Академический Документы

Профессиональный Документы

Культура Документы

Diaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working Volume

Загружено:

chauОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Diaphragm Seal With Flange Connection With Internal Diaphragm, Threaded Design Model 990.41, Large Working Volume

Загружено:

chauАвторское право:

Доступные форматы

Pressure

Diaphragm seal with flange connection

With internal diaphragm, threaded design

Model 990.41, large working volume

WIKA data sheet DS 99.32

for further approvals

see page 7

Applications

■■ Aggressive, contaminated or hot media

■■ Chemical and petrochemical industries

■■ Oil and gas industry

Special features

■■ Flange with internal welded diaphragm

■■ Wide temperature application range due to large working

volume

■■ When special materials are selected, all wetted parts are

made of the selected material

■■ Integrated flushing connections (optional)

Diaphragm seal with flange connection,

model 990.41

Description

Diaphragm seals are used for the protection of pressure By means of optionally available flushing connections, the

measuring instruments in applications with difficult media. In process side of the flange can be cleaned and flushed as

diaphragm seal systems, the diaphragm of the diaphragm required.

seal effects the separation of the instrument and the medium.

The pressure is transmitted to the measuring instrument Assembly of the diaphragm seal to the measuring instrument

via the system fill fluid which is inside the diaphragm seal may be made via a direct connection, for high temperatures

system. via a cooling element or via a flexible capillary.

For the implementation of demanding customer applications, For the material selection WIKA offers a variety of solutions,

there are a wide variety of designs, materials and system fill in which the upper body of the diaphragm seal and the

fluids available. wetted parts can be made of identical or different materials.

The wetted parts can, as an alternative, be coated.

For further technical information on diaphragm seals and

diaphragm seal systems see IN 00.06 “Application, operating

principle, designs”.

The model 990.41 diaphragm seal is ideally suited for appli-

cations with small process connections. Due to its design,

with an internal diaphragm, accurate measurements are

possible even with small flange connections.

WIKA data sheet DS 99.32 ∙ 12/2018 Page 1 of 7

Data sheets showing similar products:

Diaphragm seal with flange connection; with internal diaphragm, threaded design; model 990.12; see data sheet DS 99.31

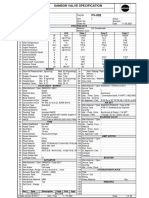

Specifications

Model 990.41 Standard Option

Level of cleanliness of wetted Oil and grease free per ASTM G93-03 Oil and grease free per ASTM G93-03 level D and

parts level F WIKA standard (< 1,000 mg/m²) ISO 15001 (< 220 mg/m²)

Origin of wetted parts International ■■ EU

■■ CH

■■ USA

Sealing ■■ FPM (max. 200 °C) ■■ Statotherm ® (max. 400 °C)

■■ PTFE (max. 260 °C) ■■ Metal C spring, silver-plated stainless steel

(max. 400 °C)

■■ Metal C spring, Inconel (max. 400 °C)

Flushing connection - ■■ Single flushing connection (G ¼, G ⅛, ¼ NPT, ⅛ NPT)

■■ Dual flushing connection (G ¼, G ⅛, ¼ NPT, ⅛ NPT)

■■ Plug screws

Connection to the measuring Axial adapter Axial adapter with G 1/2, G 1/4, 1/2 NPT or 1/4 NPT (female)

instrument

Type of mounting Direct mounting ■■ Capillary

■■ Cooling element

Retainer parts Stainless steel -

Design per NACE - ■■ MR 0175

■■ MR 0103

Vacuum service Basic service ■■ Premium service

(see IN 00.25) ■■ Advanced service

Diaphragm seals for mounting - With flame arrester and PTB certificate

to zone 0

Instrument mounting bracket - ■■ Form H per DIN 16281, 100 mm, aluminium, black

(only for capillary option) ■■ Form H per DIN 16281, 100 mm, stainless steel

■■ Bracket for pipe mounting, for pipe Ø 20 ... 80 mm,

steel (see data sheet AC 09.07)

