Академический Документы

Профессиональный Документы

Культура Документы

Design of Anchor Bolts

Загружено:

dineshАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Anchor Bolts

Загружено:

dineshАвторское право:

Доступные форматы

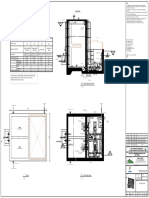

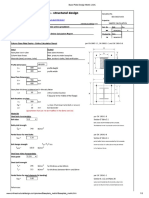

TME Techmaster Engineering Sal Made by : BKM

PP7 EXT. 3 Project Checked By : ASM

Steel Shed for Auxiliary Transformer Ref. SAR687-VE04-00UBE-B12012

Structural Design Calculations Rev : A

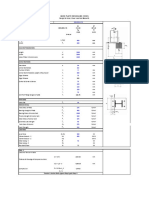

8.0 Design of Foundation bolt

Fange

Fange

Designation Area Depth web width thicknes

width

s

Size of column mm2 mm mm mm mm

IPE330 7260 327 6.5 160 10

Load case (STAAD OUTPUT FILE) 5 5

Support No(REFER STAAD OUTPUT FILE ) 2 3 Y3

Y

Axial force, P kN -1.9 -1.9

Moment, M kNm 10 10 3

PP

1 1 T a

Horizontal shear, H kN

400 M

Length of base plate, L mm 400 C

min

Width of base plate, B mm 250 250

max

Depth of the flange, D mm 160 160

Distance betn. edge of base pl.& cl. of bolt, ed 75

s

mm 75 e

Y1

Permissible stress of bolt in tension Ft N/mm2 137.88 137.88

Y2 Y1/3

Permissible stress of bolt in shear tvf,PER N/mm 2

68.94 68.94

Characteristic compressive strength of = =

concrete,fck N/mm2 37.93 37.93

Permissible stress in conc. in direct

N/mm2 13.28 13.28

compression, f'c

Increase in permissible stress 1.33 1.33

smax = P / LxB + 6xM / BxL2 N/mm2 1.49 1.49

smin = P / LxB - 6xM / BxL2 N/mm2 -1.52 -1.52

Remarks O.K. O.K.

Depth of neutral axis,

mm 198.01 198.01

Y1 = smax x L / (smax + smin)

Distance betn. cl. of base pl. & cg. of comp.

mm 134 134

Force, Y2 = L / 2 - Y1 / 3

Lever arm, Y3 = L - ed - Y1 / 3 mm 259 259

Tension (Taking moment about Compression

line) kN 39.6 39.6

T=(M - P x Y2) / Y3

bolt bolt

Remarks

required required

Dia of bolt mm 40 40

Gross area provided mm2 1257 1257

Net area provided mm 2

1006 1006

No. of bolt per side 1 1

No. of bolt Provided per side 2 2

Cal. tensile stress stf, cal N/mm2 19.69 19.69

Horizontal shear per bolt, H kN 0.5 0.5

Cal. shear stress, tvf,cal N/mm2 0.4 0.4

svf,cal / svf,PER + tvf,cal / tvf,PER 0.12 0.12

Remarks <1.4 <1.4

LENGTH OF BOLT

Width of Anchor Plate,b mm 80

Permissible Stress in shear fs=2xsqrt(f'c) N/mm2 3.64

Length of anchor bolt ,L=T / (fsx4xb) mm 148.65

Length of anchor bolt provided mm 350

Page 1+6

Вам также может понравиться

- Rev - Office Proposal - 6.11.2014-ModelДокумент1 страницаRev - Office Proposal - 6.11.2014-ModelChandra ShekarОценок пока нет

- Bridge Manual: 23.1 2 23.2 Design Specifications and Data 3Документ17 страницBridge Manual: 23.1 2 23.2 Design Specifications and Data 3mud444Оценок пока нет

