Академический Документы

Профессиональный Документы

Культура Документы

Electronic Equipment With Battery Backup System Type Rarbi: Instruction Manual For Installation - Use - Maintenance

Загружено:

Khaled RabeaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Electronic Equipment With Battery Backup System Type Rarbi: Instruction Manual For Installation - Use - Maintenance

Загружено:

Khaled RabeaАвторское право:

Доступные форматы

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

ELECTRONIC EQUIPMENT WITH

BATTERY BACKUP SYSTEM

Type RARBI

INSTRUCTION MANUAL

FOR INSTALLATION - USE - MAINTENANCE

Manual Code: S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 1 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

MANUFACTURER: GAUSS MAGNETI S.R.L.

Via S. Scaroni 27 – Fraz. Fornaci

25131 BRESCIA (Italy)

________________________________________________________________________

PLATE DATA

MODEL : RARBI 16/C55/L3

Serial number : 33095/A

Voltage : 3/400 V - 50 Hz

Electric drawing : 02295-18-33095

Complete with air conditioning system

PRELIMINARY INFORMATION

FOREWORD

This manual is integral and essential part of the supplied product.

The equipment must be devoted to the exclusive use it has been conceived for; any other use is to be

considered improper and dangerous. The manufacturer cannot be considered responsible for eventual

damages arising from not proper or wrong or use.

Any intervention going to modify the equipment structure or working cycle must be approved by the

Technical Department of Gauss Magneti Srl.

Gauss Magneti Srl is not responsible for the consequence of use of not original or not authorized spare

parts.

Read carefully these instructions and the warnings, in order to grant safety by operation and

maintenance.

HANDBOOK ADDRESSEES

This handbook is addressed to:

People responsible for plant, yard, work

Personnel charged of installation

Equipment operators

Personnel charged of maintenance

This handbook must be looked after by a person in charge, in a suitable site, and must be always

available for consultation in its best preservation condition.

In case of loss or deterioration, a copy of this documentation can be obtained from:

GAUSS MAGNETI S.r.l. - Via Scaroni 1 - 25131 Fornaci - Brescia - Italy

Lifting dept.: Tel. + 39-030-3580375 Fax + 39-030-3580846

INDICATIONS AND NORMS

Please refer to the ones indicated in the enclosed CE Declaration (or attached to the

machine).

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 2 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

SAFETY INFORMATION

INTRODUCTION

In this section the safety norms to be complied with during installation, use and maintenance of the

electric equipment are reported.

Warnings:

Read carefully these instructions and examine the equipment in order to make oneself familiar with it

before starting any setting at work, use or maintenance operation. The following warnings may

appear in different part of this documentation or the equipment itself to warn out for risks or to draw

attention on information intended to clarify or simplify a procedure.

The following warnings point out the circumstances where indications must be complied

With in order to avoid serious mistakes and damages to the equipment and risks for people' s safety

and even life.

Warnings can be split into:

DANGER

This warning means that a faulty compliance to these warnings can jeopardize people' s safety (with

venture of life) or bring to damages to the equipment and plant components.

WARNING

Means a situation of potential danger, which, if not avoided, can jeopardize people' s safety or bring

to damages to the equipment and plant components

DANGEROUS VOLTAGES

This warning means that a faulty compliance to these warnings can jeopardize people' s safety (with

venture of life) or bring to damages to the equipment and plant components.

QUALIFIED PERSONNEL

Setting at works and operation of the plant or of its parts, electromagnets included, must be carried

out according to the instructions of this handbook

Any intervention onto the equipment must be only carried out by specialized and trained

personnel. This is intended to be personnel which has the qualification to connect, earth and

insert, according to safety standards, electrical circuits, equipments, systems.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 3 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

REMARK

This handbook is an instruction manual for QUALIFIED PERSONNEL ONLY.

Faulty compliance to these warnings can jeopardize people' s safety (with venture of life) or bring to

damages to the equipment and plant components.

Before making any intervention on the components of the equipment and before using it, it is

mandatory to read the information reported in this section.

Any operation of electric plant drawing up (connections, earth connection, setting at works,

maintenance and every intervention inside the electric equipment or on any component) must be

carried out by specialized and trained personnel, which must operate within the valid laws and rules.

Also operation must be carried out only by trained personnel.

Any operation, manoeuvre, action or behaviour not listed in the present manual cannot be carried

out if not agreed with and authorized in writing by Gauss Magneti s.r.l.

ELECTRIC BOARD

AGREED USE: COMMAND OF ELECTROMAGNETS

The technical data and the electric connections according to the enclosed electric diagrams must be

complied with in order to use correctly the equipment.

Uses different from the technical data reported in the electric diagrams and in the section “General

characteristics of the electric board” are not allowed.

Uses different from the ones cited in this handbook are not allowed.

All operations of maintenance on the electric board must be carried out by personnel specialized

and trained in the electro technical and electronic technology.

DANGER

When the magnet is activated, if a fault occurs in the electrical equipment, in the supply line or inside

the magnet itself, the load falls down.

The presence of batteries cannot prevent the load from falling in any occasion; it is only an

alternative supply line in case of mains failure.

WARNING

The electric equipment and all electric components within the scope of supply must be suitably

earthed by specialized personnel.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 4 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

WARNING

The electric equipment and all electric components within the scope of supply must be suitably

earthed by specialized personnel.

NEVER try to carry out interventions in the electric board or on any component with fed

equipment. Open the main switch and use a measure instrument to check that no voltage is

in the equipment. Only after this check the intervention can be carried out.

This procedure must always be followed when acting on the electric board or on the magnet.

DANGER

Cutting off the electric supply with magnet under voltage, because of faulty maneuvers, represents a

source of danger, as electric arcs of large dimensions and intensity can occur on the components

under direct voltage.

These electric arcs can be dangerous to people's safety (venturing their life) and to the equipment

components.

Faulty maneuvers:

Do not open the magnet supply line with inserted magnet. For emergency switching off, open the

3-phase net switch.

Do not open the fuses with inserted magnet

Do not disconnect wires from their terminal with inserted magnet

Do not disconnect plug sockets wit inserted magnet

Do not open connecting boxes with inserted magnet

Do not remove any protection from the electric components in the equipment.

Do not carry out interventions on magnet when it is under voltage. Deactivate the magnet by

means of the relevant commands and open the main switch (check that there is no voltage using

a suitable measuring instruments)

WARNING

All operations of maintenance on the magnet must be carried out by specialized and trained

personnel.

NEVER carry out interventions on the magnet when it is on. Deactivate the magnet by means of

relevant commands and open the net supply switch. Use a measure instrument to check that no

voltage is in the equipment. Only after this check the intervention can be carried out.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 5 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

DANGER

The electromagnet is fed by the net through the converter ABB DCS 800. When the electromagnet

is not magnetized, it is not physically disconnected from the 3-phase supply net, being the power

section of the converted controlled by semiconductors.

This means that even when deactivated the magnet IS NOT INSULATED from the electric net.

The electric part connecting the electromagnet or the electromagnet itself could give rise to sudden

dangerous voltages, because of failures or anomalies of the converter internal circuit.

In order to avoid risky situations to persons never carry out interventions on the magnet or on

electric components if the net switch IS NOT OPEN.

Never carry out the following operations, if previously the net supply has not been disconnected.