WIKA data sheet DS 99.32 ∙ 12/2018 Page 2 of 7

Example: Diaphragm seal model 990.41 with mounted pressure gauge

Not included in Sealing

delivery

Mating flange

Pressure gauge

Direct mounting

Diaphragm seal

Diaphragm

(welded to diaphragm seal) d4

Sealing k

Raised face D

b

Legend:

D Outer diameter of diaphragm seal

f

d4 Sealing face diameter

14242891.01

k Pitch circle diameter

b Flange thickness

f Height of raised face

Following DIN EN 1092-1

Process connection, flange

Standard Flange size Sealing face

Standard Option

Following DIN EN 1092-1 DN 15 Form B1 Form B2

Form C (tongue)

DN 20 Form D (groove)

Form E (spigot with form B1)

DN 25 Form E (spigot with form B2)

Form F (recess with form B1)

DN 40 Form F (recess with form B2)

Form G (O-ring spigot)

DN 50

Form H (O-ring groove)

Following ASME B16.5 ½" RF 125 ... 250 AA RFSF

Flat face

¾" Small tongue

Large tongue

1" Large male face

Small male face

1 ½" Small groove

Large groove

2"

Small female face

Large female face

2 ½"

RJF groove

Following JIS DN 25A - RF 125 … 250 AA

DN 40A

DN 50A

Further flanges and options on request

WIKA data sheet DS 99.32 ∙ 12/2018 Page 3 of 7

Material combinations

Upper body of dia- Wetted parts Maximum permissible

phragm seal process temperature ²⁾

Lower body of diaphragm seal ¹⁾ Diaphragm in °C (°F)

and sealing face

Stainless steel 1.4404 Stainless steel 1.4404 / 1.4435 400 (752)

Stainless steel 1.4404 (316L)

(316L) (316L), standard version

Stainless steel 1.4539 (904L) Stainless steel 1.4539 (904L)

Stainless steel 1.4541 (321) Stainless steel 1.4541 (321)

Stainless steel 1.4571 (316Ti) Stainless steel 1.4571 (316Ti)

ECTFE coating ECTFE coating 150 (302)

PFA (perfluoroalkoxy) coating, FDA PFA (perfluoroalkoxy) coating, FDA 260 (500)

PFA (perfluoroalkoxy) coating,

PFA (perfluoroalkoxy) coating, antistatic

antistatic

Stainless steel 1.4404 (316L) Gold plating 400 (752)

Stainless steel 1.4404 (316L) Wikaramic® coating

Hastelloy C22 (2.4602) Hastelloy C22 (2.4602) 260 (500)

Hastelloy C276 (2.4819) Hastelloy C276 (2.4819) 400 (752)

Inconel 600 (2.4816) Inconel 600 (2.4816)

Inconel 625 (2.4856) Inconel 625 (2.4856)

Incoloy 825 (2.4858) Incoloy 825 (2.4858)

Monel 400 (2.4360) Monel 400 (2.4360)

Nickel 200 (2.4060, 2.4066) Nickel 200 (2.4060, 2.4066) 260 (500)

Titanium class 2 (3.7035) Titanium class 2 (3.7035) 150 (302)

Titanium class 7 (3.7235) Titanium class 7 (3.7235)

Tantalum Tantalum 300 (572)

Stainless steel 1.4435 400 (752)

Stainless steel 1.4435 (316L) Stainless steel 1.4435 (316L)

(316L)

Stainless steel 1.4539

Stainless steel 1.4539 (904L) Stainless steel 1.4539 (904L)

(904L)

Stainless steel 1.4541

Stainless steel 1.4541 (321) Stainless steel 1.4541 (321)

(321)

Stainless steel 1.4571

Stainless steel 1.4571 (316Ti) Stainless steel 1.4571 (316Ti)

(316Ti)

Duplex 2205 (1.4462) Duplex 2205 (1.4462) Duplex 2205 (1.4462) 300 (572)

Superduplex (1.4410) Superduplex (1.4410) Superduplex (1.4410)

Hastelloy C22 (2.4602) Hastelloy C22 (2.4602) Hastelloy C22 (2.4602) 400 (752)

Hastelloy C276 (2.4819) Hastelloy C276 (2.4819) Hastelloy C276 (2.4819)

