat failures if

protection for the most vulnerable part of the system. the contaminants are allowed to reach and remain in

A set of access valves should be provided on the filter the crankcase of the replacement compressor. This

or filter-drier, to facilitate checking the pressure drop. situation can be prevented by following proper clean up

procedures after a burnout.

An additional benefit of a suction line filter or filter-

drier is the added protection given the system if a Flushing out a refrigeration system with R-11 should

burnout should occur. The filter will effectively prevent not be considered since scientific evidence has linked

contamination resulting from the failure from traveling ozone depletion to R-11 emissions. In case of a motor

back through the suction line into the other parts of burn, Emerson recommends the filter-drier cleaning

the system. An additional benefit of a suction line procedure. Basically this involves the use of approved

filter-drier is to capture any acid generated during the filter-driers incorporating an adequate desiccant (not

burnout before it causes any additional damage. This a filter only) in both the liquid and suction lines. This

will minimize the contamination remaining in the system system cleaning procedure has been used in countless

when the inoperative compressor is removed. installations over the years, and when this procedure

has been properly followed, we do not know of a single

System Evacuation instance where after proper cleaning there has been a

Another important step in effectively cleaning a second failure.

system before operation is proper evacuation. Air is

© 2008 Emerson Climate Technologies 1

Printed in the U.S.A.

Application Engineering

B U L L E T I N AE24-1105 R5

The filter-drier procedure has proven to be very necessary, remove all installed filter-driers and

economical, especially when the refrigerant in the clean or replace any filters or strainers. Install an

system is recovered using safe recovery techniques. Emerson HMI or AMI moisture indicator to precisely

This can be easily accomplished if the compressor is monitor system moisture conditions if the system

fitted with service valves. does not have one.

It is the only practical method we know of which can 5. Install the recommended size Emerson suction

assure proper cleaning, especially where long lines and line filter-drier and oversized Emerson liquid line

multiple evaporators and circuits are involved. filter-drier.

The size of the filter-driers (see Table 1) used to clean up Go to Step 7.

the system should be such that the maximum pressure 6. For systems without service valves, including

drop under normal operating conditions is within the refrigerant recovery, evacuate the system, following

limits shown. The connections on the filter-drier should the procedures previously recommended. Perform

normally be the same size as the connecting lines. the inspections and filter-drier changes listed in

steps 4 and 5, and charge through a filter-drier with

Exercise caution. Use rubber gloves and safety the refrigerant which was removed and recovered.

glasses and ventilate the work space. The oil from Add additional refrigerant as necessary.

a burnout could cause serious skin irritation and

possibly burns. In some cases, the fumes are toxic. 7. Start the compressor and put the system in

operation. As the contaminants in the system are

1. If possible, close the compressor service valves to filtered out, the pressure drop across the filter-drier

isolate the compressor from the system. In order to will increase. Observe the pressure differential

avoid losing refrigerant to the atmosphere Emerson across the filter-driers for a minimum of four hours,

strongly recommends recovering refrigerant using preferably by means of one gauge and a manifold

standard recovery procedures and equipment. At to eliminate gauge error. If the pressure drop

that point, remove the inoperative compressor, and exceeds the maximum limits shown in Table 1 for

install the replacement. a temporary installation, replace the filter-drier and

restart the system.

2. Since the normal color of refrigerant oil varies from

oil to oil, take a sample of oil from the replacement 8. After the completion of step 7, allow the unit to

compressor and seal in a small glass bottle for operate for 48 hours. Check the odor (warning,

comparison purposes after the cleaning operation is smell cautiously) and compare the color of the oil

complete. Suitable two ounce bottles are obtainable with the sample taken in step 2. Use of an Emerson

at any drug store. If the compressor does not have Universal Acid Alert test kit is recommended to

service valves, see Step 6. test for acid content. If the oil is discolored, has

an acid odor, is acidic, or if the moisture indicator

3. If the compressor has service valves, evacuate the indicates a high moisture content in the system,

compressor only, using the procedures previously change the filter-driers.The compressor oil can be

outlined, since the rest of the system will be isolated. changed if considered desirable. Allow the system

After evacuation, open the compressor service to operate for an additional 48 hours, and recheck

valves, close the liquid line valve, close any other as before. Repeat until the oil remains clean, odor

available shut-off valves which will minimize the and acid free, and the color approaches that of the

amount of refrigerant to be handled during pump- original sample.

down, and pump the system down.

9. Replace the liquid line filter-drier with an Emerson

Although some contaminants will be returned to the EK of the normally recommended size. Remove the

compressor during the pump down procedure, the suction line filter-drier and replace with permanent

compressor will not be harmed by the short period type suction line filter or filter-drier.

of operation required, and the contaminants will be

removed as they are circulated through the system 10. After the cleaning procedure is completed,

after the installation of the filter-driers. recheck in approximately two weeks to ensure that

the system condition and operation is completely

4. Inspect all system controls such as expansion satisfactory.

valves, solenoid valves, check valves, reversing

valves, contactors, etc. Clean or replace if

© 2008 Emerson Climate Technologies 2

Printed in the U.S.A.