- Unit 10 Gantry Girders: StructureДокумент54 страницыUnit 10 Gantry Girders: StructureMahendra DewasiОценок пока нет

- Provision For JointДокумент3 страницыProvision For Jointfazle rabbiОценок пока нет

- Design of Purlin (Rectangular Sections Only)Документ3 страницыDesign of Purlin (Rectangular Sections Only)Amit Parikh100% (1)

- Week 6 Lecture Material - WatermarkДокумент59 страницWeek 6 Lecture Material - WatermarkVaibhav SharmaОценок пока нет

- For Battened Columns For Strength Cal 10% Increase in The KL/RДокумент4 страницыFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukОценок пока нет

- Specification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeДокумент5 страницSpecification For Rhomboidal Steel Wire Rope Net Panels For Rock Fall Protection 1) ScopeSOMNATH JANAОценок пока нет

- Bearing Capacity of FoundationsДокумент4 страницыBearing Capacity of FoundationsTshepiso NthiteОценок пока нет

- Tension Member Double AngleДокумент1 страницаTension Member Double AnglechaОценок пока нет

- 1.wind Load BNBC Aisc Open Code 60mДокумент9 страниц1.wind Load BNBC Aisc Open Code 60mAnonymous ep7LE5ZdP5Оценок пока нет

- Seismic Comparison UBC97 and ASCE7-05Документ4 страницыSeismic Comparison UBC97 and ASCE7-05Julius PcОценок пока нет

- Purlin Designation Input Data: Purlin Geometry: Design of Z PurlinsДокумент13 страницPurlin Designation Input Data: Purlin Geometry: Design of Z Purlinsarif_rubinОценок пока нет

- Jacking Pad DesignДокумент3 страницыJacking Pad DesignAmarjit KulkarniОценок пока нет

- Steel Column DesignДокумент4 страницыSteel Column Designanshutomar7915100% (2)

- Reactions As Per The ModelДокумент2 страницыReactions As Per The Modelwaweng22Оценок пока нет

- Capacity Charts For The Hydraulic Design of Highway CulvertsДокумент95 страницCapacity Charts For The Hydraulic Design of Highway CulvertsphisitlaiОценок пока нет

- Vertical Drain Rev 1.0Документ32 страницыVertical Drain Rev 1.0Koko Putra AriadiОценок пока нет

- 8224 Grating No HeaderДокумент69 страниц8224 Grating No HeadervishalnalwarОценок пока нет

- Fire-Pump Room - Rev.cДокумент1 страницаFire-Pump Room - Rev.cwael72Оценок пока нет

- Steel I Beam Web Shear CapacityДокумент1 страницаSteel I Beam Web Shear CapacityArjun RajaОценок пока нет

- AASHTO Simplified Shear CalcДокумент9 страницAASHTO Simplified Shear CalcSharyn PolleyОценок пока нет

- Bolt CalculationДокумент7 страницBolt CalculationneynaaaОценок пока нет

- Gantry Girder V0 - 1Документ1 страницаGantry Girder V0 - 1Rahul SheokandОценок пока нет

- Cantilever BeamДокумент3 страницыCantilever BeamFeliciano Esteban DominguezОценок пока нет

- Design of Shear KeyДокумент13 страницDesign of Shear KeyRonnie SmithОценок пока нет

- Chapter Five, Plate GirdersДокумент21 страницаChapter Five, Plate GirdersZeleke TaimuОценок пока нет

- Design of Raft FoundationДокумент3 страницыDesign of Raft FoundationBikram BhusalОценок пока нет

- Design of FoundationДокумент66 страницDesign of FoundationShaikh Muhammad Ateeq100% (2)

- Fixed Column BaseДокумент3 страницыFixed Column BasemontavarОценок пока нет

- 2018 May 29 Circular Tank With WaterДокумент4 страницы2018 May 29 Circular Tank With WaterPRAKASHОценок пока нет

