Академический Документы

Профессиональный Документы

Культура Документы

Near-Wellbore Formation Damage Effects On Well Performance: A Comparison Between Underbalanced and Overbalanced Drilling

Загружено:

hkaqlqОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Near-Wellbore Formation Damage Effects On Well Performance: A Comparison Between Underbalanced and Overbalanced Drilling

Загружено:

hkaqlqАвторское право:

Доступные форматы

Near-Wellbore Formation Damage Effects

on Well Performance: A Comparison

Between Underbalanced and

Overbalanced Drilling

Y. Ding, SPE, B. Herzhaft, and G. Renard, SPE, Inst. Français du Pétrole

Summary anced drilling. Thus, if underbalanced conditions cannot be main-

Prediction of formation damage that occurs while drilling horizon- tained 100% of the time, severe losses can occur, which may result

tal wells is a critical point for optimizing an oil field’s develop- in formation damage. Overbalanced conditions may result from bit

ment. The economic impact of near-wellbore drilling-induced trips, running in, or other situations in which wellbore intervention

damage and cleanup efficiency has led to significant progress be- is necessary. Spontaneous imbibition is particularly important in

ing made in both experimental and numerical studies to assess tight gas reservoirs.

wellbore flow properties during oil production. As a result, a nu- Even though UBD has many advantages over OBD, it is nec-

merical model has been developed to study the impact of various essary to quantify production improvement and possible formation

parameters related to the properties of drilling fluids on well in- damage, which is an important factor in evaluating the economic

flow performance. feasibility of UBD projects (Bennion and Thomas 1994; Bennion

This paper describes a numerical approach developed in this et al. 1994; Bennion et al. 1998; Cade et al. 2003; Suryanarayana

model to simulate near-wellbore formation damage caused by un- et al. 2003; Xiong and Shan 2003).

derbalanced drilling (UBD). It is generally expected that UBD will This paper presents a numerical model allowing us to calculate

be of benefit by preventing formation damage. However, this ben- well productivity reduction owing to possible formation damage

efit can be lost for various reasons. For instance, an overbalanced during UBD, such as temporary overbalanced drilling or sponta-

pressure can be applied on the formation during short periods of neous imbibition.

time for various operational reasons and can cause severe forma- The modeling of well performance in OBD has already been

tion damage because of the absence of external cake protection and presented (Ding et al. 2002; Ding and Renard 2003). Both internal

huge filtrate invasion. Another possible cause of formation damage and external cakes are considered in the model, and filtrate inva-

in UBD is related to spontaneous imbibition, which induces water- sion is calculated using a two-phase flow equation. Polymer ab-

blocking, which was observed while drilling tight gas reservoirs. sorption/retention, phase trapping, and wettability alteration are

A methodology for the modeling of possible formation damage globally represented using a hysteresis of relative permeabilities.

during UBD is presented. Crossflow phenomena caused by sponta- Nonuniform formation damage along the well is represented by

neous imbibition is taken into account to model the filtrate invasion variable-specific skin factors through an optimization procedure.

from the well to the porous media, as the well is in production. The change of well performance can therefore be calculated using

a flow simulator by taking into account these variable skin factors.

In this paper, a methodology for the modeling of possible for-

Introduction mation damage during UBD is presented. Formation damage re-

It is well known that formation damage caused by drilling fluid has lated to temporary overbalanced pressure is considered. Spontane-

a huge impact on a well’s oil and gas productivity, especially for ous imbibition is modeled using two-phase flow simulation with

openhole completed horizontal wells. During overbalanced drilling capillary pressure. When capillary forces are important, counter-

(OBD), mud and mud filtrate penetrate the near-wellbore forma- current imbibition occurs with the flow of reservoir fluids toward

tion because of this overbalanced pressure, altering near-well flow the well while the filtrate invades the formation. Spontaneous im-

properties. As a result, well productivity is dramatically reduced. It bibition is particularly important in tight gas reservoirs. Like the

is generally recognized that UBD can be used to minimize prob- modeling of OBD, a hysteresis of relative permeabilities is used to

lems associated with invasive formation damage. When correctly represent globally various physics during drilling and backflow.

performed, UBD reduces or eliminates invasive formation damage, The impacts of formation damage on well productivity are

improves access to reserves, and provides potential for reservoir simulated by the numerical model and are compared for both un-

evaluation while drilling. Additional benefits of UBD are the reduc- derbalanced and overbalanced drilling. The sensitivity to various

tion in drilling time, high rates of penetration, and increase of bit life. parameters related to drilling conditions (underbalanced or over-

UBD has recently proven its efficiency in numerous situations balanced) and reservoir parameters is presented. Simulations show

in which serious problems were encountered with classical drilling that formation damage in UBD depends on reservoir and applied

techniques. For example, heavy loss formations or depleted zones drilling conditions. Damage is sometimes severe because of no

are ideal candidates for UBD. During normal UBD, the negative filter-cake protection. Therefore, operational precautions should be

pressure drop between the wellbore and the formation prevents taken during UBD to prevent such damage. The proposed numeri-

drilling fluids from entering the formation. However, this benefit cal model can be used as a selection guide between OBD and UBD

can be lost in at least two situations owing to possible sources of for both well performance predictions and calculation of the best

failure such as temporary overbalanced conditions or spontaneous economic benefits on long-term production, assuming that

imbibition. When drilling underbalanced, the fluid system is not some damage can be done to the near-wellbore formation while

designed to contain cake-building solids as in the case of overbal- drilling underbalanced.

