Академический Документы

Профессиональный Документы

Культура Документы

Paca - Lift: Winding Drum Residential Elevator

Загружено:

Agnelo FernandesОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Paca - Lift: Winding Drum Residential Elevator

Загружено:

Agnelo FernandesАвторское право:

Доступные форматы

PACA - LIFT WINDING DRUM RESIDENTIAL ELEVATOR

Series 018

CAPACITY - 1,000 lb. ELECTRIC SUPPLY - 208 or 230 volts, single phase.

A separate 120-volt circuit is required for car

CAR SIZE - Maximum of 15 sq. ft. lighting, 208 requires buck boost

TRAVEL - up to 50 ft. DRIVE - variable speed frequency control for

controlled acceleration and deceleration

STOPS - up to 5 stops CONTROLS - fully automatic at car and landings,

car light switch with auto light time out,

NOMINAL SPEED - 40 feet per minute emergency light, in-use indicator at landings,

position indicator in car, field programmable,

PIT DEPTH - 8” minimum pit required homing feature, modular car wiring, digitally

addressed hoistway wiring

OVERHEAD - 12” minimum overhead clearance SIGNAL SYSTEMS - wall mount phone jack,

required above the car’s inside dimension height emergency alarm

GUIDE RAIL - Two 3/16” steel MACHINE LOCATION - multiple remote

J-channel rails with 21” in be- locations

tween

for a very smooth and stable HOISTWAY DOOR INTERLOCKS - required at

ride each landing

MOTOR - inverter controlled, 3 CONTROLLER LOCATION - remote location

HP outside of hoistway, locked control box

GEARBOX - high ratio, direct

EMERGENCY LOWERING - manual hand wheel

mounted and coupled

and battery powered emergency lowering

DRUM - single drum with out-

board bearing CAR - Frameless car with power accordion gate

standard

BRAKE - electrically released,

spring applied ADDITIONAL OPTIONS -

are available, for

SLACK CABLE/BROKEN ROPE - twin details contact your

instantaneous, broken and slack cable local dealer.

applied by retained compression spring

CABLE - two 3/8” 8 x 19 steel cables

ky

P ac

rm

Th

e

Wa de

TH

u p aca PA

N Y

EW

A U PA C OM

C A E L E V AT O R

2/12 1726 N. Ballard Road - Appleton, WI 54911 - 1-800-238-8739 - 920-991-9082 - www.waupacaelevator.com

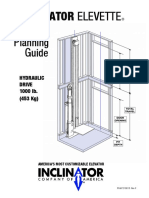

Planning Guide

Paca-Lift

Elevator

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.1

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.2

We are a proud member of the Accessibility Equipment Manufacturers

Association. This symbol assures you of our commitment to high quality

and accessibility to everyone.

Waupaca Elevator Mission Statement

Our company’s mission is to supply and service products that meet or

exceed our customers’ expectations of high quality, value, delivery and

longevity. Our success is a direct reflection of our employees’ involve-

ment and commitment to excellence. We strive to continuously improve

our products to ensure meeting the future requirements of our custom-

ers and facilitate competitive growth.

CSI 3-Part Specifications

Customize and download CSI 3-Part Specifications by logging on to:

www.arcat.com - specify Waupaca Elevator as the requested manufacturer

www.waupacaelevator.com - go to “Architect Section” click on linking icon

SpecWizard is a faster easier way to customize CSI 3-part residential elevator

specifications. Follow the above website information and choose the Spec

Wizard icon. The drop down menus couldn’t be any easier to use, just click

on your choice of listed options and within a couple of minutes you have a

completely customized specification.

Table of Contents

Introduction ......................................................................................................... 4

Minimum and Maximum Dimensions ........................................................ 6

Car Opening Configurations .......................................................................... 6

Hoistway Layout ..............................................................................................7-9

Hoistway Illustration .......................................................................................10

Hoistway Specifications .................................................................................11

Ceiling Height and Elevation........................................................................12

Controller/Electrical Space ...........................................................................13

Elevator Equipment .........................................................................................14

Elevator Series 018 ...........................................................................................15

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.3

Introduction

This Planning Reference Guide is to be used as a guide to determine parameters

of installation and steps taken to achieve a proper elevator installation. This

guide may be used by the architect, contractor, dealer or home owner. The

information in this guide is intended as an overview, each installation will have

job specific specifications that must be followed. Do not attempt to construct

a hoistway on this information alone.

Elevator installation is to be done by an authorized elevator contractor, and

in accordance with installation instructions provided by the manufacturer.

