Академический Документы

Профессиональный Документы

Культура Документы

Ra For Night PDF

Загружено:

soliman fathyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ra For Night PDF

Загружено:

soliman fathyАвторское право:

Доступные форматы

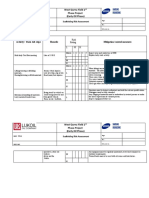

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

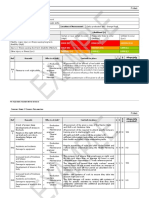

Subject of Assessment Night and shift work

Task/Activity Introduction of night shifts

Assessor Soliman fathi Location of Assessment AHWC 22 MIGD DESALIATION PLANT AT RAK

Risk Rating Matrix (RR) Likelihood (L)

Certain or near certain to occur Reasonably likely to occur Unlikely to occur

Severity (S)

(High) (Medium) (Low)

Fatality; major injury or illness causing long term

HIGH (H) HIGH (H) MEDIUM (M)

disability (High)

Injury or illness causing short term disability (Medium) HIGH (H) MEDIUM (M) LOW (L)

Other injury or illness (Low) MEDIUM (M) LOW (L) LOW (L)

R Adequately

Ref Hazards Who is at risk? Controls in place L S

R controlled?

• Production All personnel will be offered a free health assessment

workers before they start working nights and on a regular basis

• Maintenance after that (a follow-up examination by a HSE )

RA

Fitness to work night shifts engineer Records of anyone refusing a free health assessment will M L L YES

1

• Cleaner be kept

• Shift A health questionnaire will be given to all personnel

Manager

ORION HSE Assessor

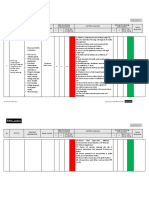

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

R Adequately

Ref Hazards Who is at risk? Controls in place L S

R controlled?

A lack of proper sleep • Production All personnel will be given a copy of the Mentor Night

Developments of stress on workers and Shift work Guidance Note AS A TBT

the body • Maintenance All personnel will be required to attend specific company

RA

People on the night shift end engineer training prior to starting night work ( INDCTION ) M M M YES

2

up tired and worn down, • Cleaner All night and shift workers will be provided with

developing fatigue and • Shift sufficient information, instruction and training to ensure

irritability. Manager their health and safety whilst undertaking tasks in TBT

• Production

Accidents and incidents workers Regular monitoring of night and shift worker health and

RA3 • Maintenance welfare will be undertaken using the Health Monitoring H H M NO

Damage to equipment Form in ( in a accident report ) or near mess report

engineer

• Cleaner

Increased levels of tiredness • Production The company will ensure that employees on night work

and fatigue workers do not work more than on average 48 hours a week

• Maintenance calculated over a successive 17 week reference period

Accidents and incidents

RA4 engineer The company will ensure that night workers’ normal L L L YES

Damage to equipment • Cleaner working hours do not exceed more than an average of

Development of stress on the • Shift eight hours in each 24 hour period as calculated over a

body Manager successive 17 week reference period

Increased levels of tiredness Review safe systems of work to ensure they take into

and fatigue • Production

account night and work

Accidents and incidents workers

RA5 • Maintenance The Shift Manager will review existing safe systems of H H M NO

Damage to equipment work for specific activities to ensure that they have

engineer

Development of stress on the • Cleaner adequately addressed the additional psychological and

body physiological hazards

ORION HSE Assessor

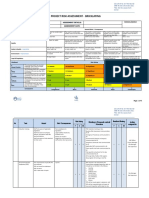

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: WORKING NEAR OR WITH ELECTRICAL EQUIPMENTS / TOOLSSERVICES RA No: ORION/RAK 01

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Competent Electrician for Installation and Repair.

• Electrical power to be de-energized locked out and tagged out before

doing any repair / maintenance.

• To be installed, maintained and used as per manufactures instruction

manual.

Installation, use, repair and Supervisor /

Electrocution, • All electrical hand tools to be grounded or double insulated.

01. maintenance by untrained 3X5 Foreman, L

Burn, Fatality. • Use of Standard equipments and fittings.

personnel. Electrician.

• Correct Routing of Cables and proper connections.

• Proper ELCB and RCD to be installed in electrical circuits.

• Do not Place the Cables on Wet Surface or in Water.

• Person using the Tools / Equipments should be trained / experienced in

that particular item.

Unguarded Equipment / Serious Injury, Supervisor /

02. 3X4 • Guard to be provided to all moving / rotating parts of the equipments. L

Tools. Amputation. Foreman

Minor / serious • Cables to be routed properly away from access and do not place the Supervisor /

03. Tripping 3X4 L

injury. equipments on the access. Foreman

• All electrical tools and equipment to be connected through ELCB / RCD.

• Do not use improper / damage cables.

• Do not overload the electrical circuits / cables.

Fire due to short circuit / Burn,

• All electrical tools to be grounded or double insulated.

over load / loose contact Material / property Supervisor /

04. 3X5 • Proper insulation of terminals and cables. L

and incorrect use and damage. Foreman

• Avoid loose contact.

electric shock. electrocution

• All electrical equipments / tools to be protected from water.

• Use of standard fitting.

• Daily inspection of equipments, tools, cables and fittings.

Hearing loss.

• Job rotation to be adopted.

White finger Supervisor /

05. Vibration / Noise/strike 3X4 • PPE (Gloves, Ear plug / Muffler) to be used. All services shall be L

(HAVS) electric Foreman

investigated and identified. A look out system shall be implemented.

shock .

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: OCCUPATIONAL HEALTH AND ENVIRONMENTAL IMPACT - NOISE RA No: ORION/RAK 02

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Selected equipment, good maintenance of machineries, plant &

equipments.

• Close the engine covers during use.

• Provide sound proof enclosure to high level noise producing machineries.

• Keep noisy equipment away from working or public area.

• Consider alternative methods of work to reduce possible noise. Eg: Use

electric powered breakers instead of Pneumatic one.

Stress, • If using noisy equipment, avoid using it during busy hours.