Description of the Problem

Fluid Invasion During UBD. UBD is a drilling operation in

Copyright © 2006 Society of Petroleum Engineers

which the hydrostatic head pressure of drilling fluid is maintained

This paper (SPE 86558) was first presented at the 2004 SPE International Symposium and at a value less than formation pore pressure. Formation damage

Exhibition on Formation Damage Control, Lafayette, Louisiana, 18–20 February, and re-

vised for publication. Original manuscript received for review 19 May 2004. Revised manu-

caused by conventional OBD with mud and mud-filtrate invasion

script received 21 July 2005. Paper peer approved 21 July 2005. can be reduced or eliminated theoretically with UBD. However,

February 2006 SPE Production & Operations 51

this benefit of UBD can be lost in cases of temporary overbalanced pressure ph is usually higher than the filtrate pressure pf in the

conditions and/or spontaneous imbibition. formation. But the well flowing pressures are the same for these

During a UBD operation, it is difficult to guarantee that the two phases because there is no capillary pressure in the wellbore.

drilling fluid pressure is always in underbalanced conditions. An For UBD, the well flowing pressure is lower than the hydrocarbon

overbalanced pressure can be applied on the formation during pressure, so we produce hydrocarbons while drilling. Generally,

short periods of time for various operational reasons, such as the hydrocarbon pressure is close to well flowing pressure in the well

case with bit trips or well intervention, and this can cause severe vicinity. If the capillary pressure is strong, well flowing pressure

formation damage because of the absence of external cake protec- becomes higher than the filtrate pressure in the formation. As a

tion and huge filtrate invasion. Moreover, underbalanced fluids result, countercurrent occurs, and filtrate invades the reservoir.

such as foams do have large amounts of tensioactive molecule in In a standard reservoir simulator, phase flow rates are generally

their formulation in order to stabilize the bubbles by reducing the calculated using the same pressure difference: namely, reference

surface tension. These surfactants may change the wettability of pressure, which is usually the oil pressure. In this case, counter-

the formation by modifying the fluid contact angle, leading to an current flow between the reservoir and the well cannot be simu-

impairment of the relative permeability. Even though laboratory lated because the filtrate flow rate in Eq. 4 is calculated using the

tests help the selection of drilling fluids to minimize the effect in same pressure difference as for the hydrocarbon one.

chemical incompatibility of invading fluid with in-situ rock matrix For the evaluation of formation damage around a horizontal

and in-situ fluids, filtrate invasion is characterized by phase trap- well, the permeability anisotropy effect should be considered. The

ping, fine migration, polymer absorption/retention, and wettability modeling of fluid flow in the vicinity of the horizontal well in

alteration. All these phenomena reduce near-well permeability and anisotropic media is described in Ding and Renard (2003). A ra-

oil mobility. They can be globally represented by a hysteresis of dial/elliptic-type grid, which follows near-well streamlines, is used

relative permeabilities during backflow production. for numerical simulation.

A Numerical Model Skin Calculation

As with OBD, a two-phase flow model is used for the modeling of Formation damage is usually characterized by skin factors. Skin

invasive formation damage during UBD. To simulate temporary factor is a criterion for well-performance evaluation. It can also

overbalanced periods of time, the model developed for OBD (Ding be used in the reservoir simulator for well-productivity calcula-

et al. 2002) can be directly used by reducing the drilling time to the tions. To better describe nonuniform damage along horizontal

overbalanced duration. To simulate spontaneous imbibition, wells, specific-variable skin factors along the well length need to

counter-current flow has been modeled using capillary pressure. be determined.

The two-phase flow equation is given by A technique to determine specific skins along the well is de-

冋 册

veloped based on an optimization procedure. Formation damage is

冦

⭸ f Kkrf first simulated using the model presented previously. Then, a clas-

共f Sf兲 = div 共ⵜPf − f gⵜz兲

⭸t f sical reservoir simulator, which does not integrate the modeling of

冋 册

, . . . . . . . . . . . . . (1) formation damage mechanisms, is used to match the flow rate

⭸ Kkrh along the well calculated by the formation damage model. The

共hSh兲 = div 共ⵜPh − hgⵜz兲

⭸t h unknown parameters to be determined are skins associated to each

wellblock of the reservoir simulator. The objective function to be

where S is the saturation (subscript f for filtrate and h for hydro- minimized is defined as follows:

carbon), P is the pressure, K = 冉 冊 kx

ky

kz

is the absolute per- J共S兲 =

NP

兺 关Q − q 共S兲兴 ,

i=1

i i

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (5)

meability of the formation, kr is the relative permeability of each where Qi is the well flow rate at perforation i simulated using the

fluid as a function of Sf , g is the gravity factor, is the porosity, formation damage model, NP represents the number of perfora-

is the density, and is the viscosity. The pressures in filtrate and tions (wellblocks), and qi is the well flow rate calculated with the

oil phases are related by using the capillary pressure: standard reservoir simulator. The unknown parameters are the skin

factors S in each wellblock. Specific skins can therefore be deter-

pc共Sf兲 = ph共Sf兲 − pf 共Sf兲 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) mined along the well.

