Академический Документы

Профессиональный Документы

Культура Документы

Schneider-Corto Circuito y Arco Electrico-Aaa

Загружено:

JOSE LUIS FALCON CHAVEZОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Schneider-Corto Circuito y Arco Electrico-Aaa

Загружено:

JOSE LUIS FALCON CHAVEZАвторское право:

Доступные форматы

0600DB1303

White Paper 06/2013

Selective Coordination vs Arc Flash Requirements

Retain for future use.

Abstract Present industry standards require higher system performance and

protection against arc flash hazards for individuals exposed to dangerous

levels of incidental energy. However, in most cases, high system

performance achieved through selective coordination, required in changes

to the National Electric Code® (NEC®), results in increased arc flash

energy. This conflict between selective coordination and arc flash is

explained in this paper through real world examples. The resolution to this

conflict is provided through both existing and future solutions which achieve

a balance between total selectivity and arc flash hazard levels. This paper

also discusses the two levels of selective coordination commonly employed:

0.1 seconds and total selectivity; and the affects each has on calculated arc

flash hazards.

Introduction

Selective Coordination Selective coordination refers to the selection and setting of overcurrent

protective devices (OCPDs) in an electric power system in such a manner so

as to cause the smallest possible portion of the system to be de-energized

due to an overload condition:

Per the 2011 NEC Article 100 – “Localization of an overcurrent condition to

restrict outages to the circuit or equipment affected, accomplished by the

choice of overcurrent protective devices and their ratings or settings.”

This ensures any overcurrent event is cleared by the smallest circuit breaker

in the system before allowing a larger line-side circuit breaker to operate on

the fault. This limits the service interruption to only the circuit experiencing

the problem and does not shut down a larger portion of the facility.

Specific selective coordination requirements were first introduced in NEC

1996, Article 620.62 for elevators, dumbwaiters, escalators, moving walks,

wheelchair lifts and stairway chair lifts. Subsequent articles were added to

the NEC:

1. Emergency and legally-required standby power systems, NEC 2011

Articles 700.27 and 701.27, respectively.

2. Health-care facilities, NEC Article 517.26, which says that the essential

electrical system should meet the requirements of Article 700.

3. Critical operations power systems (COPS), NEC Article 708.54.

While the rationale for selective coordination is self-evident – clearing and

isolating faults as quickly as possible without disturbing the unaffected

portions of the system – the methods for judging OCPD to OCPD selectivity

are not as clear. No industry standards exist which define device-to-device

selectivity over their full operating ranges; no consensus has been

developed among protection engineers or inspecting authorities regarding

device-to-device selectivity thresholds. Discussions continue over the

“practicable” selectivity criteria – overlaying time-current characteristics of

OCPDs to determine selectivity are complicated by examining the current-

limiting interactions of OCPDs at maximum available fault currents. As a

© 2013 Schneider Electric All Rights Reserved

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

result, essentially two interpretations or definitions of selective coordination

have evolved:

A. 0.1 seconds and longer –This means that the time-current curves

(TCCs) of OCPDs in series should not overlap above 0.1s. Selective

coordination at 0.1s and longer includes the vast majority of fault

currents, overloads and arcing faults, but not the highest levels seen in

the instantaneous region.

B. Total selectivity – In addition to TCC coordination described for the 0.1s

definition, total selectivity takes into account the current-limiting

behaviors and interactions of OCPDs operating on the highest available

fault currents. There are variations on how total selectivity is described

(e.g. 0.01 seconds), but the intent is selectivity for the OCPDs entire

operating range up to the maximum fault current.

Arc Flash The consideration of arc flash hazards is a relatively new concern for power

system design. However, it is a concern that is rapidly gaining momentum

due to increasingly strict worker safety standards. A flash hazard is a

dangerous condition associated with the release of energy caused by an

electric arc. The energy impressed on a surface, a certain distance from the

source, generated during an electrical arc event is termed as incident

energy.

Key factors which affect the arc flash incident energy are:

A. available fault current at the equipment

B. the time taken by the upstream protective device to clear the fault

C. distance from the arcing source

In most cases achieving selective coordination comes at the cost of

increasing circuit breaker frame size and/or changing circuit breaker type

from a molded case to an electronic trip type with higher short

time/instantaneous settings. Both solutions could result in an increase in

total clearing time of protective devices during an arcing fault, thereby

causing an increase in arc flash incident energy. An example in the next

section further explains the effect of selective coordination – 0.1 second and

total – on arc flash.

Selective Coordination versus Arc

Flash Example

Selective Coordination Through In this section a five bus circuit has been used to explain the affect of total

Comparison of Time-Current Curves selectivity on arc flash. Three cases have been considered as follows:

• Case 1 – Load based coordination where devices are selected based on

typical thermal-magnetic trips for circuit breakers other than service

mains and prior to implementing NEC Article 100 requirement of

selective coordination.

