Академический Документы

Профессиональный Документы

Культура Документы

Haccp Checklist Guidiance Notes - Doc: Belema .04.2017

Загружено:

Godwin A.udo-akanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Haccp Checklist Guidiance Notes - Doc: Belema .04.2017

Загружено:

Godwin A.udo-akanАвторское право:

Доступные форматы

SHELL COMPANIES in NIGERIA (SCiN)

OCCUPATIONAL HEALTH CATERING INSPECTION REPORT - Based on Hazard Analysis and Critical Control Points

(HACCP) Principles

Read this note before commencement

HACCP CHECKLIST GUIDIANCE NOTES.doc

Catering Company: SJ ABED

Location: BELEMA Inspection Date: 23.04.2017 Last Inspection: 04.04.2017

Previous Inspection report available: Yes/No

Distribution List: OH/Line/Catering Services/Location Team Leader

Procedure For Inspection:

1 Conduct inspection at least once monthly and whenever fresh supplies are received.

2 Get a copy of last inspection report

3 Check whether

Go through all all

thefindings

items in from the previous

the checklist inspection

and rank againstmarked 'NO'

the max. haveAlso

score. beenmark

corrected.

Yes, No or NA

4 (Not applicable) and comment where necessary

5 Explain to persons involved, your findings and why it is unacceptable,where bad practice is identified.

6 Apply corrective measures.

7 File completed checklist at the end of inspection.

8 Send copies to OH Environmental Health

9 Inspection leader should load the action item(s) in Fountain.

S/N Criteria for Control Yes/No/ NA

1 Food Supply - Criteria Maximum Score Inspection Actual

team to Score TARGET

REMAR

complete DATE

KS

TOTAL SCORE 100 91

PASS MARK = 80% and above

Min.

Actual Actual Colour

Criteria for Control Max score acceptable

score Score % Score Banding

Food Supply Criteria - CLs/CCPs (Hot food not kept at

temperature below 63 0C for more than 2 hours. Cold 13 11 12 92%

food not kept at temperature above 4 oC for more than 2

hours. Clean and purpose-built delivery vehicles, carts

and containers for food. Incoming food and supplies are

inspected on receipt. Receiving area is clean and free of

waste materials. Packages intact and no visible foreign

matter. General condition of food satisfactory (odourless,

non-stinky, no dents, within date of expiration etc. Proper

handling procedures of food upon receiving and

wholesome food items are promptly moved to proper

storage area within appropriate time limit. Unwholesome

products are rejected and documented.)

OH Catering Inspection Checklist Page 1 of 7 HACCP

Food Storage - CLs/CCPs (Storage area is clean, dry

and well ventilated. All food items are stored off the floor

and walls by at least 25cm/14inches. All foods are

labelled with name, delivery date and NAFDAC No.

FIFO (First –in- first – out) and FEFO (first expiring-first 17 15 16 94%

out) are observed. Canned foods in storage are not

dented, rusty, blown, or leaking and products are not

expired. Opened bulk-foods (grains, flour, etc) are stored

in containers with tight- fitting lids. Chemicals and

cleaning supplies are stored away from food and other

food-related supplies. Adequate, clean and functional

cold storage facilities. Temperature checked twice daily

and temperature-recording sheet available. Normal

temperatures are maintained at 4 oC or lower in

refrigerators and –18 oC or lower in freezers. Foods are

arranged to allow air circulation. Cooked foods are stored

separately above raw foods. FIFO and FEFO are

observed. )

Food Preparation and Serving Criteria - CCPs

(Frozen food is thawed under refrigeration or in cold 15 12 13 87%

running water, three separate sinks are properly set up for

raw meat, vegetables and ware washing, Dedicated colour

coded chopping boards for vegetable, cooked food, raw

meat and air drying racks, Food is not allowed to be in

the ‘danger temperature zone’ i.e. between 4 oC and 63

oC for more than 2hrs, All cooking units are clean and

food is heated to 75 oC before placing in hot holding,

Temperature of cooked food is being held at 63 oC or

above and food is protected from contamination,

Temperature of cold food is being held at 4 oC or below

and food is protected from contamination)

11 9 9 82%

Personal Hygiene - CCPs (Employees wear clean

uniforms/aprons and hair restraints, Fingers are short,

unpolished and clean, Jewellery is limited to wristwatch

and plain ring, Wear hand gloves where appropriate and

change at necessary intervals, Adequate wash-hand

basins with soap, running water, and drying facilities

available, Personnel with infections (enteric illnesses,

rashes, open sores, cuts, or bandages on hands) are

restricted, Employee illnesses are documented.)

