Академический Документы

Профессиональный Документы

Культура Документы

Ball Mill Manual F

Загружено:

Shoaib PathanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ball Mill Manual F

Загружено:

Shoaib PathanАвторское право:

Доступные форматы

1

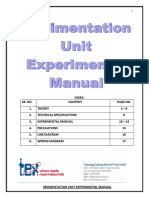

INDEX

SR NO SUBJECT PAGE NO

1. Ball mill Diagram 2

2. Theory 3–5

3. Advantages & Disadvantages 6

4. Experimental Manual 7 – 10

5. Ball Mill Detailed Diagram 11

6. Ball Mill Wiring Diagram 12

BALL MILL EXPERIMENTAL MANUAL

2

BALL MILL EXPERIMENTAL MANUAL

3

BALL MILL DIAGRAM

THEORY:

In its simplest form, the Ball Mill consists of a rotating hollow cylinder, partially

filled with balls, with its axis either horizontal or at a small angel to the

horizontal. The material to be ground may be fed in through a hollow trunnion

at one end and the product leaves through a similar trunnion at the other end

for continuous type operation. The outlet is normally covered with a coarse

screen to prevent the escape of the balls.

The inner surface of the cylinder is usually lined with an abrasion-resistant

material such as manganese steel, stoneware or rubber. Less wear takes

place in rubber-lined mills, and the coefficient of friction between the balls and

the cylinder is greater than with steel or stoneware linings. The balls are

therefore carried further in contact with the cylinder and thus drop on to the

feed from a greater height. In some cases, lifter bars are fitted to the inside of

the cylinder. A new type of ball mill is now being used to an increasing extent,

where the mill is vibrated instead of being rotated, and the slope of the mill

controls the rate of passage of material.

The ball mill is used for the grinding of a wide range of materials, including

coal, pigments, and felspar for pottery, and will take feed up to about 50 mm

in size. The efficiency of grinding increases with the hold-up in the mill, until

the voids between the balls are filled. Further increase in the quantity then

lowers the efficiency again.

The balls are usually made of flint or steel and occupy between 30 and 50 per

cent of the volume of the mill. The diameter of ball used will vary between 13

mm and 125 mm and the optimum diameter is approximately proportional to

the square root of the size of the feed, the proportionality constant being a

function of the nature of the material.

During grinding, the balls themselves wear and are constantly replaced by

new ones so that the mill contains ball of various ages, and hence of various

sizes. This is advantageous since the large balls deal effectively with the feed

and the small ones are responsible for giving a fine product. The maximum

rate of wear of steel balls, using very abrasive materials, is about 0.3 kg per

mg of material for dry grinding, and 1-1.5 kg/mg for wet grinding. The normal

charge of balls amounts to about 5 mg/m 3. In small mills where very fine

grinding is required, pebbles are often used in place of balls.

In the compound mill, the cylinder is divided into a number of compartments

by vertical perforated plates. The material flows axially along the mill and can

pass from one compartment to the next only when its size has been reduced

to less than that of the perforations in the plate. Each compartment is supplied

with balls of a different size; the large balls are at the entry end and thus

BALL MILL EXPERIMENTAL MANUAL

4

operate on the feed material, whilst the small balls come into contact with the

material immediately before it is discharged. This results in economical

operation and the formation of a uniform product. It also gives an improved

residence time distribution for the material, since a single ball mill

approximates closely to a completely mixed system.

Factors influencing the size of the product:

(a) The rate of feed. With high rates of feed, less size reduction is

effected since the material is in the mill for a shorter time.

(b) The properties of the feed material. The larger the feed the larger will

be the product under given operating conditions. A smaller size

reduction is obtained with a hard material.

(c) Weight of balls. A heavy charge of balls produces a fine product. The

weight of the charge can be increased, either by increasing the

number of balls, or by using a material of higher density. Since

optimum grinding conditions are usually obtained when the bulk

volume of the balls is equal to 50 per cent of the volume of the mill,

variation of the weight of balls is normally effected by the use of

materials of different densities.