• Case 2 - Selective coordination to 0.1 seconds and longer

• Case 3 - Total selective coordination

Table 3 on Page 17 compares arc flash category and incident energy for

each case. The results of this typical example show how selective

coordination is achieved at the cost of increased arc flash incident energy.

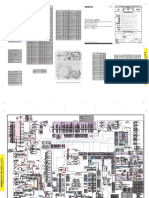

Figure 1 shows that the system is fed from two sources:

A. normal source fed by a 1000 kVA utility transformer and

B. emergency source fed by a 500 kW generator.

2 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

The protective devices shown are prior to selective coordination and are

based on load requirement only.

Figure 1: Single Line Drawing of Example System

UTILITY

SC Contribution 3P 99999 MVA

X/R 3P 8.0

UTI XFM

1000 kVA

Prl 12470 V

GEN Sec 480 V

500 kW

Z = 5.75%

625 kVA

PF 0.80 Lag

50 ft.

GM1 4–#500

PB

800AF / AS / AT SM1

PG

1200AF / AS / AT

001 GEN 005 SWBD

480 V 480 V

7.508 kA 22.507 kA

AFE AFN

LA LA

400AT 400AT

100 ft. 100 ft.

MTR LD

1–#500 1–#500

500 hp

500 kVA

X”d 0.25 PU

E N

400A ATS

002L ATS

480 V

16.753 kA

50 ft.

1–#500

003 PNL1

480 V

PB2 14.815 kA

HG

125AT

50 ft.

1–#2

004 PNL2

480 V

PB4 11.857 kA

EG

40AT

© 2013 Schneider Electric All Rights Reserved 3

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

The cable length and sizes are noted on the one line drawing shown in

Figure 1. The cables are sized per NEC 2011 Edition table 310.15(B) (16).

In order to have a worst case fault analysis, the main switchboard was

loaded with (20) 25 hp motors adding up to 500 kVA, half of the rated kVA of

the utility transformer.

The circuit breaker TCCs are plotted based on worst case three phase fault

current from an infinite source. For this example it has been assumed that

the entire system consisting of both normal and emergency sides should be

selectively coordinated for each case:

a. Case 2: 0.1 second and longer and

b. Case 3: total selectivity.

The TCC graphs shown in Figures 2 and 3 show coordination for Case 1:

without more stringent selective coordination requirements. Without

selectivity requirements the coordination achieved in Case 1 is borderline

practicable; for fault level currents load-side of PB4, mis-coordination exists

with line-side circuit breaker PB2, and mis-coordination exists for the

highest levels of fault current for all of the circuit breakers plotted. However,

when Case 2 and Case 3 are considered there are several issues, notably

for Case 3. Selectivity will be achieved by adjusting the circuit breaker TCCs

shown in Figures 2 and 3 and if required by replacing the circuit breakers

with ones ensuring better coordination. Each case includes circuit breakers

at equipment designations –PNL1 and PNL2 fed from normal and

emergency source.

4 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

Figure 2: Case 1 - TCC Graph for PNL2 Circuit Based on Normal Source Fault Current

© 2013 Schneider Electric All Rights Reserved 5

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Figure 3: Case 1 - TCC Graph for PNL2 Circuit Based on Emergency Source Fault Current

In terms of selective coordination, Case 2 is considered first: selective

coordination 0.1 seconds and longer. If Figures 2 and 3 are compared, both

have a common OCPD mis-coordination issue which exists between circuit

breakers PB2 and PB4. By replacing circuit breaker PB2 with a

PowerPact™ circuit breaker HD 125AT trip 5.2A, we can improve selectivity

to 0.1 seconds and longer. The circuit breakers AFN, AFE, SM1 and GM1

require setting adjustments in order to maintain selective coordination of 0.1

seconds and longer. The new TCC graphs are shown in Figures 4 and 5, for

normal and emergency side, respectively. In order to achieve selective

6 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

coordination for Case 2 there were few system design changes comprising

of one circuit breaker upgrade and settings adjustment of existing circuit

breakers.

Figure 4: Case 2 - TCC Graph for PNL2 Circuit Based on Normal Source Fault Current

© 2013 Schneider Electric All Rights Reserved 7

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Figure 5: Case 2 - TCC Graph for PNL2 Circuit Based on Emergency Source Fault Current

For Case 3, the selectivity table and the online selectivity tool are used in

order to improve coordination by removing the overlap in the instantaneous

region between the circuit breaker curves as shown in Figures 2 and 3. The

analysis starts at the smallest downstream circuit breaker in PNL2 and

subsequently moves up the system to the main switchboard SWBD. There

is an overlap in the instantaneous region of device PB4 with devices PB2,

AFN and SM1.

