Академический Документы

Профессиональный Документы

Культура Документы

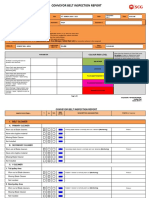

Daily Stacker Inspection Checklist

Загружено:

Fabio Gonzalez0%(1)0% нашли этот документ полезным (1 голос)

452 просмотров2 страницы1. This document is a daily inspection checklist for the stacker machine that includes tasks to verify machine status, check vacuum and air pressure readings, clean dust from precisors, and examine precisors for irregularities.

2. The checklist notes that personal protective equipment should be used and 5S cleanliness procedures followed during inspections.

3. Reference information is provided for materials safety data sheets and locations of supplies near the corfin machine.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1. This document is a daily inspection checklist for the stacker machine that includes tasks to verify machine status, check vacuum and air pressure readings, clean dust from precisors, and examine precisors for irregularities.

2. The checklist notes that personal protective equipment should be used and 5S cleanliness procedures followed during inspections.

3. Reference information is provided for materials safety data sheets and locations of supplies near the corfin machine.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0%(1)0% нашли этот документ полезным (1 голос)

452 просмотров2 страницыDaily Stacker Inspection Checklist

Загружено:

Fabio Gonzalez1. This document is a daily inspection checklist for the stacker machine that includes tasks to verify machine status, check vacuum and air pressure readings, clean dust from precisors, and examine precisors for irregularities.

2. The checklist notes that personal protective equipment should be used and 5S cleanliness procedures followed during inspections.

3. Reference information is provided for materials safety data sheets and locations of supplies near the corfin machine.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

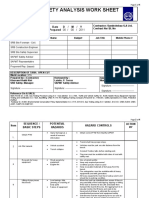

STACKER # :

Daily Stacker Inspection Checklist

Shift Morning Afternoon Night

Date :

Technician

Operator

Inspection Tasks Morning Afternoon Night

Beginning of Shift (Technician)

1 Verify the machine status , check for correct ID . (Refer to lot traveler)

2 Make sure the vacuum is at -65psi ± 10 and record the reading.

3 Make sure the compressed air pressure is 100psi ± 10 and record the reading.

Refer to MSDS provided for safety purpose.

4 Clean the dust from the TSOPS precisors with IPA.

5 Examine the TSOP precisors for any irregularity. Notify maintenance if necessary.

6 Clean the dust from the Flex precisor with IPA.

7 Examine the FLEX precisors for any irregularity. Notify maintenance if necessary.

*Ensure 5S (cleanliness of the area) procedures followed accordingly during inspection task carried out.

*Ensure Personel Protective Equipment(PPE) is used.

Verified by:

Date:

Notes: For any abnormality on the reading inform Asst.Engineer/Engineer immediately.

Remarks:

*Remarks should be verified and corrective action should be taken.

Refference:

MSDS Location

IPA beside corfin machine

Flux(SUPERIOR 40MM4) beside corfin machine

Solder(Leaded) beside corfin machine

Solder(Lead free) beside corfin machine

SC10E beside corfin machine

Mobility Aw-2 oil beside corfin machine

Mobility 600w Cyilinder oil beside corfin machine

Nitrogen(N) gas beside corfin machine

Argon(Ar) gas beside corfin machine

Dross beside corfin machine

Вам также может понравиться

- Weekly 1/G1J06 OkДокумент9 страницWeekly 1/G1J06 OkWisnu NugrahaОценок пока нет

- Equipement Checklist (Hoist & Lift)Документ2 страницыEquipement Checklist (Hoist & Lift)Bapusaheb GuthaleОценок пока нет

- Risk Assesment Form - Ball MillingДокумент6 страницRisk Assesment Form - Ball Millingbc150Оценок пока нет

- Work Method Statement: SWMS Form 007.3Документ3 страницыWork Method Statement: SWMS Form 007.3George VОценок пока нет

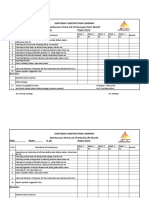

- Contractor Safety Orientation ChecklistДокумент1 страницаContractor Safety Orientation ChecklistJason 'Hogie' HoganОценок пока нет

- HEMPATHANE TOPCOAT 5521911320 en-US PDFДокумент12 страницHEMPATHANE TOPCOAT 5521911320 en-US PDFBalasubramanian AnanthОценок пока нет

- 1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerДокумент2 страницы1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerJCSОценок пока нет

- Stacker Preventive Maintenance Weekly: Clean and InspectДокумент1 страницаStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- SOP 11 - Lime Stone Circuit OprationДокумент9 страницSOP 11 - Lime Stone Circuit Oprationfaraz ahmedОценок пока нет