- Beam Design SpreadsheetДокумент23 страницыBeam Design SpreadsheetLivian TeddyОценок пока нет

- End Plate DesignДокумент4 страницыEnd Plate Designsiva0% (1)

- Steel Beam DesignДокумент4 страницыSteel Beam Designanshutomar7915100% (1)

- Composite BeamДокумент7 страницComposite Beamsaif.mullaОценок пока нет

- Design Properties For Crane Runway Beam PDFДокумент4 страницыDesign Properties For Crane Runway Beam PDFkayakeras3335Оценок пока нет

- Design of Columns and Struts in Structural SteelДокумент20 страницDesign of Columns and Struts in Structural SteelMaqsood83% (18)

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFДокумент5 страницGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargОценок пока нет

- Compression StiffenersДокумент12 страницCompression StiffenersZsuzsaОценок пока нет

- Checkered PlateДокумент2 страницыCheckered PlateIho1Оценок пока нет

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressДокумент29 страницPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDEОценок пока нет

- S&T Purlins & Girts Catalogue PDFДокумент36 страницS&T Purlins & Girts Catalogue PDFNguyen Duc CuongОценок пока нет

- M M MM MM N/MM N/MM MM MM MM MM MM 2Документ1 страницаM M MM MM N/MM N/MM MM MM MM MM MM 2D SRINIVASОценок пока нет

- Truss Design Example: CE 331, Fall 2000Документ8 страницTruss Design Example: CE 331, Fall 2000anbugobi80% (5)

- Spreadsheets To BS 8110: The Concrete CentreДокумент13 страницSpreadsheets To BS 8110: The Concrete CentreMohammad Twaha JaumbocusОценок пока нет

- ProkonДокумент7 страницProkonmark7301158Оценок пока нет

- Machine Design AssignmentДокумент9 страницMachine Design AssignmentMuhammad Fahad Khan 51-FET/BSCMET/F19Оценок пока нет

- Base Plate and Anchor Bolt Design - MailДокумент5 страницBase Plate and Anchor Bolt Design - MailMiguelRagasОценок пока нет

- Design of Connectionv.3Документ15 страницDesign of Connectionv.3Apple Grace S. Valencia100% (1)

- Api 650 RF Pad CalculationДокумент1 страницаApi 650 RF Pad Calculationfauzy2504Оценок пока нет

- Base Plate Design BS CodeДокумент3 страницыBase Plate Design BS CodeFodor ZoltanОценок пока нет

- T BEAM Rectangular Beam 3sections FinalДокумент24 страницыT BEAM Rectangular Beam 3sections FinalDipanjan MitraОценок пока нет

- Baseplate (Fixed Type 6 Bolts) 123Документ15 страницBaseplate (Fixed Type 6 Bolts) 123vijay10484Оценок пока нет

- Base Plate Design BSДокумент4 страницыBase Plate Design BSvinujohnpanickerОценок пока нет

- EndPl MomConn LSDДокумент54 страницыEndPl MomConn LSDsilroy d'saОценок пока нет

- Base Plate DesignДокумент4 страницыBase Plate DesignAbhay ThakurОценок пока нет

- Trunnion CalculationsДокумент2 страницыTrunnion Calculationspmech consultantОценок пока нет

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Документ8 страницHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshОценок пока нет

- Column Base Plate (Fixed Type)Документ13 страницColumn Base Plate (Fixed Type)KM YapОценок пока нет

- On The Correlation of Seismic Intensity Scale WithДокумент25 страницOn The Correlation of Seismic Intensity Scale WithdineshОценок пока нет

- Edoc - Pub - Transformer Foundation DesignДокумент26 страницEdoc - Pub - Transformer Foundation DesigndineshОценок пока нет

- HDPEДокумент4 страницыHDPEdineshОценок пока нет

- Seismic Risk Mapping For UzbekistanДокумент20 страницSeismic Risk Mapping For UzbekistandineshОценок пока нет