(d) The diameter of the balls. Small balls facilitate the production of fine

material but they do not deal so effectively with the larger particles in

the feed. The limiting size reduction obtained with a given size of

balls is known as the free grinding limit. For most economical

operation, the smallest possible balls should be used.

(e) The slope of the mill. Increase in the slope of the mill increases the

capacity of the plant because the retention time is reduced, but a

coarser product is obtained.

(f) Discharge freedom. Increasing the freedom of discharge of the

product has the same effect as increasing the slope. In some mills,

the product is discharged through openings in the lining.

(g) The speed of rotation of the mill. At low speed of rotation, the balls

simply roll over one another and little crushing action is obtained. At

slightly higher speeds, they are projected short distances across the

mill, and at still higher speeds they are thrown greater distances and

considerable wear of the lining of the mill takes place. At very high

speeds, the balls are carried right round in contact with the sides of

the mill and little relative movement of grinding takes place again.

The minimum speed at which the balls are carried round in this

manner is called the critical speed of the mill and, under these

conditions, there will be no resultant force acting on the ball when it

is situated in contact with the lining of the mill in the uppermost

position, that is the centrifugal force will be exactly equal to the

weight of the ball. If the mill is rotating at critical angular velocity (C),

r C2 = g

C = g/ r

(h) The corresponding critical rotational speed N c = C / (2 * ) = [1/ (2 *

)] * (g / r)

BALL MILL EXPERIMENTAL MANUAL

5

(i) Here r is the radius of the mill less than that of the particle. It is found

that the optimum speed is between one-half and three-quarters of the

critical speed.

(J) The level of material in the mill. Maintaining a low level of material in

the mill reduces power consumption, and fitting a suitable discharge

opening for the product can control this most satisfactorily. If the level

of material is raised, the cushioning action is increased and power is

wasted by the production of an excessive quantity of undersize

material.

BALL MILL EXPERIMENTAL MANUAL

6

ADVANTAGES:

It produces very fine powder (Particle size less than or equal to

10 microns).

It is suitable for milling toxic materials since it can be used in a

completely enclosed form.

Has a wide application.

It is used in milling highly abrasive materials.

DISADVANTAGES:

Contamination of product may occur as a result of wear and tear

which occurs principally from the balls and partially from the

casing.

High machine noise level especially if the hollow cylinder is made

of metal, but much less if rubber id used.

Relatively long time of milling.

It is difficult to clean the machine after use.

BALL MILL EXPERIMENTAL MANUAL

7

BALL MILL EXPERIMENTAL MANUAL

AIM:

(1) To determine Critical Speed, Work Index, Bonds Law, Rittinger’s Law

and Kick’s Law.

(2) To determine the Surface Area generated for the given amount of

feed.

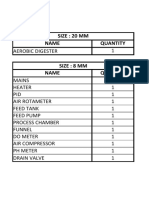

APPARATUS:

Ball Mill, Sieves, Sieve Shaker, Weighing Balance, Weight Box.

PROCEDURE:

Perform the sieve analysis of the feed at first.

Take measurements of the cylindrical shell and the metallic balls.

Take known number of balls inside the cylinder.

Charge the known weight of material to the mill, which is to be grind.

Note the time t and start the ball mill for one or half hour.

Take out the product and perform the sieve analysis.

OBSERVATION:

Quantity of feed sample =

Feed size, Df =

Time taken for 1 complete revolution (No load) =

Time taken for 1 complete revolution (Load) =

Total time the mill is put to operation =

Energy meter constant for ball mill = 1600

BALL MILL EXPERIMENTAL MANUAL

8

OBSERVATION TABLE:

Mesh Mean Mass Mass

Sr. Screen

Dia. Retained fraction Xi/Dpi

No. no. aperture

Dp, mm (1a+2a/2) gm Retained, Xi

1a.

2a.

3a.

4a.

5a.

6a.

7a.

8a.

9a.

10a.

11a.

12a.

13a.

14a.