- Audit Document - 2014Документ28 страницAudit Document - 2014Ricardo AzeredoОценок пока нет

- Ayoki Safety Monthly Initiative 27.11.21slideДокумент19 страницAyoki Safety Monthly Initiative 27.11.21slideAltafОценок пока нет

- DAR Vol1-2013Документ744 страницыDAR Vol1-2013chitransh2002Оценок пока нет

- 020.abrasive Blasting Rev.0 PDFДокумент12 страниц020.abrasive Blasting Rev.0 PDFYounis KhanОценок пока нет

- Please Tick in Appropriate Column: Roadblock / BarrierДокумент1 страницаPlease Tick in Appropriate Column: Roadblock / Barriersaji kumarОценок пока нет

- Compressed Gas Cylinder Safe Handling Use and StorageДокумент25 страницCompressed Gas Cylinder Safe Handling Use and Storageponnada shanmukha pavan kumarОценок пока нет

- SOP For Cleaning of Clinker Cooler DischargeДокумент3 страницыSOP For Cleaning of Clinker Cooler Dischargeayaskant751001Оценок пока нет

- SOP - ForkliftДокумент4 страницыSOP - ForkliftGyanendra Narayan Nayak100% (1)

- 03 - Form - PPE StockДокумент5 страниц03 - Form - PPE StockAli Rizki BudimanОценок пока нет

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaДокумент67 страницOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILОценок пока нет

- Inspection Checklist: PART-A (For All Factories)Документ29 страницInspection Checklist: PART-A (For All Factories)Ramesh KandalaОценок пока нет

- Method Statement For Hume Pipe CulvertДокумент6 страницMethod Statement For Hume Pipe CulvertRabnawaz Imam0% (1)

- 10-F20 Fuel Driven Equipment InspectionДокумент3 страницы10-F20 Fuel Driven Equipment InspectionSn AhsanОценок пока нет

- Bearing Housing Assembly Procedure EXTERNALДокумент10 страницBearing Housing Assembly Procedure EXTERNALAlejandroZegarraОценок пока нет

- Radiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderДокумент1 страницаRadiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderZeeshan RehmanОценок пока нет

- Activity-Based Risk Assessment BesmarДокумент9 страницActivity-Based Risk Assessment Besmardwi_6188Оценок пока нет

- Material Safety Data Sheet: MSDS: Lafarge Portland CementДокумент6 страницMaterial Safety Data Sheet: MSDS: Lafarge Portland Cementazer100% (1)

- Hira Ball Mill Line ReplacemenДокумент2 страницыHira Ball Mill Line Replacemenananthu.uОценок пока нет

- Job Safety Analysis: (Risk Assessment)Документ8 страницJob Safety Analysis: (Risk Assessment)Ped KapedОценок пока нет

- TDS Renderoc RGM IndiaДокумент4 страницыTDS Renderoc RGM IndiaKishore Nayak kОценок пока нет

- Flowchart IДокумент1 страницаFlowchart Ircsrm123Оценок пока нет

- Cement Processing Hol CimДокумент1 страницаCement Processing Hol CimShailesh RaneОценок пока нет

- Safety Checklists: A I, A & RДокумент37 страницSafety Checklists: A I, A & Rmd sarfaraz khanОценок пока нет

- 02 HIRA-JSA-Coal Mill Operation.Документ10 страниц02 HIRA-JSA-Coal Mill Operation.saji kumarОценок пока нет

- Taking ShortcutsДокумент3 страницыTaking ShortcutschengerangОценок пока нет

- Zincanode 620 Voc v1 Jan 2018Документ2 страницыZincanode 620 Voc v1 Jan 2018Moin AltafОценок пока нет

- 621-CC#09 Idler and Frame ChangingДокумент4 страницы621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- 7 - Concrete-1 PDFДокумент73 страницы7 - Concrete-1 PDFjinnaОценок пока нет

- FLSmidth CrossBar Cooler v2Документ8 страницFLSmidth CrossBar Cooler v2Mohammed AbdoОценок пока нет

- Job Safety Observation Form Template - JotFormДокумент4 страницыJob Safety Observation Form Template - JotFormGonzalo MazaОценок пока нет

- SOP - Maintenance of Bag FilterДокумент22 страницыSOP - Maintenance of Bag FilterAkash SharmaОценок пока нет

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Документ1 страницаPOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelОценок пока нет

- Scaffolding - ANNEXURE 20-24Документ28 страницScaffolding - ANNEXURE 20-24Suryakant SurajОценок пока нет

