Академический Документы

Профессиональный Документы

Культура Документы

3 Casting Patterns and Their Allowances

Загружено:

Liaquat Ali0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров32 страницыОригинальное название

3 Casting patterns and their allowances

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров32 страницы3 Casting Patterns and Their Allowances

Загружено:

Liaquat AliАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 32

Pattern:

❖A Pattern is a model or the replica of the

object to be casted.

❖Except for the various allowances, a pattern

exactly resembles the casting to be made.

❖Patterns may be in two or three pieces,

where as casting is a single piece.

❖A pattern is required even if one object has

to be cast.

❖The quality of casting and the final product

will be affected to a great extent by the

planning of pattern.

Selection of Pattern Materials:

The following factors assist in selecting

proper pattern material:

➢No. of castings to be produced.

➢Metal to be cast.

➢Dimensional accuracy & surface finish.

➢Shape, complexity and size of casting.

➢Casting design parameters.

➢Type of molding materials.

➢The chance of repeat orders.

➢Nature of molding process.

➢Position of core print.

The pattern material should be:

1. Easily worked, shaped and joined.

2. Light in weight.

3. Strong, hard and durable.

4. Resistant to wear and abrasion .

5. Resistant to corrosion, and to chemical

reactions.

6. Dimensionally stable and unaffected by

variations in temperature and humidity.

7. Available at low cost.

Materials for making patterns:

a. Wood

b. Metal

c. Plastic

d. Plaster

e. Wax.

Type of patterns depends upon the following

factors:

i. The shape and size of casting

ii. No. of castings required

iii. Method of moulding employed

iv. Anticipated difficulty of moulding

operation

Types of Patterns:

1. Single piece pattern.

2. Split piece pattern.

3. Match plate pattern.

4. Cope and Drag pattern.

1. Single piece (solid) pattern:

Made from one piece and does not

contain loose pieces or joints.

Inexpensive.

Used for large size simple castings.

Pattern is accommodated either in the

cope or in the drag.

Examples:

1. Bodies of regular shapes.

2. stuffing box of steam engine.

Fig: Single piece pattern

2. Split piece pattern:

Patterns of intricate shaped castings cannot be

made in one piece because of the inherent

difficulties associated with the molding operations

(e.g. withdrawing pattern from mould).

The upper and the lower parts of the split piece

patterns are accommodated in the cope and drag

portions of the mold respectively.

Parting line of the pattern forms the parting line of

the mould.

Dowel pins are used for keeping the alignment

between the two parts of the pattern.

Examples:

1. Hallow cylinder

2. Taps and water stop cocks etc.,

4. Match plate pattern:

It consists of a match plate, on either side of

which each half of split patterns is fastened.

A no. of different sized and shaped patterns may

be mounted on one match plate.

The match plate with the help of locator holes

can be clamped with the drag.

After the cope and drag have been rammed with

the molding sand, the match plate pattern is

removed from in between the cope and drag.

Match plate patterns are normally used in

machine molding.

By using this we can eliminate mismatch of cope

and drag cavities.

Fig: Match plate pattern

9. Cope and Drag patterns:

A cope and drag pattern is another form of split

pattern.

Each half of the pattern is fixed to a separate

metal/wood plate.

Each half of the pattern(along the plate) is molded

separately in a separate molding box by an

independent molder or moulders.

The two moulds of each half of the pattern are

finally assembled and the mould is ready for

pouring.

Cope and drag patterns are used for producing

big castings which as a whole cannot be

conveniently handled by one moulder alone.

Fig: Cope and drag pattern

Pattern Allowances:

A pattern is larger in size as compared

to the final casting, because it carries certain

allowances due to metallurgical and mechanical

reasons for example, shrinkage allowance is

the result of metallurgical phenomenon where

as machining, draft, distortion, shake and other

allowances are provided on the patterns

because of mechanical reasons.

Types of Pattern Allowances:

The various pattern allowances are:

1. Shrinkage or contraction allowance.

2. Machining or finish allowance.

3. Draft or tapper allowances.

4. Shake or rapping allowance.

1.Shrinkage Allowance:

All most all cast metals shrink or contract

volumetrically on cooling.