It is represented as a function of filtrate saturation Sf. Numerical Comparison Between UBD and OBD

The preceding equation is closed by the saturation relationship:

Example 1: Cross Section in an Oil Reservoir. Formation dam-

Sf + Sh = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (3) age is studied on a cross section of a horizontal well in an oil

reservoir. The considered cross section is 10 m. The reservoir

As discussed in the previous section, relative permeability hys- permeability is homogeneous on the cross section with a value of

teresis is used to globally represent the various physical pheno- 8 md. A radial grid is used for numerical discretization, and a

mena induced by filtrate during backflow that act on near-wellbore constant pressure is imposed as an outer boundary condition. Ini-

flow behavior. tial reservoir pressure is 320 bar. Wellbore radius is 0.108 m. Both

Because of capillary pressure, pressure gradients between fil- UBD and OBD are considered in simulations under different drill-

trate and oil may be in opposite directions, leading to countercur- ing conditions summarized in Table 1:

rent flow. As a result, during UBD, filtrate can invade the forma- 1. Case 1: OBD; the overbalanced pressure is 15 bar (drilling

tion, while oil is produced from the well. The well flow rate in pressure at 335 bar) for a drilling period of 2 days. To simulate

each phase is calculated using the phase pressure difference: well productivity with OBD, it is necessary to put cake properties

krh in the model (Ding et al. 2002). Permeability reduction in the zone

qh = PI共ph − pw兲 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (4a) occupied by internal cake measured from the laboratory are pre-

sented in Fig. 1. Permeability of the external cake is 0.02 md with

krf a thickness of 4 mm.

qf = PI共pf − pw兲 , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (4b) 2. Case 2: UBD; the underbalanced pressure is –20 bar (drilling

pressure at 300 bar). During operation, a temporary overbalanced

where q is the well flow rate, PI is the numerical well index, ph is pressure of 15 bar occurs accidentally for a period of 5 minutes.

the hydrocarbon pressure in the formation, pf is the filtrate pressure 3. Case 3: UBD; the underbalanced pressure is –20 bar. During

in the formation, and pw is the bottomhole-well flowing pressure. operation, a temporary overbalanced pressure of 15 bar occurs for

Because of the presence of capillary pressure, the hydrocarbon a period of 15 minutes.

52 February 2006 SPE Production & Operations

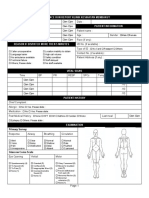

Fig. 2—Capillary pressure between filtrate and oil in reservoir.

quence, flow efficiency is reduced to 84% with 5 minutes over-

balanced pressure (Case 2) and 75% with 15 minutes overbalanced

pressure (Case 3). Important productivity losses are observed with

Fig. 1—Permeability reduction in internal cake. temporary overbalanced pressure owing to no filter-cake protec-

tion to prevent filtrate invasion for UBD. Therefore, precautions

should be taken to avoid temporary overbalanced pressure during

4. Case 4: UBD; the underbalanced pressure is –20 bar for 2

UBD in high-enough permeability reservoirs.

days. A capillary pressure between drilling fluid and oil in place

For OBD, filter cakes are formed to prevent filtrate invasion.

with a maximum of 5 bar is considered (Fig. 2).

Comparing the cases with a permeability of 100 md and 8 md, flow

In Cases 2 and 3, no capillary pressure is considered. In Case 4,

efficiency is only slightly reduced from 59 to 57%. In the presence

pressure is always underbalanced with –20 bar. Hysteresis of rela-

of capillary pressure, filtrate invasion is not deeper when compar-

tive permeability curves are considered to simulate well produc-

ing the two cases, because the maximum capillary pressure is

tivity loss. To compare formation damage caused by different

smaller than the difference between the initial pressure and the

drilling procedures, relative permeability curves are assumed to be

applied underbalanced pressure. An equilibrium is automatically

the same for all previous cases (Fig. 3). In the figure, the index i

attained with the depth of filtrate invasion.

represents imbibition curves during the drilling period and d rep-

resents drainage curves during backflow. The initial connate water

Example 2: Cross Section in a Gas Reservoir. In this example,

saturation is 0.2. After drilling, the irreducible water saturation in

formation damage is considered in a tight gas reservoir. The well con-

the invaded zone is increased to 0.35 because of waterblocking.

figuration is the same as in the previous example. The reservoir perme-

Fig. 4a presents simulated well-productivity indices in which

ability is 1 md with an initial reservoir pressure of 320 bar. Seven cases

Case 0 denotes the case without any formation damage, and Fig.

summarized in Table 2 are compared for OBD and UBD:

4b shows the flow efficiency, comparing this reference case to the

1. Case 1: OBD; the same condition as in the previous example

cases with formation damage. The flow efficiency is defined as the

with the overbalanced drilling pressure of 15 bar for a drilling

ratio of productivity index between the damaged well and the

period of 2 days. Internal cake properties are given in Fig. 1, and the

undamaged well. Fig. 4c presents the corresponding skin factor

external cake permeability is 0.02 md with a thickness of 4 mm.

obtained using the inversion procedure. Simulations show that

UBD can damage the near-wellbore formation. Temporary over-

balanced pressure during drilling also damages the well, and well

productivity loss depends on overbalanced duration. In the pres-

ence of capillary pressure, damage can occur even when the maxi-

mum capillary pressure value is lower than the pressure difference

between the initial reservoir pressure and the applied UBD pres-

sure. In fact, reservoir pressure in the well vicinity decreases rap-

idly because of the production of reservoir fluid during UBD. The

pressure difference in the near-well region and in the wellbore can

be lower than the capillary pressure. In this case, countercurrent

occurs, but filtrate cannot go very far. Productivity losses in UBD

are not very high (flow efficiencies are 95, 91, and 91% for Cases

2 through 4). However, OBD causes much higher loss of well

productivity, with a flow efficiency of 59%.