CALCULATION:

1) Energy required for crushing

E = (n1 –n) / (m x EMC)

= (53.33 – 44.44) / (0.005 x 1600)

= 8.89 / 8

= 1.1112 kW hr/Tones

2) Work index

Wi = (E) / (1/ ʃ Dp – 1 ʃ Df)

= (1.1112) / (1 / 0.02 – 0.1)

= (1.1112) / (12.5)

= 0.0888

BALL MILL EXPERIMENTAL MANUAL

9

3) Reduction ratio = Z Feed size % Product size

= 0.1 - 0.02 X 1000

= 80 %

4) Critical speed of ball mill

Nc = ½ ᴫ (ʃ g / R-r)

= ½ x 3.14 (9.8 / 0.165 – 0.0125)

= 0.5 x 3.14 (9.8 / 0.1525)

= 0.5 x 3.14 (1.4945)

= 0.5 x 4.6927

= 2.3463

Where,

n1 is the no. of revolutions of the energy meter disc during the mill operation

under load condition = 53.33

n is the no. of revolutions of the energy meter disc during the mill operation

under no load condition = 44.44

m is mass of sample in tones = 0.005 tones

EMC is energy meter constant = 1600

Dp is mass mean diameter of the product sample in mm = 0.02 m

Df is the diameter of the feed sample in mm = 0.1 m

g is acceleration due to gravity in = 9.8 m/sec2

R is radius of the Ball mill in = 0.165 m

r is the radius of Balls in = 0.0125 m

Result:

Using the Ball mill experimental setup, the following were determined:

1. Energy required for crushing = 1.1112 kW hr/Ton

2. Work index = 0.0888 kW hr ʃ mm/Ton

3. Reduction ratio = 80 %

4. Critical speed of the ball mill = 2.3463 rps

BALL MILL EXPERIMENTAL MANUAL

10

BALL MILL EXPERIMENTAL MANUAL

11

BALL MILL EXPERIMENTAL MANUAL

Вам также может понравиться

- Pamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentДокумент12 страницPamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (3)

- Ball Milling - Final FinalДокумент12 страницBall Milling - Final FinalKrishna TejaОценок пока нет

- 3 - Ball Mill GrindingДокумент78 страниц3 - Ball Mill GrindingMega Purnama Zainal91% (11)

- Tube Mill NoteДокумент6 страницTube Mill Notevvijaybhan100% (1)

- Ball MillДокумент14 страницBall MillLaxman Kumar100% (1)

- Process Train Ball MillДокумент28 страницProcess Train Ball MillvvijaybhanОценок пока нет

- Ball Charge in Ball MillДокумент11 страницBall Charge in Ball MillRanu Yadav0% (1)

- Grinding Ball Size SelectionДокумент4 страницыGrinding Ball Size Selectionggoyet100% (1)

- Ball Mill Audit and OptimizationДокумент82 страницыBall Mill Audit and Optimizationanrulo100% (4)

- The Selection and Design of Mill LinersДокумент11 страницThe Selection and Design of Mill Linersluis martinezОценок пока нет

- Ball MillДокумент8 страницBall MillHumbulaniОценок пока нет

- Grinding Course: Ball Charge Design MethodsДокумент12 страницGrinding Course: Ball Charge Design MethodsVishnu Vardhan . C100% (12)

- 1 Ball Mills 1Документ106 страниц1 Ball Mills 1BharaniChirsabesan100% (3)

- The Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceДокумент15 страницThe Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceYaser Mohamed Abas100% (1)

- Lab Manual For Trommel CitДокумент2 страницыLab Manual For Trommel CitRyle ArbonОценок пока нет

- Vertical Roller Mill State of The Art Raw GrindingДокумент4 страницыVertical Roller Mill State of The Art Raw GrindingzementheadОценок пока нет

- Mill Ops AusIMM Kirsch and DanielДокумент7 страницMill Ops AusIMM Kirsch and DanielMicheael JohnОценок пока нет

- A Ball Mill Design-Overview 2Документ32 страницыA Ball Mill Design-Overview 2Joel Miguel Angel PachecoОценок пока нет

- Ball Charge Design VДокумент13 страницBall Charge Design Vshani5573100% (1)

- Ball Mill Testingjune99Документ29 страницBall Mill Testingjune99Shakil Ahmad83% (6)