The metal shrinkage is of two types:

1. Liquid Shrinkage:

it refers to the reduction in volume when the metal

changes from liquid state to solid state at the solidus

temperature. To account for this shrinkage; riser, which

feed the liquid metal to the casting, are provided in the

mold.

2. Solid Shrinkage:

it refers to the reduction in volume caused when

metal loses temperature in solid state. To account for

this, shrinkage allowance is provided on the patterns.

Assignment 1

Cooling curve for solidification and

cooling of a). Pure Metal and b). An alloy

The contraction of metals/alloys is always volumetric, but the

contraction allowances are always expressed in linear

measures.

2. Machining Allowance:

A Casting is given an allowance for

machining, because:

i. Castings get oxidized in the mold and during

heat treatment; scales etc., thus formed need

to be removed.

ii. It is the intended to remove surface roughness

and other imperfections from the castings.

iii. It is required to achieve exact casting

dimensions.

iv. Surface finish is required on the casting.

How much extra metal or how much

machining allowance should be provided,

depends on the factors listed below:

i. Nature of metals.

ii. Size and shape of casting.

iii. The type of machining operations to be

employed for cleaning the casting.

iv. Casting conditions.

v. Molding process employed

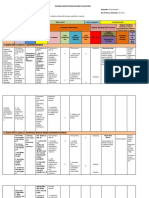

Machining Allowances of

Various Metals:

3. Draft or Taper Allowance:

▪ It is given to all surfaces perpendicular to parting

line.

▪ Draft allowance is given so that the pattern can

be easily removed from the molding material

tightly packed around it with out damaging the

mould cavity.

▪ The amount of taper depends upon:

i. Shape and size of pattern in the depth

direction in contact with the mould cavity.

ii. Moulding methods.

iii. Mould materials.

iv. Draft allowance is imparted on internal as well

as external surfaces; of course it is more on

internal surfaces.

The taper provided by the pattern maker on all

vertical surfaces of the pattern so that it can be

removed from the sand without tearing away the sides

of the sand mold and without excessive rapping by the

molder.

Figure shows a pattern having no draft allowance

being removed from the pattern. In this case, till the

pattern is completely lifted out, its sides will remain in

contact with the walls of the mold, thus tending to

break it.

Figure is an illustration of a pattern having

proper draft allowance. Here, the moment the

pattern lifting commences, all of its surfaces are

well away from the sand surface. Thus the

pattern can be removed without damaging the

mold cavity.

Fig: taper in design

4. Shake allowance:

▪ A patter is shaken or rapped by striking the same

with a wooden piece from side to side. This is

done so that the pattern a little is loosened in the

mold cavity and can be easily removed.

▪ In turn, therefore, rapping enlarges the mould

cavity which results in a bigger sized casting.

▪ Hence, a –ve allowance is provided on the pattern

i.e., the pattern dimensions are kept smaller in

order to compensate the enlargement of mould

cavity due to rapping.

▪ The magnitude of shake allowance can be

reduced by increasing the tapper.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- RYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersДокумент28 страницRYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersSerban Sebe100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 09 WA500-3 Shop ManualДокумент1 335 страниц09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationДокумент27 страницAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfОценок пока нет

- State Immunity Cases With Case DigestsДокумент37 страницState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- Industrial Thermal Utilities MT 363: Lecture ContentsДокумент7 страницIndustrial Thermal Utilities MT 363: Lecture ContentsLiaquat AliОценок пока нет

- Industrial Thermal Utilities MT 363: BoilersДокумент5 страницIndustrial Thermal Utilities MT 363: BoilersLiaquat AliОценок пока нет

- Industrial Thermal Utilities MT 363: BoilersДокумент7 страницIndustrial Thermal Utilities MT 363: BoilersLiaquat AliОценок пока нет

- Industrial Thermal Utilities MT 363: LecturerДокумент4 страницыIndustrial Thermal Utilities MT 363: LecturerLiaquat AliОценок пока нет

- Industrial Thermal Utilities MT 363: BoilersДокумент9 страницIndustrial Thermal Utilities MT 363: BoilersLiaquat AliОценок пока нет

- Applied Mechanics Lab Report: BSC Mechanical Engineering Technology Uet Lahore KSK CampusДокумент27 страницApplied Mechanics Lab Report: BSC Mechanical Engineering Technology Uet Lahore KSK CampusLiaquat AliОценок пока нет