The volume of filtrate invasion depends on reservoir perme-

ability. Fig. 5 presents the comparison of well productivity indices,

flow efficiencies, and skin factors for both OBD and UBD for the

reservoir permeability of 100 md (instead of 8 md). When pressure

is temporarily overbalanced during UBD, filtrate invasion is more Fig. 3—Relative permeability in hysteresis during drilling

important because of high formation permeability. As a conse- and backflow.

February 2006 SPE Production & Operations 53

Fig. 4—Comparison of well productivity in oil reservoir for OBD and UBD with K=8 md (Example 1). Comparisons of (a) productivity

index, (b) flow efficiency, and (c) skin.

Fig. 5—Comparison of well productivity in oil reservoir for OBD and UBD with K=100 md (Example 1). Comparisons of

(a) productivity index, (b) flow efficiency, and (c) skin.

54 February 2006 SPE Production & Operations

Fig. 6—Shape of capillary pressure between filtrate and gas

in reservoir.

Fig. 7—Relative permeability in hysteresis between filtrate and

gas in reservoir.

2. Case 2: UBD; the underbalanced pressure is –20 bar (drilling

pressure at 300 bar). During operation, a temporary overbalanced

pressure of 15 bar occurs accidentally for a period of 5 minutes. No

capillary pressure is considered.

3. Case 3: UBD, the underbalanced pressure is –20 bar. During

operation, a temporary overbalanced pressure of 15 bar occurs for

a period of 15 minutes. No capillary pressure is considered.

4. Cases 4 to 7: UBD; the underbalanced pressure is –20 bar for

2 days. A capillary pressure between drilling fluid and oil in place

is considered. The form of the curve is given in Fig. 6. The maxi-

mum value is 8 bar for Case 4, 20 bar for case 5, 50 bar for Case

6, and 100 bar for Case 7.

In Cases 2 and 3, capillary pressure is not present. In Cases 4

through 7, drilling pressure is always underbalanced. In a tight gas

reservoir, capillary pressure is generally very high (Bennion and

Thomas 1994; Bennion et al. 1994; Bennion et al. 1998). Relative

permeability curves in hysteresis are given in Fig. 7. The initial

connate water saturation is 0.1. The final irreducible water saturation

in backflow increases to 0.3 because of water-blocking phenomena.

Fig. 8a presents a well productivity index for all cases. Case 0

corresponds to the case of no formation damage. Fig. 8b shows the

flow efficiency, and Fig. 8c shows the skin factor. In a tight gas

reservoir, formation damage is generally serious. For an accidental

temporary overbalanced pressure of 15 bar lasting 5 minutes, flow

efficiency is reduced to 84%. If the duration is 15 minutes, flow

efficiency is reduced to 79%. Because no filter-cake protection

exists, the risks of damage during UBD cannot be omitted.

Cases 4 through 7 correspond to formation damage caused by

capillary force in UBD. Because capillary pressure is generally high

in a tight gas reservoir, filtrate invasion is important with countercur-

rent flow. Well productivity can be halved for high capillary pressure.

In spite of important formation damage during UBD, it is still

considered a good choice in this example because formation dam-

age with OBD is greater. In the OBD, well productivity is reduced

to 44%, even without the presence of capillary forces.

Although UBD is generally better than OBD, precautions

should be taken in fluid selection and in drilling conditions. It

seems that formation damage can be minimized by careful labo-

ratory experiments in fluid selection to minimize capillary pressure

and to improve the hysteresis effect in relative permeability by

reducing water-blocking phenomena.

Example 3: Horizontal Well in an Anisotropic Medium. In this

example, we consider a horizontal well with a length of 1000 m in

a tight gas reservoir. Permeability in the horizontal direction is 1

md. The vertical to horizontal permeability ratio is 0.1. The well-

bore radius is 0.108 m. Fluid properties (cake properties for OBD,

relative permeability, capillary pressure) are the same as in Ex-

Fig. 8—Comparison of well productivity in tight gas reservoir ample 2. A radial grid is used for numerical discretization with 14

for OBD and UBD (Example 2). Comparisons of (a) productivity blocks along the well length, 6 blocks in the angular direction, and

index, (b) flow efficiency, and (c) skin factor. 30 blocks in the radial direction. The well is drilled with an aver-

February 2006 SPE Production & Operations 55

age speed of 20 m/hr. Approximately 2 days are necessary to drill and flow efficiency for the considered cases. Temporary overbal-

the well along its full length of 1000 m. Drilling speed is taken into anced drilling of 15 minutes can reduce the well productivity 6 to

account in the simulation by opening the perforations one after 10%. The presence of capillary pressure can reduce well produc-

another in the model. This creates the well-known cone-type for- tivity from 16 to 50%. Formation damage in this example is less

mation damage along the well. The following cases summarized in serious than that in Example 2 because average drilling time is

Table 3 are compared in OBD or UBD: only 1 day with high fluid exposure time near well heel (approxi-

1. Case 1: OBD; the overbalanced pressure is 15 bar. mately 2 days) and low exposure time near well toe.

2. Case 2: UBD; the pressure is temporarily overbalanced: 15 Cone-type filtrate invasions are observed along the well length,

bar during 15 minutes at the end of drilling. because of different exposure times between the drilling fluid and the

3. Cases 3 and 4: The same as Case 2, but the overbalanced period formation. Filtrate invasion is deeper near the heel and less so near the

occurs when the drilled length is 800 and 500 m, respectively. toe. As a consequence, productivity near the toe is higher than that near

4. Cases 5 through 8: UBD; capillary pressure is considered the heel. In our case, the pressure drop in the well is omitted. Fig. 10a

with a maximum of 8 bar (Fig. 6) for Case 5, 20 bar for Case 6, 50 gives production profiles along the well for Case 1 and Cases 5 through

bar for Case 7, and 100 bar for Case 8. 8, and Fig. 10b shows the corresponding specific skin factors along the

5. In Cases 2 through 4, no capillary pressure is present. In well. The phenomenon of nonuniform formation damage is not very

Cases 5 through 8, drilling pressure is always underbalanced with significant for UBD when capillary pressure is low.