Following maneuvers are forbidden till the net line switch is not locked in open position:

NEVER open terminal boxes between electric board and electromagnet

NEVER open the brushes protection on the cable drum

NEVER open plug / sockets because of maintenance to the electric board and the electromagnet

NEVER open the electromagnet connecting box

NEVER open or remove any protection on the electric part in the equipment

Non respect of these instructions can bring to serious risks for safety (even life) of the

personnel.

THREE PHASE CONVERTER

DANGER

All operations of maintenance on the electric board must be carried out by personnel specialized

and trained in the electro technical and electronic technology.

NEVER carry out interventions on the converter when it is on. Open the net supply switch and use a

measure instrument to check that no voltage is in the equipment. Only after this check the

intervention can be carried out.

Because of the internal control circuits, even after line tension disconnection, in the converter high

and dangerous voltages can be present. Always operate with due caution.

Non respect of these instructions can bring to serious risks for safety (even life) of the

personnel.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 6 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

General warning

Controls by means of voltage must not be carried out on the converter components. Being the

converter an electronic equipment, it contains semiconductors which would not stand high voltages.

Carry out insulation measurements after having disconnected all converter connecting wires. Non

respect of these instructions can bring to serious damages to the converter.

BATTERY-CHARGER

DANGER

Any intervention on battery-charger must be carried out by qualified personnel, trained in electronic

technology.

Do not carry out interventions on battery-charger when it is ON. Open the main switch, the battery

switch and check that no voltage is present (using a voltmeter); only in this case it is possible to

intervene.

Because of internal control circuits, there can be high dangerous voltages in the battery-charger

even in case of power cable disconnection. Always operate with extreme caution.

Non respect of these instructions can cause serious risks of injuries or life for personnel.

Warning:

It is not allowed to check insulation on battery-charger components using voltage (risk of damaging

of semi-conductor electronic components).

Carry out insulation checks after having disconnected all cables of battery-charger.

Non respect of these instructions can cause serious damages to battery-charger.

BATTERY VOLTAGE CONTROL CARD

WARNING

It is not allowed to check insulation on control card using voltage (risk of damaging of semi-

conductor electronic components).

Carry out insulation checks after having disconnected all cables of control card.

Non respect of these instructions can cause serious damages to control card.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 7 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

BATTERY LINE INSERTION SWITCH

WARNING

Any intervention on this switch must be carried out by qualified personnel, trained in electronic

technology.

Do not carry out interventions on this switch when the mains voltage is connected. Open the main

switch, the battery switch and check that no voltage is present (using a voltmeter); only in this case it

is possible to intervene.

Before switching on the equipment, check that the flame arresters are in the correct position.

Non respect of these instructions can cause serious risks of injuries or life for personnel.

PLC CONTROLLER

WARNING

General warning:

Controls by means of voltage must not be carried out on the bat controller components. Being the

controller an electronic equipment, it contains semiconductors which would not stand high voltages.

Carry out insulation measurements after having disconnected all controller connecting wires. Non

respect of these instructions can bring to serious damages to the controller.

ELECTRICAL CABINET

WARNING

Do not carry out manual interventions on equipment components which can modify sequences or

electrical interlocks.

Do not remove component safety protections, unless aware of the consequent risks.

Gauss Magneti Srl is not responsible for any consequence of improper or unauthorized use.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 8 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

SCOPE OF SUPPLY

Electric board

AT TIME OF DELIVERY

When receiving the material, check absence of damages to the different part of the supply due to

transport. If missing or damaged parts are noticed, inform immediately the supplier and the

forwarder.

Check that alI components in the electric board are correctly instaIIed and firmly tightened

TRANSPORT AND STORING

All instructions of correct transport, stock and use must be complied with. Environment and climate

conditions must be according to the product specifications and to the relevant norms.

Use certified and tested lifting equipments with correct capacity.

ELECTRIC BOARD INSTALLATION

The electric board is manufactured in order to be fixed on the floor in a flat area, sheltered and with

low environment pollution.

It must also be set in vertical position, as indicated.

It is not allowed positioning the electric board in the following conditions, if not otherwise specified in

the purchasing order:

Direct sunlight

Rain

High humidity

Oil fog, oil spray

Salt fog

Powder or metallic parts in the air

Corroding gases or liquids

Radioactive substances .

Fuels

Magnetic interferences

Environment with ant bursting requirements

The back side of the electric board can be leant on a wall, as no electric devices is fixed on such

back side.

Keep the minimum distance from other boards or components installed on the right and on the left of

the electric board, according to their prescriptions, as this will enhance the thermal dissipation and

avoid mutual influence.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 9 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

SUMMARY

1.1 - APPLICATION

1.2 - PRIORITY

1.3 - GENERAL CHARACTERISTICS

1.4 - ELECTRIC BOARD COMPONENTS

2.1 - FOREWORD TO THE ELECTRIC CONNECTIONS

2.2 - ELECTRIC CONNECTIONS

2.3 - CONNECTION OF THE 3-PHASE ELECTRIC SUPPLY

2.4 - BATTERY LINE CONNECTION

2.5 - CONNECTION OF THE ELECTROMAGNET WIRES

2.6 - CONNECTION OF AUXILIARY CIRCUITS AND SIGNALS

2.7 - BATTERIES CONNECTION

3.0 - SETTING AT WORK

3.1 - BATTERIES CONNECTION CHECK - TERMINAL BOX X1

3.2 - CLOSING 14QS1 BATTERIES SWITCH

3.3 - CLOSING 1QS1 ELECTRIC SUPPLY SWITCH

3.4 - CONVERTER ALARMS

3.5 - CONVERTER ALARM RESET

4.1 - OPERATION DESCRIPTION

4.2 - MAGNETIZATION

4.3 - DEMAGNETIZATION

4.4 - SETTING BY POTENTIOMETER

4.5 - PUSH BUTTON SETTING

4.6 - OVERHEATING SIGNALLING (only for equipment provided with this control)

4.7 - CONNECTION OF SELECTABLE ELECTROMAGNETS

4.8 - DISCONNECTION OF SELECTABLE ELECTROMAGNETS

4.9 - SIGNALLING OF MAX MAGNET INSERTION TIME (only for equipment provided with this

control)

4.10- MAGNETIZATION BOOST (only for equipment provided with this control)

4.11- TOUCH SCREEN HMI PANEL FRONT DOOR

5.1 - OPERATION OF 14KM2 INVERTED POLES CONTACTOR

(NORMALLY CLOSED)

5.2 - DESCRIPTION OF BATTERIES INTERVENTION

6.1 - EMERGENCY TEST

7.1 - BATTERY CHARGER DESCRIPTION

8.1 - DISCONNECTION OF 3-PHASE ELECTRIC SUPPLY

8.2 - MAINTENANCE

9.1 - SCR FUNCTIONS CHECK

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 10 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

1.1 - APPLICATION

CONTROL OF ELECTROMAGNETS

WARNING

1.2 - PRIORITY

THE HERE DESCRIBED EQUIPMENT, BECAUSE OF ITS CHARACTERISTICS AND OF THE

PRESENCE OF BATTERIES, MUST ALWAYS BE FED BY THE ELECTRIC NETWORK, AS THE

INTERNAL CIRCUITS COULD UNCHARGED THE BATTERIES IN CASE OF LONG TIME

EQUIPMENT DEACTIVATION.

In case of disconnection of the equipment from 3-phase network, open line switch and

batteries switch.

