Академический Документы

Профессиональный Документы

Культура Документы

Single, But Twice As Safe Under High Pressure

Загружено:

munhОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Single, But Twice As Safe Under High Pressure

Загружено:

munhАвторское право:

Доступные форматы

Mechanical seal SHVI and Plan 66A for unmanned

pump station of an oil pipeline

Single, but twice as safe under

high pressure

A well-known Canadian operator of an oil

pipeline commissioned EagleBurgmann to

develop a sealing solution for crude oil

pumps. The requirement: It needed to be

a single seal that was just as safe as a

double seal with buffer pressure system.

In addition, the sealing solution was not

to be designed for only one pump type but

should be installed in various pumps of

one station.

The operating parameters were quite extensive:

The seal needed to be suitable for a pressure

range from 2.5 bar (36 PSI) to 99 bar (1,436 PSI)

as well as for shaft diameters from 115 mm

to 155 mm (4.53’’ to 6.10’’). Since the pump

stations are operated unmanned, the seal must

operate without an additional supply system. To

protect the environment and personnel, however,

the seal housing must not leak if the seal fails

unexpectedly. EagleBurgmann develops custom tailored sealing solutions for pipelines.

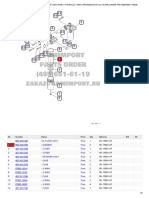

The solution: Mechanical seal SHVI

from EagleBurgmann (MOL: Main Oil Line) of all types worldwide is designed such that it always builds a parallel

for many years. For the Canadian customer, sealing gap with the stationary seat. The defor-

These requirements were best met by the SHV EagleBurgmann developed the SHVI sealing mation behavior of the seal face was optimized

series which has proven itself thousands of variant with loosely inserted seal face specifi- for use in crude oil pumps so that the seal

times over in crude oil pumps and MOL pumps cally for the high-pressure range. The seal face operates reliably even under very high pressures,

sliding velocities and temperatures as well as

pressure and temperature fluctuations.

EagleBurgmann selected a special quality of the

silicon carbide material to be used in the pumps

of the pipeline operator. This provides the seal

face with particularly good emergency running

properties and tolerance for partial dry running.

In addition, the sliding faces have extremely

precisely ground grooves which allow the seal

face to be lifted quickly even in the low pressure

range and contribute to stable operation in a

wide pressure range.

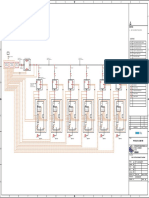

Safety: optimized API plan 66A

Plan 66A, which has been available since intro-

duction of API 682 4th Edition, was the obvious

choice for the safety concept. Accordingly, the

seal housing contains two throttles, and the seal

The SHVI single seal from EagleBurgmann is specifically designed for high pressures and speeds. chamber is connected to a pressure transmitter.

API Plan 66a EagleBurgmann optimized the plan and uses a

special inner, floating throttle. This can withstand

a product pressure of 99 bar (1,440 PSI) in an

FI PIT emergency. The pressure transmitter detects

pressure changes in the seal chamber and

signals an alarm if certain values are exceeded.

At the same time, the seal leakage accumulated

under low pressure is discharged to a central

collection system in the pump station.

Test and acceptance

The SHVI seal and the optimized Plan 66A were

subjected to dynamic and static tests individually

and together on EagleBurgmann test benches.

2 1 3 4 The constant and reliable sealing performance in

all operating states and the safe function of Plan

66A in the event of a fault provided impressive

results. The required system safety was provided

at all times.

There are plans to convert further pumps of the

pipeline operator. The new concept of the SHVI

single seal with optimized Plan 66A is econo-

mical, modular, reliable in operation and offers

the safety of a double seal. For other customers

as well, this type of seal has since proven itself

in MOL pumps for several thousand operating

hours.