–20 bar. Fig. 9 presents a comparison of well productivity index

Conclusions

UBD is often presented as a solution to eliminate formation dam-

age. But in cases of temporary overbalanced periods, deep inva-

Fig. 9—Comparison of well productivity for horizontal well in

OBD and UBD in a tight gas reservoir (Example 3). Comparisons Fig. 10—Nonuniform formation damage along the well. (a) Flow

of (a) productivity index and (b) flow efficiency. rate distribution along the well; (b) specific skin along the well.

56 February 2006 SPE Production & Operations

sion of the reservoir by the drilling fluid can occur because there Cade, R. et al.: “Does Underbalanced Drilling Really Add Reserves?”

is no filter-cake protection. Even in constant underbalanced con- paper SPE 81626 presented at the 2003 IADC/SPE Underbalanced

ditions, the effect of capillary pressure may induce spontaneous Technology Conference and Exhibition, Houston, 25–26 March.

imbibition and generate damage of the near-wellbore formation. Ding, Y. et al.: “Modeling of Both Near-Wellbore Damage and Natural

Numerical modeling is presented to quantify the near-wellbore Cleanup of Horizontal Wells Drilled With a Water-Based Mud,” paper

formation damage. The productivity losses are compared in ex- SPE 73733 presented at the 2002 SPE International Symposium and

amples for UBD and OBD, considering temporary overbalanced Exhibition on Formation Damage Control, Lafayette, Louisiana, 20–21

periods and effects of capillary pressure for underbalanced drilling. February.

The results obtained show that formation damage can be signifi- Ding, Y. and Renard, G. : “Modelling of Near-Wellbore Formation Dam-

cant in UBD, especially for high capillary pressures or high- age for Openhole Horizontal Wells in Anisotropic Media,” paper SPE

permeability reservoirs. Although UBD is generally better than 82255 presented at the 2003 SPE European Formation Damage Con-

OBD, precautions should be taken in fluid selection and in drilling ference, The Hague, 13–14 May.

conditions. It seems that formation damage can be minimized by Suryanarayana, P.V. et al.: “Development of a Probabilistic Model To

careful laboratory experiments in fluid selection to minimize cap- Estimate Productivity Improvement due to Underbalanced Drilling,”

illary pressure and to improve the hysteresis effect in relative paper SPE 81639 presented at the 2003 IADC/SPE Underbalanced

permeability by reducing water-blocking phenomena. Technology Conference and Exhibition, Houston, 25–26 March.

Nomenclature Xiong, H. and Shan, D.: “Reservoir Criteria for Selecting Underbalanced

g ⳱ gravity factor Drilling Candidates,” paper SPE 81621 presented at the 2003 IADC/

SPE Underbalanced Technology Conference and Exhibition, Houston,

kr ⳱ relative permeability of each fluid as a function of Sf

25–26 March.

q ⳱ well flow rate

qi ⳱ well flow rate calculated with the standard reservoir

simulator

Qi ⳱ well flow rate at perforation i simulated using the SI Metric Conversion Factors

formation damage model bar × 1.0* E+05 ⳱ Pa

NP ⳱ number of perforations (wellblocks) ft × 3.048* E–01 ⳱ m

pf ⳱ filtrate pressure in the formation

*Conversion factors are exact.

ph ⳱ hydrocarbon pressure in the formation

pw ⳱ bottomhole well flowing pressure

P ⳱ pressure

Yu Ding is a senior research engineer at Inst. Français du Pé-

PI ⳱ numerical well index

trole (IFP) in Rueil Malmaison, France. His research interests in-

S ⳱ saturation (subscript f for filtrate and h for clude numerical modeling, reservoir simulation and character-

hydrocarbon) ization, complex wells, and near-well flow. He holds a BS de-

⳱ viscosity gree in mathematics from Peking U. and MS and PhD degrees

⳱ density in applied mathematics from U. de Paris. Benjamin Herzhaft

has been a research engineer at IFP since 1997. His research

⳱ porosity interests include projects on mud logging and well productiv-

ity. He is coauthor of several SPE papers, mainly on drilling fluids

References for different applications as foams for underbalanced drilling,

Bennion, D.B. and Thomas, F.B.: “Underbalanced Drilling of Horizontal rheological properties of muds, and hydrates in drilling muds.