1.3 - GENERAL CHARACTERISTICS

RARBI electronic equipment consists of a digital, two-directional type, 3-phase AC / CC converter

(drive), used for electromagnet command, of an electromechanical system for batteries intervention

in case of loss of supply voltage or failure by the digital converter and of a battery charger for

complete battery charging and holding.

The magnet command consists of the main commands: magnetization, demagnetization, setting by

push button or potentiometer.

SUPPLY VOLTAGE 3 /400 Vac, 50 Hz

MAX POWER FROM NETWORK 39 KVA

BATTERY VOLTAGE 220 Vdc,

BATTERY CAPACITY 65 Ah

MAGNET VOLTAGE 220 V dc

MAX. MAGNET POWER 16000 W

AUX CIRCUITS VOLTAGE 24 Vdc

COOLING FORCED

OPERATING TEMPERATURE 0° ÷ +55 °C

RELATIVE HUMIDITY 20 - 90 %

PROTECTION GRADE IP 54

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 11 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

DRIVER PROTECTIONS:

In order to limit the short-circuit current, to reduce net voltage swinging and net current

di/dt: commutations reactances.

RC filters on tyristors

Protection from short-circuit: extra-fast fuses

From overload: Current limitation (Alarm F502)

From phase failure: alarm F512

From over-temperature: by thermal pad on the dissipater; alarm F504

LINE TO ELECTROMAGNET

Stop for disconnected magnet (only for equipment provided with this control)

The drive stop because of disconnected magnet is active 6 seconds after magnetization command.

It gets active if a current threshold is over passed.

The signal of disconnected magnet is shown by blinking of the magnetization warning light. The

converter remains blocked till opening the magnetization command.

Remark:

In case of potentiometer in the equipment, the signal of disconnected magnet is enabled if the

potentiometer is set over 10% of its end value.

WARNING

During the phase of “stop for disconnected magnet”, the drive does not deliver energy but the

system is in magnetization phase.

Therefore the battery insertion command is activated.

In this condition, operate immediately the demagnetisation command in order to deactivate the

system.

1.4 - ELECTRIC BOARD COMPONENTS

See the electrical diagram enclosed

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 12 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

2.0 INSTALLATION NORMS

2.1 FOREWORD TO THE ELECTRIC CONNECTIONS

Any operations referring to the electric circuit design, lay-out, connecting, setting at works,

maintenance and any intervention in the electric equipment or in the batteries must be carried out by

specialized personnel.

2.2 ELECTRIC CONNECTIONS

Respect all earthling connections according to existing norms and use material complying with

Norm CEI EN-60204-1, carry out all connections to terminal boxes according to enclosed drawings,

use wires with sections suitable to their current as per enclosed electric drawings.

2.3 NET SUPPLY CONNECTION

See enclosed electric drawing

connect earth wire to relative earth terminal or bar

2.4 BATTERY LINE CONNECTION

WARNING

See enclosed electric drawing

BEFORE CARRYING OUT THE CONNECTION, VERIFY BATTERY SWITCH TO BE IN OFF

POSITION. BATTERIES MUST BE CONNECTED AT LAST.

TERMINAL BOARD X1

L1-L2-L3 : TERMINALS FOR NET SUPPLY CONNECTION

- 235 terminal for wire from - battery terminal

+ 230 terminal for wire from + battery terminal

WARNING: incorrect batteries connection can damage the equipment

2.5 ELECTROMAGNET CONNECTION

See enclosed electric drawing

(no polarity to be paid attention to)

connect earth wire to relative earth terminal or bar

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 13 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

2.6 AUXILIARY CIRCUIT CONNECTION

See the electrical diagram enclosed

connect earth wire to relative earth terminal or bar

If no potentiometer is used in the equipment, bridges the terminals according to the electric drawing

2.7 BATTERY CONNECTION

DANGEROUS VOLTAGES

BATTERIES ARE ALREADY CHARGED AND THEREFORE BETWEEN THEIR POLES THERE

IS A VOLTAGE OF ABOUT 12.2 V .

CARRY OUT BATTERIES CONNECTION USING INSULATING GLOVES AND INSULATED

SPANNERS.

Before connecting the batteries, make sure that the main switch and batteries switch OFF.

The wires in the electric board must already be connected to relative terminals - 235 and + 230.

1) consult connection electric drawing

2) batteries must be connected in series. Total voltage between connected batteries between void

terminals is 220 Vdc

3) before connecting batteries, make sure that batteries switch is OFF.

4) connect wire - 235 from electric board to negative battery terminal

5) connect wire + 230 from electric board to positive battery terminal

WARNING

Attention: a wrong batteries connection can damage the whole equipment

BEFORE SUPPLYING THE ELECTRICAL EQUIPMENT, CHECK ALL THE CONNECTIONS

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 14 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

3.0 SETTING AT WORKS

DANGEROUS VOLTAGES

During this phase it is necessary to read the converter display for eventual alarms and to carry out

functions tests. It is recommended to take actions to protect physical safety of all involved

personnel.

OPERATION SEQUENCE BY FIRST CONNECTION

During this operation, disconnect the magnets disconnecting plug / socket or acting on the magnet

power terminals (see el. dwg)

3.1 BATTERY CONNECTION CHECK – ELECTRIC BOARD TERMINAL BOX

DANGEROUS VOLTAGES

Batteries are already charged and therefore between their poles there is a voltage of about 12.2 V, if

no anomaly arises.

In case voltage drops under 190 Vdc, consult Gauss Magneti Service Department.

Use a DC voltmeter with minimum range 300 Vdc

1) apply voltmeter negative test lead on - 235 terminal

2) apply voltmeter positive test lead on + 230 terminal

3) Read value must be positive (for example 220 Vdc)

if read value is negative (for example - 220 Vdc), connection is wrong. Change connection

between electric board and batteries before proceeding.

3.2 CLOSING BATTERIES SWITCH 14QS1

DANGEROUS VOLTAGES

By closing battery switch, the following conditions must take place:

1) 14KM2 coil ON

2) 14KM2 excites and open power contacts (with disconnected coils the contacts are closed)

These conditions must occur and stay after battery switch closing.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 15 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

3.3 CLOSING 1QS1 MAIN SWITCH

DANGEROUS VOLTAGES

BEFORE CLOSING THE ELECTRIC EQUIPMENT MAIN SWITCH, CHECK THAT LINE

VOLTAGE LAYS IN A RANGE + 10 % - 15 % AND 45-65 HZ

Batteries switch must be in ON (closed) position, according to above description.

close 1QS1 line switch

14KM2 contactor must stay ON

Converter display

After initial scanning, a point appears on the drive display; it means “drive OK”.

If the converter display shows other alarms, consult the converter instruction handbook

BATTERY CHARGER WHEN CLOSING THE MAIN SWITCH

1. Warning light for discharged batteries turns (see el. drw.)

2. The battery charger run LED must get “ON” when closing line switch 1QS1

3. When closing main switch 1QS1 complete batteries charging starts (see battery charger

description)

4. Wait till charging is complete charged batteries before acting magnetization command.

If the above mentioned conditions are fulfilled, close the electric board doors, connect the

electromagnet power plug and carry out the function test.

Note for equipments supplied with transformer in separate box (electrical connections

carried out by the user).

If the led “run” of battery-charger is ON but the battery-charger does not deliver energy,

the connection between transformer (IF ANY) and cabinet terminal board is wrong.

Check on the electrical drawing.

Before carrying out this operation, open the main switch and the battery switch; check that no

voltage is present downstream the main switch (using an ac voltmeter) and downstream the

battery switch (using a dc voltmeter).