Loss of • Use of ear protection (PPE) if noise level exceeds 90 dBA.

concentration, • Job rotation to be adopted in the exposed area as per Permissible

Loss of hearing or Exposure Limit. Supervisor /

01. High noise level. hearing 3X4 M • Provide signage where high level noise exists. L

Foreman

impairment,

Tinnitus, Permissible Noise Exposure Limit

Environmental

pollution. Duration per Day Sound Level

8 Hours 90 dBA

6 Hours 92 dBA

4 Hours 95 dBA

3 Hours 97 dBA

2 Hours 100 dBA

• Consider alternative methods of work to reduce possible dust.

• If using dusty equipment, avoid using it during busy hours.

Employees and • Use suitable (PPE) that is suited for the job. Supervisor /

02. Dust 3X4 M

public • Job rotation to be adopted in the exposed area. Foreman L

• Provide signage and if able fencing.

• Keep area dump to compress dust.

ORION HSE Assessor

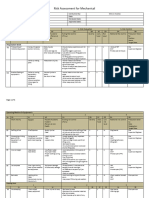

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: MANUAL HANDLING RA No: ORION/RAK 03

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Safe manual handling techniques to be adopted at all times. Bent knees,

straight back firm solid grip on load, legs to be used to lift loads not back.

• Ensure sufficient space and safe access prior to lift.

• Avoid twisting, stooping or reaching to lift or place the load. Insure firm and

flat ground where possible.

• Provide proper training.

Muscle and

• Oversized or awkward sized loads to be carried by more than 1 person.

ligament tears.

• Regular TBT’s to be conducted on correct posture and safe manual Supervisor /

01. Poor posture. Slipped disc, knee, 3X3 M L

handling techniques. Foreman

ankle and

• If in doubt of correct manual lifting / handling techniques please speak the

shoulder injuries.

HSE department.

• Persons with known physical problems / issues are not to be included in

manual handling tasks.

• Persons to declare any issue that may prevent them safely manual

handling materials, tools and or equipment. Medical evidence may be

required.

• Weight of the load to be assessed prior to lift.

• Avoid manual handling and mechanical aid to be used to lift heavy loads or

provide enough people. 25KG / Person.

• Correct manual handling techniques to be adopted.

Muscle and

• Rainy and wet conditions to be avoided if heavy manual lifting is to take

ligament tears.

place. Supervisor /

02. Heavy load. Slipped disc, knee, 3X3 M L

• Insure that whole area of lift zone is clear and without any form of clutter Foreman

ankle and

and or trip hazards. Clear area of all tools, materials or other people if

shoulder

needs be.

• People to make sure loads are always controlled, out stretched arms are

not a controlled load, the closer to the chest the more control is had.

• Continual heavy lifting teams must be given regular breaks.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: MANUAL HANDLING RA No: ORION/RAK 03

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Good and firm grip i0s to be assured for all manual lifting.

• If possible size of the load to be reduced prior to lift.

• Appoint enough people to handle the load. 25kg / person

• Lifting path to be assessed / checked for any obstructions prior to start

Laceration. handling.

Muscle and • Use handling aids to lift / move the load.

Over sized (Too high, long, Supervisor /

03. ligament tears. 3X3 M • Mechanical aids (Crane, Forklift, Loader, Trolley, Wheel barrow etc...) to L

wide etc…) objects / load. Foreman

Minor / serious be used if at all possible.

injury • Adverse weather conditions to be monitored when lifting of loads manually,

rain and wind may cause manual lifting to be stopped depending on

severity, wind above 17 knots and heavy rain HSE department must be

consulted to insure the safety of persons and materials / equipment.

• Stability of the load to be assessed prior to lift.

Muscle and

• Stabilize / secure the load if possible.

ligament tears.

• Use suitable bags / cages for unstable load. Supervisor /

04. Unstable / loose loads. Slipped disc, knee, 3X3 M L

• Appoint experienced persons to handle the load. Foreman

ankle and

• Mechanical may be the best options if loads can’t be secured by manual

shoulder.

handling.

• Sharp edges to be covered before handling.

Cut, bruises and • Use handling aids to lift the load.

Sharp or slippery object / laceration. • PPE”s (Hand gloves, Safety Shoe, overall, apron etc…) to be used at all Supervisor /

05. 3X4 M L

load. Material damage times. Foreman

Body Injury. • Proper Hand protection is required for all lifting, loose fitting cotton gloves

are of no use, instead tighter fitting rigger gloves will be more suitable.

• Provide extra manpower or use mechanical aid.

Serious / Minor • Material handling path to be leveled, loose materials to be removed and

Uneven ground / floor Supervisor /

06. injury. 3X4 M penetrations to be closed. L

condition. Foreman

Material damage. • Proper supervision.

• Ensure that floor isn’t wet.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: MANUAL HANDLING RA No: ORION/RAK 03

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Ensure the load will not obstruct the vision.

Serious / Minor

• Provide adequate lighting. Supervisor /

07. Poor visibility. injury. 3X4 M L

• Manual lifting during times of fog is not advised and needs to be properly Foreman

Material damage.

assessed by HSE and construction team at location of lift.

• MSDS to be referred and instructions to be followed while handling.

Dermatitis, Allergy, Supervisor /

08 Contact with Chemicals. 3X4 M • Precautions mentioned in the MSDS must be taken. L

Burn etc Foreman

• Please see COSHH RA for more in-depth detail.

• Proper access, light and ventilation.

• Insure adequate PTW has been acquired and requirements have been

Serious / Minor met prior to entry. Supervisor /

09 Confined / Restricted area 3X4 M L

Injury • Split the load in to small pieces if possible. Foreman

• Proper Supervision.

• Please see Confined Space RA for more details.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: CONFINED SPACE - GENERIC RA No: ORION/RAK 04

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• Operatives must be physically fit for carry out confined space activities.

Site Manager

• Person experienced / Trained in confined space activity to be assigned for

Unfit / untrained Suffocation, Engineers

01 4X4 the job. L

Operatives. Death. Supervisor,

• SWMS and Risk Assessment must be addressed to all operatives prior to Foreman

enter.

• Work permit must be taken, pre-entry checklist to be completed and all

precaution must be taken prior to enter.

• Provide safe access and exit to and from the confined space as much as

possible. (Manhole size requirement - Min. 450 mm X 407 mm or 457 mm

Dia.)