Wells: Does it Really Eliminate Formation Damage?” paper SPE He holds an Msc degree from ESPCI in Paris and a PhD degree

27352 presented at the 1994 SPE Formation Damage Control Sympo- in physics from the U. of Paris VI. Gerard Renard is a principal

sium, Lafayette, Lousiana, 7–10 February. research engineer at IFP. His research interests are in reservoir

engineering aspects of horizontal wells and EOR, especially in

Bennion, D.B. et al.: “Underbalanced Drilling and Formation Damage—Is

thermal recovery methods. He holds degrees in fluid mechan-

It a Total Solution?” paper presented at the 1994 Annual Meeting of the ics from the École Natl. Supérieure d’Electronique, d’Electro-

Petroleum Society of CIM, Calgary, 12–15 June. technique, d’Informatique, et d’Hydraulique de Toulouse and

Bennion, D.B. et al.: “Underbalanced Drilling: Praises and Perils,” SPEDC in petroleum engineering from the École Natl. Supérieure du

(1998) 13, No. 4, 214. Pétrole et des Moteurs.

February 2006 SPE Production & Operations 57

Вам также может понравиться

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceОт EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceОценок пока нет

- Advances in the iterative coupling between flow-geomechanical simulators: applied to cases with different contour conditionsОт EverandAdvances in the iterative coupling between flow-geomechanical simulators: applied to cases with different contour conditionsРейтинг: 5 из 5 звезд5/5 (1)

- (Full Permission)Документ11 страниц(Full Permission)mohamadi42Оценок пока нет

- Spe 59260 MsДокумент5 страницSpe 59260 MsБатырхан ИзбасарОценок пока нет

- Comparison of Under-Balanced and Managed-Pressure Drilling TechniquesДокумент10 страницComparison of Under-Balanced and Managed-Pressure Drilling TechniquesJessica Cecilia Silva Angulo100% (1)

- Effect of Drilling Fluids & Underbalance drillingDrillingFluidДокумент18 страницEffect of Drilling Fluids & Underbalance drillingDrillingFluidAhmed MamdouhОценок пока нет

- SPE 114186 Underbalanced Drilling: "Remedy For Formation-Damage, Lost-Circulation, and Other Related Conventional-Drilling Problems"Документ11 страницSPE 114186 Underbalanced Drilling: "Remedy For Formation-Damage, Lost-Circulation, and Other Related Conventional-Drilling Problems"Alejo ParraОценок пока нет

- A New Approach To Estimate Invasion Radius of Water-Based-Drilling-Fluid Filtrate To Evaluate Formation Damage Caused by Overbalance DrillingДокумент11 страницA New Approach To Estimate Invasion Radius of Water-Based-Drilling-Fluid Filtrate To Evaluate Formation Damage Caused by Overbalance DrillingAndres RomeroОценок пока нет

- Balanced Drilling With Coiled TubingДокумент9 страницBalanced Drilling With Coiled TubingMin Thant MaungОценок пока нет

- Notes 3Документ26 страницNotes 3Ruben ChirinosОценок пока нет

- Spe 205265 Ms FarFieldДокумент14 страницSpe 205265 Ms FarFieldKutbuddin BhatiaОценок пока нет

- IADC World Drilling 2003Документ12 страницIADC World Drilling 2003gplese0Оценок пока нет

- Underbalanced Drilling (UBD)Документ5 страницUnderbalanced Drilling (UBD)dca13Оценок пока нет

- 019 022 EyvazovДокумент4 страницы019 022 EyvazovCeyhun MahmudovОценок пока нет

- DrillingДокумент9 страницDrillingAhmad HassanОценок пока нет

- Exploring Underbalanced Drilling: A Comprehensive Review: International Journal For Multidisciplinary ResearchДокумент6 страницExploring Underbalanced Drilling: A Comprehensive Review: International Journal For Multidisciplinary Researchgaurobkalita2001Оценок пока нет

- SPE 90836 Well-Completion Techniques and Methodologies For Maintaining Underbalanced Conditions Throughout Initial and Subsequent Well InterventionsДокумент15 страницSPE 90836 Well-Completion Techniques and Methodologies For Maintaining Underbalanced Conditions Throughout Initial and Subsequent Well Interventionskoroko SinseiОценок пока нет

- PRJ p333 PDFДокумент5 страницPRJ p333 PDFjhon berez223344Оценок пока нет

- 19 Numerical PDFДокумент14 страниц19 Numerical PDFIJAERS JOURNALОценок пока нет

- Formation Damage and Horizontal WellsДокумент14 страницFormation Damage and Horizontal WellsAdhi100% (1)

- Energies 04 01728 PDFДокумент20 страницEnergies 04 01728 PDFAoru SamuelОценок пока нет

- Perforated Well CloggingДокумент16 страницPerforated Well Clogging1234abcdОценок пока нет

- Elliott 2012Документ7 страницElliott 2012Jeffrey JohnsonОценок пока нет

- Reservoir and Wellbore Damage Estimation Using Pressure Transient Analysis (PTA) .Документ13 страницReservoir and Wellbore Damage Estimation Using Pressure Transient Analysis (PTA) .International Journal of Innovative Science and Research TechnologyОценок пока нет

- Evaluation of The Effectiveness of Mud Acid in Well StimulationДокумент7 страницEvaluation of The Effectiveness of Mud Acid in Well StimulationRaed fouadОценок пока нет

- UBD Reservoir DesignДокумент22 страницыUBD Reservoir DesignAli MuseОценок пока нет

- IPTC 13826 Underbalanced Drilling in Shale - Perspective of Factors Influences Mechanical Borehole InstabilityДокумент19 страницIPTC 13826 Underbalanced Drilling in Shale - Perspective of Factors Influences Mechanical Borehole InstabilityBuddy OmorogbeОценок пока нет

- Underbalanced Drilling and Managed Pressure Drilling - Two Methods For Optimising DrillingДокумент2 страницыUnderbalanced Drilling and Managed Pressure Drilling - Two Methods For Optimising Drillingjahehe2000Оценок пока нет