OH Catering Inspection Checklist Page 2 of 7 HACCP

Cleaning and Sanitation - CCPs (Cleaning procedures

are in place for structures, equipment utensils and general

deep cleaning, Wearing of hand gloves where appropriate 11 9 10 91%

and changed at necessary intervals.).

Chemical Handling - CCP (SHOC cards available for

all cleaning chemicals and storage area clean). 1 1 1 100%

Structure - CCPs - (Floors, walls, ceilings, intact, well

maintained and cleaned during food preparation and at

the end of each day. 3 2 3 100%

Food Contact Surfaces - CCPs Work tables and work

surfaces are clean to sight and touch, and washed and

sanitized between operations). 2 2 2 100%

Equipment & Utensils - CCPs/CLs (Small equipment

and utensils including deep fryers, hot plates, boilers,

cutting boards, knives, pots, pans, can openers, etc are

thoroughly cleaned between uses and in good working

condition. Refrigerators, freezers, are thawed and cleaned

with other storage areas at least once weekly. All

equipment clean, tablewares and utensils are properly 4 3 3 75%

stored in a clean area away from dust.)

4.0 3 3 75%

Pest control - CCPs (Doors/windows screened and in

good condition, functional fly catchers/pest control

program available, no evidence of pest infestation )

3.0 2 3 100%

Waste Disposal - CCPs (pedal operated bins in kitchen)

3.0 2 3 100%

Potable Water Supply - CCPs (Available in quantity,

quality, tested for potability for consumption)

Fitness to Work - CCPs (compliance with FTW 3.0 2 3 100%

screening process, questionaire following illness,

documented staff illness, pre-employment and post illness

screening procedures)

Staff Competency and Training - CCPs (training 3.0 2 3 100%

schedule, contents, coverage and records of training in

food handling and HSSE)

HSE in General -CCPs (availability and use of PPE, 4.0 3 4 100%

functional fire extinguishers, fire blankets and smoke

detectors, adequate ventilation, marked fire exits)

Records and Administration CCPs (complaint 3.0 2 3 100%

procedure, documented customer complaints, facility

HACCP plan)

OH Catering Inspection Checklist Page 3 of 7 HACCP

100 80 91 91%

Total

REMARKS: Satisfactory

Catering Score RAG Green+ Status

≥ 90%

80-89%

Green

ü

Amber

50% of food offerings are

healthy +

< 80% Red

No. Findings Action required Action Party Target Date

1 No chopping board shelve or racker Provide chopping board racker IEF 5/15/2017

Scoping done awaiting

2 No waste shade. IEF/PNES 1 6/30/2017

contractual process.

3 Oven not working uptimally Repair faulty Oven IEF/FP FLOTEL 5/6/2017

4 Restaurant door not self closing Replace door hinges IEF/FP FLOTEL 5/6/2017

Remove carpets replaced with

5 Defaced carpets on kitchen floors IEF/FP FLOTEL 5/6/2017

tiles

One faulty dryer and one faulty washing machine in the Replace equipments with

6 IEF/FP FLOTEL 5/31/2017

laundry industrial washing machines

Provide adequate butchery area

7 inadequate butchery area and thawing process IEF 5/31/2017

for thawing

8 No beans grinder in the kitchen Provide beans grinder IEF 5/31/2017

Provide hand drier in the

9 No hand drier in the kitchen IEF/FP FLOTEL 5/6/2017

kitchen

10 Two faulty burners in the kitchen Repair faulty burners IEF/FP FLOTEL 5/13/2017

Inspection Team:

NAME DEPT SIGNATURE DATE REMARKS

ALTRAIDE EMMANUEL JEIN SHU/ON 4/23/2017

JUMBO JULIUS LOCATION FC 4/23/2017

AHMED, MOHAMMED SJ ABED 4/23/2017

ONYEBUCHI DENNIS HSE -SUPPORT 4/23/2017

OH Catering Inspection Checklist Page 4 of 7 HACCP

GF

OH Catering Inspection Checklist Page 5 of 7 HACCP

OH Catering Inspection Checklist Page 6 of 7 HACCP

OH Catering Inspection Checklist Page 7 of 7 HACCP

Вам также может понравиться

- CAC Codex HACCP Check ListДокумент14 страницCAC Codex HACCP Check ListEdward Danish83% (6)