3.4 CONVERTER ALARMS

The alarm intervention bringing to the converter stop is always visualized on the display by a

number identifying it and by a short description of the alarm type. Refer to the converter

handbook for failure identification.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 16 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

3.5 CONVERTER ALARM RESET

When an alarm occurs, which brings to the converter stop, the converter logical structure

carries out the reset. The warning light Drive OK accomplishes then the following

functions:

- OFF Drive OK ( IF SIGNAL PROGRAMMED FAULT – SEE ELECTRICAL

DIAGRAM)

- ON Drive OK ( IF SIGNAL PROGRAMMED DRIVE OK – SEE ELECTRICAL

DIAGRAM)

- slow blinking, 1 sec. on – 8 sec. off, auto reset attempts, alarm does not reset. Read on

the drive segment display the alarm code.

By cutting voltage, the alarm is reset, but reoccurs if the condition bringing to the anomaly

is still present.

Warning lamp drive OK

6 seconds ON - 2 seconds OFF = Fault drive -U1 (6 sec. ON = alarm signal - 2 sec. OFF =

autoreset)

If the alarm does not reset, constantly repeats 6 sec. ON - 2 sec. OFF. Read on the

segment display of the drive U1, the alarm code.

If the alarm resets, the lamp remains off.

(By powering the equipment after opening the cabinet, the message will appear again if

the fault is still present)

2) Blinking, 1 sec. ON - 600 ms OFF: the "magnetize" control has been executed and the

drive has detected that the magnet is not connected. Run the "demagnetize" control.

Connect the magnet or check the 220 Vdc power circuit which feeds the magnet.

4.1 OPERATION

DANGEROUS VOLTAGES

IT IS RECOMMENDED BEFORE CONNECTING OR DISCONNECTING THE

INSERTED PLUG IN THE BRIDGE CRANE SOCKET TO MAKE SURE THAT THE

ELECTROMAGNET IS NOT IN FUNCTION.

NEVER CONNECT OR DISCONNECT THE PLUG WITH OPERATING

ELECTROMAGNET !

Connect the electromagnet plug in the power plug installed on the bridge crane hook

Close electric net 1QS1 switch and 14QS1 battery switch.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 17 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

4.2 MAGNETIZATION

DANGER

When the magnet is activated, if a fault occurs in the electrical equipment, in the supply line or

inside the magnet itself, the load falls down.

The presence of batteries cannot prevent the load from falling in any occasion; it is only an

alternative supply line in case of mains failure.

Pressing magnetization button, the command can be activated if the following conditions are

present:

- aux circuit voltage ON

- batteries charged

- drive OK

- battery insertion contactor ON

- 220 Vdc battery voltage present

- other conditions for non-standard equipments: see el. dwg.

Magnetization contactor excites driving converter in run.

The converter starts feeding energy to the electromagnets at voltage 220 Vdc if the potentiometer

terminals are bridged. In presence of potentiometer, at voltage set by the potentiometer itself.

4.3 DEMAGNETIZATION

WARNING

By acting on the push button, the magnetization command is carried out if the following conditions

are fulfilled:

By acting on demagnetization push button, demagnetization contactor is excited.

1. Converter brings output voltage from 220 Vdc to 0 Vdc

2. When voltage attains 0 Vdc the converter reverses output voltage and starts again feeding

energy to the electromagnets for the time set by timer. This sequence is called COUNTER

EXCITATION and has purpose to give rise to a repulsive force on the material stuck onto the

electromagnet.

COUNTER EXCITATION consists in the electromagnets voltage polarity inversion.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 18 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

4.4 SETTING BY POTENTIOMETER (only equipment with this control)

WARNING

By acting on the push button, the magnetization command is carried out if the following conditions

are fulfilled:

Setting by potentiometer can be useful during magnetization in order to lift a reduced material

quantity, or, when magnetization has been carried out, in order to release excess material.

In both cases, before starting moving the charged, the potentiometer must be set at its max. value.

The use of the potentiometer in the push-button panel must be protected against eventual fault

maneuvers.

Gauss Magneti hold no liability for consequences due to not proper or not authorized use

4.5 SETTING BY PUSH-BUTTON

WARNING

By acting on the push button, the magnetization command is carried out if the following conditions

are fulfilled:

The push button (see el. dwg.) with operating converter, acts as a setting device.

Setting by push button can be useful when magnetization has been carried out, in order to release

excess material.

By pushing the button the converter starts a descending ramp down to 0 V voltage. When the

button is released, the converter delivers again the maximum voltage.

The use of push button must be protected against eventual fault maneuvers.

The press-button must be protected against wrong operations, as an accidental command of

this press-button would bring to the fall of material lifted by the electromagnet

WARNING !!!

USE OF SLOW RELEASING PRESS BUTTON FOR USES OTHER THAN THE INDICATED

ONES IS NOT ALLOWED; IN PARTICULAR THIS PRESS-BUTTON MUST NOT BE PRESSED

AND RELEASED WITH HIGH FREQUENCY.

Any other action not indicated is not allowed by PRESS – BUTTON SLOW RELEASING

A NOT PROPER USE OF THIS BUTTON CAN DAMAGE IRREVERSIBLY THE EQUIPMENT.

Gauss Magneti hold no liability for consequences due to not proper or not authorized use

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 19 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

4.6 OVERHEATING SIGNALLING (only equipment with this control)

When the magnet reaches a dangerous internal temperature, acoustic and visual

alarms are activated (horn with an intermittent sound and lamp blinking, see

enclosed electric drawing).

It is necessary to remove the magnet from the heating source, demagnetize and let it

cool.

The alarms continue for approx 10 min, then it is possible to operate again the

magnet.

If the alarms appear again, it is necessary to let the magnet cool for a longer period

of time.

4.7 CONNECTION OF SELECTABLE ELECTROMAGNETS

(ONLY FOR EQUIPMENT WITH SELECTABLE MAGNETS)

The connection of a selectable magnet is carried out by means of an external selector, commanding

the power contactor insertion.

Connection can follow only when not active magnetization

WARNING

IT IS NOT ALLOWED TO MANUALLY FORCE THE CONTACTOR OR THE MECHANICAL

RETAINER IN ORDER TO INSERT THE SELECTION.

Gauss Magneti Srl is not responsible for any consequence of improper or unauthorized use.

4.8 DISCONNECTION OF SELECTABLE ELECTROMAGNETS

(ONLY FOR EQUIPMENT WITH SELECTABLE MAGNETS)

The disconnection of a selectable magnet is carried out by means of an external selector,

commanding the unlock of the mechanical locks and opening the power contactors.

Disconnection can follow only when not active magnetization

WARNING

IT IS NOT ALLOWED TO MANUALLY FORCE THE CONTACTOR OR THE MECHANICAL

RETAINER IN ORDER TO INSERT THE SELECTION.

WITH MAGNET ACTIVATED, THE IMPROPER SELECTION UNLOCK EXCLUDES THE

CONTROL CIRCUIT AND CAN DAMAGE SERIOUSLY THE EQUIPMENT AND CAN CAUSE

INJURIES TO PERSONNEL.

Gauss Magneti Srl is not responsible for any consequence of improper or unauthorized use.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 20 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

4.9 - SIGNALLING OF MAX MAGNET INSERTION TIME (only for equipment provided with this

control)

A timer inside the PLC check the magnet insertion time, at end of counting a horn with intermittent

sound is activated..

