Академический Документы

Профессиональный Документы

Культура Документы

JSA Painting Aut Tranformer Unit 3 Outage

Загружено:

MarhendraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JSA Painting Aut Tranformer Unit 3 Outage

Загружено:

MarhendraАвторское право:

Доступные форматы

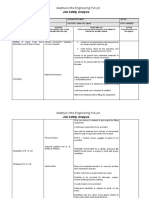

JOB SAFETY ANALYSIS

(RISK ASSESSMENT)

Area to be Access and/or Equipment Tag No. (KKS No.) : Auxiliary Transformer Unit 3 (see attached drawings)

Work to be Done : AUT TRANSFORMER PAINTING DURING UNIT 3 OUTAGE #PR155318

LOW HIGH Underwater Work Confined Space Excavation Hot Work

Risk Category Job :

Refer to Paiton Instruction : PI-05-03-01 Complex Lifting Work Working at High On Line Low & High Voltage

Work Order No. : Priority No. PAS Application No.

Work Period Date & Time Start Date & Time Finish

Operation

Applicant Health & Safety Work Parties Engineer

Supervisor

Signature :

Date : Time :

Ref. PI-05-03-01-F01 Page 1

Ref. PI-05-03-01-F01 Page 2

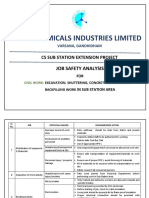

Work sequence Hazards Risk Control Measures

A. Prepartion

Mobilization tools, Good manual handling practices to be used (min. 2 person

equipment and materials Manual handling Musculoskeletal injuries

lift); Use hand gloves

to the work place Use mechanical aids where required

Improper electrical

Electrical tools/equipment Electrical Shock Ensure all electrical equipment in good condition

tools/equipment

Ensure all electrical equipment has been checked before use

and has valid tagging

B. Preparation

Install scaffolding by certificate scaffolder & tag by IPMOMI

Damage to exsisting facilities/

Scaffolding crumple safety officer. Always check regularly

equipment , personal injury

Secure exsisting facilities/equipment

Assembly of platform & Install scaffolding by certificate scaffolder & tag by IPMOMI

Falling down from the elevated

scaffold on the ground Personal injury safety officer. Always check regularly

structure

Have certification TKBT 2 for working at heights

Working at open area Dehydration Provide drinking water

Do not climb scaffold frame. Do not remove rails or bracing,

slip, fall or stepping through do not move scaffolding. Always close the hatch when

Personal injury

open door hatch entering new level

Have certification TKBT 2 for working at heights

Working on the scaffolding Getting hit in the head from tools Know what is below and above you at all time. Use standard

or equipment dropped from Personal injury or death safety helmet. Use safety rope where necessary to secure

above items

Working at open area Dehydration Provide drinking water

Working on the transformer Install tag line for attached fullbody hardness

Falling down from the elevated

Personal injury All worker shall wear proper safety shoes to prevent slip

structure

Have certification TKBT 2 for working at heights

Unauthorized energizing Electrical shock Identify & confirm the switchgear feeding electrical power to

the equipment; isolate safety electrical isolation through

proper tools

install sign and do not operated without the permission from

engineering

Ref. PI-05-03-01-F01 Page 3

Work sequence Hazards Risk Control Measures

Working at open area Dehydration Provide drinking water

Woks zone must be completely femced in and of a sufficient

Exposure of the public to falling

Personal injury distance away from sidewalks to remove any hazard to the

debris

public

All workes on site shall wear hard hats

Falling / Flying Debris Personal Injury

Have certification TKBT 2 for working at heights

Surface preparation A supply of dust masks shall be kept on hand to fill workes

Dust inhalation Resiratory injury

requests

Eyes Injuries Eyes Injury All workers shall wear safety glasses

Workers handling debris from the demolition will wear work

Cuts/Scrapes/Abrasions Personal Injury

gloves

C. Painting work

Painter shall be provided with standard PPE

No Hot work allowed. (at immediate area)

Hazard to health : Accidentally Personal injury Flammable liquids shall be stored and dispensed only from

inhaled, ingseted, eyes & skin approved type containers

Painting irritation No bulk storage of paint material at site (designated area

only)

Flammable material Fire MSDS for the paint need to be place prior to work starting