Installation must also be in compliance with requirements of the National

Electric Code, American Society of Mechanical Engineers safety code, and

state and local building codes. Waupaca Elevator’s products are designed to

meet the requirements of ASME - 17.1 National Elevator Codes for residential

elevators and are fully certified by a registered professional engineer. Waupaca

Elevator Company, Inc. elevators manufactured and installed under the proper

parameters are warranted for 2 years. Manufacturer assumes no liability for

equipment not installed in compliance with these codes.

Planning Steps

1. - Locate local dealer and together determine the following:

A - Select drive system, car type and design specifications

B - Address national, state and local code requirements

C - Hoistway size

D - Car size, layout and options

E - Machine room location and layout

F - Electrical requirements

2. - Obtain and follow site specific field drawings while building hoistway,

doorways and any other construction related to the elevator.

3. - Coordinate with dealer to install elevator.

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.4

Paca-Lift

Winding Drum Elevator

Series 018

Advantages

• Limited Machine Room Space

• Decreased Installation Time

• Advanced Fieldbus Electrical System

• Reliable

• Quiet Operation

• Smooth Ride

• Emergency Battery Descent

• Automatic Gate Operator

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.5

Hoistway Layout - Paca-Lift

Minimum and Maximum Dimensions

Finished

Hoistway

53-1/2" Minimum

67" Maximum

2" 2"

7-3/4"

* Single Opening - 42 - 3/4” O.D.

Finished D A

Hoistway * 49-1/2" O.D. Min. (outside dimension) minimum

43-3/4" Minimum (** 63" O.D. Max.)

61-3/4" Maximum (rail is not centered in hoistway)

32" O.D. Min.

(50" O.D. Max.) ** Single Opening - 62-1/2” O. D.

C B (outside dimensions) maximum

4-1/2"

NOTE: 1) Minimum D A dimensions reflect rail centered in hoistway

2) Minimum D A dimension for car without a gate recess is 36” O.D.

(outside dimension)

3) Car I.D. (inside dimensions) can not exceed 15 sq. ft. for 1,000 lbs.

Car Opening Configurations and Coding

RAIL RAIL RAIL

Left Same Side Right Same Side Front

Opening Opening Opening

CODE 1 CODE 2 CODE 3

RAIL RAIL RAIL

Opposite Right Adjacent Left Adjacent

Openings 90° Openings 90° Openings

CODE 4 CODE 5 CODE 6

1- The D A is the side on which the rail is mounted.

RAIL

2 - The first letter refers to the attachment location of the gate.

D A

3 - The second letter refers to the location of the strike plate.

C B 4 - If present, the third letter “R” denotes a recessed gate.

Example: ABR DCR

D A

Opposite First Gate - ABR Second Gate - DCR

Openings A- gate attachment D - gate attachment

ABR DCR

C B B - strike plate C - strike plate

R - recessed gate R - recessed gate

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.6

Hoistway Layout - Paca-Lift

• Use specified rail backing from architect to frame into wall.

• Hoistways illustrations below show finished dimensions. Finished hoistway

dimensions include drywall, plaster and paint.

• A maximum of 3” (see “g” below) are allowed between the closed hoistway door

and the outer edge of the landing sill.

• Determine height of hall station by local code.

• Rough frame door in place with an extra inch of space on each side of the door

to allow for door installation.

The following examples are of a 1,000 lb. unit. Elevators are illustrated with

accordion gates.

These symbols are listed beside the car size Waupaca Elevator believes to be best

suited for use by wheelchair passengers and their accompanying attendant.

Recommended size for wheelchair passenger

Recommended size for both wheelchair and attendant passengers

DCR CDR

LEFT SAME SIDE OPENING LEFT SAME SIDE OPENING

CODE 1 CODE 1

b b

c c

d d

e e

D A D A

h

a g i a

f i f

g h

C B C B

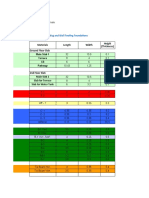

ELEVATOR PACA LIFT ELEVATOR HOISTWAY DIMENSIONS

HOISTWAY FINISHED HOISTWAY DIMENSIONS

LAYOUT CAR SIZE

a b c d e f g h i

CODE 1 DCR 48" x 36" 50.25" 54.5" 27.25" 27.5" 8.75" 36" 3" 48" 36"

LEFT

SAME DCR 54" x 40" 54.25" 60.5" 30.25" 27.5" 12.75" 36" 3" 54" 40"

SIDE

OPENING DCR 60" x 36" 50.25" 66.5" 33.25" 27.5" 8.75" 36" 3" 60" 36"

CODE 1 CDR 48" x 36" 51.25" 54.5" 27.25" 27.5" 8.75" 36" 3" 48" 36"

LEFT

SAME CDR 54" x 40" 53.75" 60.5" 30.25" 27.5" 8.75" 36" 3" 54" 40"