Inconel 600 (2.4816) Inconel 600 (2.4816) Inconel 600 (2.4816)

Inconel 625 (2.4856) Inconel 625 (2.4856) Inconel 625 (2.4856)

Incoloy 825 (2.4558) Incoloy 825 (2.4858) Incoloy 825 (2.4858)

Monel 400 (2.4360) Monel 400 (2.4360) Monel 400 (2.4360)

Nickel 200 (2.4060,

Nickel 200 (2.4060, 2.4066) Nickel 200 (2.4060, 2.4066)

2.4066)

Titanium 3.7035 Titanium class 2 (3.7035) Titanium class 2 (3.7035)

Titanium 3.7235 Titanium class 7 (3.7235) Titanium class 7 (3.7235)

1) The lower body of the diaphragm seal is optionally available with up to two flushing connections.

2) The maximum permissible process temperature is limited by the joining method and by the system fill fluid.

Further material combinations for special process temperatures on request

WIKA data sheet DS 99.32 ∙ 12/2018 Page 4 of 7

Flange connection following DIN EN 1092-1, form B1

11571781.01

Legend:

Mb Effective diameter of diaphragm

D Outer diameter of diaphragm seal

b Flange thickness

d₃ Sealing face diameter

f Height of raised face

k Pitch circle diameter

G₁ Thread

x Number of screws

DN PN Dimensions in mm (in) G1 x

in bar Mb D b d3 f k

15 16 89 (3.504) 160 (6.299) 36 (1.417) 45 (1.772) 2 (0.079) 65 (2.559) M12 4

100 150 (5.905) 32 (1.26) 75 (2.953) M12

20 16 160 (6.299) 38 (1.496) 58 (2.283) M12

100 150 (5.905) 33 (1.299) 90 (3.543) M16

25 16 160 (6.299) 36 (1.417) 68 (2.677) 85 (3.346) M12

100 150 (5.905) 32 (1.26) 100 (3.937) M16

40 16 160 (6.299) 35 (1.378) 88 (3.465) 110 (4.331) M16

100 170 (6.693) 38 (1.496) 125 (4.921) M20

50 16 165 (6.496) 35 (1.378) 102 (4.016) M16

100 195 (7.677) 28 (1.102) 145 (5.709) M24

Further dimensions and higher nominal pressures on request

WIKA data sheet DS 99.32 ∙ 12/2018 Page 5 of 7

Flange connection per ASME B 16.5, RF 125 ... 250 AA

11571781.01

Legend:

Mb Effective diameter of diaphragm

D Outer diameter of diaphragm seal

b Flange thickness

d₃ Sealing face diameter

f Height of raised face

k Pitch circle diameter

G Thread

x Number of screws

DN Class Dimensions in mm (in) G1 x

Mb D b d3 f k

½" 150 89 (3.504) 150 (5.905) 37 (1.467) 34.9 (1.374) 2 (0.079) 60.3 (2.374) ½"-13 UNC 4

300 36 (1.417) 66.7 (2.656)

600 40 (1.575) 7 (0.276)

¾" 150 150 (5.905) 35 (1.378) 42.9 (1.689) 2 (0.079) 69.9 (2.752)

300 34 (1.339) 82.6 (3.252) ⅝"-11 UNC

600 40 (1.575) 7 (0.276)

1" 150 150 (5.905) 32 (1.26) 50.8 (2) 2 (0.079) 79.4 (3.126) ½"-13 UNC

300 88.9 (3.5) ⅝"-11 UNC

600 37 (1.467) 7 (0.276)

1 ½" 150 150 (5.905) 30 (1.181) 73 (2.874) 2 (0.079) 98.4 (3.874) ½"-13 UNC

300 155 (6.102) 36 (1.417) 114.3 (4.5) ¾"-10 UNC

600 40 (1.575) 7 (0.276)

2" 150 150 (5.905) 28 (1.102) 92.1 (3.626) 2 (0.079) 120.7 (4.752) ⅝"-11 UNC

300 165 (6.496) 127 (5) 8

600 33 (1.299) 7 (0.276)

Further dimensions and higher nominal pressures on request

WIKA data sheet DS 99.32 ∙ 12/2018 Page 6 of 7

Approvals

Logo Description Country

EAC (option) Eurasian Economic Community

Pressure equipment directive

- CRN Canada

Safety (e.g. electr. safety, overpressure, ...)