Cans/bottles for storage paint/thinner must be labeled from

IMPOMI

Working on the A knowledgeable mechanical enginner or safety officer must

scaffolding / on high inspect and approve scaffolding before general use

the collapse of scaffolding Personal injury

Install scaffolding by certificate scaffolder & tag by IPMOMI

safety officer. Always check regularly

Do not climb scaffold frame. Do not remove rails or bracing,

stepping through open door do not move scaffolding. Always close the hatch when

Personal injury from slip, fall

hatch entering new level

Have certification TKBT 2 for working at heights

Falling down from the elevated Personal injury Install tag line for attached fullbody hardness

structure All worker shall wear proper safety shoes to prevent slip

Have certification TKBT 2 for working at heights

Ref. PI-05-03-01-F01 Page 4

Work sequence Hazards Risk Control Measures

There is a dropping hazard. Take a minimum of equipment

Damage the installed equipment or

Dropped items and secure loose item. Use pocket, buckets, or bags to keep

component below

item secure

Getting hit in the head from tools Know what is below and above you at all time. Use standard

or equipment dropped from Personal injury or death safety helmet. Use safety rope where necessary to secure

above items

Dust mask for housekeeping crew when necessary

Dust dispersion Respiration system injury

Bundles bind or contained securely to prevent slippage

F. Housekeeping

Keep tools, equipment, extension cords, ropes etc. Out of

Disorganized tool & material Trip, slips, falls

walk ways

Additional Note :

1.

2.

3.

4.

5.

Ref. PI-05-03-01-F01 Page 5

The following test are required to assess the atmospheric conditions in the nominated space :

Ref. PI-05-03-01-F01 Page 6

TEST REQUIRED

TEST FOR Permissible Exposure Limit (PEL)

YES NO

Ammonia Less than 25 ppm √

Carbon Dioxide Less than 5000 ppm √

Carbon Monoxide Less than 25 ppm √

Chlorine Less than 0.5 ppm √

Hydrogen Sulfide Less than 10 ppm √

Oxygen Greater than 19.5% & Less than 23.5% √

Ozone Less than 0.1 ppm √

Sulphur Dioxide Less than 2 ppm √

Hydrogen LEL = 4% & UEL = 75.6% √

LEL Less than/ ≤ 4% √

Note :

1. Reference (OSHA PEL – 2013)

2. For clarification on the test required to be carried out refer PI-05-03-02 (Testing of Confined Space)

Ref. PI-05-03-01-F01 Page 7

Вам также может понравиться

- EPC-3 Gasoline package Assembly & Erection JSAДокумент3 страницыEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- Gas Cutting JsaДокумент4 страницыGas Cutting JsaMohammed Minhaj100% (1)

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineДокумент3 страницыYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewОценок пока нет

- Use of Power ToolsДокумент3 страницыUse of Power ToolsNisanth ThulasidasОценок пока нет

- 5.19 JSP Electrical Power InstallationДокумент4 страницы5.19 JSP Electrical Power InstallationDarius DsouzaОценок пока нет

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingДокумент12 страницRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetДокумент4 страницыHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟Оценок пока нет

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyДокумент9 страницJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- Job Safety Analysis for Oil Sealed Vacuum Pump PMДокумент8 страницJob Safety Analysis for Oil Sealed Vacuum Pump PMGajanan NalegaonkarОценок пока нет

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Документ5 страницCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaОценок пока нет

- Fabrication Work Risk AssessmentДокумент11 страницFabrication Work Risk Assessmentstansilous100% (1)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YДокумент4 страницыJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Form JSA Lifting CraneДокумент6 страницForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA Install Automatic Parking GateДокумент6 страницJSA Install Automatic Parking GateMarhendraОценок пока нет

- JSA Install Automatic Parking GateДокумент6 страницJSA Install Automatic Parking GateMarhendraОценок пока нет

- How to Calculate PayrollДокумент87 страницHow to Calculate PayrollMichael John D. Natabla100% (1)

- Lesson Learned RegisterДокумент2 страницыLesson Learned Registernasir habibОценок пока нет

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresДокумент3 страницыProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Job Safety Analysis Sheet: Operation Concrete Batching PlantДокумент2 страницыJob Safety Analysis Sheet: Operation Concrete Batching Plantzabiulla100% (7)

- S6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Документ26 страницS6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Rona Dindang100% (1)

- Environmental Change Steel Structure Dismantling and Erection JSAДокумент1 страницаEnvironmental Change Steel Structure Dismantling and Erection JSASamuel Hugos100% (4)