Operating conditions

D

Shaft diameter: d = 115 … 155 mm

(4.53” … 6.10”)

The mechanical seal SHVI with Plan 66A on the atmosphere side: The inner throttle withstands a product pressure of

99 bar (1,436 PSI) in the event of sealing function failure. Leakage is drained through Connection D. On the product side, Suction pressure: p = 2.5 … 99 bar

the seal is supplied with Plan 11 (circulation from the discharge port through an orifice into the seal chamber). (36 … 1,436 PSI)

Outlet pressure: max. 138 bar (2,001 PSI)

SHVI1170 © EagleBurgmann Temperature: t = +10 °C … +70 °C

(+50 °F … +158 °F)

1 Seal face FI Flow indicator Yellow areas: rotating parts of the seal

Speed of rotation: n = 720 … 1,980 min-1

2 Stationary seat PIT Pressure indicator transmitter Blue areas: stationary parts of the seal

Medium: Crude oil with diluted bitumen

3 High pressure throttle D Drainage Gray areas: Pump shaft and housing parts

contents

4 Second throttle

Contact

D16062 / E2 / 04.18 / 8 © EagleBurgmann Group Marketing, Germany

Do you have a similar requirement? Please

contact us: eagleburgmann.com/en/contact

eagleburgmann.com

info@eagleburgmann.com

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Euro-Diesel Dynamic Rotary Ups - Drups: Presentation To Ideal Solutions OmanДокумент62 страницыEuro-Diesel Dynamic Rotary Ups - Drups: Presentation To Ideal Solutions Omanmunh100% (2)

- Hydraulics Pneumatics QuestionДокумент29 страницHydraulics Pneumatics QuestionSenthilvel C100% (1)

- 50 BBL Surge Tank Design CalculationДокумент22 страницы50 BBL Surge Tank Design CalculationLaskar Pejuang100% (1)

- Fuel System Schematic DiagramДокумент1 страницаFuel System Schematic DiagramAbhilash100% (1)

- Velocity and Friction Loss Calculation in PipesДокумент4 страницыVelocity and Friction Loss Calculation in Pipesmazzam75Оценок пока нет

- Proper Steam Turbine OperationДокумент32 страницыProper Steam Turbine OperationBalasubramanian C100% (1)

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Oxygen Generator PDFДокумент8 страницOxygen Generator PDFAndres Rojas100% (1)

- ELGI Air Compressors 12 PDFДокумент45 страницELGI Air Compressors 12 PDFSuresh NathОценок пока нет

- Storm Choke K Safety ValveДокумент2 страницыStorm Choke K Safety ValveHIPAP100% (5)

- Bit Hydraulic e CD CalculatorДокумент1 страницаBit Hydraulic e CD CalculatorJeffrey HoОценок пока нет

- Ats 1200Документ2 страницыAts 1200munhОценок пока нет

- QSX 15 Oil CoolerДокумент3 страницыQSX 15 Oil CoolermunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- 1000 Hours LT36590 Brochure-4-19Документ4 страницы1000 Hours LT36590 Brochure-4-19munhОценок пока нет

- Fuel Return Overflow ValveДокумент2 страницыFuel Return Overflow ValvemunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент4 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент3 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Fuel Filter (Spin-On Type)Документ5 страницFuel Filter (Spin-On Type)munhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Fuel Lift Pump Check and Repair GuideДокумент7 страницFuel Lift Pump Check and Repair GuidemunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент3 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- C8.3-C215 6C8.3 Not Available: Engine Dataplate - (Original) ESN: 48302112 VINДокумент1 страницаC8.3-C215 6C8.3 Not Available: Engine Dataplate - (Original) ESN: 48302112 VINmunhОценок пока нет

- Hydraulic Tank (Transmission Oil Filter) (Inner Parts) (#15001-15024)Документ2 страницыHydraulic Tank (Transmission Oil Filter) (Inner Parts) (#15001-15024)munhОценок пока нет

- Oil Filter (For Chassis Mount) (#610002-)Документ2 страницыOil Filter (For Chassis Mount) (#610002-)munhОценок пока нет

- Operator's Cab (Filter Box) (For Air Conditioner) (#15001-)Документ1 страницаOperator's Cab (Filter Box) (For Air Conditioner) (#15001-)munhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Cylinder Block Service KitsДокумент6 страницCylinder Block Service KitsmunhОценок пока нет

- SolFly Druckscheibenfilter - en X240Документ2 страницыSolFly Druckscheibenfilter - en X240munhОценок пока нет