SIDE

OPENING CDR 60" x 36" 51.25" 66.5" 33.25" 27.5" 8.75" 36" 3" 60" 36"

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.7

Hoistway Layout - Paca-Lift

ABR BAR

RIGHT SAME SIDE OPENING RIGHT SAME SIDE OPENING

CODE 2 CODE 2

b b

c c

d d

e e

D A D A

h

a a i g f

i f

g h

C B C B

ELEVATOR PACA LIFT ELEVATOR HOISTWAY DIMENSIONS

HOISTWAY FINISHED HOISTWAY DIMENSIONS

LAYOUT CAR SIZE

a b c d e f g h i

CODE 2 ABR 48" x 36" 50.25" 54.5" 27.25" 27.5" 8.75" 36" 3" 48" 36"

RIGHT

SAME ABR 54" x 40" 54.25" 60.5" 30.25" 27.5" 12.75" 36" 3" 54" 40"

SIDE

OPENING ABR 60" x 36" 50.25" 66.5" 33.25" 27.5" 8.75" 36" 3" 60" 36"

CODE 2 BAR 48" x 36" 51.25" 54.5" 27.25" 27.5" 8.75" 36" 3" 48" 36"

RIGHT

SAME

BAR 54" x 40" 53.75" 60.5" 30.25" 27.5" 8.75" 36" 3" 54" 40"

SIDE

OPENING BAR 60" x 36" 51.25" 66.5" 33.25" 27.5" 8.75" 36" 3" 60" 36"

BC CB

LEFT FRONT OPENING RIGHT FRONT OPENING

CODE 3 CODE 3

b b

c c

d d

D A D A

a h h a

i i

C

g B C g B

f e e f

ELEVATOR PACA LIFT ELEVATOR HOISTWAY DIMENSIONS

HOISTWAY FINISHED HOISTWAY DIMENSIONS

LAYOUT CAR SIZE

a b c d e f g h i

CODE 3 BC 48" x 36" 48.25" 56.5" 29.5" 27.5" 15" 36" 3" 48" 36"

LEFT BC 54" x 40" 52.25" 62.5" 32.5" 27.5" 21" 36" 3" 54" 40"

FRONT

OPENING BC 60" x 36" 48.25" 68.5" 35.5" 27.5" 27" 36" 3" 60" 36"

CODE 3 CB 48" x 36" 48.25" 56.5" 29.5" 27.5" 15" 36" 3" 48" 36"

RIGHT CB 54" x 40" 52.25" 62.5" 32.5" 27.5" 21" 36" 3" 54" 40"

FRONT

OPENING CB 60" x 36" 48.25" 68.5" 35.5" 27.5" 27" 36" 3" 60" 36"

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.8

Hoistway Layout - Paca-Lift

ABR - DCR BAR - CDR

OPPOSITE OPENING OPPOSITE OPENING

CODE 4 CODE 4

b b

c c

d d

e e

D A D A

h

a f a i g f

i

g h

C B C B

ELEVATOR PACA LIFT ELEVATOR HOISTWAY DIMENSIONS

HOISTWAY FINISHED HOISTWAY DIMENSIONS

LAYOUT CAR SIZE

a b c d e f g h i

CODE 4 ABR-DCR 48" x 36" 50.25" 55" 27.50" 27.5" 8.75" 36" 3" 48" 36"

OPPOSITE ABR-DCR 54" x 40" 54.25" 61" 30.50" 27.5" 12.75" 36" 3" 54" 40"

OPENING

ABR-DCR 60" x 36" 50.25" 67" 33.50" 27.5" 8.75" 36" 3" 60" 36"

CODE 4 BAR-CDR 48" x 36" 51.25" 55" 27.50" 27.5" 8.75" 36" 3" 48" 36"

OPPOSITE BAR-CDR 54" x 40" 53.75" 61" 30.50" 27.5" 8.75" 36" 3" 54" 40"

OPENING

BAR-CDR 60" x 36" 51.25" 67" 33.50" 27.5" 8.75" 36" 3" 60" 36"

ABR BC DCR-CB

RIGHT ADJACENT 90° OPENINGS LEFT ADJACENT 90° OPENINGS

CODE 5 CODE 6

b c c b

d d

e e

D A D A

h h

a g f f g a

i

I i

I

B C

C B

k j j k

ELEVATOR PACA LIFT ELEVATOR HOISTWAY DIMENSIONS

HOISTWAY FINISHED HOISTWAY DIMENSIONS

LAYOUT CAR SIZE

a b c d e f g h i j k

CODE 5 ABR-BC 48" x 36" 48.25" 56.5" 27.25" 27.5" 8.5" 32" 3" 48" 36" 15.5" 36"