(see enclosed el. dwg)

4.10- MAGNETIZATION BOOST (only for equipment provided with this control)

At magnetization command, the magnet is supplied with an over-voltage to accelerate current slope

and consequently reduce magnetization time.

When the current reaches the max value, voltage is reset to the rated value.

4.11- TOUCH SCREEN HMI PANEL FRONT DOOR

On controller front door there is an HMI panel that has three screen shots.

(N.B.: Images only for informations, not binding)

To be able to move within the three screen shots press the right or left arrow.

R key is the refresh to check the batteries status.

The main screen shot shows:

Batteries current (Adc)

Batteries voltage (Vdc)

In the lower part of the HMI screen shot there is a blue status bar where is displayed the system status and

the alarms.

SYSTEM READY

The system is ready it is possible to magnetize.

FAST CHARGE BATTERIES

Alarm that batteries are the fast charging phase, in this status the batteries are under charging.

It is not possible to magnetize.

FAULT BATTERIES

Alarm batterieries fault, in this status it is not possible to magnetize.

EMERGENCY BATTERIES ACTIVATED

The batteries are feeding the magnets, in this status the horn rings.

FAULT FUSES DC DRIVE

Fuses 3FU3, that protect the drive 3G1 have intervened

BATTERIES SWITCH OFF

The batteries switch is not ON, in this status it is not possible to magnetize.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 21 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

ELECTROMAGNET ON

Electromagnet activated, lamp 16H3 blinking means that the power is controlled by the

potentiometer, lamp 16H3 fix means that the power is at its maximum.

FAULT DC DRIVE

The drive 3G1 is in alarm, on its operator panel it is possible to see the related alarm code.

POWER LINE FAULT

The relay 1RSF reports a fault on the mains that feed the controller.

The second screen shot shows some default settings made by Gauss Magneti:

Current threshold (fast charging disabled)

Batteries fault current threshold (f.i batteries circuit failure, battery charger fuses fault, battery

charger fault or battery fuses fault)

Batteries fault voltage threshold (f.i batteries circuit failure, battery charger fuses fault, battery

charger fault or battery fuses fault)

Max electromagnet insertion time (magnetization)

Batteries Voltage (Vdc)

The third screen shot shows the status of the PLC Input/Output.

5.1 OPERATION OF THE 14KM2 INVERTED POLES CONTACTOR

(NORMALLY CLOSED)

Powered coil 220 Vdc “on”, open power contacts and magnets disconnected from batteries.

Non powered coil 220 Vdc “off”, closed power contacts and magnets connected to batteries.

5.2 DESCRIPTION OF BATTERY INTERVENTION

WARNING

The system can be supplied by batteries only for the time indicated in the order technical

specification; a longer time can damage seriously the batteries and the control circuits.

It is therefore necessary to demagnetize within the indicated time.

Gauss Magneti Srl is not responsible for any consequence of improper or unauthorized use.

REVERSE POLE CONTACTOR OPERATION (NORMALLY CLOSED) FOR INSERTION OF

BATTERY LINE

- 220 Vdc coil powered (ON): power contacts open, magnets disconnected from the batteries

- Coil not powered (OFF): power contacts closed, magnets connected to the batteries

The contactor in the normal operating condition is ON either with magnets switched on or off.

The causes that lead to the closing of the power contacts (unpowered coil OFF) with the subsequent

connection of the electromagnets to batteries, can be of the following type:

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 22 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

• interruption of the three phase supply for more than 0.4 seconds

In this condition the power contacts 14KM2 close and the magnets are powered by batteries.

WARNING

The system is powered by batteries in state of emergency, the discharge time of the batteries

cannot be higher than the contractually agreed upon purchase, a longer time irreparably damages

the batteries and compromises the correct functioning of command and control electrical circuits

installed inside the electrical panel, it is mandatory to demagnetize the magnets within the stipulated

time.

Gauss Magnets assumes no responsibility for any consequences arising from the improper or

unauthorized use caused by non-observance of this rule.

To exit from the state of emergency (magnets powered by batteries):

- The system can be automatic, if the power supply comes back, the contactor coil for battery

insertion switches ON and the batteries are disconnected from the magnets.

- Acting on the demagnetize buttons, the magnetization relay switches OFF, which will command

ON the coil of the contactor 14KM2 disconnecting the batteries from the magnets.

The demagnetize command is active even in the absence of mains voltage, when the system is in

the emergency phase supplied by the batteries.

6.1 TEST OF EMERGENCY (at least once a month)

- Run the command magnetize

- Cut off mains power to equipment

- The horn turns ON

- Verify that the material remains attracted by the electromagnets

Get out of the state of emergency in one of the following ways:

a) supply the cabinet with the mains voltage

b) press the button “demagnetize”

1a) supplying the cabinet, the batteries are switched off and the acoustic alarm stops.

1b) by pressing the button “demagnetize” contactor 14KM2 is energized, excluding batteries and

buzzer.

The command “demagnetize” is active even in the absence of the mains voltage, when the system

is in the emergency phase supplied by the batteries.

Check of the status of the battery capacity

This operation must be performed by qualified personnel trained in the use of electrical technology.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 23 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

WARNING

WE RECOMMEND NOT TO LEAVE THE BATTERIES INSERTED FOR MORE THAN 10

MINUTES, a longer time can irreparably damage the batteries and compromise the correct

functioning of electrical circuits for monitoring and control installed inside the electrical cabinet.

Gauss Magnets assumes no responsibility for any consequences arising from the improper or

unauthorized use of this equipment, caused by non-observance of this rule.

The battery capacity must be measured under load, the system in an emergency phase, battery-

powered magnets. The measure, if not performed under load, is not valid and not real.

To check the status of the battery capacity, measure the battery voltage during the emergency

phase, after 10 minutes after the emergency, the battery voltage should not be less than 200 Vdc.

7.1 DESCRIPTION OF BATTERY-CHARGER OPERATION

The battery charge is carried by its converter, the charge cycles are controlled by the PLC and the

volt-meter relay.

It is essential that the equipment remains always energized even if it is not used for a long period, to

allow the charger automatically keep the batteries in trickle charge.

Otherwise the batteries could discharge quickly, irreparably compromising their durability and

function.

CHARGE CYCLE

The charging cycle of the battery charger is shown in Figure 3:

First phase (K):

When the current absorbed by the batteries exceeds the threshold value Is (0.3 x I), the phase of

fast charge constant current I begins (section K of the curve) where there is a gradual increase in

the battery voltage up to 2,41 V / cell (approximately 260Vdc for a 220VDC battery pack, and about

130Vdc for a 110Vdc one).

Second stage (S):

When the voltage has reached the value of 2,41 V / cell., charging continues with constant voltage

and decreasing current until the latter falls below the threshold value Is (0.3 x I) (S portion of the

curve ).

Third phase (M):

At this point through the threshold ammeter the voltage supplied to the batteries switches to a value

of 2.23 V per cell (about 240Vdc for a 220VDC battery pack, and about 120Vdc for a 110 Vdc one)

that corresponds to the maintenance charge.

During this phase, if there is no current absorption, there is a gradual reduction in current

consumption (section M of the curve).

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 24 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

CHARGING PHASE CYCLE

Tensione K S M

Corrente I

2.41V/el.

2.23V/el.