- HACCP Plan Content ChecklistДокумент2 страницыHACCP Plan Content ChecklistIsaac ArthurОценок пока нет

- 13 - Food Safety Training Organizations and Materials PDFДокумент8 страниц13 - Food Safety Training Organizations and Materials PDFjeyesbelmenОценок пока нет

- HACCP Infomation All 1102Документ98 страницHACCP Infomation All 1102Rose DNОценок пока нет

- Weekly Food Safety AuditДокумент4 страницыWeekly Food Safety AuditNina YoungОценок пока нет

- Haccp ManualДокумент55 страницHaccp ManualMohammad Abd Alrahim Shaar0% (1)

- Allergen Information ManualДокумент39 страницAllergen Information ManualAhmedAmer1100% (1)

- HACCP Course PowerPoint Slides Chapter 10Документ26 страницHACCP Course PowerPoint Slides Chapter 10jesse100% (1)

- HACCP Hotel CateringДокумент29 страницHACCP Hotel CateringHACCPEuropaОценок пока нет

- 1.3 Food Safety Policy Statement WebДокумент1 страница1.3 Food Safety Policy Statement Webジョンナ メイ ハイミОценок пока нет

- HACCP Plan PDFДокумент13 страницHACCP Plan PDFAnonymous qfCJwxib7Оценок пока нет

- ISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)Документ16 страницISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)NabilKnouzi100% (1)

- Allergen Control PlanДокумент9 страницAllergen Control Planramstories100% (1)

- Food Audit Checklist For KitchenДокумент2 страницыFood Audit Checklist For KitchenArush BhatnagarОценок пока нет

- Food Product Flow: Objective: in This Chapter The Student Will Able ToДокумент15 страницFood Product Flow: Objective: in This Chapter The Student Will Able ToRosiee Salazar TejadaОценок пока нет

- HACCP Plan CateringДокумент29 страницHACCP Plan CateringHACCPEuropa95% (20)

- HACCP ChecklistДокумент3 страницыHACCP ChecklistTim Qu100% (4)

- Food Hygiene Basic CourseДокумент33 страницыFood Hygiene Basic CourseHACCPEuropaОценок пока нет

- Sunnyside HACCP Plan 2012V1.2Документ42 страницыSunnyside HACCP Plan 2012V1.2fisherkiddОценок пока нет

- Haccp Manual: Hawaii International Seafood, IncДокумент70 страницHaccp Manual: Hawaii International Seafood, IncCamelia Stremtan0% (1)

- Appendix A Suggested Content For Program DescriptionДокумент21 страницаAppendix A Suggested Content For Program Descriptionmohd_shaarОценок пока нет

- Comparison of TS ISO 22002-1 & PAS 223Документ4 страницыComparison of TS ISO 22002-1 & PAS 223AnilZapateОценок пока нет

- Room Temperature Monitoring SheetДокумент25 страницRoom Temperature Monitoring Sheetpharmacy medidasОценок пока нет

- Haccp PlanДокумент1 страницаHaccp PlanFrance Cedrick GarciaОценок пока нет

- Ifs Audit ReportДокумент74 страницыIfs Audit ReportOzlem Mep67% (3)

- ISO 22000 Awareness SessionДокумент30 страницISO 22000 Awareness SessionArvion Winchester100% (1)

- ISO 22000 Implementation Package Brochure 2018 PDFДокумент25 страницISO 22000 Implementation Package Brochure 2018 PDFfrmgsОценок пока нет

- Thawing Temperature Log SheetДокумент1 страницаThawing Temperature Log SheetibrahimОценок пока нет

- 3 HACCP Overview Training DemoДокумент17 страниц3 HACCP Overview Training Demoammy_75Оценок пока нет

- RS Hse Manual PDFДокумент10 страницRS Hse Manual PDFSpreading KnowledgeОценок пока нет

- Model Hazard and Critical Control Point of Meat PieДокумент68 страницModel Hazard and Critical Control Point of Meat PieWafi Rosli100% (1)

- Allergen Handbook 0208Документ24 страницыAllergen Handbook 0208bobmonkeys100% (2)