8 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

Per Schneider Electric data bulletin 0100DB0501 [1] the circuit breakers HG

125AT [PB2] and EGB 40AT [PB4] are totally selective up to 1300 A. The

available fault current at PNL2 is 11.857kA which is greater than 1300 A.

Hence in case of a fault PB2 may trip along with PB4 resulting in lack of total

selectivity for faults above 1300 A. In order to achieve total selectivity

between circuit breakers PB2 and PB4 the following design options exist:

A. Change the thermal magnetic circuit breaker PB2 to an electronic trip type

of same size with an adjustable short time and instantaneous setting.

B. Increase the trip and frame size of circuit breaker PB2, thereby having a

higher instantaneous trip region. Note that the higher trip size would

require an increase in cable size. Increased cable size will have lower

impedance which in turn will increase the fault current at the panel PNL2.

C. Introduce an isolation transformer between ATS load side and PNL1.

The isolation transformer will reduce the fault current.

D. Redesign the cable lengths to insure lower fault currents by increasing

the cable length and impedance. This is a worst case option when total

selectivity is required and there are no circuit breaker pairs available.

Drawbacks of “D” are that the building may not be conducive to the

longer cable runs required to reduce the fault current, or there may be

voltage drop issues created by the long runs. Typically options a), b),

and c) are considered first, in that order, before opting for d).

For our example option A) is chosen which has the least amount of system

design changes. In order to select circuit breakers to achieve selective

coordination the design engineer can refer to manufacturer published

tables. The instantaneous region of the device bands tend to show an

overlap on a TCC (plotted by most commercially available analysis software

programs) for many circuit breakers because the curves have been based

on the standalone characteristic curves for the maximum three-phase bus

fault values. If dynamic impedance is considered for this region, then the

fault current observed at the upstream circuit breaker may not be high

enough to trip before the downstream circuit breaker reaches its maximum

trip time for the manufacturer’s tolerances for instantaneous faults.

Different combinations of circuit breakers can be tested to show coordination

at or below certain fault values even though the software-generated TCC

device bands overlap each other in the instantaneous region. Schneider

Electric has published data bulletin 0100DB0501 - “Short Circuit Selective

Coordination for Low Voltage Circuit Breakers” to present short circuit

selective coordination data for various combinations of Schneider Electric low

voltage circuit breakers. They were determined by comparing the current let-

through of the downstream circuit breaker with the minimum instantaneous

trip characteristic of the upstream circuit breaker, taking into account

manufacturing tolerances. Thus the maximum level of selective coordination

was determined for various pairings of upstream and downstream circuit

breakers. Table 1 shows a table in 0100DB0501 for L-frame selectivity with

QO™ and E-frame circuit breakers shows the option for upstream circuit

breaker (PB2).

© 2013 Schneider Electric All Rights Reserved 9

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Table 1: Schneider Electric Selective Coordination Table for L-Frame Low-Voltage Circuit Breakers

Circuit Breaker Voltage

Current One-Line Diagram

Main Branch

QO(B0 10–60 A 18

QO(B)-H

L-W, 250 A 240 V

QO(B)-VH

70–125 A 10

QH

QO(B0

L-W, 400 A QO(B)-H

15–150 A 240 V 30

L-W, 600 A QO(B)-VH

QH

L-W, 250 A 240 V 30 kA

L-W, 400 A E-Frame 115-125 A

L-2, 600 A 480Y/277 30 kA

Based on the choices provided in Table 1, the new PowerPact L-W

400AF/125AT mission critical circuit breaker is selected. The circuit breaker

LG-W selectively coordinates with circuit breaker EGB up to 30 kA at 480 V,

which is higher than our available fault current of 11.857 kA. The LG-W

mission critical circuit breaker has the same circuit breaker curve as LG trip

5.3A shown in our example in Figures 8 and 9, on Pages 14 and 15,

respectively. The difference between L-Frame and L-Frame mission critical

lies in their tripping mechanism; the L-frame mission-critical circuit breaker

has an inherent 5 ms delay and, for high fault currents, operates on load-

side energy rather than peak current. This effectively allows the J- and

L-frame mission-critical circuit breakers to distinguish between load-side

faults and let-through currents of load-side circuit breakers operating on

faults. This energy-based tripping improves selectivity and has an arc flash

advantage in that clearing time is not different than other molded case

circuit breakers.

There is an additional data bulletin for transformer protection 0100DB0902 -

“Guide to Low Voltage Transformer Protection and Selective Coordination”

[2]. For a quick check Schneider Electric has an online selective

coordination tool: click here. It does up to three levels of total selectivity

look-up with user-input fault values or it can do simple fault calculations.