Is

Time

I : Fast charging current, I= 0,15 x C10 (C10= battery capacity in Ah

referred to 10 hours)

Is: Threshold value Is = 0,3 x I

2.41V/el. : fast charge voltage

2.23V/el. : maintenance charge voltage

( figure 3 )

It is not possible to define a general criterion for the choice of the charging current as a function of

the battery capacity, it also depends a lot on the duty cycle and on the use of batteries.

The longer the time available for charging and the lower will be the charging current required.

Ultimately the relation between the fast charge current I and the battery capacity is expressed by the

following formula:

I = A x C10

C10 = battery capacity in Ah (the capacity is related to the discharge regime of 10 hours)

A = constant which depends on the operating needs (usually between 0.1 and 0.25).

8.1 DISCONNECTION OF THE EQUIPMENT FROM MAINS

THE EQUIPMENT, IN VIEW OF ITS CHARACTERISTICS AND THE PRESENCE OF BATTERIES,

MUST ALWAYS BE SUPPLIED FROM THE MAINS SINCE INTERNAL CIRCUITS CAN

DISCHARGE THE BATTERIES IN THE EVENT OF LONG PERIOD DEACTIVATION.

In the case of exclusion of the equipment from the mains, open the main switch.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 25 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

8.2 MAINTENANCE

Maintenance consists mainly of a periodic inspection to check the equipment conditions.

It is recommended a particular care and maintenance of the equipment, due to the importance of

emergency safety batteries.

DANGER

BEFORE CARRYING OUT ANY MAINTENANCE OPERATION ON ANY EQUIPMENT

COMPONENT, OPEN 3-PHASE LINE SWITCH AND BATTERY SWITCH

ELECTRIC BOARD

- open main switch, battery switch and power fuses

- check visually board conditions

- check terminal locking

- check all components connections

- clean the device

Do not use inflammable, conductive or explosive liquids or materials for cleaning.

Any damaged or worn component should be immediately replaced

BATTERIES

DANGEROUS VOLTAGES

VOLTAGE IN THE BATTERY BOX, WITH ALL BATTERIES CONNECTED IN SERIES, IS 220

VDC

THIS 220 VDC VOLTAGE IS PRESENT ON THE BATTERIES ALSO WHEN LINE SWITCH AND

BATTERY SWITCH ARE OPEN.

THEREFORE NEVER OPEN THE BOX AND NEVER APPROACH THE OPEN BATTERY BOX

WITH METAL OBJECTS

- check that batteries are not damaged or deformed.

- check with protection gloves and insulated wrenches terminals locking.

- check battery positioning

- cleaning

Do not use inflammable, conductive or explosive liquids or materials for cleaning.

Any damaged or worn component should be immediately replaced

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 26 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

ADDITIONAL INFORMATION ON THE USE AND STORAGE OF LEAD BATTERIES

Instructions for the discharge

- After a discharge, batteries must always be recharged.

- After a discharge test or during storage, the voltage of batteries should not drop below 1.8 V per

cell. If this happen, a reduction in capacity and life of batteries is likely.

Operating climatic conditions

- Batteries must be used in a temperature range 0 to 45°C.

Recharging during storage

To safeguard life and efficiency of batteries, it is recommended to recharge the batteries during

storage according to the time intervals indicated below:

Storage temperature recharging interval

0 ÷ 20°C 9 months

20 ÷ 30°C 6 months

30 ÷ 40°C 3 months

CABLE DRUM

- check brushes conditions and that they press the collector and that they are not worn

out, otherwise replace them

- check that the cable is not damaged and specially its insulation condition

- check terminal locking

- check that all components are steadily connected

- cleaning

ELECTROMAGNETS

- check terminal locking inside socket-plugs

- replace socket and plug if they do not grant a good mechanical lock

- check electromagnet wires and plug sheath, replace them if damaged

- check connections in terminal boxes, if available

- check terminal locking

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 27 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

9.1 S.C.R. FUNCTION TEST

DANGEROUS VOLTAGES

OPEN THE 3-PHASE MAIN SWITCH AND THE BATTERY SWITCH; BEFORE STARTING

OPERATING MAKE SURE THAT THE ELEMENTS WHICH YOU ARE GOING TO WORK ON

ARE NOT LIVE.

This test allows to check if the s.c.r. are still efficient after intervention of fast-blow fuses .

A tester is necessary to carry out the check:

1. remove fast-blow fuses

2. set the tester on a scale not higher that 10 K

3. connect a tester point to the converter terminal C1

4. connect the other tester point to co n v e r t e r terminal U1

5. read the value on the tester

if value is higher than 1 K, first branch s.c.r. are OK

if value is lower than 1 K (normally about 2-3 ) , an s.c.r. is defective and must be

replaced.

6. repeat the same sequence on converter terminal V1 and W1, keeping a tester

point on terminal C1.

if value is higher than 1 K, first branch s.c.r. are OK

if value is lower than 1 K (normally about 2-3 ) , an s.c.r. is defective and must be

replaced.

7. connect a tester point on the converter terminal D1

8. connect the other point on the converter terminal U1

9. read the value on the tester

if value is higher than 1 K, first branch s.c.r. are OK

if value is lower than 1 K (normally about 2-3 ) , an s.c.r. is defective and must be

replaced.

10. repeat the same sequence on converter terminal V1 and U1, keeping a tester point

on terminal D1.

if value is higher than 1 K, first branch s.c.r. are OK

if value is lower than 1 K (normally about 2-3 ) , an s.c.r. is defective and must be

replaced.

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 28 / 29

Instruction Manual Factory

for installation - use – maintenance BRESCIA

Electronic equipment RARBI Dept. Quality Assurance

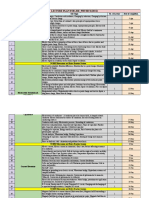

THE FOLLOWING TABLE SHOWS THE S.C.R. VALUES, WHEN CORRECTLY

WORKING

Terminal NO. Terminal NO. Value IN OHM Result

C1 U1 › 1000 OK

C1 V1 › 1000 OK

C1 W1 › 1000 OK

D1 U1 › 1000 OK

D1 V1 › 1000 OK

D1 W1 › 1000 OK

The following table gives the position of the defective s.c.r.

Terminal Terminal Value in S.C.R. to be

NO. NO. OHM replaced

C1 U1 0 - 1000 G24 C24

C1 V1 0 - 1000 G26 C26

C1 W1 0 - 1000 G22 C22

D1 U1 0 - 1000 C14 G14

D1 V1 0 - 1000 C16 G16

D1 W1 0 - 1000 C12 G12

EXAMPLE: with values as per the following table, s.c.r. G22 C22 / C16 G16 must be

replaced

Terminal Terminal Value in S.C.R. to be

NO. NO. OHM replaced

C1 U1 › 1000 G24 C24

C1 V1 › 1000 G26 C26

C1 W1 0 - 1000 G22 C22

D1 U1 › 1000 C14 G14

D1 V1 0 - 100 C16 G16

D1 W1 › 1000 C12 G12

Form N° Prep. by Approv. by File Rev. Date Page

S 10-80 UT DIR S10-80-RARBI-TRI-DCS800+AMS90-e-2016 rev 23_02_2016 29 / 29

Вам также может понравиться

- I63601X - R08 EngДокумент38 страницI63601X - R08 EnggdwkpfpipbxnmkpilcОценок пока нет

- Fronius IG2000Документ92 страницыFronius IG2000Jimmy F HernandezОценок пока нет

- I63605X - R06 EngДокумент38 страницI63605X - R06 EnggdwkpfpipbxnmkpilcОценок пока нет