- MTSCHS (option) Kazakhstan

Permission for commissioning

Certificates (option)

■■ 2.2 test report per EN 10204 (e.g. state-of-the-art

manufacturing, material proof, indication accuracy for

diaphragm seal systems)

■■ 3.1 inspection certificate per EN 10204 (e.g. material

proof for wetted metallic parts, indication accuracy for

diaphragm seal systems)

Approvals and certificates, see website

Ordering information

Diaphragm seal:

Diaphragm seal model / Process connection (standard, flange size, nominal pressure, sealing face) / Materials (upper body,

lower body, sealing face, diaphragm, sealing) / Retainer parts (screws, retainer flange) / Flushing connection / Level of

cleanliness of wetted parts / Origin of wetted parts / Design per NACE / Connection to the measuring instrument / Certificates

Diaphragm seal system:

Diaphragm seal model / Pressure measuring instrument model (per data sheet) / Mounting (direct mounting, cooling

element, capillary) / Materials (upper body, sealing face, diaphragm) / Min. and max. process temperature / Min. and max.

ambient temperature / Vacuum service / System fill fluid / Certificates / Height difference / Level of cleanliness of wetted

parts / Origin of wetted parts / Design per NACE / Diaphragm seal for mounting to zone 0 / Instrument mounting bracket /

Process connection (standard, flange size, nominal pressure, sealing face)

© 03/2012 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

04/2018 EN

WIKA data sheet DS 99.32 ∙ 12/2018 Page 7 of 7

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Вам также может понравиться

- Diaphragm Seal With Flange Connection With Flush Diaphragm Model 990.27Документ10 страницDiaphragm Seal With Flange Connection With Flush Diaphragm Model 990.27Chau TranОценок пока нет

- Diaphragm Seal With Flange Connection With Internal Diaphragm Model 990.26Документ7 страницDiaphragm Seal With Flange Connection With Internal Diaphragm Model 990.26Chau TranОценок пока нет

- DS DS9929 en Co 2282Документ8 страницDS DS9929 en Co 2282Amanda PorterОценок пока нет

- DS DS9901 en Co 2317Документ7 страницDS DS9901 en Co 2317Ismail AdebiyiОценок пока нет

- DS DS9939 en Co 2374Документ5 страницDS DS9939 en Co 2374Gia Minh Tieu TuОценок пока нет

- Ds ds9934 en CoДокумент6 страницDs ds9934 en Co9033301054Оценок пока нет

- In-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionДокумент5 страницIn-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionchauОценок пока нет

- Threaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignДокумент2 страницыThreaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignchauОценок пока нет

- DS DS9927 en Co 1240Документ12 страницDS DS9927 en Co 1240islamfarag2Оценок пока нет

- DS DS9901 GB 2317Документ4 страницыDS DS9901 GB 2317mohsenhfdОценок пока нет

- Wika Diaphragm Seal, Flange Connection Model 990.27Документ4 страницыWika Diaphragm Seal, Flange Connection Model 990.27Syed Imtiaz HussainОценок пока нет

- Sigraflex UniversalДокумент6 страницSigraflex UniversalJan SmitОценок пока нет

- Ds ds9507 en CoДокумент5 страницDs ds9507 en CoNirav ShahОценок пока нет

- Threaded Process Connection, Diaphragm Seals Model 990.10, Threaded DesignДокумент2 страницыThreaded Process Connection, Diaphragm Seals Model 990.10, Threaded DesignhoamnОценок пока нет

- Wika Type M93X.D1 Pressure Gauge Data SheetДокумент5 страницWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioОценок пока нет

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionДокумент10 страницServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineОценок пока нет