• Rescue procedure / system (Tripod with hoisting device, Rescue Harness

Serious Injury, Engineers

Limited access and Exit. etc) in place and sufficient trained persons are available for the rescue

02 Suffocation, 4X4 Supervisor, L

Fall of person / Materials operation.

Fatality. Foreman

• All persons in the confined space must wear safety harness for rescue

purpose.

• Display appropriate warning signs and appoint one full time stand by

person in the entrance.

• Access and all openings to be protected to prevent fall of materials /

persons.

• Carry out atmospheric test and ensure there is sufficient level of oxygen

present in the area prior to enter. Site Manager

Oxygen deficiency /

Suffocation, • Use forced air ventilation / exhaust fan to remove toxic gases from Engineers

03 enrichment, lack of 3X5 L

Death. confined space. Supervisor,

ventilation.

• Shift working schedule as per condition to be made and strictly followed. Foreman

Oxygen percentage. (Permissible limit – 19.5% to 23.5%

• Carry out atmospheric test and ensure there are no flammable / toxic

gases present in the area prior to enter.

A. Flammable gas or vapors.(Permissible limit - <10% of LFL)

Serious Injury, Site Manager

B. Carbon Monoxide. (Permissible limit - <50ppm)

acute / long Engineers

04 Flammable / toxic gases. 3X5 C. Hydrogen sulfide. (Permissible limit - <10ppm) L

latency illness, Supervisor,

• Do not operate any exhaust gas emitting equipments inside the confined

Death Foreman

space.

• Do not keep any compressed / flammable gas cylinders inside the

confined space.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: CONFINED SPACE - GENERIC RA No: ORION/RAK 04

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• All COSHH materials must have MSDS and precautions in the MSDS

must be followed.

• Provide adequate exhaust fans for proper ventilation.

• Always use flameproof electrical equipments inside the confined space.

• Use positive pressure breathing apparatus in confined space.

• Hot work permit must be taken prior to do any hot work operation.

• Sufficient exhaust fan must be provided for ventilation / extracting the

welding fumes.

• Ensure there is no flammable gas / vapors present in the confined space.

Serious Injury, Engineers

• Do not keep compressed gas cylinders, combustion engine powered

05 Hot work / Fire Property Damage, 3X5 Supervisor, L

welding machine inside the confined space.

Death Foreman

• Sufficient fire protection / extinguishing equipment must be provided in the

work area.

• Do not use CO2 fire extinguishers inside the confined space.

• All operatives must wear required PPE’s.

• Sufficient lights (Flameproof) shall be provided in the confined space.

• Proper communication facility (Walky-talky / Radio / Alarm system) should

Engineers

Lack of Lights & Serious or minor be provided for confined space activities.

06 4X4 Supervisor, L

Communication Facility. Injury, Death • One fulltime standby person with communication facility shall be

Foreman

appointed outside the entrance.

• Confined space register to be kept outside and strictly maintained.

Fatigue and • Provide sufficient cool drinking water and oral dehydration fluids.

drowsiness. Site Manager

• Provide adequate ventilation and fan at the work place.

High Temperature / Lack of Engineers

07 3X5 • Avoid working in humid environment for long time. L

Humidity concentration. Supervisor,

Heat Stroke • Shift system based on the humid condition to be strictly followed. Foreman

Fatality. • Close supervision and communication at all time.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: LOADING PLATFORM ERECTION AND DISMANTLING RA No: ORION/RAK 05

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

Serious Injury, • To be erected by competent Operatives as per drawing.

Supervisor,

01 Unsafe erection Material Damage, 3 X5 • Ensure close supervision by a competent supervisor. L

Foreman

Fatality. • SWMS and Risk Assessment to be addressed to the erectors.

• Erection area must be cleaned prior to remove the edge protection.

• Underneath area to be barricade while doing the erection and dismantling.

• Remove all loose materials from the platform prior to lift.

Serious Injury, • Props to be secured / braced after erection.

Supervisor,

02 Fall of material. Material Damage, 3 X5 • Bottom of the props must be bolted to the I-beam. L

Foreman

Fatality. • Detach all props from platform prior to lift.

• Tool strings must be attached to all tools using in floor edges.

• Gap between platform and floor must be covered immediately after

erection.

• Work area to be kept free from loose materials.

• Life line to be provided to anchor the safety harness prior to remove the

edge protection.

• All people should wear Full body safety harness with energy absorbing

Serious Injury, lanyard. Supervisor,

03 Fall of person 3 X5 L

Fatality. • Edge protection to be fixed immediately after erection / removal of the Foreman

platform.

• Don’t lean and try to catch the tag line, let the tag line come closer to the

floor.

• Ensure free movement of tag lines while removing the platform.

• Competent Banks man available in the area with communication radio for

signaling.

Serious Injury,

• Tag line to be used to control the movement of load. Supervisor,

04 Struck with moving load. Amputation, 3X5 L

• Always maintain enough space for maneuvering and do not insert body Foreman

Fatality.

parts under the load.

• Close supervision at all time.

• Safe manual handling techniques to be adopted.

Minor /Serious

• Ensure sufficient space and safe access prior to lift. Supervisor,

05 Improper Manual Handling Injury, Material 4 X3 L

• Provide sufficient manpower and proper training. Foreman

Damage

• Avoid twisting, stooping or overreaching to lift or place the load.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT

ACTIVITY: LOADING PLATFORM ERECTION AND DISMANTLING RA No: ORION/RAK 05

RISK CONTROLLE RESIDUAL

S. N. HAZARD HARM CONTROL MEASURES

LXS L M H D BY WHOM RISK

• PPE”s as per Risk Assessment must be used.

Serious Injury,

• Do not carry out the erection and dismantling if wind speed is more than Supervisor,

06 Bad Weather. Material Damage, 3X5 L

40km/h low visibility and rainy conditions. Foreman

Fatality.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

RISK ASSESSMENT RA No: ORION/RAK 05

TOPICS: PROJECT POTENTIAL HAZARDS ASSESSMENT

RISK CONTROLLED RESIDUAL

S. N. ACTIVITY / HAZARD HARM CONTROL MEASURES

LXS L M H BY WHOM RISK

• Minor / • Trained and 3rd party certified operatives. • Managemen

Incompetent

Serious • In house training t

operatives (Lack of

injury - STARRT (Safety Task Analysis Risk Reduction • Supervisor /

1 knowledge about the 5X5 H L

• Material Talk) and Tool Box Talk prior commencement of Foreman

work, Regulation and

damage work.

