Академический Документы

Профессиональный Документы

Культура Документы

The Falcon, From Stolt Comex Seaway To GSP - Multi-Lay

Загружено:

Dak KaizОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Falcon, From Stolt Comex Seaway To GSP - Multi-Lay

Загружено:

Dak KaizАвторское право:

Доступные форматы

The Falcon, from Stolt Comex Seaway to GSP

A Reel Lay System with Firing Line

deepLay-eks-2020-078 deepLay, June 2020

The Falcon, from Stolt Comex Seaway to GSP

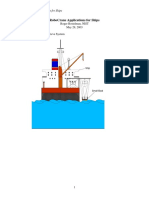

Seaway Falcon

The Seaway Falcon is a Rigid

and Flexible Lay Vessel, with

Tiltable J-Lay Tower on the stern

for Rigid Pipeline and Vertical

Lay System on the midship

through a moonpool.

She can store 2000te of pipe on

board and 1600te of Flexible

flowline and umbilical. A deck

mounted reel can also be

deployed for the piggyback line.

Picture source refers to https://www.offshore-technology.com/projects/scarab/

The Falcon, from Stolt Comex Seaway to GSP

GSP Falcon

From the above pictures, it shows that GSP removed the Vertical Flex-Lay System and changed the

Seaway Falcon crane to a Knuckle Boom type of Crane.

Picture source refers to https://www.balticshipping.com/vessel/imo/7409401

The Falcon, from Stolt Comex Seaway to GSP

Seaway Falcon

Vertical Lay

Deck Radius Controller

Ramp Radius Controller

System

Deck Tensioner

Weld Station area Weld Station area

Carousel

Moon pool Pipe Storage Area Under Deck

Piggyback Reel

Lay Tower

Pipe Storage at Deck

Pictures / images are presented for illustration purposes only.

The Falcon, from Stolt Comex Seaway to GSP

deepLay notes

Generally, Reel-Lay vessel is the most economical pipelay system. The vessel comes to spoolbase, spool-

on the pipe and go to the field and lay the pipe but when the pipeline length is longer than reel capacity,

the Reel-Lay vessel needs to go back to spoolbase for the next spooling-on trip. And if spoolbase is far

from the installation field, the travelling time will incur high cost to overall installation campaign.

However, the beauty of "Falcon" is to install the pipeline like J-Lay Reel Vessel along with firing line

welding stations like S-Lay. Even if the spoolbase is far from the field and/or the Spooling Trips is more

than a single trip, the Falcon is more economical than any general Reel-Lay Vessel.

Falcon is a very successful installation vessel during Stolt Comex Seaway, Stolt Offshore and Acergy. She

has been sold to GSP, and since then her works on Reel-Lay installation has become unknown.

The Reel-Lay pipeline installation work requires an experienced offshore team to cooperate with the

onshore engineering team; without those reliable and seamless supports, it will be difficult for the vessel to

win jobs and to execute them.

THANK YOU

Please kindly refer to deepLay Energy

LinkedIn post to retrieve the full presentation.

http://www.linkedin.com/company/deeplay-energy-services/

Вам также может понравиться

- L07 - RisersДокумент31 страницаL07 - RisersU Kyaw Kyaw Naing100% (4)

- L01 - Introduction To SPS PDFДокумент39 страницL01 - Introduction To SPS PDFariful islamОценок пока нет

- L1 - FPSO IntroductionДокумент32 страницыL1 - FPSO IntroductionZulkamal RoseleyОценок пока нет

- By/ Geo - Mohamed M.HamdyДокумент43 страницыBy/ Geo - Mohamed M.HamdyMax OdehОценок пока нет

- Jitorres - 2. Sistema de ElevaciónДокумент44 страницыJitorres - 2. Sistema de ElevaciónYulieth Vanessa Ayala FerreiraОценок пока нет

- Capability Sheet: A Seagoing Selfpropelled Vessel With A FallpipeДокумент2 страницыCapability Sheet: A Seagoing Selfpropelled Vessel With A Fallpipefandy sipataОценок пока нет