RIGHT

ADJACENT ABR-BC 54" x 40" 52.25" 62.5" 30.25" 27.5" 8.5" 36" 3" 54" 40" 21.5" 36"

90°

OPENING ABR-BC 60" x 36" 48.25" 68.5" 33.25" 27.5" 8.5" 32" 3" 60" 36" 27.5" 36"

CODE 6 DCR-CB 48" x 36" 48.25" 56.5" 27.25" 27.5" 8.5" 32" 3" 48" 36" 15.5" 36"

LEFT

ADJACENT DCR-CB 54" x 40" 52.25" 62.5" 30.25" 27.5" 8.5" 36" 3" 54" 40" 21.5" 36"

90°

OPENING DCR-CB 60" x 36" 48.25" 68.5" 33.25" 27.5" 8.5" 32" 3" 60" 36" 27.5" 36"

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.9

Hoistway Illustration - Paca-Lift

TOP PLATE

TRUSS

LAMINATED

The typical layouts shown VENEER LUMBER

here may vary from your actual

hoistway. The purpose of

these layouts are for a general

understanding. Please refer to OVERHEAD

CLEARANCE

the Waupaca Elevator drawings BOTTOM PLATE

and specifications that will be

provided by the company. HOISTWAY

OPENING

FLOOR JOIST

HEADER

STUD

FLOOR

HEIGHT

HOISTWAY

OPENING

PIT FLOOR

TOTAL

CAR

TRAVEL

DOORWAY

EXAMPLE OF A ROUGH

CENTER LINE FRAMED HOISTWAY

Of RAIL WALL PIT WITHOUT DRYWALL

13-3/4" 13-3/4"

37"

18-1/2" 18-1/2"

(4) 1-3/4" X 9-1/2"

LAMINATED VENEER LUMBER (LVL)

USED TO ANCHOR RAIL BRACKETS

These drawings depict

sample construction only.

It is the responsibility

of the installer/contrac-

tor or engineer to design

EXAMPLE

OF and specify structural

TYPICAL

LAYOUT supports. All construction

to be in compliance with

local codes.

PIT

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.10

Hoistway Specifications - Paca-Lift

Refer to Illustration on previous page

ATTENTION CONSTRUCTION CONTRACTOR:

This is an example of a winding drum hoistway. Job specific documentation will

be provided by Waupaca Elevator from which to construct the hoistway.

Hoistway Construction Requirements

(to be completed prior to elevator installation by contractor)

1. Electrical Requirements:

- Dedicated 230 VAC 30 AMP Circuit Single Phase with a 25 AMP slow blow fuse.

- Power supply to be installed in a lockable fused disconnect.

- 120 VAC 15 Amp Circuit Single Phase with manual disconnect & 15 AMP protection.

- Electrical wiring to comply with applicable codes.

2. Unfinished/Un-installed Door - Installation company may prefer a minimum of one

hoistway door and associated framing be left unfinished/un-installed to accommodate

elevator installation equipment and to prevent accidental damage to door and framing

(preferably at grade level).

3. Plumb and Square Hoistway - Hoistway must be plumb within 1/8 inch per 10 ft. of

height and square at any point within 1/4 inch based on difference in diagonal

measurements.

4. Supportive Structure - Structure must be capable of supporting the appropriate loads.

Local engineering support is recommended.

5. Telephone Connection - Code requires a telephone connection to the elevator car,

therefore, a phone line must be installed leading to the controller.

6. ASME 17.1 Part 5.3 - Hoistway to be constructed in accordance with ASME17.1 Part 5.3

and all local codes.

7. Hoistway Door Security (Interlocks) - All hoistway doors require interlocks as well as a

door handle and a latch set. Interlocks will be installed by the elevator installers.

Waupaca Elevator recommends the use of solid core doors.

8. Temperature Requirements - Hoistway and machine room temperature

should be maintainable between 60° F- 110° F and should not be exposed to the elements.

9. No Alterations - Any alterations to the equipment without written authorization by

Waupaca Elevator will void all warranties.

10. Pit Floor Strength - A pit floor must be designed to withstand a load of 4,000 lbs. When

used, concrete must be a minimum of 4” thick and rated at 3500 PSI.

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.11

Elevation and Hoistway Ceiling

Heights - Paca-Lift

Waupaca Elevator’s Paca Lift

offers a total of five stops and a

total travel distance of 50 feet.

Minimum

Minimum Hoistway

Hoistway Ceiling Heights*

Ceiling Height

Inside Cab

Dimension 6’ 10” 7’ 0” 7’ 4” 8’ 0”

Minimum

Hoistway 7’ 10” 8’ 0” 8’ 4” 9’ 0”

Ceiling

Top Height

Floor

* Custom sized cabs will

Additional alter these dimensions. Waupaca

Floors Elevator will provide you with the

appropriate dimensions.