The next coordination issue exists between circuit breakers PB4 and PB2

with AFN. The online selective coordination tool is used for selecting circuit

breaker AFN as shown in the screenshots in Figures 6 and 7:

10 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

Figure 6: Screenshot of Schneider Electric Online Selective Tool

© 2013 Schneider Electric All Rights Reserved 11

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Figure 7: Result of Online Selectivity Tool for 3 Tier System

For this example the fault currents are manually filled in at three zones

starting with Zone 1 – 22.507 kA at SWBD, Zone 2 – 14.816 kA at PNL1 and

Zone 3 –11.857 kA at PNL2, as shown in Figure 6. Based on the available

fault current and circuit breaker types - EGB340 (PB4), LGUW3400-125AT

(PB2), there are two options for circuit breaker AFN – a) PG3400 and b)

PK3400, as shown in Figure 7. Both options selectively coordinate with

downstream circuit breakers up to 21.6 kA which is higher than our available

fault current at Zones 1 and 2. However, option a) is selected based on lower

short circuit withstand rating. The short circuit withstand rating of PG circuit

breaker at 35 kA is adequate for the available fault current of 22.507 kA at

Zone 1.

12 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

Table 2: Schneider Electric Selective Coordination Table for 400 A / 480 Vac Downstream Circuit Breaker

Downstream Circuit Breaker - Type/kAIR

Upstream Circuit Breaker

Maximum Level of Selective Coordination Shown in kA

Maximum LA- LH-

LA LH DG DJ LD LG LJ LL LC LE LX LI LXI PG PJ PL

Continuous MC MC

kAIR Type

Current

Rating 30 30 35 35 35 65 18 35 65 100 65 65 65 200 200 35 65 100

PG 21.6 21.6 21.6 21.6 35.0 35.0 18.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 21.6 21.6 21.3

35

RG 30.0 30.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0 35.0

NT-NH 1200 A 30.0 30.0 35.0 35.0 35.0 50.0 18.0 35.0 50.0 50.0 50.0 50.0 50.0 50.0 50.0 35.0 35.0 35.0

50

PK 21.6 30.0 35.0 35.0 35.0 50.0 18.0 35.0 50.0 50.0 50.0 50.0 50.0 50.0 50.0 21.6 21.6 21.6

NT-L1 1200 A 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0

1200 A

NW-N 2000 A 30.0 30.0 35.0 35.0 35.0 65.0 18.0 35.0 65.0 65.0 65.0 65.0 65.0 65.0 65.0 35.0 35.0 35.0

65 PJ 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0

RJ 30.0 30.0 35.0 35.0 35.0 65.0 18.0 35.0 65.0 65.0 65.0 65.0 65.0 65.0 65.0 35.0 40.8 40.8

RK 30.0 30.0 35.0 35.0 35.0 65.0 18.0 35.0 65.0 65.0 65.0 65.0 65.0 65.0 65.0 35.0 65.0 51.3

NT-L 1200 A 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0 9.0

The only circuit breaker which is lacking selectivity on the normal side is the

main circuit breaker SM1 in switchboard SWBD. Table 2 shows the table in

0100DB0501 for UL 480 Vac 400 A Selective Coordination. Based on

Table 2, PowerPact RG 1200AT is selected as the main circuit breaker SM1.

The RG circuit breaker has total selectivity with circuit breaker AFN-PG

400AT. With the help of Schneider Electric data bulletin 0100DB0501 and the

online selectivity tool, total selectivity is achieved for the normal side of the

system as shown in Figure 8.

© 2013 Schneider Electric All Rights Reserved 13

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Figure 8: Case 3 - TCC Graph for PNL2 Circuit Based on Normal Source Fault Current

After ensuring total selectivity for the normal side the emergency side of the

system is evaluated. When fed from an emergency source, the panel PNL2

has an available fault current of 6 kA which is lower than 11.857 kA from

normal source. Hence the devices selected for total selectivity for normal

source will continue to have total selectivity when fed from the generator.

Even though circuit breakers PB2 and PB4 have total selectivity amongst

14 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

themselves there is still cause for concern as circuit breaker AFE

(LA 400AT) still lacks coordination with PB2 and PB4 as shown in Figure 3

on Page 6. The selection process for AFE is simplified by using the same

circuit breaker as AFN. Both AFE and AFN are feeding the same load and

as stated above the emergency source has lower fault current, so that what

works for the normal side will continue to work for the emergency side.