- L03 - Drilling & Subsea WellheadДокумент23 страницыL03 - Drilling & Subsea WellheadU Kyaw Kyaw Naing100% (4)

- RoboCrane For ShipsДокумент25 страницRoboCrane For ShipsaliОценок пока нет

- Understanding Api 4f StructuresДокумент16 страницUnderstanding Api 4f StructuresGordan KanižajОценок пока нет

- Understanding Heavy Lifting and Transportation Equipment, Processes, and CalculationsДокумент36 страницUnderstanding Heavy Lifting and Transportation Equipment, Processes, and CalculationszmahfudzОценок пока нет

- C04 Cable Way Installations eДокумент4 страницыC04 Cable Way Installations eAida TeskeredžićОценок пока нет

- Seismic Performance of Wall-type RC Bridge Piers Retrofitted with AFRPДокумент7 страницSeismic Performance of Wall-type RC Bridge Piers Retrofitted with AFRPSanjay ShelarОценок пока нет

- Naval Terms and PhraseologiesДокумент20 страницNaval Terms and PhraseologiesTALINGDAN, AGNER CHRISTIAN FULGENCIO0% (1)

- Flexible - Cable - Hitachi CARДокумент11 страницFlexible - Cable - Hitachi CARMIKELAM09Оценок пока нет

- Flexible Cable CatalogДокумент48 страницFlexible Cable Catalogachmad maulanaОценок пока нет

- Texas Deck PDFДокумент12 страницTexas Deck PDFanon_766233880Оценок пока нет

- The Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationДокумент9 страницThe Performance and Service Life of Wire Ropes Under Deep Koepe and Drum Winders Conditions - Laboratory SimulationRicardo Ignacio Moreno MendezОценок пока нет

- Russian Docking Compartment and Airlock PirsДокумент1 страницаRussian Docking Compartment and Airlock PirsBob Andrepont100% (1)

- 4.RC Precast Plank & Joist: 1.precast RC Filler Slab 3.precast RC Waffle SlabДокумент9 страниц4.RC Precast Plank & Joist: 1.precast RC Filler Slab 3.precast RC Waffle SlabDhanashri MirajkarОценок пока нет

- Precast RC Plank & Joist roofing systemДокумент2 страницыPrecast RC Plank & Joist roofing systemDhanashri MirajkarОценок пока нет

- Planning of Hydropower ProjectsДокумент66 страницPlanning of Hydropower ProjectsSivaganesan S100% (1)

- Understanding General Cargo Ships and Bulk CarriersДокумент78 страницUnderstanding General Cargo Ships and Bulk CarriersJais100% (1)

- Ship Terms and Definitions: © C.G.DaleyДокумент22 страницыShip Terms and Definitions: © C.G.DaleyAjesh mohanОценок пока нет

- Unit 4 Weirs and Barrages: StructureДокумент7 страницUnit 4 Weirs and Barrages: StructureBobbyОценок пока нет

- Ship TermsДокумент22 страницыShip TermsKarin Setia MuktiОценок пока нет

- Hydrosphere's Jetty Mast Systems for Navigation LightsДокумент2 страницыHydrosphere's Jetty Mast Systems for Navigation LightsbenОценок пока нет

- L06 - Pipelines & FlowlinesДокумент26 страницL06 - Pipelines & FlowlinesU Kyaw Kyaw Naing100% (7)

- Pipelay Equipment FamiliarisationДокумент49 страницPipelay Equipment Familiarisationisidoro VillarrealОценок пока нет

- Kim Lighting VRB Series Vandal Resistant Bollard Brochure 1996Документ12 страницKim Lighting VRB Series Vandal Resistant Bollard Brochure 1996Alan MastersОценок пока нет

- GA of DifFERENT VESSELSДокумент9 страницGA of DifFERENT VESSELSসৌরভОценок пока нет

- Chaper Three 1Документ22 страницыChaper Three 1natiz addisОценок пока нет

- 1914 - ImperatorДокумент11 страниц1914 - ImperatorTom BatesОценок пока нет

- Internal Floating Roof VesselДокумент2 страницыInternal Floating Roof Vesselumair saeed100% (1)

- DeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveДокумент13 страницDeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveGunawan SuwarnoОценок пока нет

- Design of Slab BridgeДокумент17 страницDesign of Slab BridgeAYUSH PARAJULIОценок пока нет

- ANCHOR and CABLEДокумент16 страницANCHOR and CABLEMitanshu Chadha100% (1)

- Pump StationsДокумент1 страницаPump StationswpsbОценок пока нет

- Arch Bridge ConstructionДокумент8 страницArch Bridge Constructionjim1893Оценок пока нет

- Anchor WorkДокумент9 страницAnchor WorkAman Chawla100% (1)

- OffshoreДокумент3 страницыOffshorelaleye_olumideОценок пока нет

- En Seilwinden 170301 KIS ScreenДокумент24 страницыEn Seilwinden 170301 KIS ScreenDEBAPRIYA GOSWAMIОценок пока нет

- Components of Hydropower Projects DesignsДокумент127 страницComponents of Hydropower Projects DesignsNoli CorralОценок пока нет

- Advanced Dam Engineering 08 (219-255)Документ37 страницAdvanced Dam Engineering 08 (219-255)chandra adriawanОценок пока нет

- Tweet TutorialДокумент1 страницаTweet TutorialFILE 1131Оценок пока нет

- PC TutorialДокумент1 страницаPC TutorialFILE 1131Оценок пока нет

- Cable Stayed BridgeДокумент9 страницCable Stayed BridgeJassimar SinghОценок пока нет

- LWR From SWRДокумент18 страницLWR From SWRdeepakОценок пока нет

- Kasawari PL - SowДокумент102 страницыKasawari PL - SowRaphael Owusu kyeremateng100% (2)

- Movable Span Structures BridgeДокумент8 страницMovable Span Structures BridgeAnish TayadeОценок пока нет

- CALM Buoy: For The The Western Libyan Gas Project Wafa PlantДокумент4 страницыCALM Buoy: For The The Western Libyan Gas Project Wafa PlantGОценок пока нет

- Performance: Palfinger Advanced Package As Standard!Документ4 страницыPerformance: Palfinger Advanced Package As Standard!Joel VillalbaОценок пока нет

- Design of Slab BridgeДокумент20 страницDesign of Slab BridgeAshish Karki82% (11)

- Webinar FX Supartono Aerodynamic 2021-06-03Документ136 страницWebinar FX Supartono Aerodynamic 2021-06-03FX SupartonoОценок пока нет

- Pipe Sticks SupportДокумент8 страницPipe Sticks SupportAmitОценок пока нет

- SPX POWER TEAM FC 2200 4400lbs MOBILE FLOOR CRANEДокумент1 страницаSPX POWER TEAM FC 2200 4400lbs MOBILE FLOOR CRANELLuis Alberto PintoОценок пока нет

- Rigless Well Abandonment: Cutting Costs Through TechnologyДокумент32 страницыRigless Well Abandonment: Cutting Costs Through TechnologyRizwan FaridОценок пока нет

- Offshore Drilling Rig EquipmentДокумент51 страницаOffshore Drilling Rig EquipmentZeeshan SharifОценок пока нет

- Hopper Discharge Systems PDFДокумент8 страницHopper Discharge Systems PDFcachorrexОценок пока нет

- Hull Inspection Course: Reporting Findings and ConditionsДокумент17 страницHull Inspection Course: Reporting Findings and ConditionsG.O.D 7Оценок пока нет

- SSFI Tech Bulletin - Standards That Apply To ShoringДокумент1 страницаSSFI Tech Bulletin - Standards That Apply To ShoringDak KaizОценок пока нет

- Read MeДокумент1 страницаRead MeAulia AnnisaОценок пока нет

- ETPM Deepsea Norlift Reel-Lay Vessel HistoryДокумент6 страницETPM Deepsea Norlift Reel-Lay Vessel HistoryDak KaizОценок пока нет

- CV Yohana Felicia Candra PDFДокумент1 страницаCV Yohana Felicia Candra PDFDak KaizОценок пока нет