Safety Requirements)

• Fatality

• Proper and clear Access and Exit.

• Provide hard barricade where required. • Supervisor /

• Minor /

Insufficient / Unsafe / • Display prominently sufficient Access and Exit signs. Foreman

2 Serious 4X4 H L

Poor Site Access • Provide hazard tapes where required to identify the • Safety

injury

access clearly. Department

• Ensure proper housekeeping at all times.

• Safe workplace to be provided. Ensure:-

- Cleanliness (Proper Housekeeping)

- Proper Working Platform

• Serious - Sufficient Light and Ventilation

Unsafe work place / • Supervisor /

3 injury 4X4 H - Proper task lighting for the job L

unsafe condition Foreman

• Fatality - Edge and Floor Protection where required

- Proper Access and Exit

- Use of correct PPE

- Safety Caution Signs and Barricade

Working at Height

• Provide Safe Workplace

• Fall of:-

• Secure the materials and tools correctly

- Persons • Serious

• Maintain exclusion zone with hard barricade and

- Materials injury

caution signs and watcher • Supervisor /

4 - Tools • Fatality 4X5 H L

• Provide proper access and light Foreman

- Debris • Material

• Flying Object • Use of safety harness to proper anchoring point

damage

• Ensure proper housekeeping

• Insufficient

Precaution • Stop working in extreme / extreme weather

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

Excavation / Trenches

/ Floor Opening:-

• Proper edge protection

• Falling into

• Protect / cover the Floor opening properly

Tranches /

• Serious • Provide caution signs

Excavation

injury • Follow Permit System to work

• Falling through • Supervisor /

5 • Fatality 4X5 H • Use Safety Harness correctly L

floor opening Foreman

• Property • Proper Working Platform

• Collapse of

Tranches /

damage • Specific Risk Assessment to follow / Refer:-

Excavation - Excavation

• Vehicle / Plant - Working at Height

overturning

• Use standard and good conditioned power tools

• Portable Appliances Testing (PAT) to be used to test all

power tools

Use of Power Tools:-

• Ensure regular inspection and colour coding

• Defective • Electric

• Ensure all rotating / moving parts of the equipment /

• Without Guards shock

tools are protected • Supervisor /

6 • Incorrect use • Serious 4X5 H L

• Job rotation when using Jack Hammer / Heavy drilling Foreman

• Untrained injury

machine

operatives • Amputation

• Never use power tools without guards

• Vibration

• Never use power tools if you are not trained

• Use the tools for the intended purpose only

• Do not use defective / damaged tools.

Incorrect / Unsafe

• Use only 3rd party certified lifting tackles and crane

Lifting Operation:-

• Inspect lifting tackles before use daily

• Materials falling • Serious • Crane Optr /

• Do not stand under Suspended load

7 • Failure of lifting Injury 3X5 H Banksman L

• Ensure competent Operator and Rigger

belt / slings / lifting • Fatality • Supervisor

tackles • Follow correct slinging and ensure no loose materials in

the load

• Untrained

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

Operators and

Rigger

• Serious • Check the weight of the load before lifting

Over loading /

Injury • Rigger and Operator must know the SWL of Plant / • Operatives

exceeding SWL of

8 • Fatality 4X4 H Equipment and Lifting Tackles • Rigger / L

Plant / Equipment and

• Material • Do not over load Banksman

Lifting Tackles

damage • Follow manufacture’s instruction strictly

Electricity:-

• Exposure to

electricity

• Use electrical tools and equipment as per manufactures

• Exposed live cable

• Electric recommendation

/ wire

Shock • Do not use damaged cable

• Overloading DB or

• Electrocutio • Use proper cable joint

cable

n • Do not overload electrical circuits / Cable / DB

9 • DB without ELCB 4X5 H All L

• Burn • Ensure ELCB is working properly

• Incorrect cable

• Fire • Keep tools and cable out of water / wet surface

routing

• Material • Use wooden stands to elevate cables

• Routing of cable –

damage • Route the cable through pipes and buried when

cross the access /

crossing road

Road, on wet

surface, steel

structure / slab

• Use face / filter mask as required

10 Exposure to Dust 4X3 M • Use safety goggles All L

• Spray water to suppress dust emission

• Storage, handling and use as per MSDS of substance

• Dermatitis • All items should be stored in the dedicated store only

Incorrect Storage, • Allergy • Training for the operatives

Handling and use of

• Burn • PPE as per MSDS to be used

hazardous substances • Storekeeper

11 • Suffocation 4X5 H • Copy of MSDS should be available in the store and First L

(chemicals, Acids, • Foreman

Solvents, Fumes, • Asphyxiatio Aid room

Gases etc.) n • Register (Inventory) for all items should be maintained

• Fatality • All containers must be labeled

• MSDS must be addressed to the peoples handling

Exposure to

12 • Deafness 3X4 M • Use of Ear Muffs / Ear plug All L

Excessive Noise

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

• Hearing • Work only as per permissible exposure limit

impediment PERMISSIBLE EXPOSURE LIMIT

Per Day 8 hours – 90 dBA (sound level)

“ 6 hours – 92 dBA (sound level)

“ 4 hours – 95 dBA (sound level)

“ 3 hours – 97 dBA (sound level)

“ 2 hours – 100 dBA (sound level)

• Fire • Strictly follow Hot Work Permit System

• Material • Precautions as per permit must be strictly followed

damage • All hot work to be closely monitored during and after the

Uncontrolled Hot Work • Electrocutio Hot Work

• Supervisor

13 – Welding, Cutting, n 4X5 H • Use good conditioned Welding Machine / Cutting Set / L

• Foreman

Grinding • Burn Grinding Machine

• Fatality • Ensure Flash Back Arrestors are fitted with cutting set

• Serious and correct handling of Gas Cylinders

injury • Trained Operatives

• Fire

• Material • No Smoking Policy should be strictly implemented on

damage Site and Office

14 Smoking • Burn 4X5 H • Smoke only in dedicated areas All L

• Fatality • Do not smoke to prevent health deterioration

• Injurious to • Do not smoke for the sake of safety

health

• Ensure workplace & access are clear of Slip, Trip and

• Serious Fall

15 Slip, Trip and Fall 3X5 H All L

injury - Hazards (Rubbish, Cable routing, Scraps, Debris

Materials, Oil Spillage, Wet Floor etc.)