Figure 9: Case 3 - TCC Graph for PNL2 Circuit Based on Emergency Source Fault Current

© 2013 Schneider Electric All Rights Reserved 15

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

The final coordination issues for the generator fed system are between

circuit breaker GM1 and downstream devices. In Figure 3 on Page 6, the

GM1 (PG 800AT) circuit breaker does not overlap with the downstream

circuit breakers. The same does not hold true after the upgrade of

downstream circuit breakers. We have to increase the short time and

instantaneous settings of GM1 in order to avoid mis-coordination at the

short time and instantaneous region. Figure 9 shows the new time current

coordination graph for the emergency side of the system having total

selectivity between the protective devices.

Arc Flash Analysis Arc flash analysis can be performed only after the protective devices have been

adjusted for best possible coordination. With the help of a computer analysis

through SKM Power Tools we are able to calculate the arc flash incident energy

and categories at each piece of equipment. This is the most efficient way to

calculate the incident energies and flash protection boundaries where multiple

sources exist which must be taken into account (such as generators and

motors). The SKM tool uses the National FIre Protection Association (NFPA)

70E 2012 Annex D.7 [3] and Institute of Electrical and Electronics Engineers®

(IEEE®) 1584 [4] standards to determine the incident energy and arc flash

boundaries.

An arc flash analysis was performed for both normal and emergency side of

the system with protective device settings as per

• Case 1 – Load-based coordination where devices are selected based on

typical thermal-magnetic trips for circuit breakers other than service

mains and prior to implementing NEC Article 100 requirement of

selective coordination.

• Case 2 – Selective coordination to 0.1 seconds and longer

• Case 3 – Total selective coordination

Based on the IEEE 1584 requirement for arc flash analysis both minimum

and maximum three phase fault current have been considered. Arcing

current is significantly lower than bolted current and based on typical

calculations it can be as low as 52% of bolted fault current at 480 V [5].

Hence, to expect that total selectivity achieved at maximum three phase

bolted current will yield optimized arc flash results at arcing current of

minimum three phase bolted current is not reasonable, as shown in Table 3.

Table 3 shows a comparison between the arc flash results for Case 1,

Case 2, and Case 3. From the table it is clear that, for a totally selectively

coordinated system, the incident energy levels are significantly higher for

the transfer switch 002L ATS, panels - 003 PNL1 and 004 PNL2. However,

the arc flash incident energy remained the same for most equipment in

Case 2 except for an increase in panel PNL1. The new instantaneous

settings in both the cases resulted in higher trip time for the protective

devices and thereby higher arc flash energy. This difference in incident

energy and risk category in Case 2 and 3, is one of the reasons for

preferring selective coordination to 0.1 seconds and longer, over, total

selectivity. The increase in arc flash energy may pose a greater threat to

personnel and could increase the amount of equipment damage in an arc

flash event.

16 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

Table 3: Arc Flash Comparison Table

Required Required Required

Arc Flash Incident Protective Arc Arc Flash Incident Protective Arc Arc Flash Incident Protective Arc

Bus Name Energy in cal/cm2 Rated Clothing Energy in cal/cm2 Rated Clothing Energy in cal/cm2 Rated Clothing

(Case 1) Characteristics (Case 2) Characteristics (Case 3) Characteristics

(Case 1) (Case 2) (Case 3)

001 GEN 12.44 Category 3 12.44 Category 3 12.44 Category 3

002L ATS 0.51 Category 0 0.51 Category 0 11.91 Category 3

003 PNL1 0.46 Category 0 9.80 Category 3 11.68 Category 3

004 PNL2 0.38 Category 0 0.62 Category 0 2.37 Category 1

005 SWBD 80.00 Dangerous 80.00 Dangerous 80.00 Dangerous

The arc flash incident energies of generator panel 001 GEN and main

switchboard 005 SWBD do not change. This is because the results for both

were based on maximum trip time of 2 seconds for all three cases. For the

rest of the equipment (ATS, PNL1 and PNL2), there is considerable

increase in incident energy as we go from load based coordination to

selective coordination at 0.1 seconds and above and finally to total selective

coordination. Hence, solely from an arc flash perspective, it is best to opt for

selective coordination to 0.1 seconds and longer.

Conclusion In order to ensure reliability as well as safe working conditions, optimized

selective coordination and arc flash mitigation have to work in tandem. The

NFPA has already taken a step in that direction through NFPA 99-2012 [6]

for health care facilities. NFPA 99-2012 requires that the essential electrical

system be coordinated to 0.1 seconds for all types of fault current generated

by the alternate source. In emergency, legally required, and critical

operation power systems, NFPA 110-2010 [7] requires that the OCPDs

feeding the automatic transfer switch(s) be selectively coordinated to the

extent practicable. The IEEE color books – Brown [8], Buff [9] and Orange

[10], recognize the difficulty in achieving these opposing goals, and

recommend selective coordination as far as practicable. The draft

International Electrotechnical Commission® (IEC®) technical report [11]

states that, “Selectivity over the whole range of fault current up to the

prospective fault current at the point of installation is not always possible or

necessary. A more economic solution may be found in many cases by

accepting a limited selectivity, particularly taking into account the low

probability of a high short-circuit fault current”.