- Design Manual Fixed PDFДокумент7 страницDesign Manual Fixed PDFDak KaizОценок пока нет

- 02 - Freyssinet Webinar2 - Reinforced Earth Indonesia - Dewi Zuhari - 250620 PDFДокумент76 страниц02 - Freyssinet Webinar2 - Reinforced Earth Indonesia - Dewi Zuhari - 250620 PDFDak KaizОценок пока нет

- Notes Design Process PDFДокумент11 страницNotes Design Process PDFDak KaizОценок пока нет

- ETPM Deepsea Norlift Reel-Lay Vessel HistoryДокумент6 страницETPM Deepsea Norlift Reel-Lay Vessel HistoryDak KaizОценок пока нет

- Marine & Offshore Rules, Rule Notes and Guidance NotesДокумент6 страницMarine & Offshore Rules, Rule Notes and Guidance NotesDak KaizОценок пока нет

- LEEA Foundation Certificate - Refresher DaysДокумент1 страницаLEEA Foundation Certificate - Refresher DaysDak KaizОценок пока нет

- SPM Operations Maintenance Manual Issue 3Документ16 страницSPM Operations Maintenance Manual Issue 3George Van BommelОценок пока нет

- Jis G4051Документ7 страницJis G4051tnchsgОценок пока нет

- Arbrit TrainingCalendar PDFДокумент1 страницаArbrit TrainingCalendar PDFDak KaizОценок пока нет

- External Training Calendar 2020 PDFДокумент1 страницаExternal Training Calendar 2020 PDFDak KaizОценок пока нет

- Arbrit TrainingCalendar PDFДокумент1 страницаArbrit TrainingCalendar PDFDak KaizОценок пока нет

- Fac-Simile CV - Eng 0Документ1 страницаFac-Simile CV - Eng 0Dak KaizОценок пока нет

- ETPM Deepsea Norlift Reel-Lay Vessel HistoryДокумент6 страницETPM Deepsea Norlift Reel-Lay Vessel HistoryDak KaizОценок пока нет

- Indonesian fib-YMG Webinar Series-III PDFДокумент3 страницыIndonesian fib-YMG Webinar Series-III PDFDak KaizОценок пока нет

- How To Deal With The Annoying Quot Hot Spots Quot in Finite Element AnalysisДокумент7 страницHow To Deal With The Annoying Quot Hot Spots Quot in Finite Element AnalysisDak KaizОценок пока нет

- Chap2 - Nonlinear FEA ProceduresДокумент29 страницChap2 - Nonlinear FEA ProceduresRaymond ChanОценок пока нет

- Lampiran IДокумент95 страницLampiran IDak KaizОценок пока нет

- Ps5instructions PDFДокумент1 страницаPs5instructions PDFDak KaizОценок пока нет

- No Lineal Introduction PDFДокумент32 страницыNo Lineal Introduction PDFBenhjaОценок пока нет

- Chapter 5Документ428 страницChapter 5YONAS GOSAОценок пока нет

- 0 4811 1Документ36 страниц0 4811 1Lasantha DadallageОценок пока нет

- Career Objective:: Ahmed Mohammed Ibrahim Mosa - El-Qanater, Qalyubiamob: 01140644111Документ2 страницыCareer Objective:: Ahmed Mohammed Ibrahim Mosa - El-Qanater, Qalyubiamob: 01140644111Dak KaizОценок пока нет

- Chap2 - Nonlinear FEA ProceduresДокумент29 страницChap2 - Nonlinear FEA ProceduresRaymond ChanОценок пока нет

- Problem Set 8: 13.122 Ship Structural Design and AnalysisДокумент2 страницыProblem Set 8: 13.122 Ship Structural Design and AnalysisDak KaizОценок пока нет

- Fac-Simile CV - Eng 0Документ1 страницаFac-Simile CV - Eng 0Dak KaizОценок пока нет

- Christopher Taylor - The Real GhostДокумент11 страницChristopher Taylor - The Real GhostVagner AlmeidaОценок пока нет