- Seismic Risk Assessment of Built Environment in PakistanДокумент10 страницSeismic Risk Assessment of Built Environment in PakistandineshОценок пока нет

- Calculation of Seismic Protective Qualities of Dampefer and AbsorterДокумент4 страницыCalculation of Seismic Protective Qualities of Dampefer and AbsorterdineshОценок пока нет

- Design of Foundation For 220 KV ElectricalДокумент7 страницDesign of Foundation For 220 KV ElectricaldineshОценок пока нет

- MSP 2018-2023 Final AdoptedДокумент28 страницMSP 2018-2023 Final AdopteddineshОценок пока нет

- UNit Transformer GA DrawingДокумент3 страницыUNit Transformer GA DrawingdineshОценок пока нет

- Base Plate Design Metric UnitsДокумент3 страницыBase Plate Design Metric UnitsdineshОценок пока нет

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataДокумент10 страницAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshОценок пока нет

- RAM Connection Standalone CE Report - 11Документ2 страницыRAM Connection Standalone CE Report - 11dineshОценок пока нет

- Probabilistic Seismic Hazard Analysis For YemenДокумент16 страницProbabilistic Seismic Hazard Analysis For YemendineshОценок пока нет

- Schedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PriceДокумент10 страницSchedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PricedineshОценок пока нет

- Steel Design Parameter - EuroДокумент11 страницSteel Design Parameter - EurodineshОценок пока нет

- Seismic Code Developments For Steel & Composite StructuresДокумент23 страницыSeismic Code Developments For Steel & Composite StructuresdineshОценок пока нет

- Nuclear CodesДокумент4 страницыNuclear CodesdineshОценок пока нет

- Aisc Asd ParametersДокумент9 страницAisc Asd ParametersdineshОценок пока нет

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Документ13 страницBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshОценок пока нет

- Comparative Study of Diagrid Structures With and Without Corner ColumnsДокумент6 страницComparative Study of Diagrid Structures With and Without Corner ColumnsdineshОценок пока нет

- Indian Codes - Steel Design Per IS 800:2007Документ3 страницыIndian Codes - Steel Design Per IS 800:2007dineshОценок пока нет

- Design of BracingДокумент10 страницDesign of BracingdineshОценок пока нет

- Spun PilesДокумент4 страницыSpun Pilesdinesh100% (1)

- Cross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3Документ12 страницCross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3dineshОценок пока нет

- Crane Girder Beam Design - ExampleДокумент6 страницCrane Girder Beam Design - Exampledinesh100% (3)

- Design of Biaxial ColumnДокумент5 страницDesign of Biaxial ColumndineshОценок пока нет

- Lecture 3Документ51 страницаLecture 3Kostas FrantzikОценок пока нет

- Fundamentals of Engineering Heat and Mass Transfer - R. C. Sachdeva PDFДокумент213 страницFundamentals of Engineering Heat and Mass Transfer - R. C. Sachdeva PDFKuldeep Bhatt47% (30)

- Nano-And Biocomposites: Emerging Nanotechnologies For ManufacturingДокумент1 страницаNano-And Biocomposites: Emerging Nanotechnologies For ManufacturingshahramОценок пока нет

- Metals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersДокумент46 страницMetals: The Chemistry of Engineering Materials Lecture Notes 05 Chemistry For EngineersLorielle OlivaОценок пока нет

- Thermal Stress - WikipediaДокумент2 страницыThermal Stress - WikipediaAbu AnzarОценок пока нет

- Lecture 8 Critical State Soil Mechanics PDFДокумент31 страницаLecture 8 Critical State Soil Mechanics PDFZar MaghustОценок пока нет

- Interview Questions122Документ75 страницInterview Questions122Sai GnanadeepОценок пока нет

- Non-Linear Hyperbolic Model & Parameter SelectionДокумент24 страницыNon-Linear Hyperbolic Model & Parameter SelectionNestor Bellido AñancaОценок пока нет