Schneider Electric recognizes the importance of worker safety by reduced

incident energy and uninterrupted supply by improved selectivity, hence

extensive research has been done to ensure both, and improve OCPD

performance. One technique developed by Schneider Electric in each case

a) in practice and b) in process of finalization, is as follows:

A. Zone selective interlocking (ZSI) allows electronic trip devices to

communicate with each other so that a short-time trip or ground fault will

be isolated and cleared by the nearest upstream circuit breaker with no

intentional time delay. Devices in all other areas of the system (including

upstream) remain closed to maintain service to unaffected loads. Without

ZSI, a coordinated system results in the circuit breaker closest to the fault

clearing the fault, but usually with an intentional delay. With ZSI, the

device closest to the fault will ignore its preset short-time and/or ground

fault delays and clear the fault with no intentional delay. Zone-selective

interlocking eliminates intentional delay, without sacrificing coordination,

resulting in faster tripping times. This limits fault stress by reducing the

amount of let-through energy the system is subjected to during an

overcurrent. At low voltage (600 V and below), Schneider Electric

© 2013 Schneider Electric All Rights Reserved 17

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

MasterPact™ low-voltage power circuit breakers, offer increased arc-flash

protection due to faster clearing times, especially at higher current levels.

In addition to superior arc-flash protection inherent in their design,

MasterPact and PowerPact circuit breakers can be configured in a variety

of Zone Selective Interlocking schemes to further enhance protection with

no impact on selectivity. At higher voltages, SepamTM overcurrent relays

can also be applied in ZSI solutions. (AF protections using ZSI is achieved

only with the ST-ZSI option.)

Often ZSI is specified only within the main distribution board, though a

more likely location for a fault occurrence is on a feeder circuit leaving

the switchboard, or even lower in the system. To maximize the

protection offered by using ZSI, as many levels of the system as

possible need to be interlocked. This way, devices at the lower levels of

the system will trip without any intentional delay, when necessary,

without sacrificing coordination. This provides true selective coordination

and maximum protection against fault stress. Additionally in certain

areas of the system it is necessary to self-restrain a circuit breaker to

maintain the delay before tripping during a fault condition. This results in

the circuit breaker always introducing a time delay before tripping on a

short circuit or a ground fault (the time delay is always activated). Cases

where self-restraint should be applied are:

— The interlocked device is feeding a non-interlocked device

downstream (or a number of non-interlocked devices in a panel).

— A time delay is desired for short-circuit and/or ground-fault

occurrences (usually to avoid false tripping during transients and

inrushes).

— Minimal tripping time would compromise coordination.

For more information on ZSI and self-restraint refer to data bulletin

06000DB0001 [12].

B. Energy based discrimination – The new mission critical PowerPact J-

and L–frame circuit breakers developed by Schneider Electric have

energy based discrimination. The energy based method with its

consistency allows the line-side circuit breaker to effectively distinguish

between load-side faults and let-throughs of load-side circuit breakers

operating on faults further downstream. This method for achieving

selectivity uses supplemental trip systems in conjunction with specially

designed primary trip systems. The primary trip system will not trip

during the first half-cycle of a fault regardless of the fault current. The

intentional delay that allows the reflex tripping to see load-side energy

does not reduce overall clearing time, resulting in higher levels of

selective coordination without necessarily unleashing higher levels of

fault energy, including arc flash incident energy.

For more information on energy based tripping refer to papers [13] and

[14].

18 © 2013 Schneider Electric All Rights Reserved

0600DB1303 Selective Coordination vs Arc Flash Requirements

06/2013 White Paper

References [1] Short Circuit Selective Coordination for Low Voltage Circuit Breakers,

“0100DB0501R01/12-03/12”.

[2] Guide to Low Voltage Transformer Protection and Selective

Coordination, “0100DB0902R04/11-04/2011”.

[3] NFPA 70E-2012, Standard for Electrical Safety in the Workplace.

[4] IEEE Std. 1584-2002, IEEE Guide for Performing Arc-Flash Hazard

Calculations.

[5] Arc Flash Hazard Calculations: Myths, Facts, and Solutions, H. Wallace

Tinsley III, Michael Hodder, and Aidan M. Graham, IEEE Industry

Applications Magazine, Jan/Feb 2007, originally presented at the 2006

IEEE/IAS Pulp and Paper Industry Conference, pp. 59, 60.

[6] NFPA 99-2012, Health Care Facilities Code.