Pit Depth

When the machine is located in the

pit, the minimum pit depth is 24”.

All other layouts require a minimum

Total of 8” pit.

Travel

Inside Cab

Dimension

First

Floor

Pit Depth

Minimum 8"

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.12

Controller Space - Paca-Lift

Typical Layout

12" 1. The Controller requires

MINIMUM minimum clear space of 30” x 36”

OVERHEAD located directly in front of the

controller (refer to illustration).

2. A lockable service disconnect

must be placed within sight of

the controller and must be

7'-0" easily accessible, from the latch

STANDARD side of the doorway (if door is

CAR present).

HEIGHT

3. Controller space must be

50' MAXIMUM provided for the operating

TRAVEL LENGTH equipment that meets national

18" MINIMUM electrical code clear space

TRAVEL BETWEEN requirements and all local

FLOORS codes. Controller space

must provide a convenience

outlet and light with switch.

Temperatures must be main-

tained between 60°-110°F

(with a relative humidity not to

exceed 95%).

8" MINIMUM PIT DEPTH

CONTROLLER SIZE

STANDARD 24" x 18" x 8"

SURFACE MOUNTED

DISCONNECT

30"

36"

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.13

Elevator Equipment - Paca-Lift

Typical

• Powerhead • Main Rail • Gear Box

• Interlocks • Motor • Drum

MOTOR - III Phase,

3 HORSEPOWER,

GEAR BOX - HIGH RATIO, INSTANT REVERSING.

DIRECT MOUNTED AND

COUPLED.

2000 LB.

STOPPING DEVICES 300 LB.

MAGNETIC TAPE READER

DRUM - SINGLE DRUM WITH

FOR LEVELING ACCURACY &

OUTBOARD BEARING FOR SUPPORT.

TOP FINAL LIMIT SWITCHES.

RAIL EMI - III

INTERLOCK

300 LBS. MAX.

TENSION PER

FASTENER

HOISTWAY DOOR INTERLOCKS

300 LBS. MAX. EMI required at each opening to

SHEAR PER prevent hoistway or elevator

FASTENER access while elevator is operating.

Travel 2000 lb. 2000 lb.

2000 lb.

Sheaves 2000 lb.

2000 lb.

2000 lb.

2000 lb.

OVERHEAD

PIT TRAVELING DIVERTER

TRAVELING

2000 lb.

2000 lb. 2000 lb.

2000 lb. (TO RAIL)

2000 lb.

ADJACENT MACHINE TRAVELING

TRAVELING FLOOR ROOM WALL SHEAVE SHEAVE

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.14

Paca-Lift Elevator Series 018

FINAL

RAIL LIMIT

BRACKET CAM

WIRE

ROPE RAIL

STEEL

CAR

TAPE

STABILIZER

BRACKETS

HAND

WHEEL

SLING

EXTENSIONS

POWERHEAD BACKING

FINAL

SHACKLES LIMITS

SLING CAR

TOP

GATE BOX

OPERATOR LIGHTS

DISCONNECT

CONTROLLER

CAR

EMI

INTERLOCK ACCORDIAN

GATE

HALL

STATION

GATE CAR

TRACK OPERATING

PANEL

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.15

PMQ0600-C 1726 North Ballard Road • Appleton, WI 54911

05/20/2010 Phone 920-991-9082 • www.waupacaelevator.com

PACA-LIFT ELEVATOR PLANNING GUIDE PMQ0600.16

Вам также может понравиться

- Unistar: High Capacity Soil SeparatorДокумент6 страницUnistar: High Capacity Soil SeparatorFabianoОценок пока нет

- Yaska L1000a Ac DriveДокумент16 страницYaska L1000a Ac DriveShahid YousafОценок пока нет

- Leaflet Face Master 2.3-1BДокумент2 страницыLeaflet Face Master 2.3-1Blorenzo henerОценок пока нет

- Technical Data: TimberjackДокумент4 страницыTechnical Data: TimberjackOgnjen KovacevicОценок пока нет

- 5 300 HP - 3 PHASE, 50/60 HZДокумент2 страницы5 300 HP - 3 PHASE, 50/60 HZtuОценок пока нет

- Lutron Malv Specs MAW 600H WHДокумент10 страницLutron Malv Specs MAW 600H WHPeruskia PapОценок пока нет

- Alliance Electronics LTD Powervamp Products 2018Документ8 страницAlliance Electronics LTD Powervamp Products 2018Alliance Transport Technologies LtdОценок пока нет

- CAT XQ125 350 BrochureДокумент4 страницыCAT XQ125 350 BrochureArturo SánchezОценок пока нет

- 340 Datasheet Iss H 6Документ5 страниц340 Datasheet Iss H 6EdyCruzОценок пока нет