Vehicles / Plant / • Driver / Operators with valid license

Equipment on site • Proper Traffic Management Plan

• Uncontrolled • Serious • Flagman to control traffic

movement injury • Strictly follow speed limit • Logistic

16 • Speeding • Material 3X5 H • Proper edge protection and caution signs for excavation Manager L

• Over turning damage • Trained riggers to offload • Site Safety

• Falling in the • Fatality • Ensure reverse alarm and flashing lights are working

excavation • Proper traffic control at main gate by security

• Falling from Trailer / • Trained and competent Operator and Driver

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

Vehicles • Separate access for pedestrian

• Struck or run over by • Dedicated Flagman when loading Truck with Shovel

moving vehicles / • Do not use Shovel / Excavator to lift/shift materials

plant • Refueling should be done at dedicated area using

• Loading Truck with safe/correct system

Shovel • Maintenance / Servicing of Plant and Equipment should

• Load lifting / shifting not be carried out on site

with Shovel /

excavator

• Refueling on site

• Maintenance /

Servicing of Plant /

Vehicle / Equipment

on site

Defective / Poorly

maintained Plant and • Servicing / maintenance as per manufacture’s

Equipment:- • Serious / recommendation

Minor injury

• Unwanted stress for • Trained operatives

• Property / • Plant

the Operator • Periodical inspection

Material Manager

17 • Unwanted Incident 3X5 H • Rectify the defects immediately on detection L

damage • Supervisor

• Oil Spillage • Daily inspection using proper check list

• Fire • Foreman

• Excess Exhaust • Inspection and certification by 3rd party

• Atmospheri

Emission • Servicing / repair / maintenance by authorized agencies

c pollution

• Unguarded moving • Tyre condition and rotation to be monitored

parts

• Muscle and

ligament

tears

• Correct posture

• Slipped

• Use handling aids and mechanical aids

Manual Handling:- Disc, Knee,

• Use sufficient manpower • All

• Wrong posture Angle and

18 3X3 M • Ensure moving path is clear • Work L

• Lifting over weight / Shoulder

• Sharp edges to be covered before lifting Incharge

over size load • Serious /

Minor injury • If two or more people lifting one load ensure clear

understanding of team

• Cut,

Bruises and

laceration

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

• Place the ladder on leveled and stable ground

• Do not use ladder at the floor edge

• Ladder to be secured correctly

• Straight ladder to be placed in an angle of 75° (1:4)

Incorrect use of

• Serious • Avoid over reaching • Work

ladders:-

19

• Fall of ladder

injury 3X5 H • Ladder should be extended minimum 1 mtr. above from Incharge L

• Fatality the landing area • All

• Fall from ladder

• One person on a ladder at a time

• Always face the ladder and follow 3 point contact rule

• Do not use damaged or locally made wooden ladder

• Always stand 3 steps below on ladder

• Trained and competent persons to operate

• Servicing / maintenance as per manufactures

Incorrect use / Use of • Serious recommendation • Work

20 defective elevating injury 3X5 H • Rectify the defects immediately on detection Incharge L

platform • Fatality • Daily / periodical inspection and maintenance as per • Operatives

manufacture’s recommendation

• Inspection and certification by 3rd party

• Fire

• Keep workplace neat and tidy at all times

• Serious

• Housekeeping to be carried on each shift / daily basis

injury

21 Untidy workplace 3X5 H • Stack materials correctly on site All L

• Fatality

• Do not keep flammable materials and gas cylinders at

• Unwanted

workplace

stress

• Serious • Be aware of potential hazards at workplace

Trapped by something

22 injury 3X5 H • Take precautions as required All L

collapsing / overturning

• Fatality • Use only proper access and egress

Working in confined • Suffocatio • Provide proper Access, Light and forced ventilation

space:- n • Check oxygen level (atmospheric check)

• Limited Access • Serious • Check pressure of Toxic / Flammable gases

• Fall of Person injury • Follow shift working system • Supervisor

23 4X5 H L

• Oxygen Deficiency • Fatality • Work permit to be obtained and followed • Foreman

• Lack of Ventilation • Fire • Sufficient Exhaust Fan

• Toxic Gases • Heat • Provide proper communication system

• Flammable Gases stroke • Do not keep compressed / flammable gas cylinders

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

• Lack of light • Fatigue inside confined space

and • Ensure Rescue arrangement and First Aid facilities are

drowsines provided as per Risk Assessment

s • Use of required PPE.

• Lack of • Sufficient drinking water

Concentrat

ion

• Minor • Use of mandatory PPE at all times

injury • Use of specific / standard PPE as per Risk Assessment

Incorrect use or not using

24 • Major 3X5 H / MSDS All L

required PPEs

injury • Ensure proper storage of PPE

• Fatality • Correct use of PPE

• Major

injury • Properly understand the Site Safety requirement as per

Nonadherence of Site • Material Safe Work Method Statement, Risk Assessment, local

25 3X5 H All L

Safety Requirement damage authority requirement, company safety plan etc. and

• Fire strictly follow them.

• Fatality

Unsafe Act:-

• Altering scaffolds

• Removing edge

protection • Serious

• Safety Induction

• Removing floor injury

• Tool Box Talk • Supervisor /

opening • Fatality

26 3X5 H • Training Foreman L

• Blocking of access • Fire

• Safety Awareness Talk • All

• Misuse of Plant, • Material

• Proper Supervision.

Equipment, Power damage

Tools, Temporary

Electric, Site Facilities

etc.

• Serious • Supervisor /

• Safety Awareness Talk

27 Horse Play injury 3X5 H Foreman L

• Close Supervision

• Fatality • All

• Serious • Detailed Work Procedures (Safe Work Method • Managemen

Lack of System /

28 injury 3X5 H Statement) should be developed and used t L

Procedures

• Fatality • Risk Assessment should be carried out and followed • Supervisor

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

• Fire • All Safety precautions must be in place.