[7] NFPA 110-2010, Standard for Emergency and Standby Power Systems.

[8] IEEE Recommended Practice for Protection and Coordination of

Industrial and Commercial Power Systems, IEEE Std 242-2001 (Buff Book),

pp. 3-5, 607.

[9] IEEE Recommended Practice for Power Systems Analysis, IEEE Std

399-1990 (Brown Book), pp. 367.

[10] IEEE Recommended Practice for Emergency and Standby Power

Systems for Industrial and Commercial Applications, ANSI/IEEE Std 446-

1987 (Orange Book), pp. 175.

[11] Draft IEC/TR 61912-2 Ed.1.0: Low-voltage switchgear and controlgear

– Overcurrent protective devices – Selectivity under overcurrent conditions,

International Electrotechnical Commission, March 23, 2007, committee draft

updated after Copenhagen, pp. 11.

[12] Reducing Fault Stress with Zone-Selective Interlocking,

“0600DB0001R11/11-04/12”.

[13] Energy-based discrimination for low-voltage protective devices, Marc

Serpinet and Robert Morel, Cahier Technique n° 167, March 1998.

[14] Energy Based Tripping and Its Effect on Selective Coordination, John

Carlin & Josh Allen, Schneider Electric, May 2013.

© 2013 Schneider Electric All Rights Reserved 19

Selective Coordination vs Arc Flash Requirements 0600DB1303

White Paper 06/2013

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

Schneider Electric USA, Inc. consequences arising out of the use of this material.

1415 S. Roselle Road © 2013 Schneider Electric All Rights Reserved

Palatine, IL 60067 USA Schneider Electric, Square D, PowerPact are trademarks owned by Schneider

1-888-778-2733 Electric Industries SAS or its affiliated companies. All other trademarks are the

www.schneider-electric.us property of their respective owners.

20

Вам также может понравиться

- AAA-SKM-Overcurrent Coordination Basic TransformerДокумент5 страницAAA-SKM-Overcurrent Coordination Basic TransformerJOSE LUIS FALCON CHAVEZОценок пока нет

- ELR-517.16 Use of Isolated Ground ReceptaclesДокумент3 страницыELR-517.16 Use of Isolated Ground ReceptaclesJOSE LUIS FALCON CHAVEZОценок пока нет

- ELECTRICAL KNOWHOW-Power and Distribution Transformers Sizing CalculationsДокумент89 страницELECTRICAL KNOWHOW-Power and Distribution Transformers Sizing CalculationsJOSE LUIS FALCON CHAVEZ100% (1)

- Sti-Art 342 Intermediate Metal Conduit (Imc)Документ2 страницыSti-Art 342 Intermediate Metal Conduit (Imc)JOSE LUIS FALCON CHAVEZОценок пока нет

- ANSI C84-1-Tabla de VoltajesДокумент1 страницаANSI C84-1-Tabla de VoltajesJOSE LUIS FALCON CHAVEZОценок пока нет

- UL-Understanding Ground Fault and Leakage Current ProtectionДокумент3 страницыUL-Understanding Ground Fault and Leakage Current ProtectionJOSE LUIS FALCON CHAVEZОценок пока нет

- Sti-Art 358 Electrical Metallic Tubing (Emt)Документ2 страницыSti-Art 358 Electrical Metallic Tubing (Emt)JOSE LUIS FALCON CHAVEZОценок пока нет

- ANESKEY-Lightning and Electrical InjuriesДокумент7 страницANESKEY-Lightning and Electrical InjuriesJOSE LUIS FALCON CHAVEZОценок пока нет

- Caterpillar-Diesel Generator Set-Continuos PDFДокумент6 страницCaterpillar-Diesel Generator Set-Continuos PDFJOSE LUIS FALCON CHAVEZОценок пока нет

- Electricians Exam Preparation Guide 8th Edition by Dale C Brickner and John E Traister PDFДокумент355 страницElectricians Exam Preparation Guide 8th Edition by Dale C Brickner and John E Traister PDFJOSE LUIS FALCON CHAVEZ100% (5)

- Power Distribution SystemДокумент120 страницPower Distribution SystemSagar ThotaОценок пока нет

- MERCK MANUAL-Electrical InjuriesДокумент6 страницMERCK MANUAL-Electrical InjuriesJOSE LUIS FALCON CHAVEZОценок пока нет

- GE Arc Flash GuideДокумент26 страницGE Arc Flash GuideJOSE LUIS FALCON CHAVEZОценок пока нет

- CPA-Arc Flash Protection-ASTM 1506-NFPA 70EДокумент16 страницCPA-Arc Flash Protection-ASTM 1506-NFPA 70EJOSE LUIS FALCON CHAVEZОценок пока нет