- Tal A40 - Tal A42 - Tal A44Документ17 страницTal A40 - Tal A42 - Tal A44BilalОценок пока нет

- 1266AR Datasheet enДокумент5 страниц1266AR Datasheet enROHIT SINGHОценок пока нет

- TE-B Series: Solid State StartersДокумент4 страницыTE-B Series: Solid State StartersWilly garciaОценок пока нет

- FAW 15kva 3 Phase SpecsДокумент2 страницыFAW 15kva 3 Phase SpecsfosterОценок пока нет

- Dongfeng: Technical SpecificationsДокумент2 страницыDongfeng: Technical Specificationsเสกสรรค์ จันทร์สุขปลูกОценок пока нет

- Yaskawa Ac DriveДокумент16 страницYaskawa Ac DriveLe Quang VuОценок пока нет

- Low Voltage Alternators - 4 Pole: Tal A40 - Tal A42-Tal A44Документ17 страницLow Voltage Alternators - 4 Pole: Tal A40 - Tal A42-Tal A44HERS14Оценок пока нет

- LV SSS - TE-H Series Brochure Rev 190129Документ4 страницыLV SSS - TE-H Series Brochure Rev 190129Carlos AlvarezОценок пока нет

- 22 Kva Standby FAWДокумент2 страницы22 Kva Standby FAWTanaka MasochaОценок пока нет

- Power Wave S700: Stick, TIG, MIG, Pulsed MIG, Flux-Cored, Tandem MIG, Carbon Arc Gouging K3279-1 Power Wave S700Документ8 страницPower Wave S700: Stick, TIG, MIG, Pulsed MIG, Flux-Cored, Tandem MIG, Carbon Arc Gouging K3279-1 Power Wave S700rahmankhan823Оценок пока нет

- Dokumen - Tips Heinzmann TrainingДокумент10 страницDokumen - Tips Heinzmann Trainingmarius.chitigaОценок пока нет

- Heinzmann TrainingДокумент10 страницHeinzmann TrainingTiên Lê Trần MỹОценок пока нет

- en Ca 01Документ1 страницаen Ca 01_at_to_Оценок пока нет

- LV SSS - TE2 Series Brochure Rev 1901229Документ4 страницыLV SSS - TE2 Series Brochure Rev 1901229Carlos AlvarezОценок пока нет

- Restaurador S&CДокумент5 страницRestaurador S&CScarlettОценок пока нет

- 32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen FreeДокумент12 страниц32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen Freejorge gerОценок пока нет

- Ground Support Equipment FlyerДокумент6 страницGround Support Equipment FlyerWilliam Jaldin CorralesОценок пока нет

- En Perkins 1500 2500Документ2 страницыEn Perkins 1500 2500Leandro Macedo100% (1)

- Catalogo Visa PDFДокумент36 страницCatalogo Visa PDFDANE80Оценок пока нет

- Berkey Colortran Dimmer Pack Systems Brochure 1973Документ6 страницBerkey Colortran Dimmer Pack Systems Brochure 1973Alan MastersОценок пока нет

- Se-4e15 Avr Manual 2021Документ10 страницSe-4e15 Avr Manual 2021Kostas Ioannou50% (2)

- Rotary Ups: Performances and Characteristics Standard FeaturesДокумент1 страницаRotary Ups: Performances and Characteristics Standard Featuresedson_spinaОценок пока нет

- Technical Specifications: Extra EquipmentsДокумент2 страницыTechnical Specifications: Extra EquipmentsLuca GarofitaОценок пока нет

- Brosur SMA STP 8-10 - 3AV-40 - HDPДокумент2 страницыBrosur SMA STP 8-10 - 3AV-40 - HDPadi brwОценок пока нет

- Operation and Maintenance Manual Bulletin Nh220Документ4 страницыOperation and Maintenance Manual Bulletin Nh220Cordova MarcosОценок пока нет

- En Perkins 10 50Документ2 страницыEn Perkins 10 50Djamel Beddar100% (1)

- Ulotka Production Master 2.3 - 0Документ2 страницыUlotka Production Master 2.3 - 0AlokОценок пока нет

- Yonos 1Документ20 страницYonos 1Dim VatОценок пока нет

- Mine Master Fm2.3-2bДокумент2 страницыMine Master Fm2.3-2bCristopher QuiñonesОценок пока нет

- Mine Master Fm2.3-2bДокумент2 страницыMine Master Fm2.3-2bCristopher QuiñonesОценок пока нет

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLДокумент8 страницDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88Оценок пока нет

- Boom Truck: Maximum Lifting Capacity: 18tonДокумент6 страницBoom Truck: Maximum Lifting Capacity: 18tonSusi AndraОценок пока нет