- Pressure Gauge Per EN 837-1 With Mounted Diaphragm Seal With Clamp Connection Model DSS22FДокумент5 страницPressure Gauge Per EN 837-1 With Mounted Diaphragm Seal With Clamp Connection Model DSS22FKo SãiОценок пока нет

- Thermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9Документ3 страницыThermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9chauОценок пока нет

- ZTND Sihi PDFДокумент19 страницZTND Sihi PDFVladimir Illich Pinzon BallenОценок пока нет

- F T Poliuretano 24022020Документ3 страницыF T Poliuretano 24022020FedericoОценок пока нет

- NTTДокумент8 страницNTTIon FloareaОценок пока нет

- Klima-Set Differential Pressure Switch For Air KS A2-7Документ4 страницыKlima-Set Differential Pressure Switch For Air KS A2-7Edison SinchiguanoОценок пока нет

- TR 10 RTD PDFДокумент5 страницTR 10 RTD PDFJhon Piter ManaluОценок пока нет

- Air Measuring Station With VCD-42 Control Damper: Velocity: LeakageДокумент5 страницAir Measuring Station With VCD-42 Control Damper: Velocity: LeakageAnkit JainОценок пока нет

- JUMBO24+4: Order Number: 7250017 Type: JUMBO24+4Документ2 страницыJUMBO24+4: Order Number: 7250017 Type: JUMBO24+4sébastien BonteОценок пока нет

- Pressure SwitchДокумент11 страницPressure Switchaswinpisharat1997Оценок пока нет

- Bombas ZTN Aceite TermicoДокумент47 страницBombas ZTN Aceite Termicoandreshuertascalderon02Оценок пока нет

- Technical D-313 CLEANROOM Datasheet ENДокумент2 страницыTechnical D-313 CLEANROOM Datasheet ENnikola.markovicОценок пока нет

- Sanitary Diaphragm Valve: Type 612Документ6 страницSanitary Diaphragm Valve: Type 612Hilux PabloОценок пока нет

- Threaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignДокумент4 страницыThreaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignchauОценок пока нет

- Fisa Tehnica Placi PVC-CAW SimonaДокумент2 страницыFisa Tehnica Placi PVC-CAW SimonaAdrian SuciuОценок пока нет

- Technical Specification Cranefrigor VX Qvo 446Документ6 страницTechnical Specification Cranefrigor VX Qvo 446Jefferson dos Santos XavierОценок пока нет

- Product Overview: Valves Actuators Automation TechnologyДокумент36 страницProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaОценок пока нет

- Guth Non-Return Valve: A Good ChoiceДокумент4 страницыGuth Non-Return Valve: A Good ChoiceВалентин КовальчукОценок пока нет

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2Документ4 страницы2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2MacakafkaОценок пока нет

- Diaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MAДокумент11 страницDiaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MARida RoudiОценок пока нет

- Technical D-313 Datasheet ENДокумент2 страницыTechnical D-313 Datasheet ENnikola.markovicОценок пока нет

- Pneumatic Equipment Montabert PDFДокумент4 страницыPneumatic Equipment Montabert PDFJorge CarvajalОценок пока нет

- Applications: DCS200 SeriesДокумент3 страницыApplications: DCS200 SeriesAgus YulfizarОценок пока нет

- Technical Data Sheet: Item Description Unit Data To Be Filled in by The ContractorДокумент9 страницTechnical Data Sheet: Item Description Unit Data To Be Filled in by The ContractorFarhan SaitОценок пока нет

- Technical Data Sheet SIMONA Pvc-CawДокумент2 страницыTechnical Data Sheet SIMONA Pvc-Cawstephen arkadiОценок пока нет

- Diaphragm Pressure Gauge Guard MDM 902: Corrosion-Free Pressure Transmission For Aggressive MediaДокумент4 страницыDiaphragm Pressure Gauge Guard MDM 902: Corrosion-Free Pressure Transmission For Aggressive Mediathiago weniskleyОценок пока нет

- Amex Seals Product Data SheetsДокумент13 страницAmex Seals Product Data SheetscloantafОценок пока нет

- MITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog ENДокумент4 страницыMITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog ENGeorge DobreОценок пока нет