- Spe-215029-Ms - Successful Deepwater MPD Application in Drilling and Cementing Through Depleted Formation With Wellbore Instability and Loss Circulation Challenge Offshore of SabaДокумент12 страницSpe-215029-Ms - Successful Deepwater MPD Application in Drilling and Cementing Through Depleted Formation With Wellbore Instability and Loss Circulation Challenge Offshore of SabaRodrigo BarretoОценок пока нет

- Spe 82249 PaДокумент15 страницSpe 82249 PaMicaela Flores LanzaОценок пока нет

- Bennion 1999Документ6 страницBennion 1999Andres CaОценок пока нет

- Advantages of Managed Pressure Drilling and The Recent Deployment of The Technology in Vietnam PDFДокумент9 страницAdvantages of Managed Pressure Drilling and The Recent Deployment of The Technology in Vietnam PDFYudha Yusriansyah100% (1)

- MPD UBD ReportДокумент76 страницMPD UBD ReportArjit KumarОценок пока нет

- MsДокумент30 страницMsZadira AyuОценок пока нет

- Formation DamageДокумент26 страницFormation DamagerajneeshgogoiОценок пока нет

- 2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFДокумент11 страниц2011 Horizontal Underbalanced Drilling Technology Successfully Applied in Field AA - Libya PDFcarlorgsОценок пока нет

- Loss Circulation in Drilling and Well Construction: The Significance of Applications of Crosslinked Polymers in Wellbore Strengthening: A ReviewДокумент13 страницLoss Circulation in Drilling and Well Construction: The Significance of Applications of Crosslinked Polymers in Wellbore Strengthening: A ReviewAdrianОценок пока нет

- Assessment of Total Skin Factor in Perforated WellsДокумент22 страницыAssessment of Total Skin Factor in Perforated WellsDania RodriguezОценок пока нет

- Spe 184863 MSДокумент18 страницSpe 184863 MSSSОценок пока нет

- Coiled Tubing-The Future of Underbalanced DrillingДокумент5 страницCoiled Tubing-The Future of Underbalanced DrillingJuanito GutierrezОценок пока нет

- Managing Borehole Stability ProblemsДокумент8 страницManaging Borehole Stability ProblemsWai HtutОценок пока нет

- Managed Pressure Drilling VietnamДокумент27 страницManaged Pressure Drilling VietnamVINCENTIUS ADVEN BRILIANОценок пока нет

- MPD SchemeticДокумент9 страницMPD Schemeticsaif khudhairОценок пока нет

- A New Slogan For Drilling Fluids EngineersДокумент14 страницA New Slogan For Drilling Fluids EngineersRachid TouatiОценок пока нет

- Spe 69718 MSДокумент14 страницSpe 69718 MSAbo Hanif Al EmranОценок пока нет

- Particulars in Killing Gas Production Wells: KristaforДокумент6 страницParticulars in Killing Gas Production Wells: KristaforbengamОценок пока нет

- Arma2018 916 HaiderqassimДокумент10 страницArma2018 916 HaiderqassimNabaa M. Al-KhazrajiОценок пока нет

- Foreword: UBD Background and OverviewДокумент3 страницыForeword: UBD Background and OverviewdafneОценок пока нет

- Formation Damage and The Components of SkinДокумент45 страницFormation Damage and The Components of SkinBrian OmbogoОценок пока нет

- Shokufe Afzali 2022 Fhokufe Afzali Computational Fluid Dynamic Simulation of Multi-Phase Flow in FracturedДокумент16 страницShokufe Afzali 2022 Fhokufe Afzali Computational Fluid Dynamic Simulation of Multi-Phase Flow in FracturedmadadmrdОценок пока нет

- Lost CirculationДокумент11 страницLost CirculationNwaokorie IkechiОценок пока нет

- SPE-180491-MS Customized Drilling & Completion Fluids Designed For Horizontal Wells To Address The Drilling and Production Challenges - Case HistoryДокумент14 страницSPE-180491-MS Customized Drilling & Completion Fluids Designed For Horizontal Wells To Address The Drilling and Production Challenges - Case HistoryKd FaОценок пока нет

- Wellbore Stability, Stabilization and StrengtheningДокумент14 страницWellbore Stability, Stabilization and StrengtheningAshishОценок пока нет

- Horizontal Barriers For Controlling Water ConingДокумент8 страницHorizontal Barriers For Controlling Water ConingMomha Jean-AlainОценок пока нет

- Overbalanced & Underbalanced Drilling: Dr. Amit VermaДокумент16 страницOverbalanced & Underbalanced Drilling: Dr. Amit Vermabhavik PanchalОценок пока нет

- Krueger 1988Документ24 страницыKrueger 1988JERSEY KHATLEENОценок пока нет

- Evaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellДокумент6 страницEvaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellTrần Hoàng ChươngОценок пока нет

- 68 - Cartalos Et Dupuis (1993)Документ11 страниц68 - Cartalos Et Dupuis (1993)Hicham HichamОценок пока нет

- OTC 26162 MS Alernative Technologies in Drill in Fluids For Depleted ReservoirsДокумент18 страницOTC 26162 MS Alernative Technologies in Drill in Fluids For Depleted ReservoirsBolsec14Оценок пока нет

- The Fabrication of Materials: Materials TechnologyОт EverandThe Fabrication of Materials: Materials TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- Ilovepdf MergedДокумент10 страницIlovepdf MergedhkaqlqОценок пока нет