- Atlas Copco ManualДокумент152 страницыAtlas Copco ManualtatasrbaОценок пока нет

- 42 0410 0828 94517 SnapshotДокумент92 страницы42 0410 0828 94517 Snapshotgronci5410Оценок пока нет

- MPC-385 OpManДокумент73 страницыMPC-385 OpManToomas PruudenОценок пока нет

- Siemens Micromaster 440 Quick Start GuideДокумент68 страницSiemens Micromaster 440 Quick Start Guideeng_karamazabОценок пока нет

- Siemens Micromaster 430 ManualДокумент118 страницSiemens Micromaster 430 ManualMmusi KehetileОценок пока нет

- Mars 40: Installation/Service ManualДокумент67 страницMars 40: Installation/Service Manualkrimo biomédical33% (3)

- Siemens Micro Master 420 ManualДокумент218 страницSiemens Micro Master 420 Manualamiteshdinda100% (1)

- Siemens Micromaster 440 Manual PDFДокумент312 страницSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)

- 8902 LS (Parker)Документ20 страниц8902 LS (Parker)abdohalim248Оценок пока нет

- Sinamics V20 Getting Started: Compact Operating InstructionsДокумент24 страницыSinamics V20 Getting Started: Compact Operating InstructionsAlonso AguilarОценок пока нет

- 440 Siemens InverterДокумент308 страниц440 Siemens InverterPavan Kumar100% (1)

- K Range Series 1 PDFДокумент214 страницK Range Series 1 PDFSean MoffittОценок пока нет

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceДокумент28 страницLow Voltage Alternator - 4 Pole: Installation and MaintenanceAllen AnyayahanОценок пока нет

- Emerson Control WaveДокумент62 страницыEmerson Control WaveChristian CampaОценок пока нет

- WEG Regulador Autom Tico de Tens o Avr A Opt 06 400hz Manual Portugu S Ingl S EspanholДокумент66 страницWEG Regulador Autom Tico de Tens o Avr A Opt 06 400hz Manual Portugu S Ingl S EspanholKarel GómezОценок пока нет

- CautionДокумент470 страницCautionElla MariaОценок пока нет

- P521 - en M - C63Документ503 страницыP521 - en M - C63Rajiv Selvaraj100% (1)

- Ma Abb VSC (En)Документ28 страницMa Abb VSC (En)Wiliam CopacatiОценок пока нет

- P521 en M C31Документ450 страницP521 en M C31Sarah BreckenridgeОценок пока нет

- RCS-9798AB - Instruction Manual - EN - General - X - R1.02 - (EN - TXZZ0104.0086.0003)Документ77 страницRCS-9798AB - Instruction Manual - EN - General - X - R1.02 - (EN - TXZZ0104.0086.0003)robert mihayoОценок пока нет

- 48 kHIPEPTZInstMan050GBv2 1-1Документ86 страниц48 kHIPEPTZInstMan050GBv2 1-1Vlad VasiliuОценок пока нет

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceДокумент28 страницLow Voltage Alternator - 4 Pole: Installation and MaintenanceAllen AnyayahanОценок пока нет

- Low Voltage Alternators - 4 Pole: Installation and MaintenanceДокумент24 страницыLow Voltage Alternators - 4 Pole: Installation and MaintenanceAnas BasarahОценок пока нет

- 240H - Service Instructions - Ver.5 PDFДокумент107 страниц240H - Service Instructions - Ver.5 PDFJuan Eladio Lorenzo100% (2)

- Lsa 49.3Документ28 страницLsa 49.3Rafki ChandraОценок пока нет

- 512C ManualДокумент37 страниц512C Manualcs.makeОценок пока нет

- PT-R4300 Um PDFДокумент167 страницPT-R4300 Um PDFEduardo Clauman0% (1)

- Areva Manual Book p126-p127Документ546 страницAreva Manual Book p126-p127Vijayaganthaan VisvanatthanОценок пока нет

- Micromaster 440: 0.12 KW - 250 KWДокумент308 страницMicromaster 440: 0.12 KW - 250 KWTumenbayar LkhagvatserenОценок пока нет

- ABB Vacuum Contactor - InstructionsДокумент48 страницABB Vacuum Contactor - InstructionsVishal KumarОценок пока нет

- Handleiding Arcapro 827a Fieldbus 2Документ42 страницыHandleiding Arcapro 827a Fieldbus 2indraОценок пока нет

- PCS-902 X Instruction Manual en Overseas General X R1.06 (En XLBH5102.0086.0017)Документ484 страницыPCS-902 X Instruction Manual en Overseas General X R1.06 (En XLBH5102.0086.0017)Se SamnangОценок пока нет

- s600 User Manual v2Документ83 страницыs600 User Manual v2Prakash SharmaОценок пока нет

- JHS-183 Instruction Manual PDFДокумент128 страницJHS-183 Instruction Manual PDFVictorMejiaОценок пока нет

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОт EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОценок пока нет

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsОт EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsРейтинг: 3.5 из 5 звезд3.5/5 (14)

- The IEE Wiring Regulations Explained and IllustratedОт EverandThe IEE Wiring Regulations Explained and IllustratedРейтинг: 4 из 5 звезд4/5 (14)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesОт EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusОт EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusОценок пока нет

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageОт EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageОценок пока нет

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОт EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОценок пока нет

- Management of Ageing and Obsolescence of Instrumentation and Control Systems and Equipment in Nuclear Power Plants and Related Facilities Through ModernizationОт EverandManagement of Ageing and Obsolescence of Instrumentation and Control Systems and Equipment in Nuclear Power Plants and Related Facilities Through ModernizationОценок пока нет

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityОт EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Power Transformer Online Monitoring Using Electromagnetic WavesОт EverandPower Transformer Online Monitoring Using Electromagnetic WavesОценок пока нет

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsОт EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsОценок пока нет

- 97 Design PDFДокумент8 страниц97 Design PDFKhaled RabeaОценок пока нет

- New Technology For Control Panel DesignДокумент8 страницNew Technology For Control Panel DesignKhaled RabeaОценок пока нет

- Contactor PDFДокумент5 страницContactor PDFKhaled RabeaОценок пока нет

- Enclosure Accessories Catalog SectionДокумент52 страницыEnclosure Accessories Catalog SectionKhaled RabeaОценок пока нет

- Contactor PDFДокумент5 страницContactor PDFKhaled RabeaОценок пока нет

- Electrical Wiring Diagrams 10-10Документ21 страницаElectrical Wiring Diagrams 10-10Rami Reddy100% (8)

- EOT CraneДокумент84 страницыEOT CraneSambhav Poddar80% (5)

- PahaДокумент2 страницыPahaSeyfeAlemayehuОценок пока нет

- Transducer: Mechanical and Electrical TransducersДокумент4 страницыTransducer: Mechanical and Electrical TransducersKhaled RabeaОценок пока нет

- 32 1735xexx Product Specification: Standard CollectionДокумент2 страницы32 1735xexx Product Specification: Standard CollectionKhaled RabeaОценок пока нет

- Monitoring and Controlling-751 PDFДокумент10 страницMonitoring and Controlling-751 PDFKhaled RabeaОценок пока нет

- Electromagnets and Electropermanent Magnets For Coils HandlingДокумент2 страницыElectromagnets and Electropermanent Magnets For Coils HandlingKhaled RabeaОценок пока нет