- Ball MillДокумент2 страницыBall Millpadma26327Оценок пока нет

- Audit of Ball Mill Circuits PDFДокумент128 страницAudit of Ball Mill Circuits PDFTOULASSI-ANANI Yves Lolo100% (3)

- Ball MillДокумент23 страницыBall MillSyed Muhammad Saqib BariОценок пока нет

- Ball Mill Grinding MediaДокумент47 страницBall Mill Grinding Mediamahreza189100% (3)

- Roller Mill FundamentalsДокумент11 страницRoller Mill Fundamentalshidrastar123100% (1)

- Sag Moly CopДокумент29 страницSag Moly CopVolney Quispe Ayala100% (2)

- Ball Mill HandbookДокумент9 страницBall Mill HandbookSonny MoersaliОценок пока нет

- Ball Mill EDMДокумент47 страницBall Mill EDMMKPashaPasha100% (1)

- Ball Mill Degree of Filling CalculationДокумент4 страницыBall Mill Degree of Filling Calculationvvijaybhan100% (2)

- Circulating Load: in The Crushing and Milling CircuitДокумент17 страницCirculating Load: in The Crushing and Milling Circuitaghilif100% (1)

- Hydrocyclone Design For Large Sag Mill CircuitsДокумент12 страницHydrocyclone Design For Large Sag Mill CircuitsFrancisco CampbellОценок пока нет

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsДокумент44 страницыGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Ball Mill GrindingДокумент78 страницBall Mill Grindingarafat100% (7)

- Ball MillДокумент3 страницыBall MillpassionОценок пока нет

- Ball MillДокумент11 страницBall MillAkhil Bhadouria0% (1)

- Ball Mill OptimizationДокумент7 страницBall Mill OptimizationWael Fanous100% (1)

- Factors Influencing The Grinding EfficiencyДокумент27 страницFactors Influencing The Grinding Efficiencygrameshkreddy2013Оценок пока нет

- Ball, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Документ131 страницаBall, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Tsakalakis G. Konstantinos100% (7)

- Rotary DryerДокумент12 страницRotary DryerImam Baliqin100% (1)

- B Ball Mill MaintenanceДокумент7 страницB Ball Mill MaintenanceJoel Miguel Angel PachecoОценок пока нет

- Ball Mill PresentationДокумент34 страницыBall Mill PresentationISLAM I. Fekry100% (18)

- 132 Loesche Mills For Solid Fuels Coal Mill E 2016Документ24 страницы132 Loesche Mills For Solid Fuels Coal Mill E 2016Verananda Ariyanto100% (1)

- 02 Comminution TheoryДокумент28 страниц02 Comminution TheoryPham tony1604Оценок пока нет

- Grate KilnДокумент8 страницGrate KilnAnggiet HerdayantiОценок пока нет

- Vega LinersДокумент80 страницVega LinersAnonymous knICax100% (2)

- Flotation Equipment Selection - OutotecДокумент13 страницFlotation Equipment Selection - Outoteclouza8Оценок пока нет

- Ball MillДокумент9 страницBall MillTaufik AchmadОценок пока нет

- Better Grinding Systems: Figure 1: DeglomeratorДокумент5 страницBetter Grinding Systems: Figure 1: DeglomeratorSrikanth Mankala100% (1)

- Communition Theory Reference and FormulasДокумент10 страницCommunition Theory Reference and Formulasharishkumar.ravichandranОценок пока нет

- Ball Mill Grinding Media Max Ball Size CalculationДокумент2 страницыBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- Media Charge - Linear Wear - Ball MillsДокумент5 страницMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaОценок пока нет

- Polycom Process-CalculationДокумент42 страницыPolycom Process-Calculationdarkcorsair100% (4)

- Nordberg Grinding Mills Ball Rod and PebbleДокумент24 страницыNordberg Grinding Mills Ball Rod and PebbleTsakalakis G. Konstantinos100% (4)

- FLS - Ball Mill Liners Brochure - DIGITALДокумент9 страницFLS - Ball Mill Liners Brochure - DIGITALaliОценок пока нет