• Serious • Sufficient competent supervisory staff • Project

Manager /

injury • Supervisor / Foreman should ensure safe execution of

29 Lack of Supervision 3X5 H Site L

• Fire job as per SWMS & RA

Manager /

• Fatality • Close supervision of work

Supervisor

• No Smoking policy should be implemented strictly in

Site Offices, Stores and work site

• Controlled Hot Work

• Burn • Proper Site Housekeeping

• Property • Correct Storage, Handling and Use of COSHH items,

• Site

damage Chemicals, Gas Cylinders etc.

Manager

30 Fire • Fatality 4X5 H • Correct installation and use of temporary electric on site L

• Site Staff

• Pollution • Proper use of Power Tools

• Site Safety

• Unexpecte • Regular inspection

d loss • Correct refueling of Plant, Equipment and Vehicles on

site

• Proper maintenance / Repair of temporary Electric,

Vehicles, Plant & Equipment, Power Tools

Insecured Site:- • Stealing

• Unauthorised entry • Property

• Establish proper perimeter hoarding

• Unsafe condition damage

• Provide proper Gate and Barrier • Project

• Insecured Property • Property

31 4X5 H • Identify Vulnerable Points and Provide Security Manager L

• Infiltration loss

• Security to control all Gate / Access • Site Manager

• Fire due to smoking • Serious

• Regular inspection

• Accident injury

• Indiscipline • Fatality

WELFARE & HEALTH

Unhygienic Site Facilities:- • Ensure pure drinking water for employees

• Contaminated drinking • Keep site facilities neat and clean at all time

water • Spread of • Report lapses if any to Safety Department for corrective

32 • Poorly disinfected:- germs, 4X4 H action. All L

- Toilet diseases • Regular inspection of site facilities

- Wash Area • Proper Ventilation in rest area

- Canteen • Proper cool area / room to store food

- Eating Area

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

- Rest Area

- Food Storage Area

• Intrusion of

germs / • Hands should be washed properly before eat • All

Eating without cleaning

33 bacteria into 4X4 H • Sufficient washing facilities • Management L

hands

human • Soap should be provided at wash place • Safety

body

• Stress,

Tension,

High Blood

• Do not allow the peoples to work after consuming Alcohol /

Pressure

Drugs

Working under the • Serious

34 3X5 H • Establish checking at site entry point to identify the people

influence of Alcohol / Drugs injury

coming after consuming Alcohol / Drugs

• Material /

• Safety Awareness Talk.

Equipment

damage

• Fatality

• Avoid working in Adverse Weather

• If the job is unavoidable and the weather is not very bad:-

• Minor / - Ensure safe work place

Working in Adverse - Provide suitable PPE

Weather:- Serious

injury - Rain Coat, Fan, Drinking water etc.as per condition

• Heavy Wind - Proper Supervision • Site Manager

• Material /

• Dust Strom - Avoid lone working / Supervisor /

35 Properly 4X5 H L

• Heavy Rain - Do not keep loose and light weight materials near floor Engineer

damage

• High Temperature edge. • Safety

• Get sick

• High Humidity - Do not stack light weight materials on the open slab or on

• Heat Stroke

• Dehydration top of the building

• Fatality - No loose materials on the working platforms

- Scaffold boards / Toe boards on the working platform

secured properly with clamp or rope

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

Hazard

Additional control Assigned to Date Completed L S RR

Ref

Training will specifically include the implementation of shift

patterns, managing the impact of night work on

employees’ health and the importance of additional rest

breaks.

Training will also include the following – a) information on

how to teach your body to function better at night by

taking advantage of your "circadian" rhythm. Your rhythm

is a natural clock that your body has. Each day, stay up an

extra thirty minutes to reset your time clock and within a

couple of weeks, your body will learn to adjust. By the time

RA2 you start your new job, you will feel better and be able to L L L

work a full shift without getting that groggy feeling. Upon

returning home, stick to a set bedtime and allow your body

at least seven to eight continuous hours of sleep.

b) making your bedroom sleep friendly by not allowing full

light into your room, get light filtering shades and curtains

that will block out the sunlight during the day or use a

sleep mask to keep out the light.

c) Advised to let your family and friends know your work

schedule. Make time for get-togethers on your days off to

keep in touch.

Periodically assess accident records to identify any trends

in accidents and ensure that serious injuries are On-going

appropriately reported

RA3 Monitoring routines will be carried to ascertain working L L L

patterns and human behavior. The night Shift Manager is

On-going

authorized to make any required changes with immediate

effect.

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

Hazard

Additional control Assigned to Date Completed L S RR

Ref

The night Shift Manager will liaise with all section leaders on a

weekly basis to ascertain if existing safe systems of work are

Night Shift Manager On-going

adequate and being adhered to

RA5 L L L

The night Shift Manager will liaise with the company’s

Night Shift Manager

Occupational Health Support Manager for professional advice On-going

(OCC HSE)

on health matters

Signature

Assessor SOLIMAN FATHI

APPROVED BY

Signature

ORION HSE Assessor

ORIN CONTRACTING COMPANY

HSE DEPARTMENT

in case of emergency at night

DRIVER FOR EMERGENCY SADIQ 0555653129

SAFETY OFFICER MOHSIN 0559499741

ENG . Ahmed El Deeb 0552314791

ENG. Mohamed El nady 0557013093

ORION HSE Assessor

Вам также может понравиться

- Risk Assessment FOR: Over Head Crane ErectionДокумент9 страницRisk Assessment FOR: Over Head Crane ErectionZameer AhmedОценок пока нет

- Risk Assessment:: Corresponding Permit To Work NoДокумент4 страницыRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamОценок пока нет

- Heavy Lifting Safety ChecklistДокумент1 страницаHeavy Lifting Safety ChecklistMock ProjectОценок пока нет

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSДокумент4 страницыHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanОценок пока нет

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGДокумент2 страницыJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioОценок пока нет

- Risk Assessment for Canal Construction WorksДокумент9 страницRisk Assessment for Canal Construction WorksAshoka Indunil WickramapalaОценок пока нет