- Ultra-High Strength Circular Short CFST Columns - Axisymmetric Analysis, Behaviour and Design, 2019 (V.I. Patel)Документ16 страницUltra-High Strength Circular Short CFST Columns - Axisymmetric Analysis, Behaviour and Design, 2019 (V.I. Patel)Phan Đào Hoàng HiệpОценок пока нет

- Kelken US Metric Chart ASTM F1554 Grade 55 PDFДокумент1 страницаKelken US Metric Chart ASTM F1554 Grade 55 PDFAkash BogaОценок пока нет

- Bridge PortionДокумент16 страницBridge PortionNagara SelvarajОценок пока нет

- Cleat Angle ConnectionДокумент38 страницCleat Angle ConnectionMadhubalan AlagarОценок пока нет

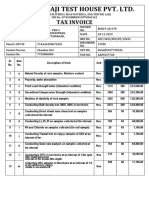

- Afcon Tax Invoice 20-11-2019Документ2 страницыAfcon Tax Invoice 20-11-2019SAURABHОценок пока нет

- Lab 3Документ7 страницLab 3Mehmet Safa YılmazОценок пока нет

- Thermodynamic Properties, Equations of State, Methods Used To Describe and Predict Phase EquilibriaДокумент20 страницThermodynamic Properties, Equations of State, Methods Used To Describe and Predict Phase EquilibriaanisfathimaОценок пока нет

- Design of Slender Reinforced Concrete Bridge Columns Considering The Interaction Between ColumnsДокумент10 страницDesign of Slender Reinforced Concrete Bridge Columns Considering The Interaction Between ColumnsTeo Peng Keat100% (1)

- Experimental Investigation On Behavior of Bamboo Reinforced Concrete Member PDFДокумент5 страницExperimental Investigation On Behavior of Bamboo Reinforced Concrete Member PDFJoji Ann UayanОценок пока нет

- (BS en 13084-2-2007) - Free-Standing Chimneys. Concrete ChimneysДокумент28 страниц(BS en 13084-2-2007) - Free-Standing Chimneys. Concrete ChimneysMichał KisielewskiОценок пока нет

- IPS E-Max ZirCAD Prime PDFДокумент16 страницIPS E-Max ZirCAD Prime PDFAstalanas KaraОценок пока нет

- Thermal Stresses GatewoodДокумент248 страницThermal Stresses Gatewoodsekharsamy100% (2)

- MaterialsДокумент4 страницыMaterialsSilvio VarricchioОценок пока нет

- Experiment No:4 Bending Testing: ObjectivesДокумент5 страницExperiment No:4 Bending Testing: ObjectivesNarjes Ibrahem Khaled 2K21/PHDCH/02Оценок пока нет

- Viscosity and Fluid Flow PDFДокумент3 страницыViscosity and Fluid Flow PDFLy Ca TieuОценок пока нет

- Isostud Isostud: 08 1213-CPD-4454 EN 13967Документ1 страницаIsostud Isostud: 08 1213-CPD-4454 EN 13967Alexandru PelinОценок пока нет

- Hardox 450 Plate: General Product DescriptionДокумент2 страницыHardox 450 Plate: General Product Descriptiongorane11Оценок пока нет

- Comprehensive ExamДокумент211 страницComprehensive ExamReshab Rathi100% (1)

- Bridge Bearing2Документ10 страницBridge Bearing2sandbad2Оценок пока нет

- MDSP Set 1Документ53 страницыMDSP Set 1Dhin TolentinoОценок пока нет

- MATSCI 210 - Lecture 2 - Polymer Physics Part 1Документ33 страницыMATSCI 210 - Lecture 2 - Polymer Physics Part 1Samanoske AkechiОценок пока нет

- Chapter 1 ProblemsДокумент4 страницыChapter 1 ProblemsMarco Ramos Jacob57% (7)