- Single Stage Sag-Ag Milling DesignДокумент11 страницSingle Stage Sag-Ag Milling DesignrobigedОценок пока нет

- Ball Mill Experimental ManualДокумент14 страницBall Mill Experimental ManualShoaib PathanОценок пока нет

- Lab Report GROUP3Документ70 страницLab Report GROUP3Maheshree GohilОценок пока нет

- Ball Mill: Experiment No.-5Документ2 страницыBall Mill: Experiment No.-5SagarОценок пока нет

- Practical 1 Ball MilingДокумент8 страницPractical 1 Ball MilingRaymond Godfrey DagwasiОценок пока нет

- Apparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FДокумент13 страницApparatus For Measurement of Thermal Conductivity of Good and Bad Conductors Manual FShoaib PathanОценок пока нет

- Cre Lab EquipmentДокумент1 страницаCre Lab EquipmentShoaib PathanОценок пока нет

- Apparatus For Friction Losses in Pipe Fittings ManualДокумент17 страницApparatus For Friction Losses in Pipe Fittings ManualShoaib PathanОценок пока нет

- Basket CentrifugeДокумент1 страницаBasket CentrifugeShoaib PathanОценок пока нет

- Forced Draft Tray DryerДокумент1 страницаForced Draft Tray DryerShoaib PathanОценок пока нет

- Sedimentation Equipment: Technical SpecificationДокумент1 страницаSedimentation Equipment: Technical SpecificationShoaib PathanОценок пока нет

- Leaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherДокумент1 страницаLeaching Apparatus: Technical Specifications: The Equipment Consists Mainly of The Following: 1) Percolation LeacherShoaib PathanОценок пока нет

- Wetted Wall Column: Technical SpecificationsДокумент1 страницаWetted Wall Column: Technical SpecificationsShoaib PathanОценок пока нет

- Vibrating Screen: Technical SpecificationДокумент1 страницаVibrating Screen: Technical SpecificationShoaib PathanОценок пока нет

- Cocurrent and Counter Current Liquid-Liquid ExtractorДокумент2 страницыCocurrent and Counter Current Liquid-Liquid ExtractorShoaib PathanОценок пока нет

- Cyclone Separator and Water Scrubber: Technical SpecificationsДокумент1 страницаCyclone Separator and Water Scrubber: Technical SpecificationsShoaib PathanОценок пока нет

- Cyclone Seperator Experimental ManualДокумент12 страницCyclone Seperator Experimental ManualShoaib PathanОценок пока нет

- Heat Pipe DemonstratorДокумент10 страницHeat Pipe DemonstratorShoaib PathanОценок пока нет

- Sedimentation Unit Experimental ManualДокумент17 страницSedimentation Unit Experimental ManualShoaib PathanОценок пока нет

- Force Draft Tray Dryer Experimental ManualДокумент21 страницаForce Draft Tray Dryer Experimental ManualShoaib Pathan100% (2)

- Leaching Apparatus Experimental ManualДокумент12 страницLeaching Apparatus Experimental ManualShoaib PathanОценок пока нет

- Leaf Filter Experimental ManualДокумент12 страницLeaf Filter Experimental ManualShoaib Pathan67% (3)

- Wetted Wall Column Experimental ManualДокумент17 страницWetted Wall Column Experimental ManualShoaib PathanОценок пока нет

- Vibrating Screen Experimental ManualДокумент16 страницVibrating Screen Experimental ManualShoaib Pathan50% (2)

- Heat Pipe DemonstratorДокумент10 страницHeat Pipe DemonstratorShoaib PathanОценок пока нет

- Brochure Ball Mills en 1Документ16 страницBrochure Ball Mills en 1Charith Liyanage100% (1)

- enДокумент22 страницыenAnonymous iI88LtОценок пока нет

- Industrial Chemistry Henry Kreitzer (Ebooksread - Com)Документ547 страницIndustrial Chemistry Henry Kreitzer (Ebooksread - Com)Pyae Sone KyawОценок пока нет

- Ball Mill MaintainanceДокумент3 страницыBall Mill MaintainanceKritish ShettyОценок пока нет