- Risk Assessment - Hand ToolsДокумент2 страницыRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulОценок пока нет

- Samsung Scaffold Risk Assesment 2Документ7 страницSamsung Scaffold Risk Assesment 2Saleem AkhtarОценок пока нет

- Environmental, Health and Safety Risks AnalysisДокумент3 страницыEnvironmental, Health and Safety Risks AnalysisKrishna PatilОценок пока нет

- Plant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingДокумент11 страницPlant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingRAMAОценок пока нет

- Plant and Equipment Risk Assessment Fgoc - NewДокумент13 страницPlant and Equipment Risk Assessment Fgoc - Newmajid khanОценок пока нет

- Risk Assessment ForkliftДокумент2 страницыRisk Assessment Forkliftmohamed ghaly100% (2)

- 31.HIRA - Boom Placer OperationДокумент3 страницы31.HIRA - Boom Placer OperationMMRDACA07 SAFETYОценок пока нет

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectДокумент5 страницJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyОценок пока нет

- Job Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air CompressorДокумент4 страницыJob Hazard Analysis (Jha) Worksheet: To Run Portable Diesel Air Compressorlatiplambosi100% (1)

- Brazing (Oxygen and Acetylene)Документ6 страницBrazing (Oxygen and Acetylene)My Zain100% (1)

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Документ3 страницыRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanОценок пока нет

- Job Safety Analysis - Pipeline Bending (38 charactersДокумент6 страницJob Safety Analysis - Pipeline Bending (38 charactersMoaatazz NouisriОценок пока нет

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesДокумент10 страницRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaОценок пока нет

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentДокумент4 страницыCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniОценок пока нет

- Risk Assessment Construction of Lighting Pole at Site OfficeДокумент9 страницRisk Assessment Construction of Lighting Pole at Site OfficeSinaОценок пока нет

- AHA - Working On Slope RoofДокумент2 страницыAHA - Working On Slope RoofTopsun EnergyОценок пока нет

- Construction Safety: Page 1 of 4Документ4 страницыConstruction Safety: Page 1 of 4ryan.aniceteОценок пока нет

- Job Safety Analysis: 10.06.2017 Page 1 of 7Документ7 страницJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuОценок пока нет

- Shifting of Materials by Double HydraДокумент1 страницаShifting of Materials by Double HydraShahid RazaОценок пока нет

- 01 WI HSE 001 - Risk Assessment GroutingДокумент4 страницы01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- Risk Assessment - Site Establishment - 2021Документ6 страницRisk Assessment - Site Establishment - 2021Asakundwi MukhwaОценок пока нет

- Risk Assess T-23 - Hilti Cartridge Tool OperationДокумент2 страницыRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityДокумент2 страницыActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityYug DobariyaОценок пока нет

- Daily JSA - Diesel FillingДокумент3 страницыDaily JSA - Diesel Fillingshoaib akhtarОценок пока нет

- Risk Assessment MasonryДокумент1 страницаRisk Assessment Masonrymohamed ghalyОценок пока нет

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Документ13 страницRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayОценок пока нет

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionДокумент168 страницAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathОценок пока нет

- Final Risk AssessmentДокумент8 страницFinal Risk Assessmentapi-514194726Оценок пока нет

- Critical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsДокумент2 страницыCritical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsdnmuleОценок пока нет

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyДокумент4 страницыJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqОценок пока нет

- Abrasive Wheels Risk AssessmentДокумент4 страницыAbrasive Wheels Risk AssessmentAhmed El-sherpiniОценок пока нет

- RA - 8 - For WaterproofingДокумент13 страницRA - 8 - For WaterproofingIbrahim EsmatОценок пока нет

- SWMS - Blind IstallationДокумент12 страницSWMS - Blind IstallationParasОценок пока нет

- Environmental, Health and Safety Risks AnalysisДокумент2 страницыEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- RA For Block Works For 10 VillasДокумент5 страницRA For Block Works For 10 VillasFrancis Enriquez TanОценок пока нет

- PTW272 - Asphalt Paving 17-01-2023Документ22 страницыPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Risk Assessment For Mechanical: Preparation WorkДокумент3 страницыRisk Assessment For Mechanical: Preparation Workahmedalderbi801Оценок пока нет

- Confined Space Entry Safety AnalysisДокумент2 страницыConfined Space Entry Safety AnalysisDheeraj Kapoor /QOGIL/QuippoworldОценок пока нет

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageДокумент3 страницыEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanОценок пока нет

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesДокумент2 страницыEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazОценок пока нет

- HAZARD IDENTIFICATION AND RISK ASSESSMENTДокумент31 страницаHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarОценок пока нет

- GENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISДокумент2 страницыGENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISsakthi venkatОценок пока нет

- Cuplocks Scaffolding JSA UtilityДокумент4 страницыCuplocks Scaffolding JSA UtilitysoubhagyaОценок пока нет

- BackfillingДокумент2 страницыBackfillingGyanendra Narayan NayakОценок пока нет

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Документ2 страницыComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsОценок пока нет

- HARZAD IDENTIFICATION AND RISK ASSESSMENTДокумент14 страницHARZAD IDENTIFICATION AND RISK ASSESSMENTAmitkumar SinghОценок пока нет

- Job Risk Asessment. Excavation 8-6-22Документ3 страницыJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- Fan InstallationДокумент2 страницыFan InstallationKrishna PatilОценок пока нет

- Weekly HSE Inspection Closeout Report - 01Документ2 страницыWeekly HSE Inspection Closeout Report - 01niyas100% (1)

- Personal Protective Equipment Hazard AssessmentДокумент5 страницPersonal Protective Equipment Hazard AssessmentKrsnaPentayah100% (1)

- Risk Assessment-1 PDFДокумент17 страницRisk Assessment-1 PDFDayanandaОценок пока нет

- Risk Assessment Cutting Plates Oxygen-Di AcetyleneДокумент2 страницыRisk Assessment Cutting Plates Oxygen-Di AcetyleneandreОценок пока нет

- Job Hazard Analysis: Rohan Builders (I) PVT LTDДокумент4 страницыJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaОценок пока нет