- Hygiene Ratings - FSSAI ChecklistДокумент5 страницHygiene Ratings - FSSAI ChecklistsendthilОценок пока нет

- Guide To Food Safety Training L1Документ50 страницGuide To Food Safety Training L1Elzy100% (1)

- FSSC 22000 Awareness Training - Bagian 1Документ14 страницFSSC 22000 Awareness Training - Bagian 1Nugraheni Wahyu PermatasariОценок пока нет

- HACCP For Yoghurt ProductionДокумент29 страницHACCP For Yoghurt ProductionLim Che YanОценок пока нет

- Food Defence - Specific Threat AssessmentДокумент3 страницыFood Defence - Specific Threat AssessmentRevanthОценок пока нет

- Culinary Arts 1Документ113 страницCulinary Arts 1Ying WuОценок пока нет

- H.7 Supplier Approval QuestionnaireДокумент4 страницыH.7 Supplier Approval QuestionnairePrabhu Prabhu100% (1)

- Checklist ISO 22000Документ21 страницаChecklist ISO 22000anggirasti100% (1)

- Allergen Control Checklist Manufacturer 0908Документ4 страницыAllergen Control Checklist Manufacturer 0908shakeyken100% (1)

- III Haccp PDP 2016-17 NewДокумент190 страницIII Haccp PDP 2016-17 NewBharathGunafg100% (1)

- Catering Health and Safety Plan Prepared By: Merzougui Sofien Reviewed By: Chouaieb FahdДокумент39 страницCatering Health and Safety Plan Prepared By: Merzougui Sofien Reviewed By: Chouaieb FahdHSE CERI100% (4)

- Sample Audit Checklist For HACCPДокумент16 страницSample Audit Checklist For HACCPAprilJoyBascosОценок пока нет

- HACCP Catering ManualДокумент161 страницаHACCP Catering ManualLuel Rasika Jaganath50% (2)

- ISO 22000 Gap Analysis Section 6Документ1 страницаISO 22000 Gap Analysis Section 6stevierayo100% (1)

- Food Poisoning and Its Prevention: Baked GoodsДокумент4 страницыFood Poisoning and Its Prevention: Baked GoodsOrlando ALVARADOОценок пока нет

- SC5 2012 InspectionДокумент6 страницSC5 2012 Inspectionwidi ekoОценок пока нет

- Allergen Management Best PracticesДокумент44 страницыAllergen Management Best Practicescb2web100% (1)

- Sample Check ListДокумент9 страницSample Check Listpat5355Оценок пока нет

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorДокумент16 страницSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghОценок пока нет

- FSMS - PRPsДокумент207 страницFSMS - PRPsSidОценок пока нет

- Standard Operating Procedure Index - Food Hygiene & SafetyДокумент1 страницаStandard Operating Procedure Index - Food Hygiene & SafetyBAlaОценок пока нет

- Canteen Process Flow and Quality Control StandardsДокумент6 страницCanteen Process Flow and Quality Control StandardsCarlos Dungca100% (1)

- GDD&WD Ceha FindingsДокумент3 страницыGDD&WD Ceha Findingscrni rokoОценок пока нет

- Hazard Analysis Critical Control Point (HACCP) Application Checklist Sous Vide - Reduced Oxygen Packaging (ROP)Документ3 страницыHazard Analysis Critical Control Point (HACCP) Application Checklist Sous Vide - Reduced Oxygen Packaging (ROP)JoeОценок пока нет

- St. Joseph Catholic School Nutrition Services Food Safety - HACCP ManualДокумент48 страницSt. Joseph Catholic School Nutrition Services Food Safety - HACCP ManualsurajОценок пока нет

- Audit ChecklistДокумент4 страницыAudit Checklistgkiyer7100% (2)

- 4 Food Haccp 1 08Документ12 страниц4 Food Haccp 1 08Shiva KumarОценок пока нет

- Hygiene and Sanitation Inspection Checklist and RecordДокумент6 страницHygiene and Sanitation Inspection Checklist and RecordSaleem Akhtar100% (1)

- Bnl-Inv-21 (2) 18.02.2021Документ1 страницаBnl-Inv-21 (2) 18.02.2021Godwin A.udo-akanОценок пока нет

- Tabla 8.1 para No Tubulares AWS D1.1 2020 PDFДокумент1 страницаTabla 8.1 para No Tubulares AWS D1.1 2020 PDFRONALD100% (1)