Application Engineering

B U L L E T I N AE24-1105 R5

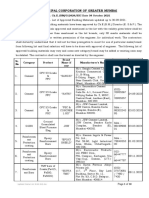

Table 1

Maximum Recommended Pressure Drop for Suction Line Filter-Drier PSI (bar)

Permanent Installation Temporary Installation

Refrigerant

System

R22, R404A, R22, R404A,

R407C, R410A, R12, R134a R407C, R410A, R12, R134a

R502, R507 R502, R507

Air-Conditioning 3 (.21) 2 (.14) 8 (.55) 6 (.41)

Commercial 2 (.14) 1.5 (.10) 4 (.28) 3 (.21)

Low Temperature 1 (.07) 0.5 (.03) 2 (.14) 1 (.07)

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its affiliates

(collectively "Emerson"), as applicable, reserve the right to modify the design or specifications of such products at any time without notice. Emerson

does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Emerson product remains solely with the purchaser or end user.

© 2008 Emerson Climate Technologies 3

Printed in the U.S.A.

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its affiliates

Вам также может понравиться

- Air Conditioning and Ventilation SystemДокумент46 страницAir Conditioning and Ventilation SystemJhon Lester KinakinОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 4 Bedroom 2 Storey ResidenceДокумент7 страниц4 Bedroom 2 Storey ResidenceJoel Victor Amicay100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- WCD Densopol Tapes - IfU 2020Документ5 страницWCD Densopol Tapes - IfU 2020Makamu Max Las MokgaoganyiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- SE980120 Specification GuideДокумент1 страницаSE980120 Specification GuideivanpersunОценок пока нет

- 10TH13F CryocarДокумент19 страниц10TH13F Cryocarnajan33Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Unit Price For Retrofitting WorksДокумент2 страницыUnit Price For Retrofitting Workslaxmi29Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Richa BrochureДокумент28 страницRicha Brochureknight1729Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Exam July AnswersДокумент30 страницExam July AnswersLuis Enrique MadureriОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Kaisai Service Manual PDFДокумент215 страницKaisai Service Manual PDFTom WtomОценок пока нет

- Office Cost Study PDFДокумент16 страницOffice Cost Study PDFandyoch86Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Heat ExchangersДокумент66 страницHeat ExchangerssafwanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- DZL 4-1.25-AiiДокумент10 страницDZL 4-1.25-AiiSamulaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Basic Design Approach For Geogrid Base ReinforcementДокумент3 страницыBasic Design Approach For Geogrid Base ReinforcementTrader RedОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Catalog HV Cable ConnectorsДокумент220 страницCatalog HV Cable ConnectorsdomiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- BN - 5687 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A2)Документ3 страницыBN - 5687 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A2)MSD ENGRОценок пока нет

- Chapter 2 MasonryДокумент81 страницаChapter 2 MasonryNabin MahatoОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Chap 11 The Bernoulli Equation & Crocco's TheoremДокумент4 страницыChap 11 The Bernoulli Equation & Crocco's TheoremJohn BirdОценок пока нет

- Civil Breadth Mor Question 1 Sample PDFДокумент7 страницCivil Breadth Mor Question 1 Sample PDFSharifОценок пока нет

- Purpose of Master Batch PPA in PEДокумент49 страницPurpose of Master Batch PPA in PEin_abhay2706Оценок пока нет

- Hayward Pro Series Side Mount BrochureДокумент2 страницыHayward Pro Series Side Mount BrochureEng Mostafa ElsayedОценок пока нет

- JFK Airport, UsaДокумент8 страницJFK Airport, UsadivugoelОценок пока нет

- Fire Protection System: Unit-I Building Utility & ServicesДокумент109 страницFire Protection System: Unit-I Building Utility & ServicesRohit KhannaОценок пока нет

- Pipe Production CatalogueДокумент35 страницPipe Production CatalogueAlp ÖzleyenОценок пока нет

- Basic Die MakingДокумент2 страницыBasic Die Makingabdul khalimОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Updated Product List 30.09.2021Документ10 страницUpdated Product List 30.09.2021sabhay2Оценок пока нет

- 6-Surface Hardening PDFДокумент11 страниц6-Surface Hardening PDFSohanur RahmanОценок пока нет

- Electrode SelectionДокумент1 страницаElectrode SelectionRachel ThompsonОценок пока нет

- Low Cost Tile Box CookerДокумент3 страницыLow Cost Tile Box CookerHarish KumarОценок пока нет

- The Cunard Building, LiverpoolДокумент2 страницыThe Cunard Building, LiverpoolIbrahim FawwazОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 65 Series Lubricated OmДокумент12 страниц65 Series Lubricated Omalex_alfonso9407Оценок пока нет