- 1109 Process Pressure Gauge: Data SheetДокумент2 страницы1109 Process Pressure Gauge: Data SheetchienncОценок пока нет

- Bimetal Thermometer Process Version Per ASME B40.200 Model TG53Документ10 страницBimetal Thermometer Process Version Per ASME B40.200 Model TG53SAM AZОценок пока нет

- en Actionair Thermshield FDДокумент8 страницen Actionair Thermshield FDYlenia BonelloОценок пока нет

- Disc ValvesДокумент8 страницDisc ValvesMahesh KumarОценок пока нет

- Walter Perform Line 2016 en 1Документ44 страницыWalter Perform Line 2016 en 1Taner AkkaşОценок пока нет

- DKM CP DN25-65 En1Документ24 страницыDKM CP DN25-65 En1brilian pungkyОценок пока нет

- Ds pv3331 en CoДокумент7 страницDs pv3331 en Co9033301054Оценок пока нет

- TC FLS Sihi ZTND enДокумент19 страницTC FLS Sihi ZTND enFosseni DialloОценок пока нет

- Technical Specification Cranefrigor WDV Qvo 465Документ4 страницыTechnical Specification Cranefrigor WDV Qvo 465Jefferson dos Santos XavierОценок пока нет

- Manual 7331 PIДокумент10 страницManual 7331 PIfranciscocruz29Оценок пока нет

- 7800 Spec PDFДокумент2 страницы7800 Spec PDFxnbsxОценок пока нет

- Iaphragm Alves: Broad Material AvailabilityДокумент6 страницIaphragm Alves: Broad Material AvailabilityrodgerОценок пока нет

- Zrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Документ4 страницыZrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Joao MoreiraОценок пока нет

- 6240 SpecДокумент2 страницы6240 SpecCarlos Miguel Barrena TorresОценок пока нет

- Magnetic Switch For Bypass Level Indicators Model BGU: ApplicationsДокумент10 страницMagnetic Switch For Bypass Level Indicators Model BGU: ApplicationschauОценок пока нет

- Diaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarДокумент4 страницыDiaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarchauОценок пока нет

- Appendix: Cross Reference BFTДокумент7 страницAppendix: Cross Reference BFTchauОценок пока нет

- In-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionДокумент5 страницIn-Line Diaphragm Seal With Sterile Connection For Sanitary Applications Models 981.22, 981.52 and 981.53, Clamp ConnectionchauОценок пока нет

- Valve Manifold For Differential Pressure Gauges Model 910.25Документ4 страницыValve Manifold For Differential Pressure Gauges Model 910.25chauОценок пока нет

- Threaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignДокумент2 страницыThreaded Process Connection, Diaphragm Seals Model 990.31, Plastic DesignchauОценок пока нет

- Thermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9Документ3 страницыThermowell With Flange (Fabricated) Version Per DIN 43772 Form 2F, 3F Models TW40-8, TW40-9chauОценок пока нет

- Process Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmДокумент14 страницProcess Transmitter Model UPT-20, With Pressure Port Model UPT-21, With Flush DiaphragmchauОценок пока нет

- Threaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignДокумент4 страницыThreaded Process Connection, Diaphragm Seals Model 990.34, Welded DesignchauОценок пока нет

- Machine Glass Thermometers Model 32, V-Form: ApplicationsДокумент5 страницMachine Glass Thermometers Model 32, V-Form: ApplicationschauОценок пока нет

- Bimetal Thermometer Model 52, Industrial Series: ApplicationsДокумент6 страницBimetal Thermometer Model 52, Industrial Series: ApplicationschauОценок пока нет

- Bimetal Thermometer Model 54, Industrial Series: ApplicationsДокумент7 страницBimetal Thermometer Model 54, Industrial Series: ApplicationschauОценок пока нет

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Документ11 страницBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55chauОценок пока нет

- ASET AI & AMI Engine Mechanical Specs, Torque Values, Etc.Документ33 страницыASET AI & AMI Engine Mechanical Specs, Torque Values, Etc.Meadows TruckОценок пока нет