- Activity No. 7 Film: Cri227L (253) Forensic PhotographyДокумент2 страницыActivity No. 7 Film: Cri227L (253) Forensic PhotographyPotpot LacedaОценок пока нет

- Probably FRAGMENT - The - Emperor-Frederick - ForsythДокумент15 страницProbably FRAGMENT - The - Emperor-Frederick - ForsythchamniezbuntowanyОценок пока нет

- Shimano 2015 ExportДокумент212 страницShimano 2015 Export123anthonyОценок пока нет

- Money Honey Slot Machine Operating InstructionsДокумент20 страницMoney Honey Slot Machine Operating InstructionsPhilОценок пока нет

- Ryobi 2079r Trimmer ManualДокумент24 страницыRyobi 2079r Trimmer ManualJoe SheldoneОценок пока нет

- ShopNotes Issue 41 PDFДокумент32 страницыShopNotes Issue 41 PDFbenignoОценок пока нет

- LAKES AND DAMSДокумент6 страницLAKES AND DAMSSaad Ahmed KhawajaОценок пока нет

- The Louisiana Conservationist Second Quarter 1979Документ32 страницыThe Louisiana Conservationist Second Quarter 1979SusanОценок пока нет

- HSE sheet on winding machine safetyДокумент6 страницHSE sheet on winding machine safetyOsmar JrОценок пока нет

- Daiwa Tanacom Bull 1000 Operating ManualДокумент38 страницDaiwa Tanacom Bull 1000 Operating Manualffbss29871% (7)

- EMI 400 250 Ton Instalation GuideДокумент84 страницыEMI 400 250 Ton Instalation GuideDaniel VillarroelОценок пока нет

- Manual Daiwa Tanacom 500 PDFДокумент37 страницManual Daiwa Tanacom 500 PDFHenrique BelliniОценок пока нет

- Catalog Sportex 2010Документ44 страницыCatalog Sportex 2010Romeo CismasОценок пока нет

- Dam2020 PDFДокумент348 страницDam2020 PDFJspinmasterОценок пока нет

- Byasghat and Brigadier ChakrabortyДокумент9 страницByasghat and Brigadier ChakrabortySubroto MukerjiОценок пока нет

- Engineering Vol 69 1900-05-25Документ31 страницаEngineering Vol 69 1900-05-25ian_newОценок пока нет

- Gunki Fishing RodsДокумент9 страницGunki Fishing RodspikemanserbiaОценок пока нет

- Winder Two DrumДокумент13 страницWinder Two Drumavandetq15Оценок пока нет

- Millermatic 350 and Millermatic 350P: Eff w/LC447907 Thru LE443589Документ43 страницыMillermatic 350 and Millermatic 350P: Eff w/LC447907 Thru LE443589Erick VargasОценок пока нет

- Ipt - 2005 PDFДокумент669 страницIpt - 2005 PDFصباح صالح سليمانОценок пока нет

- Deepwater Riser InstallationДокумент9 страницDeepwater Riser InstallationekhwanhakimОценок пока нет

- Instruction Manual: TCR - MC TypeДокумент20 страницInstruction Manual: TCR - MC TypeKhaled RabeaОценок пока нет

- ADSS Fiber Cable Install GuideДокумент15 страницADSS Fiber Cable Install GuidecostelchelariuОценок пока нет

- 440 Cable Pulling Capstan Winches, Cable FeedersДокумент21 страница440 Cable Pulling Capstan Winches, Cable FeedersKlanac BrčkoОценок пока нет

- (1918) Picture Taking With The Brownie CameraДокумент68 страниц(1918) Picture Taking With The Brownie CameraHerbert Hillary Booker 2nd100% (1)

- MaintenanceДокумент442 страницыMaintenancetkamhlanga001Оценок пока нет

- Application of HydraulicsДокумент7 страницApplication of HydraulicsalfborbrОценок пока нет

- KomplettДокумент68 страницKomplettMirela OprisanОценок пока нет

- SURF FISHING For BeginnersДокумент7 страницSURF FISHING For BeginnersharryumolyОценок пока нет