- Siemens SIVACON S8, IEC 61439 Switchgear and Control PanelДокумент43 страницыSiemens SIVACON S8, IEC 61439 Switchgear and Control PanelGyanesh Bhujade100% (2)

- ADA Design Guide 2010Документ7 страницADA Design Guide 2010Jack BarkerОценок пока нет

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Документ6 страниц012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- SWMS - Replacement of Light BulbsДокумент5 страницSWMS - Replacement of Light BulbsHanindita Widhi PangestiОценок пока нет

- JSA For Errection of Batching PlantДокумент4 страницыJSA For Errection of Batching Plantasamrat582Оценок пока нет

- SS JSP - 063 Testing and Pre-Commissioning WorksДокумент9 страницSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahОценок пока нет

- Piaggio MP3 300 Ibrido LT MY 2010 (En)Документ412 страницPiaggio MP3 300 Ibrido LT MY 2010 (En)Manualles100% (3)

- JSA Epoxy Coating Machine ShopДокумент10 страницJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumДокумент11 страницProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0Оценок пока нет

- Jsa Psa & GisДокумент3 страницыJsa Psa & GisMohammed NouzalОценок пока нет

- Earthing of GIS Type ELK - GTIДокумент20 страницEarthing of GIS Type ELK - GTIJairo MoralesОценок пока нет

- Jsa Water Proofing For DHAДокумент13 страницJsa Water Proofing For DHAAnonymous YmINeSIFОценок пока нет

- Restaurant Supervisor Job Description Job SummaryДокумент3 страницыRestaurant Supervisor Job Description Job SummaryKumarSvОценок пока нет

- JSA Crack Injection at Scruber Basin Unit 3Документ6 страницJSA Crack Injection at Scruber Basin Unit 3MarhendraОценок пока нет

- Ups Installation Method StatementДокумент197 страницUps Installation Method StatementehteshamОценок пока нет

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- 5 S Principles ExplainedДокумент30 страниц5 S Principles Explainedamaresh nkОценок пока нет

- Jsa D. G. INSTALLATIONДокумент5 страницJsa D. G. INSTALLATIONRavi thokalОценок пока нет

- Jsa Installing BracketДокумент3 страницыJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Jsa Cooling TowerДокумент5 страницJsa Cooling TowerRavi thokalОценок пока нет

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Документ4 страницы0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Tabel Baja Profil WF PDFДокумент7 страницTabel Baja Profil WF PDFErwin d'Adventura63% (19)

- JSA Additional Lamp Paiton 3Документ10 страницJSA Additional Lamp Paiton 3MarhendraОценок пока нет

- JOB SAFETY ANALYSIS RISK ASSESSMENTДокумент12 страницJOB SAFETY ANALYSIS RISK ASSESSMENTMarhendraОценок пока нет

- Job Safety Analysis: (Risk Assessment)Документ9 страницJob Safety Analysis: (Risk Assessment)MarhendraОценок пока нет

- Hard BarricationДокумент3 страницыHard BarricationViron BaxhiaОценок пока нет

- JOB SAFETY ANALYSIS WORKSHEETДокумент2 страницыJOB SAFETY ANALYSIS WORKSHEETCherry BetonioОценок пока нет

- Adr Jsa 1711 002Документ7 страницAdr Jsa 1711 002Dada KhalandarОценок пока нет

- PT-03 JSA Dismantling of Slip Form (22-05-09)Документ10 страницPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibОценок пока нет

- Assembly of Steel StructuresДокумент2 страницыAssembly of Steel StructuresDelta akathehuskyОценок пока нет

- Fixing of Bracket in Cutout JSA HSE ProfessionalsДокумент1 страницаFixing of Bracket in Cutout JSA HSE ProfessionalsSamadov 13Оценок пока нет

- Job Safety Analysis Sheet - Alluminium Door FixingДокумент2 страницыJob Safety Analysis Sheet - Alluminium Door FixingNFRNОценок пока нет

- Staircase and Walkways Railing Work JSA HSE ProfessionalsДокумент1 страницаStaircase and Walkways Railing Work JSA HSE ProfessionalsSamadov 13Оценок пока нет

- Rebaring JSA HSE ProfessionalsДокумент1 страницаRebaring JSA HSE ProfessionalsSamadov 13Оценок пока нет

- JSA For Construction of E - P WorkshopДокумент5 страницJSA For Construction of E - P Workshopm.rehanhseОценок пока нет