- Q How Many Ways Can You Arrange The Letters in The Word STATISTICS? (E.g. SSSTTTIIAC Counts A One Arrangement.)Документ2 страницыQ How Many Ways Can You Arrange The Letters in The Word STATISTICS? (E.g. SSSTTTIIAC Counts A One Arrangement.)hkaqlqОценок пока нет

- Resistivity InterpretationДокумент9 страницResistivity InterpretationhkaqlqОценок пока нет

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFДокумент20 страницLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqОценок пока нет

- Chegg Tutors - Online Chat LessonzДокумент4 страницыChegg Tutors - Online Chat LessonzhkaqlqОценок пока нет

- Lecture Note 1 (Introduction)Документ29 страницLecture Note 1 (Introduction)hkaqlqОценок пока нет

- Lecture Note 5 (Pipeline Pigging)Документ25 страницLecture Note 5 (Pipeline Pigging)hkaqlqОценок пока нет

- Tutorial Sheet No.3: Well Design 2DДокумент11 страницTutorial Sheet No.3: Well Design 2Dhkaqlq100% (1)

- Polymer Flooding ReportДокумент17 страницPolymer Flooding ReporthkaqlqОценок пока нет

- Student Name: - IDДокумент1 страницаStudent Name: - IDhkaqlqОценок пока нет

- Tutorial Sheet No.4: Survey CalculationsДокумент11 страницTutorial Sheet No.4: Survey CalculationshkaqlqОценок пока нет

- Tutorial Sheet No.2: Well Design 2DДокумент10 страницTutorial Sheet No.2: Well Design 2DhkaqlqОценок пока нет

- Q2 Leader Manager Difference PDFДокумент2 страницыQ2 Leader Manager Difference PDFhkaqlqОценок пока нет

- 5 - Measurement While Drilling - 2 - 6 - 2020Документ28 страниц5 - Measurement While Drilling - 2 - 6 - 2020hkaqlqОценок пока нет

- Decision Making and The Role of Manageme PDFДокумент20 страницDecision Making and The Role of Manageme PDFRaadmaan RadОценок пока нет

- Tplink Eap110 Qig EngДокумент20 страницTplink Eap110 Qig EngMaciejОценок пока нет

- Space Hulk - WDДокумент262 страницыSpace Hulk - WDIgor Baranenko100% (1)

- Marketing FinalДокумент15 страницMarketing FinalveronicaОценок пока нет

- CEE Annual Report 2018Документ100 страницCEE Annual Report 2018BusinessTech100% (1)

- Computing of Test Statistic On Population MeanДокумент36 страницComputing of Test Statistic On Population MeanKristoffer RañolaОценок пока нет

- SMC 2D CADLibrary English 1Документ590 страницSMC 2D CADLibrary English 1Design IPGEОценок пока нет

- MASONRYДокумент8 страницMASONRYJowelyn MaderalОценок пока нет

- The Mantel Colonized Nation Somalia 10 PDFДокумент5 страницThe Mantel Colonized Nation Somalia 10 PDFAhmad AbrahamОценок пока нет

- Pivot TableДокумент19 страницPivot TablePrince AroraОценок пока нет

- 13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Документ10 страниц13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Jorellie PetalverОценок пока нет

- Project - New Restuarant Management System The Grill HouseДокумент24 страницыProject - New Restuarant Management System The Grill HouseMayank Mahajan100% (3)

- User S Manual AURORA 1.2K - 2.2KДокумент288 страницUser S Manual AURORA 1.2K - 2.2KEprom ServisОценок пока нет

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsДокумент19 страницHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraОценок пока нет

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptДокумент6 страницUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- Köppen Climate Classification - Wikipedia, The Free EncyclopediaДокумент15 страницKöppen Climate Classification - Wikipedia, The Free EncyclopediaAndreea Tataru StanciОценок пока нет

- AnticyclonesДокумент5 страницAnticyclonescicileanaОценок пока нет

- Nutrition and CKDДокумент20 страницNutrition and CKDElisa SalakayОценок пока нет

- Spesifikasi PM710Документ73 страницыSpesifikasi PM710Phan'iphan'Оценок пока нет

- Module 1: Overview of Applied Behaviour Analysis (ABA)Документ37 страницModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaОценок пока нет

- The Magic DrumДокумент185 страницThe Magic Drumtanishgiri2012Оценок пока нет

- Android Developer PDFДокумент2 страницыAndroid Developer PDFDarshan ChakrasaliОценок пока нет

- Soosan Crane Training: (Principles)Документ119 страницSoosan Crane Training: (Principles)Boumediene CHIKHAOUIОценок пока нет

- LetrasДокумент9 страницLetrasMaricielo Angeline Vilca QuispeОценок пока нет

- AIA1800 Operator ManualДокумент184 страницыAIA1800 Operator ManualZain Sa'adehОценок пока нет

- Appendix - Pcmc2Документ8 страницAppendix - Pcmc2Siva PОценок пока нет

- Borang Ambulans CallДокумент2 страницыBorang Ambulans Callleo89azman100% (1)

- Career Level Diagram - V5Документ1 страницаCareer Level Diagram - V5Shivani RaikwarОценок пока нет

- Sindi and Wahab in 18th CenturyДокумент9 страницSindi and Wahab in 18th CenturyMujahid Asaadullah AbdullahОценок пока нет

- FMC Derive Price Action GuideДокумент50 страницFMC Derive Price Action GuideTafara MichaelОценок пока нет