- Daily Report HSSE # 10 PDFДокумент4 страницыDaily Report HSSE # 10 PDFbisnisfendiОценок пока нет

- Scaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / CommentsДокумент1 страницаScaffold Inspection Form: NO. Items To Be Checked Condition OK Observations / CommentsArshad Mahmood100% (1)

- Fire & Safety ChecklistДокумент30 страницFire & Safety ChecklistjashnОценок пока нет

- Hazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)Документ11 страницHazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)IJRASETPublicationsОценок пока нет

- Heat-Stress-Management-Training-Program-Samir 11 R4Документ28 страницHeat-Stress-Management-Training-Program-Samir 11 R4Sheri DiĺlОценок пока нет

- Conveyor Check ListДокумент2 страницыConveyor Check Listh1549697100% (1)

- PTW Site Instruction NewДокумент17 страницPTW Site Instruction NewAnonymous JtYvKt5XEОценок пока нет

- Concrete Batching Plant Operating ProcedДокумент13 страницConcrete Batching Plant Operating ProcedAhmed Daahir AdenОценок пока нет

- Accident Investigation: Introduction To EffectiveДокумент28 страницAccident Investigation: Introduction To EffectiveBabbooОценок пока нет

- Complete ProjectДокумент79 страницComplete ProjectMithun RajОценок пока нет

- Dellag La 3-36Документ2 страницыDellag La 3-36FAIYAZ AHMEDОценок пока нет

- Form Inspection Premob - Quarterly (1) - 2Документ26 страницForm Inspection Premob - Quarterly (1) - 2Ryan Rhamdhani100% (1)

- MSDS Portland CementДокумент5 страницMSDS Portland CementMonali VarpeОценок пока нет

- 731-CC-8 Gear Box Oil Seal Changing From Hold Back SideДокумент5 страниц731-CC-8 Gear Box Oil Seal Changing From Hold Back SideBuddy HartОценок пока нет

- Monthly EPIRB Inspection ProceduresДокумент3 страницыMonthly EPIRB Inspection ProceduresshoaibОценок пока нет

- EPIRB InspectingДокумент3 страницыEPIRB InspectingEric PskdОценок пока нет

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Документ9 страниц88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemОценок пока нет

- Job Safety Analysis Work Sheet: Date Prepared D / M / YДокумент4 страницыJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

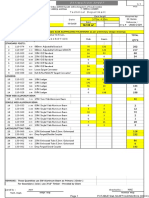

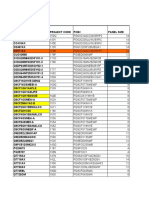

- CHART BY LINE (March)Документ5 страницCHART BY LINE (March)Fabio GonzalezОценок пока нет

- Amistar #: Daily Amistar Checklist: Inspection TasksДокумент1 страницаAmistar #: Daily Amistar Checklist: Inspection TasksFabio GonzalezОценок пока нет

- Daily AFF Inspection ChecklistДокумент1 страницаDaily AFF Inspection ChecklistFabio GonzalezОценок пока нет

- Map To Kelly PenangДокумент1 страницаMap To Kelly PenangFabio GonzalezОценок пока нет

- Map To Kelly PenangДокумент1 страницаMap To Kelly PenangFabio GonzalezОценок пока нет

- Downtime Pareto-MAR'09Документ37 страницDowntime Pareto-MAR'09Fabio GonzalezОценок пока нет

- Lean Overview For OrientationДокумент14 страницLean Overview For OrientationFabio GonzalezОценок пока нет

- Downtime Pareto-FEB'09Документ37 страницDowntime Pareto-FEB'09Fabio GonzalezОценок пока нет

- SMT Downtime: B C D E G Total HrsДокумент1 страницаSMT Downtime: B C D E G Total HrsFabio GonzalezОценок пока нет

- Juki Revised New Uph (Latest 28.2.10 12.10PM)Документ95 страницJuki Revised New Uph (Latest 28.2.10 12.10PM)Fabio GonzalezОценок пока нет

- E060 Manual of Evaluation Process 6-01-07Документ8 страницE060 Manual of Evaluation Process 6-01-07Fabio GonzalezОценок пока нет

- COP 15: The Copenhagen Accord: A Positive Step But Not Ambitious EnoughДокумент16 страницCOP 15: The Copenhagen Accord: A Positive Step But Not Ambitious EnoughFabio GonzalezОценок пока нет

- Linked To Loading Plan NEW SMT UPHДокумент39 страницLinked To Loading Plan NEW SMT UPHFabio GonzalezОценок пока нет

- Juki Revised Top BotДокумент12 страницJuki Revised Top BotFabio GonzalezОценок пока нет