- HQ 008 To HQ 120 Dimensions Technical DetailsДокумент1 страницаHQ 008 To HQ 120 Dimensions Technical DetailsadrianioantomaОценок пока нет

- TMG 135C-Cummins: ModelДокумент1 страницаTMG 135C-Cummins: ModelJayson StathamОценок пока нет

- 2100 2500 Cummins ENДокумент2 страницы2100 2500 Cummins ENMinn Thet NaingОценок пока нет

- Data Sheet TOP210PFIДокумент16 страницData Sheet TOP210PFIlobitoferozlОценок пока нет

- Esp SpoolersДокумент1 страницаEsp SpoolersSridar BОценок пока нет

- ENSA Con YANGDONG 11-35 Series (Y495D)Документ2 страницыENSA Con YANGDONG 11-35 Series (Y495D)jim perdigonОценок пока нет

- Boomer T1Документ8 страницBoomer T1Ysraels Santisteban DurandОценок пока нет

- STP 210ms 229Документ2 страницыSTP 210ms 229TATA URUSAN TEKNOLOGI & JARINGANОценок пока нет

- ECR25 Electric: Volvo Electric Compact Excavators 2.7 TДокумент12 страницECR25 Electric: Volvo Electric Compact Excavators 2.7 TMarian AntonescuОценок пока нет

- ELFA SiemensДокумент23 страницыELFA SiemensHERNANDO A BECERRA100% (1)

- Methods of Artificial Lift: Presented To: Prof DR: El Ayouty - ElsaidДокумент11 страницMethods of Artificial Lift: Presented To: Prof DR: El Ayouty - Elsaidcmrig74Оценок пока нет

- Weg Motor Catalog NumberingДокумент1 страницаWeg Motor Catalog NumberingLim SjahrialОценок пока нет

- Dab Dig 1100 1500 1800 2200 Eng LДокумент1 страницаDab Dig 1100 1500 1800 2200 Eng LAhmad KarbasiОценок пока нет

- Heinzmann TrainingДокумент10 страницHeinzmann Trainingvo phong100% (1)

- E SyboxДокумент2 страницыE Syboxnle_16948Оценок пока нет

- 951Cc Closed-Loop Efi Engine Elka Stage 5 Shocks (LTD) Team Rapid Response Clutch Standard EPSДокумент2 страницы951Cc Closed-Loop Efi Engine Elka Stage 5 Shocks (LTD) Team Rapid Response Clutch Standard EPSCarlo ValenciaОценок пока нет

- HYSTER GPS - Hyster (W40XL) (W40XT) Parts ManualДокумент13 страницHYSTER GPS - Hyster (W40XL) (W40XT) Parts ManualMelwyn FernandesОценок пока нет

- Life JacketДокумент14 страницLife JacketAgnelo FernandesОценок пока нет

- Owner's Guide: Winding Drum Residential ElevatorДокумент28 страницOwner's Guide: Winding Drum Residential ElevatorAgnelo FernandesОценок пока нет

- Buildings Systems: Start of Service of World's Fastest ElevatorДокумент6 страницBuildings Systems: Start of Service of World's Fastest ElevatorAgnelo FernandesОценок пока нет

- Planning Guide: Residential ElevatorsДокумент16 страницPlanning Guide: Residential ElevatorsAgnelo FernandesОценок пока нет

- Inclinator Broch-UpdateДокумент12 страницInclinator Broch-UpdateAgnelo FernandesОценок пока нет

- Elevette Design-Guide-1000Документ26 страницElevette Design-Guide-1000Agnelo FernandesОценок пока нет

- Drum Elevator PDFДокумент22 страницыDrum Elevator PDFAgnelo Fernandes100% (1)

- Elveron Home-Elevator-Design-and-Planning-GuideДокумент28 страницElveron Home-Elevator-Design-and-Planning-GuideAgnelo FernandesОценок пока нет

- Dumbwaiter Installation PDFДокумент20 страницDumbwaiter Installation PDFAgnelo FernandesОценок пока нет

- Inclined ElevatorДокумент22 страницыInclined ElevatorAgnelo Fernandes100% (1)

- Strainsentry: Ds Europe SRLДокумент12 страницStrainsentry: Ds Europe SRLAgnelo FernandesОценок пока нет

- Elevator Control Wiring and Simple Configuration: Button ModeДокумент7 страницElevator Control Wiring and Simple Configuration: Button ModeAgnelo FernandesОценок пока нет

- Thyssen Krupp Synergy-Elevator PDFДокумент16 страницThyssen Krupp Synergy-Elevator PDFAgnelo FernandesОценок пока нет