- 4 Various Types of Expendable Mold and Permanent Mold CastingДокумент45 страниц4 Various Types of Expendable Mold and Permanent Mold CastingLiaquat AliОценок пока нет

- Print ElectricalДокумент13 страницPrint ElectricalLiaquat AliОценок пока нет

- 2 Introduction To Casting ProcessДокумент22 страницы2 Introduction To Casting ProcessLiaquat AliОценок пока нет

- 1 Introduction To MP and Production SystemДокумент24 страницы1 Introduction To MP and Production SystemLiaquat AliОценок пока нет

- University of Engineering and Technology: Lab ReportДокумент33 страницыUniversity of Engineering and Technology: Lab ReportLiaquat Ali100% (1)

- XgxyДокумент22 страницыXgxyLïkïth RäjОценок пока нет

- 21st Bomber Command Tactical Mission Report 178, OcrДокумент49 страниц21st Bomber Command Tactical Mission Report 178, OcrJapanAirRaidsОценок пока нет

- Fidp ResearchДокумент3 страницыFidp ResearchIn SanityОценок пока нет

- Sample Annual BudgetДокумент4 страницыSample Annual BudgetMary Ann B. GabucanОценок пока нет

- Lockbox Br100 v1.22Документ36 страницLockbox Br100 v1.22Manoj BhogaleОценок пока нет

- 30 Creative Activities For KidsДокумент4 страницы30 Creative Activities For KidsLaloGomezОценок пока нет

- Danby Dac5088m User ManualДокумент12 страницDanby Dac5088m User ManualElla MariaОценок пока нет

- 5 Deming Principles That Help Healthcare Process ImprovementДокумент8 страниц5 Deming Principles That Help Healthcare Process Improvementdewi estariОценок пока нет

- Continue: Rudolf Bultmann Theology of The New Testament PDFДокумент3 страницыContinue: Rudolf Bultmann Theology of The New Testament PDFpishoi gerges0% (1)

- Dialog Suntel MergerДокумент8 страницDialog Suntel MergerPrasad DilrukshanaОценок пока нет

- Address MappingДокумент26 страницAddress MappingLokesh KumarОценок пока нет

- Amare Yalew: Work Authorization: Green Card HolderДокумент3 страницыAmare Yalew: Work Authorization: Green Card HolderrecruiterkkОценок пока нет

- 004-PA-16 Technosheet ICP2 LRДокумент2 страницы004-PA-16 Technosheet ICP2 LRHossam Mostafa100% (1)

- PLT Lecture NotesДокумент5 страницPLT Lecture NotesRamzi AbdochОценок пока нет

- ESG NotesДокумент16 страницESG Notesdhairya.h22Оценок пока нет

- How To Control A DC Motor With An ArduinoДокумент7 страницHow To Control A DC Motor With An Arduinothatchaphan norkhamОценок пока нет

- Aitt Feb 2017 TH Sem IIIДокумент6 страницAitt Feb 2017 TH Sem IIIMadhu KumarОценок пока нет

- Urun Katalogu 4Документ112 страницUrun Katalogu 4Jose Luis AcevedoОценок пока нет

- Departmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedДокумент37 страницDepartmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedGeorgina AlpertОценок пока нет

- CSEC Jan 2011 Paper 1Документ8 страницCSEC Jan 2011 Paper 1R.D. KhanОценок пока нет

- T1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurningДокумент16 страницT1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurninghosseinОценок пока нет

- Escario Vs NLRCДокумент10 страницEscario Vs NLRCnat_wmsu2010Оценок пока нет

- Oracle Exadata Database Machine X4-2: Features and FactsДокумент17 страницOracle Exadata Database Machine X4-2: Features and FactsGanesh JОценок пока нет

- Ingles Avanzado 1 Trabajo FinalДокумент4 страницыIngles Avanzado 1 Trabajo FinalFrancis GarciaОценок пока нет

- Ces Presentation 08 23 23Документ13 страницCes Presentation 08 23 23api-317062486Оценок пока нет

- Richards Laura - The Golden WindowsДокумент147 страницRichards Laura - The Golden Windowsmars3942Оценок пока нет