- Ball MillingДокумент16 страницBall MillingRodrigo GarcíaОценок пока нет

- 2021-CH-16 Muhammad Tahir-Ball MillДокумент22 страницы2021-CH-16 Muhammad Tahir-Ball MillnsfvhsfОценок пока нет

- 2015 - SAG Conference - VTM Minas-Rio PDFДокумент15 страниц2015 - SAG Conference - VTM Minas-Rio PDFMauricio Narváez100% (1)

- Size Reduction of Solid FoodsДокумент66 страницSize Reduction of Solid FoodsRhadel GantuangcoОценок пока нет

- Verticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-MeДокумент34 страницыVerticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-Mevikas100% (1)

- Ultra Fine GrindingДокумент4 страницыUltra Fine GrindingRamoutar (Ken) SeecharranОценок пока нет

- The Role of Nanomaterials in Reducing Moisture Damage of Asphalt MixesДокумент14 страницThe Role of Nanomaterials in Reducing Moisture Damage of Asphalt MixesEizu YangОценок пока нет

- Cement Seminars and Courses 2016Документ68 страницCement Seminars and Courses 2016Lucas Araújo100% (1)

- Edited Proposal Eco ParkДокумент21 страницаEdited Proposal Eco ParkAlverastine An100% (4)

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Документ14 страницCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamОценок пока нет

- Tittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant LocationДокумент5 страницTittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant Locationসাইদুর রহমানОценок пока нет

- CM-3 VRM Productivity Improvement by Seperator ModificationsДокумент12 страницCM-3 VRM Productivity Improvement by Seperator ModificationsSujay MenonОценок пока нет

- Mineral Processing: Chapter OutlineДокумент32 страницыMineral Processing: Chapter OutlineAlejandra VeraОценок пока нет

- Paint Industry - Lecture 3Документ7 страницPaint Industry - Lecture 3U SANKAR TEJOОценок пока нет

- Design, Construction and Performance Analysis of A 5 KG Laboratory Ball MillДокумент18 страницDesign, Construction and Performance Analysis of A 5 KG Laboratory Ball MillDanny WillemsОценок пока нет

- Zircon Sand: Milling MatterДокумент2 страницыZircon Sand: Milling MatterLe Hoang LongОценок пока нет

- 03 Ball Mill EDMДокумент47 страниц03 Ball Mill EDMVishnu Vardhan . C92% (13)

- Ball Mill SizingДокумент10 страницBall Mill SizingvvananthОценок пока нет

- High Energy Ball Mill Emax - The Revolution in Ultrafine GrindingДокумент20 страницHigh Energy Ball Mill Emax - The Revolution in Ultrafine GrindingDiky MudhakirОценок пока нет

- A Critical Review On Energy Use and Savings in The Cement IndustriesДокумент20 страницA Critical Review On Energy Use and Savings in The Cement IndustriesUtsav ShahОценок пока нет

- Fireworks How To Make Black Powder Quick-Skylighter KomДокумент18 страницFireworks How To Make Black Powder Quick-Skylighter KomDudeman100% (1)

- After Grinding A Tool Bit, The Cutting Edge Should Be: A. Case-Hardened B. Rubbed With Emery ClothДокумент100 страницAfter Grinding A Tool Bit, The Cutting Edge Should Be: A. Case-Hardened B. Rubbed With Emery ClothJom BautistaОценок пока нет

- Chemistry and Engineering of Cement Production. State of The Art. Sorretino PDFДокумент8 страницChemistry and Engineering of Cement Production. State of The Art. Sorretino PDFrmarin_90Оценок пока нет

- Advanced Powder Technology: V.K. Gupta, Shivani SharmaДокумент10 страницAdvanced Powder Technology: V.K. Gupta, Shivani SharmaRashmi PatelОценок пока нет

- Grinding Calculation MemoryДокумент7 страницGrinding Calculation MemoryJorge Lezma JaraОценок пока нет

- IJMGE Volume 55 Issue 2 Page 97-107Документ11 страницIJMGE Volume 55 Issue 2 Page 97-107aliОценок пока нет