- Planning Guide: Cable-Waiter Paca-WaiterДокумент24 страницыPlanning Guide: Cable-Waiter Paca-WaiterAgnelo FernandesОценок пока нет

- Gbdupszop .3@&: Psefs .34Uboebsepiof"Ctjolt - .-Jgunbufsjbm (NC)Документ40 страницGbdupszop .3@&: Psefs .34Uboebsepiof"Ctjolt - .-Jgunbufsjbm (NC)Agnelo FernandesОценок пока нет

- Assignment Booklet July 2021Документ22 страницыAssignment Booklet July 2021Saksham TiwariОценок пока нет

- Standard Cost EstimateДокумент21 страницаStandard Cost EstimateMOORTHYОценок пока нет

- World's Standard Model G6A!: Low Signal RelayДокумент9 страницWorld's Standard Model G6A!: Low Signal RelayEgiОценок пока нет

- SP Essay 1Документ14 страницSP Essay 1api-511870420Оценок пока нет

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingДокумент47 страницColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanОценок пока нет

- 18 Ray Optics Revision Notes QuizrrДокумент108 страниц18 Ray Optics Revision Notes Quizrraafaf.sdfddfaОценок пока нет

- NAT-REVIEWER-IN-PHYSICAL EDUCATIONДокумент4 страницыNAT-REVIEWER-IN-PHYSICAL EDUCATIONMira Rochenie CuranОценок пока нет

- Basic Geriatric Nursing 6th Edition Williams Test BankДокумент10 страницBasic Geriatric Nursing 6th Edition Williams Test Bankmaryrodriguezxsntrogkwd100% (49)

- Save Water SpeechДокумент4 страницыSave Water SpeechHari Prakash Shukla0% (1)

- Lafarge Interior Building Solutions BrochureДокумент24 страницыLafarge Interior Building Solutions BrochuretwinpixtwinpixОценок пока нет

- Module 4 Active Faults and Other Earthquake Sources: Learning OutcomeДокумент3 страницыModule 4 Active Faults and Other Earthquake Sources: Learning OutcomeFatima Ybanez Mahilum-LimbagaОценок пока нет

- Circle The Best Answer A, B, C, D or EДокумент4 страницыCircle The Best Answer A, B, C, D or Ewilder jackОценок пока нет

- Release From Destructive Covenants - D. K. OlukoyaДокумент178 страницRelease From Destructive Covenants - D. K. OlukoyaJemima Manzo100% (1)

- G1CДокумент12 страницG1CKhriz Ann C ÜОценок пока нет

- Learning Activity Sheets Introduction To World Religions and Belief SystemДокумент56 страницLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaОценок пока нет

- GROSS Mystery of UFOs A PreludeДокумент309 страницGROSS Mystery of UFOs A PreludeTommaso MonteleoneОценок пока нет

- 3rd Quarter Exam (Statistics)Документ4 страницы3rd Quarter Exam (Statistics)JERALD MONJUANОценок пока нет

- LG250CДокумент2 страницыLG250CCarlosОценок пока нет

- Module 1 Notes The White Bird Reading The Image Painting Analysis PDFДокумент4 страницыModule 1 Notes The White Bird Reading The Image Painting Analysis PDFMelbely Rose Apigo BaduaОценок пока нет

- Lab Report Marketing Mansi 4Документ39 страницLab Report Marketing Mansi 4Mansi SharmaОценок пока нет

- Technical Information: Range-Free Controller FA-M3 System Upgrade GuideДокумент33 страницыTechnical Information: Range-Free Controller FA-M3 System Upgrade GuideAddaОценок пока нет

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsДокумент5 страницIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqОценок пока нет

- Nivel VV-VW Board User Guide enДокумент5 страницNivel VV-VW Board User Guide enHarveyWishtartОценок пока нет

- Goliath 90 v129 eДокумент129 страницGoliath 90 v129 eerkanОценок пока нет

- Dual Op Amp and Voltage Reference Ap4310/AДокумент12 страницDual Op Amp and Voltage Reference Ap4310/AМихаил ЯненкоОценок пока нет

- Oil Whirl and Whip Instabilities - Within Journal BearingsДокумент27 страницOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirОценок пока нет

- Highway-And-Railroad-Engineering SummaryДокумент15 страницHighway-And-Railroad-Engineering SummaryRodin James GabrilloОценок пока нет

- Ficha Tecnica-Skyjack SJ3219 8mtДокумент2 страницыFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALОценок пока нет

- Seminar On Solar Mobile Charger: Submitted To: Submitted byДокумент16 страницSeminar On Solar Mobile Charger: Submitted To: Submitted byAkhila GottemukkulaОценок пока нет

- Innerwear Industry Pitch PresentationДокумент19 страницInnerwear Industry Pitch PresentationRupeshKumarОценок пока нет