- Quality Awareness TBT Presentation - 20032024Документ9 страницQuality Awareness TBT Presentation - 20032024Godwin A.udo-akanОценок пока нет

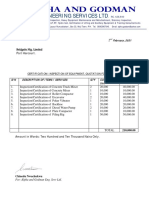

- Engineering Services LTD: Port HarcourtДокумент1 страницаEngineering Services LTD: Port HarcourtGodwin A.udo-akanОценок пока нет

- Bnl-Inv-21 (2) 18.02.2021Документ1 страницаBnl-Inv-21 (2) 18.02.2021Godwin A.udo-akanОценок пока нет

- ConcreteДокумент21 страницаConcretekmandar99Оценок пока нет

- Invoice: Engineering Services LTDДокумент1 страницаInvoice: Engineering Services LTDGodwin A.udo-akanОценок пока нет

- New Vendor Information FormДокумент1 страницаNew Vendor Information FormGodwin A.udo-akanОценок пока нет

- 0.1 - Table of ContentsДокумент4 страницы0.1 - Table of ContentsGodwin A.udo-akanОценок пока нет

- Civil ItpДокумент60 страницCivil ItpBiswas100% (1)

- Acme Corporation Strategic Plan 2014-2016Документ1 страницаAcme Corporation Strategic Plan 2014-2016Godwin A.udo-akanОценок пока нет

- Eptech Answers Additional Questions Regarding Field Trials 12 11 2020 (262425)Документ6 страницEptech Answers Additional Questions Regarding Field Trials 12 11 2020 (262425)Godwin A.udo-akanОценок пока нет

- Sakhalin - 1 Project GroutingДокумент1 страницаSakhalin - 1 Project GroutingGodwin A.udo-akanОценок пока нет

- Comformance Report Form-1Документ2 страницыComformance Report Form-1Godwin A.udo-akanОценок пока нет

- Annex A - NON CONFORMITY RESOLUTION REPORT-BridsiteДокумент8 страницAnnex A - NON CONFORMITY RESOLUTION REPORT-BridsiteGodwin A.udo-akanОценок пока нет

- Compensation: Bridgsite Nigeria LimitedДокумент2 страницыCompensation: Bridgsite Nigeria LimitedGodwin A.udo-akanОценок пока нет

- 9.1 - Exceptions and DeviationsДокумент1 страница9.1 - Exceptions and DeviationsGodwin A.udo-akanОценок пока нет

- Daily Fit-Up / Welding Inspection Report: FORM NO.: 583-VIR-001 Date: Report No.Документ1 страницаDaily Fit-Up / Welding Inspection Report: FORM NO.: 583-VIR-001 Date: Report No.Godwin A.udo-akanОценок пока нет

- 3.8 - List of Procurement ExperienceДокумент3 страницы3.8 - List of Procurement ExperienceGodwin A.udo-akanОценок пока нет

- Document Transmittal: The Documents Indicated Below AreДокумент1 страницаDocument Transmittal: The Documents Indicated Below AreGodwin A.udo-akanОценок пока нет

- 1.0 - Form of TenderДокумент3 страницы1.0 - Form of TenderGodwin A.udo-akanОценок пока нет

- 3.3 - List of Equipment ListДокумент8 страниц3.3 - List of Equipment ListGodwin A.udo-akanОценок пока нет

- Document Transmittal: The Documents Indicated Below AreДокумент1 страницаDocument Transmittal: The Documents Indicated Below AreGodwin A.udo-akanОценок пока нет

- (A) Quality Management System (QMS) Iso 9001:2015 Internal Training ScheduleДокумент1 страница(A) Quality Management System (QMS) Iso 9001:2015 Internal Training ScheduleGodwin A.udo-akanОценок пока нет

- TAG CONTROL COMPANY LTD TRAINING ATTENDANCE FORM Rev 3 NOV 2020Документ1 страницаTAG CONTROL COMPANY LTD TRAINING ATTENDANCE FORM Rev 3 NOV 2020Godwin A.udo-akanОценок пока нет

- Fortune Energy Internal ScheduleДокумент1 страницаFortune Energy Internal ScheduleGodwin A.udo-akanОценок пока нет

- Accident Incident Investigation Form NewДокумент2 страницыAccident Incident Investigation Form NewGodwin A.udo-akanОценок пока нет