- ASTM B416 98 R02 Concentric Lay Stranded Aluminum Clad Steel Conductors1Документ4 страницыASTM B416 98 R02 Concentric Lay Stranded Aluminum Clad Steel Conductors1JOSE LUIS FALCON CHAVEZОценок пока нет

- Iaei-Arc Flashes The Unseen Danger-May20Документ8 страницIaei-Arc Flashes The Unseen Danger-May20JOSE LUIS FALCON CHAVEZОценок пока нет

- GE - 240.87 Arc Energy Reduction-NEC 2014Документ16 страницGE - 240.87 Arc Energy Reduction-NEC 2014JOSE LUIS FALCON CHAVEZОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Xian XD Electric: Engineering Co.,LtdДокумент24 страницыXian XD Electric: Engineering Co.,LtdAneelОценок пока нет

- FLYGT BS - 2630-180 PUMP Operation ManualДокумент60 страницFLYGT BS - 2630-180 PUMP Operation Manualskatanthropos2492100% (1)

- QED2Документ48 страницQED2Amruta MotkaОценок пока нет

- Catalogo OrbitДокумент60 страницCatalogo OrbitrosselyОценок пока нет

- Operations Manual MCL TWTA 350W Ku Band Model MX3000Документ90 страницOperations Manual MCL TWTA 350W Ku Band Model MX3000andersonbheringОценок пока нет

- Teorie PROTECTIIДокумент177 страницTeorie PROTECTIIbdsrlОценок пока нет

- NA016 Manual 08 2010 PDFДокумент68 страницNA016 Manual 08 2010 PDFMarian AriciucОценок пока нет

- Tram Kios TCS ZA IA en 10Документ40 страницTram Kios TCS ZA IA en 10Hồ ThànhОценок пока нет

- Espresso Maker Iacobucci CMM 25-34-61 Rev - e Cc3347Документ108 страницEspresso Maker Iacobucci CMM 25-34-61 Rev - e Cc3347Nikolaos KechagiasОценок пока нет

- ABB 4028enДокумент4 страницыABB 4028enThangco HutОценок пока нет

- Plano Electrico m313c 2Документ4 страницыPlano Electrico m313c 2Krippy Kush100% (1)

- Catalogo de EnclavamientosДокумент48 страницCatalogo de EnclavamientosReynaldo GrantОценок пока нет

- E-03 Main Switch BoardДокумент116 страницE-03 Main Switch BoardJay TandelОценок пока нет

- Schneider EZC MCCB PDFДокумент13 страницSchneider EZC MCCB PDFSebastian WenasОценок пока нет

- Supply Program: Traction Power SystemsДокумент8 страницSupply Program: Traction Power SystemsRadhes Simatupang SianturiОценок пока нет

- 182 03 - 629DДокумент13 страниц182 03 - 629DAhmedОценок пока нет

- Data Sheet 6320 AisДокумент139 страницData Sheet 6320 Aisshahramkh59Оценок пока нет

- Switchgear SpecificationsДокумент29 страницSwitchgear SpecificationsNandkumar ChinaiОценок пока нет

- Overall Pee Ter CombinedДокумент509 страницOverall Pee Ter CombinedRyan Anthony Umali100% (2)

- FOX61x-Precautions and Safety-1KHW002474Документ10 страницFOX61x-Precautions and Safety-1KHW002474CESAR PEREZОценок пока нет

- Cable Sizing ExamplesДокумент27 страницCable Sizing Examplespartha_gang4526Оценок пока нет

- Fuji Electric Frn15ar1m-4aДокумент58 страницFuji Electric Frn15ar1m-4anhân thành100% (1)

- P50 Agile: GE Grid SolutionsДокумент268 страницP50 Agile: GE Grid SolutionsPrasenjit MaityОценок пока нет

- KPS Industrial BrochureДокумент24 страницыKPS Industrial Brochure45164516Оценок пока нет

- Manual Unidad PrecalentadoraДокумент23 страницыManual Unidad PrecalentadoraEliecerОценок пока нет

- DM1 AДокумент34 страницыDM1 AgonzalohghОценок пока нет

- Safty StandardsДокумент42 страницыSafty StandardsKrishan Kumar SharmaОценок пока нет

- 3VL New ETU BrochureДокумент6 страниц3VL New ETU BrochureManu PillaiОценок пока нет

- Lodestar CL25 Faulted Circuit Indicator: Lodestar CL25 - A Simple Solution in Terms of The PowerДокумент2 страницыLodestar CL25 Faulted Circuit Indicator: Lodestar CL25 - A Simple Solution in Terms of The PowerRosa TipactiОценок пока нет

- PreviewpdfДокумент26 страницPreviewpdfjigyesh29Оценок пока нет