- Idoc - Pub Night and Shift Worker Risk Assessment ExampleДокумент4 страницыIdoc - Pub Night and Shift Worker Risk Assessment Examplesoliman fathy100% (2)

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Scaffolding rental and material cost for 2M height 3M length platformДокумент1 страницаScaffolding rental and material cost for 2M height 3M length platformsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Orion Contracting Company LLC.: Safety Material RequestДокумент1 страницаOrion Contracting Company LLC.: Safety Material Requestsoliman fathyОценок пока нет

- Safe Practice Observations (SPO) Vehicles: ObservationДокумент2 страницыSafe Practice Observations (SPO) Vehicles: Observationsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- 60 Safety Poster - Mandatory Sign (Safety Gloves Must Be Worn)Документ1 страница60 Safety Poster - Mandatory Sign (Safety Gloves Must Be Worn)soliman fathyОценок пока нет

- Environmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution ControlДокумент6 страницEnvironmental Site Walk Down: Implemented? Remarks Inspection Items N/A 1. Air Pollution Controlsoliman fathyОценок пока нет

- 58 Safety Poster - Mandatory Sign (Now Wash Your Hands)Документ1 страница58 Safety Poster - Mandatory Sign (Now Wash Your Hands)soliman fathyОценок пока нет

- Cambridge International AS & A Level: BIOLOGY 9700/21Документ20 страницCambridge International AS & A Level: BIOLOGY 9700/21jamalОценок пока нет

- Test Bank For High Acuity Nursing 6th Edition Kathleen Dorman WagnerДокумент18 страницTest Bank For High Acuity Nursing 6th Edition Kathleen Dorman WagnerDavidRobinsonfikq100% (35)

- Cpep Approved CoursesДокумент4 страницыCpep Approved CourseskiranОценок пока нет

- MCN - The Childbearing and Childbearing Family in The CommunityДокумент91 страницаMCN - The Childbearing and Childbearing Family in The CommunityAndrea Marie SevillaОценок пока нет

- Cancer of Unknown PrimaryДокумент12 страницCancer of Unknown Primaryraul gutierrezОценок пока нет

- Chapter 048Документ24 страницыChapter 048dtheart282160% (10)

- Optic Disk Drusen in ChildrenДокумент14 страницOptic Disk Drusen in ChildrenPriscila VerduzcoОценок пока нет

- ANTIBODYДокумент52 страницыANTIBODYVysakhОценок пока нет

- Totalpsa ArcДокумент8 страницTotalpsa Arctesteste testeОценок пока нет

- Content CDC and MDДокумент7 страницContent CDC and MDAmir Ahmed GezaОценок пока нет

- Dengue Duo Engue ns1 Ag Igg Igm SD BiolineДокумент4 страницыDengue Duo Engue ns1 Ag Igg Igm SD Biolinersmbgss575Оценок пока нет

- Mastitis, Breast Abscess, and Granulomatous Mastitis: Ramesh Omranipour and Mahtab VasighДокумент9 страницMastitis, Breast Abscess, and Granulomatous Mastitis: Ramesh Omranipour and Mahtab VasighAlejandro Abarca VargasОценок пока нет

- The Comfort TheoryДокумент25 страницThe Comfort TheoryLuna Astaneh100% (1)

- INBDE Day 2Документ11 страницINBDE Day 2Mirza Hammad Ul-HaqОценок пока нет

- Test Bank Lutzs Nutrition and Diet Therapy 7th Edition Erin e MazurДокумент104 страницыTest Bank Lutzs Nutrition and Diet Therapy 7th Edition Erin e MazurMicheal Singh100% (23)

- Basic Malaria Microscopy Part One Certificate PDFДокумент16 страницBasic Malaria Microscopy Part One Certificate PDFafakatowОценок пока нет

- Tacrolimus Induced Early Graft Dysfunction Due to Acute Tubular NecrosisДокумент4 страницыTacrolimus Induced Early Graft Dysfunction Due to Acute Tubular NecrosisToddwilliam57Оценок пока нет

- Manual Reprocessing Final Version 2.0Документ29 страницManual Reprocessing Final Version 2.0Enaj AzilgОценок пока нет

- Cancer and Its Treatment: An OverviewДокумент7 страницCancer and Its Treatment: An OverviewIJAR JOURNALОценок пока нет

- Deoferio v. Intel Technology Philippines, Inc PDFДокумент9 страницDeoferio v. Intel Technology Philippines, Inc PDFMonica FerilОценок пока нет

- MA Paid Family Leave FormДокумент9 страницMA Paid Family Leave FormMarisa RebeloОценок пока нет

- NCLEX Strategy QuestionsДокумент9 страницNCLEX Strategy QuestionsPaulo de Jesus100% (1)

- Therapeutic Exercise: Foundation & Techniques: Resource Person: Dr. Rahat Ayub PT SHS.326.Lec.13Документ30 страницTherapeutic Exercise: Foundation & Techniques: Resource Person: Dr. Rahat Ayub PT SHS.326.Lec.13Mustafa ,GhulamОценок пока нет

- Management of Benign Breast Conditions: Part 1 - Painful BreastsДокумент3 страницыManagement of Benign Breast Conditions: Part 1 - Painful BreastsNajeebuddin AhmedОценок пока нет

- IgG4 Related DiseaseДокумент12 страницIgG4 Related DiseaseSofia SimpertigueОценок пока нет

- Mr. Souvik Tewari Souvik Tewari: Curriculum Vitae Curriculum VitaeДокумент17 страницMr. Souvik Tewari Souvik Tewari: Curriculum Vitae Curriculum VitaeSouvik TewariОценок пока нет

- A Case Study On Occupational Health and Safety of Footwear Manufacturing IndustryДокумент6 страницA Case Study On Occupational Health and Safety of Footwear Manufacturing IndustryZakir KhanОценок пока нет

- COVID-19 Nepal: Preparedness and Response Plan (NPRPДокумент56 страницCOVID-19 Nepal: Preparedness and Response Plan (NPRPKrishnaОценок пока нет

- DVH Limits 4Документ1 страницаDVH Limits 4Dioni SandovalОценок пока нет

- Question BankДокумент6 страницQuestion Bankkoang lual gachОценок пока нет