- Accident Incident Investigation Form NewДокумент2 страницыAccident Incident Investigation Form NewGodwin A.udo-akanОценок пока нет

- Fortune Letter Headed PaperДокумент1 страницаFortune Letter Headed PaperGodwin A.udo-akanОценок пока нет

- Rev 00 - NLNG Project Execution Plan - Minor Electrical WorksДокумент35 страницRev 00 - NLNG Project Execution Plan - Minor Electrical WorksGodwin A.udo-akanОценок пока нет

- Guide 3Документ39 страницGuide 3bonaji5766Оценок пока нет

- MKMKMKДокумент8 страницMKMKMKSesivamОценок пока нет

- Sir Alex Ferguson LeadershipДокумент11 страницSir Alex Ferguson LeadershipJhanzaib Aslam100% (2)

- Traditional Philippines Composers of The 20TH CenturyДокумент13 страницTraditional Philippines Composers of The 20TH CenturyFlorayde PasayloonОценок пока нет

- Emergency DescentДокумент5 страницEmergency Descentpraveenpillai83Оценок пока нет

- Jumanji 2 BeginningДокумент20 страницJumanji 2 Beginningthorney33Оценок пока нет

- Mahabharat (1988 TV Series) - WikipediaДокумент15 страницMahabharat (1988 TV Series) - WikipediaPiyushОценок пока нет

- 5 Themes of Geography: Universal StudiosДокумент13 страниц5 Themes of Geography: Universal Studiosapi-549496737Оценок пока нет

- Unit 12Документ5 страницUnit 12Freddy Miguel Ospino ospinoОценок пока нет

- Standard Sheet Metal GaugesДокумент2 страницыStandard Sheet Metal Gaugesa_toupsОценок пока нет

- Rockaway Times 6718Документ52 страницыRockaway Times 6718Peter J. MahonОценок пока нет

- EG Basics MCQ - 1Документ8 страницEG Basics MCQ - 1WAJID AJMALОценок пока нет

- Julius Caesar Guided Questions Act 2Документ1 страницаJulius Caesar Guided Questions Act 2api-315186689Оценок пока нет

- S3 Proofreading Answer 1-10Документ10 страницS3 Proofreading Answer 1-10Edwin FongОценок пока нет

- 2017 State 5th Grade ANSWER KEYДокумент2 страницы2017 State 5th Grade ANSWER KEYJosifShapkalievskiОценок пока нет

- Colossus March 2019 PDFДокумент76 страницColossus March 2019 PDFMarmik ShahОценок пока нет

- Tourism Awareness and Tour GuidingДокумент25 страницTourism Awareness and Tour GuidingAnnalyn PeñaОценок пока нет

- Muay Thai BackgroundДокумент2 страницыMuay Thai BackgroundAbraham Domínguez SilvaОценок пока нет

- Esio TrotДокумент4 страницыEsio TrotThe GisseStyleОценок пока нет

- Q1 2019 Price Pages - Excavators PDFДокумент252 страницыQ1 2019 Price Pages - Excavators PDFvitaliyОценок пока нет

- Smart Card TechnologyДокумент21 страницаSmart Card TechnologyKariveda SwethaОценок пока нет

- NL Mememan Ws Intermediate 612844Документ1 страницаNL Mememan Ws Intermediate 612844KrisОценок пока нет

- Soldiers of Christ AriseДокумент2 страницыSoldiers of Christ AriseRodrigo LuisОценок пока нет

- Unit Color Compendium 1702 Double PagesДокумент144 страницыUnit Color Compendium 1702 Double PagesStarslayer RNC100% (3)

- Cookery - 10 - Summative - 1 - Quarter 4Документ4 страницыCookery - 10 - Summative - 1 - Quarter 4Marie-Cris QuintoОценок пока нет

- Fall For YouДокумент4 страницыFall For YouAtikaDarmalaBertaОценок пока нет

- 60 B 6239955 A 4 A 916310696Документ10 страниц60 B 6239955 A 4 A 916310696akira nakazawa50% (2)

- Stack Eg6Документ4 страницыStack Eg6Juanpe HdezОценок пока нет

- Unit 8 Test A: Grammar VocabularyДокумент3 страницыUnit 8 Test A: Grammar VocabularyDato Javakhishvili100% (1)

- Sanskrit Essays LinkДокумент2 страницыSanskrit Essays LinkShabari MaratheОценок пока нет