- Process Pumps - Api-610: Single Stage Volute Casing PumpsДокумент5 страницProcess Pumps - Api-610: Single Stage Volute Casing Pumpsmehrzad1373Оценок пока нет

- Eaton Brass Products Master CatalogДокумент166 страницEaton Brass Products Master CatalogMarvin Nta DgzОценок пока нет

- Heyco Liquid Tight Cordgrips Pre AssembledДокумент1 страницаHeyco Liquid Tight Cordgrips Pre AssembledGioj MejОценок пока нет

- E1FW/M: CMP Products Cable Gland CatalogueДокумент1 страницаE1FW/M: CMP Products Cable Gland CataloguesubramanyaОценок пока нет

- ISV Product Summary SB-300.13 Rev00 - WebДокумент8 страницISV Product Summary SB-300.13 Rev00 - WebLuis Gustavo HernandezОценок пока нет

- Samson Valve Specification: Process DataДокумент49 страницSamson Valve Specification: Process DataMuhammed TamerОценок пока нет

- 56 Accesories enДокумент2 страницы56 Accesories enSyed AsadullahОценок пока нет

- Hand Test Pumps: Operating InstructionsДокумент12 страницHand Test Pumps: Operating InstructionssaratchandranbОценок пока нет

- f20 Manual Feb 2000 - Rev. 1Документ20 страницf20 Manual Feb 2000 - Rev. 1Larry JorgensonОценок пока нет

- ParkerLegris Catalog 0540 PDFДокумент450 страницParkerLegris Catalog 0540 PDFedhy_03Оценок пока нет

- ANSI Valves Forged Steel Gate Valves ANSI Class # 800Документ2 страницыANSI Valves Forged Steel Gate Valves ANSI Class # 800HimanshuОценок пока нет

- QSLP100 AC Parts Manual 65015-CCДокумент82 страницыQSLP100 AC Parts Manual 65015-CCfredd0% (1)

- AdvantEDGE Manual Rev 4Документ104 страницыAdvantEDGE Manual Rev 4Flor F. MendivilОценок пока нет

- Hydac FilterДокумент6 страницHydac FilterAlexander Ruiz IbagueОценок пока нет

- Foxboro Pneumatic Positioner - MI EVE0101 AДокумент32 страницыFoxboro Pneumatic Positioner - MI EVE0101 Apaulo cesar hernandez mijangosОценок пока нет

- 102 103 Differential Pressure Switches Cat388Документ16 страниц102 103 Differential Pressure Switches Cat388Fake AccountОценок пока нет

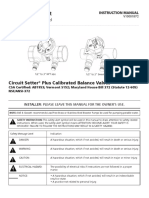

- Circuit Setter Bell & GrossetДокумент6 страницCircuit Setter Bell & GrossetKevinCostasCaceresОценок пока нет

- Parker AccesoriesДокумент14 страницParker Accesoriesabelmonte_geotecniaОценок пока нет

- 52 PAP enДокумент2 страницы52 PAP enGulf Trans PowerОценок пока нет

- Test Equipment - 2018Документ16 страницTest Equipment - 2018Anonymous HvDSpkgVОценок пока нет

- Leser Compact Performance CatalogДокумент28 страницLeser Compact Performance CatalogLudi D. LunarОценок пока нет

- 4 AdaptorsДокумент76 страниц4 AdaptorsjovicasurОценок пока нет

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Документ6 страниц0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahОценок пока нет

- VARCO - May 2014Документ48 страницVARCO - May 2014Pumper MagazineОценок пока нет

- PMH Series Pipe Fittings A-30 A-29 PMH Series Pipe FittingsДокумент31 страницаPMH Series Pipe Fittings A-30 A-29 PMH Series Pipe FittingsJitendra GahalotОценок пока нет

- Instrumentation FittingsДокумент32 страницыInstrumentation FittingsTochukwu OnuohaОценок пока нет

- Parts Manual Berkeley PumpsДокумент111 страницParts Manual Berkeley PumpsVladimirCarrilloОценок пока нет

- 903 OW Windsocks PQS and PDSДокумент11 страниц903 OW Windsocks PQS and PDSJerilyn BaldriasОценок пока нет