- 5.19 JSP ScaffoldДокумент4 страницы5.19 JSP Scaffoldpoorm879Оценок пока нет

- Pre-task planning and PCW pipe installationДокумент2 страницыPre-task planning and PCW pipe installationfatimah100% (1)

- Electrical Installation Works SafetyДокумент2 страницыElectrical Installation Works SafetyCherry BetonioОценок пока нет

- JSA For SURGE VESSEL WorkДокумент6 страницJSA For SURGE VESSEL Workathul subashОценок пока нет

- 021 Manual Excavation JSA For FLS SiteДокумент3 страницы021 Manual Excavation JSA For FLS SiteViron BaxhiaОценок пока нет

- CS Sub Station JsaДокумент4 страницыCS Sub Station JsaEHS Unit IIОценок пока нет

- Builder Hoist Erection JSA HSE ProfessionalsДокумент2 страницыBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDOОценок пока нет

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Документ2 страницыJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaОценок пока нет

- 004 Piling JSAДокумент4 страницы004 Piling JSAIdada EzekielОценок пока нет

- Job Safety Analysis (Jsa) : DQE International Iraq BranchДокумент4 страницыJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- FPS 008 - WeldingREV1Документ3 страницыFPS 008 - WeldingREV1grantОценок пока нет

- Steel Cutting, Bending, Welding and Grinding Work JsaДокумент2 страницыSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALIОценок пока нет

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsДокумент2 страницыStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RОценок пока нет

- RISK ASSESSMENT FOR 300MW MASINLOC COAL PLANTДокумент9 страницRISK ASSESSMENT FOR 300MW MASINLOC COAL PLANTResearcherОценок пока нет

- JSA 12-Rev.02 - Pipe or spool erection by using of chain blocks or rope pulleyДокумент3 страницыJSA 12-Rev.02 - Pipe or spool erection by using of chain blocks or rope pulleygolusinghdataОценок пока нет

- SikaGrout 215 SDS en - MYДокумент9 страницSikaGrout 215 SDS en - MYMarhendraОценок пока нет

- Protect Your Eyes When Working With Sika Injection-201 CE (AДокумент9 страницProtect Your Eyes When Working With Sika Injection-201 CE (AMarhendraОценок пока нет

- Sikaflex - 221Документ2 страницыSikaflex - 221MarhendraОценок пока нет

- SDS Sika Injection-201 CE (B) Safety Data SheetДокумент10 страницSDS Sika Injection-201 CE (B) Safety Data SheetMarhendraОценок пока нет

- BA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMДокумент4 страницыBA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMMarhendraОценок пока нет

- Schedule Booster FanДокумент1 страницаSchedule Booster FanMarhendraОценок пока нет

- 3.LINE 1,2 S9129 InletDuctingSketchДокумент1 страница3.LINE 1,2 S9129 InletDuctingSketchMarhendraОценок пока нет

- Technical Clarification Form-PR171982Документ11 страницTechnical Clarification Form-PR171982MarhendraОценок пока нет

- 2.LINE 1,2 GAExistingSealBoosterAirFanДокумент1 страница2.LINE 1,2 GAExistingSealBoosterAirFanMarhendraОценок пока нет

- Schedule Booster FanДокумент1 страницаSchedule Booster FanMarhendraОценок пока нет

- 1.LINE 1,2 GANewSealBoosterAirFanДокумент1 страница1.LINE 1,2 GANewSealBoosterAirFanMarhendraОценок пока нет

- Design Calculation Rail 350 X 175 For PTW PreparationДокумент9 страницDesign Calculation Rail 350 X 175 For PTW PreparationMarhendraОценок пока нет

- This constructi-WPS OfficeДокумент1 страницаThis constructi-WPS OfficeMarhendraОценок пока нет

- Access Gate Fence Pole FoundationДокумент1 страницаAccess Gate Fence Pole FoundationMarhendraОценок пока нет

- JSA Replace Exsisting Strainer at FGD 8Документ8 страницJSA Replace Exsisting Strainer at FGD 8MarhendraОценок пока нет

- Desain Rak PerlengkapanДокумент1 страницаDesain Rak PerlengkapanMarhendraОценок пока нет

- JSA Building Paving FactoryДокумент12 страницJSA Building Paving FactoryMarhendraОценок пока нет