- Kolmetz Handbook of Process Equipment Design - Process Flow SheetДокумент29 страницKolmetz Handbook of Process Equipment Design - Process Flow SheetPritishMukherjee100% (2)

- Class C vs. Class D: TechnicalДокумент1 страницаClass C vs. Class D: TechnicalKhaled RabeaОценок пока нет

- En 12 Relay FinderДокумент9 страницEn 12 Relay Findermigas_migue2856Оценок пока нет

- Cross Limit Switch Series Alpha Item Code ALP006Документ3 страницыCross Limit Switch Series Alpha Item Code ALP006Khaled RabeaОценок пока нет

- Cross Limit Switch Lambda / AlphaДокумент8 страницCross Limit Switch Lambda / AlphaKhaled RabeaОценок пока нет

- Assembly and Operation Manual: Geared Motor, Type TPДокумент15 страницAssembly and Operation Manual: Geared Motor, Type TPKhaled Rabea0% (1)

- Transmission de Donnees Fiche Commerciale GB 20150730 PDFДокумент2 страницыTransmission de Donnees Fiche Commerciale GB 20150730 PDFKhaled RabeaОценок пока нет

- Misia Overload Limiter (Grey)Документ5 страницMisia Overload Limiter (Grey)Khaled RabeaОценок пока нет

- Qi-Power Meter-485-300Документ2 страницыQi-Power Meter-485-300Khaled RabeaОценок пока нет

- 3ADW000192R0701 DCS800 Technical Catalog e G PDFДокумент28 страниц3ADW000192R0701 DCS800 Technical Catalog e G PDFAnshid AshirОценок пока нет

- 15P0056B1 - Ams90 - 1 - en - R03 - Half-Controlled Acdc Single-Phase DriveДокумент20 страниц15P0056B1 - Ams90 - 1 - en - R03 - Half-Controlled Acdc Single-Phase DriveKhaled RabeaОценок пока нет

- Name Plate: Specifications:: SensorschutzbeschaltungДокумент3 страницыName Plate: Specifications:: SensorschutzbeschaltungKhaled RabeaОценок пока нет

- Features: 70 Series - Line Monitoring RelayДокумент9 страницFeatures: 70 Series - Line Monitoring RelayGoran PanticОценок пока нет

- Instruction Manual: TCR - MC TypeДокумент20 страницInstruction Manual: TCR - MC TypeKhaled RabeaОценок пока нет

- Static Relays: Static Relays Are Superior To Electro-Magnetic Relays in The Following AspectsДокумент7 страницStatic Relays: Static Relays Are Superior To Electro-Magnetic Relays in The Following AspectsKhaled RabeaОценок пока нет

- Motor ProtectionДокумент47 страницMotor ProtectionKhaled RabeaОценок пока нет

- Chapter 7Документ15 страницChapter 7Khaled RabeaОценок пока нет

- WS 5 5.281 00 WS 5 5 Stepper Motor Driver Berger Lahr ManualДокумент50 страницWS 5 5.281 00 WS 5 5 Stepper Motor Driver Berger Lahr ManualPablo GonzalezОценок пока нет

- RE22R1KMR DatasheetДокумент6 страницRE22R1KMR DatasheetGustavo PérezОценок пока нет

- 2014physics WДокумент85 страниц2014physics WpappadutОценок пока нет

- Powersync II 12 KW Manual TRANSFORMADORДокумент9 страницPowersync II 12 KW Manual TRANSFORMADORAntonio DacostaОценок пока нет

- Amplificador 1 THD stk4432Документ7 страницAmplificador 1 THD stk4432Juan Moya BlasОценок пока нет

- INMVD-101 ACS 1000 Medium Voltage Drive-Operation and Maintenance-Rev-AДокумент1 страницаINMVD-101 ACS 1000 Medium Voltage Drive-Operation and Maintenance-Rev-AMohamed DОценок пока нет

- Speed Control of A Conveyor BeltДокумент24 страницыSpeed Control of A Conveyor BeltSumu Talal50% (2)

- Lecture Planner - Physics - LAKSHYA JEE 2022 PLANNER - PhysicsДокумент7 страницLecture Planner - Physics - LAKSHYA JEE 2022 PLANNER - PhysicsprekshaОценок пока нет

- Color TV: Service ManualДокумент22 страницыColor TV: Service ManualAdlpal AccountОценок пока нет

- Control Concepts Surge Protective Device Training ManualДокумент23 страницыControl Concepts Surge Protective Device Training ManualCatagña AnyОценок пока нет

- Cisco 4000 Series Integrated Services RoutersДокумент30 страницCisco 4000 Series Integrated Services RouterseskielllОценок пока нет

- Time Delay OmronДокумент22 страницыTime Delay OmronNima MahmoudpourОценок пока нет

- Chapter 5 - Special OccupanciesДокумент4 страницыChapter 5 - Special OccupanciesEdisonValerioBaylonОценок пока нет

- IGEE 401 - Power Electronic Systems Solution To Midterm Examination Fall 2004Документ9 страницIGEE 401 - Power Electronic Systems Solution To Midterm Examination Fall 2004marina silvaОценок пока нет

- DSE8610 Operators Manual PDFДокумент118 страницDSE8610 Operators Manual PDFjul50% (2)

- Flujometro ABB 50xm1000Документ124 страницыFlujometro ABB 50xm1000Capacitacion TodocatОценок пока нет

- Simplified Control Method For Unified Power Quality Conditioner (UPQC)Документ5 страницSimplified Control Method For Unified Power Quality Conditioner (UPQC)vj4249Оценок пока нет

- AC Lab Oscilloscope Rev03Документ8 страницAC Lab Oscilloscope Rev03Abdelaziz AbdoОценок пока нет

- EnaSolar - Installation Manual v1 2Документ44 страницыEnaSolar - Installation Manual v1 2Ian AinsworthОценок пока нет

- Inverter User ManualДокумент40 страницInverter User ManualArianna IsabelleОценок пока нет

- DB Hikra Sol1500v 2308 enДокумент2 страницыDB Hikra Sol1500v 2308 enmolina0271Оценок пока нет

- Goodrive300-LIFT: Series Inver TerДокумент164 страницыGoodrive300-LIFT: Series Inver TerKhaled ZakariaОценок пока нет

- 1SFA898121R7000 pstx1250 600 70Документ4 страницы1SFA898121R7000 pstx1250 600 70payam sarwarОценок пока нет

- UsДокумент86 страницUsSugar RayОценок пока нет

- Chassis CX-B29FB Manual de Servicio-1 PDFДокумент49 страницChassis CX-B29FB Manual de Servicio-1 PDFReynaldo MarcaОценок пока нет

- Inverter @1500KW SpecsДокумент90 страницInverter @1500KW SpecsJayjay Famadico IcawaloОценок пока нет

- T 1000 PLUS: Secondary Injection Relay Test SetДокумент8 страницT 1000 PLUS: Secondary Injection Relay Test SetKrisada ThongkamsaiОценок пока нет

- Inversores Fronius PrimoДокумент2 страницыInversores Fronius PrimoGissette Ivonne Cortés AlarcónОценок пока нет

- Rock N Moon Rally Service ManualДокумент41 страницаRock N Moon Rally Service ManualblasrebecakarinaОценок пока нет

- 11-Stem: Science, Technology, Engineering, Mathematics - Reyneth B. OcampoДокумент5 страниц11-Stem: Science, Technology, Engineering, Mathematics - Reyneth B. OcamporeynethОценок пока нет