- Fuel Pre-Filter (Service Only) (#610014-)Документ1 страницаFuel Pre-Filter (Service Only) (#610014-)munhОценок пока нет

- Hydraulic Tank (Return Filter) (#15001-15024)Документ2 страницыHydraulic Tank (Return Filter) (#15001-15024)munhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Secure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionДокумент2 страницыSecure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionmunhОценок пока нет

- Convincing High Pressure Seals For Pipeline Pumps: Sealing Solution SHVI-CGSH For Unmanned Pump StationsДокумент2 страницыConvincing High Pressure Seals For Pipeline Pumps: Sealing Solution SHVI-CGSH For Unmanned Pump StationsmunhОценок пока нет

- SeccoMix R PaddleDryer EN 1907Документ2 страницыSeccoMix R PaddleDryer EN 1907munhОценок пока нет

- Alternator Wiring HarnessДокумент2 страницыAlternator Wiring HarnessmunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент3 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент3 страницыElectronic Parts Catalog - Option DetailmunhОценок пока нет

- Hydraulic Fracturing Design Procedure Using PKN ModelДокумент3 страницыHydraulic Fracturing Design Procedure Using PKN ModelJatin RamboОценок пока нет

- Sanitary Butterfly Valve WellgreenДокумент12 страницSanitary Butterfly Valve WellgreenRoger ChenОценок пока нет

- SPK Au NZ Water Xh150 c13 PoaДокумент2 страницыSPK Au NZ Water Xh150 c13 PoaPTCОценок пока нет

- High-Pressure Pump: Under The Scenes of Our LivesДокумент5 страницHigh-Pressure Pump: Under The Scenes of Our Lives김기준Оценок пока нет

- TPL-B: Our 2-Stroke Turbocharging Propulsion BoosterДокумент8 страницTPL-B: Our 2-Stroke Turbocharging Propulsion BoosterМаксим АгеевОценок пока нет

- YAR104-2-1 WaterДокумент42 страницыYAR104-2-1 WaterNancy TessОценок пока нет

- GTG Information Sharing: Components, Systems & MaintenanceДокумент30 страницGTG Information Sharing: Components, Systems & Maintenanceaden mng100% (1)

- Heat Balance CalculationsДокумент2 страницыHeat Balance CalculationsmariodalОценок пока нет

- FLUID POWER SYSTEMS Theory and PracticeДокумент31 страницаFLUID POWER SYSTEMS Theory and PracticeRAMAR MОценок пока нет

- Echometer Gas Separator With Packer and Tubing Anchor Running Instructions 20130816Документ9 страницEchometer Gas Separator With Packer and Tubing Anchor Running Instructions 20130816judsonlobОценок пока нет

- Sulzer SMN SBRДокумент8 страницSulzer SMN SBRMarsinta PurbaОценок пока нет

- Table A. Equivalent Length, (L/D) of Valves and Pipe FittingsДокумент7 страницTable A. Equivalent Length, (L/D) of Valves and Pipe Fittingst_i_f_anoОценок пока нет

- Load Control ValvesДокумент18 страницLoad Control ValvesMusa ArysОценок пока нет

- Desig EntryДокумент55 страницDesig Entrymohammad qaruishОценок пока нет

- In and Ex System DescДокумент5 страницIn and Ex System DescAli KuncoroОценок пока нет

- Midea Ductable DetailsДокумент9 страницMidea Ductable DetailsYUVI RAJОценок пока нет

- Monthly Inspection: Automatic Sprinkler SystemsДокумент1 страницаMonthly Inspection: Automatic Sprinkler SystemsPOLPMEОценок пока нет

- Xtra Report Template 1Документ6 страницXtra Report Template 1MMarwantoОценок пока нет

- Hydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuДокумент42 страницыHydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuCarlos Alberto BaptistaОценок пока нет

- Flow Meter - Piusi-K24 - enДокумент2 страницыFlow Meter - Piusi-K24 - enRafael LecuОценок пока нет

- CV Turbine Field OperatorДокумент2 страницыCV Turbine Field OperatorShambhu MehtaОценок пока нет