- JSA Replace Exsisting Strainer at FGD 8Документ6 страницJSA Replace Exsisting Strainer at FGD 8MarhendraОценок пока нет

- Column Layout and Detail PlanДокумент1 страницаColumn Layout and Detail PlanMarhendraОценок пока нет

- BoQ of Additional Lamps For Some P3 Area 2020 - R1Документ3 страницыBoQ of Additional Lamps For Some P3 Area 2020 - R1MarhendraОценок пока нет

- Sow To Provide Additional Lamp On Some Area of Paiton 3 - 2020 R1Документ21 страницаSow To Provide Additional Lamp On Some Area of Paiton 3 - 2020 R1MarhendraОценок пока нет

- AtoZ PicsДокумент7 страницAtoZ PicsMarhendraОценок пока нет

- Access Gate FoundationДокумент1 страницаAccess Gate FoundationMarhendraОценок пока нет

- Bibie Evana OsmanДокумент6 страницBibie Evana OsmanStabat Jaya TrademarkОценок пока нет

- MSE 2103 - Lec 12 (7 Files Merged)Документ118 страницMSE 2103 - Lec 12 (7 Files Merged)md akibhossainОценок пока нет

- Bio ViberДокумент7 страницBio ViberMarco BuntОценок пока нет

- App 17 Venmyn Rand Summary PDFДокумент43 страницыApp 17 Venmyn Rand Summary PDF2fercepolОценок пока нет

- Deadline Anchors BrochureДокумент3 страницыDeadline Anchors Brochurejlmunozv100% (2)

- Rajasthan PET Chemistry 1997 Exam with Detailed SolutionsДокумент34 страницыRajasthan PET Chemistry 1997 Exam with Detailed SolutionsYumit MorwalОценок пока нет

- Rawat Inap Rumah Sakit Santa Elisabeth Medan Englin Moria K. Tinambunan, Lindawati F. Tampubolon, Erika E. SembiringДокумент14 страницRawat Inap Rumah Sakit Santa Elisabeth Medan Englin Moria K. Tinambunan, Lindawati F. Tampubolon, Erika E. SembiringafrilianaОценок пока нет

- Catalogo Unidad Enfriadora Trane R-407C PDFДокумент8 страницCatalogo Unidad Enfriadora Trane R-407C PDFJUAN FRANCISCO AYALAОценок пока нет

- DOC023.97.80076 - 3ed Sensores ORPДокумент148 страницDOC023.97.80076 - 3ed Sensores ORPAlejandroОценок пока нет

- Concept PaperДокумент6 страницConcept Paperapple amanteОценок пока нет

- Biosafety FH Guidance Guide Good Manufacturing Practice enДокумент40 страницBiosafety FH Guidance Guide Good Manufacturing Practice enMaritsa PerHerОценок пока нет

- Delta C200 Series AC Drives PDFДокумент5 страницDelta C200 Series AC Drives PDFspОценок пока нет

- Partial Defoliation of Vitis Vinifera L. Cv. Cabernet SauvignonДокумент9 страницPartial Defoliation of Vitis Vinifera L. Cv. Cabernet Sauvignon1ab4cОценок пока нет

- HBV Real Time PCR Primer Probe Sequncence PDFДокумент9 страницHBV Real Time PCR Primer Probe Sequncence PDFnbiolab6659Оценок пока нет

- SK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Документ30 страницSK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Viktor RégerОценок пока нет

- EPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsДокумент4 страницыEPF, EPS, Gratuity, Superannuation & Group Life Insurance Nomination FAQsHemanth DhananjayОценок пока нет

- PR Cuisine vs US CuisineДокумент2 страницыPR Cuisine vs US CuisineJannette HernandezОценок пока нет

- Lesson 5 - The Problem of EvilДокумент10 страницLesson 5 - The Problem of Evilsemmerson4896Оценок пока нет

- 670W Bifacial Mono PERC ModuleДокумент2 страницы670W Bifacial Mono PERC Modulemabrouk adouaneОценок пока нет

- Final Profile Draft - Zach HelfantДокумент5 страницFinal Profile Draft - Zach Helfantapi-547420544Оценок пока нет

- Airborne Life Support Systems In-House Infant Transport Sys 185A Infant Incubator - Manufacturer SpecificationsДокумент2 страницыAirborne Life Support Systems In-House Infant Transport Sys 185A Infant Incubator - Manufacturer SpecificationsAsistir Biomedica SASОценок пока нет