Академический Документы

Профессиональный Документы

Культура Документы

Riblene FF20

Загружено:

Stefan PopaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Riblene FF20

Загружено:

Stefan PopaАвторское право:

Доступные форматы

Blown Film Resins

Technical Data Sheet

Riblene® FF20

Low Density Polyethylene

DESCRIPTION

Riblene® FF20 is a high molecular weight low density polyethylene (LDPE) suitable

for blown film extrusion. Riblene® FF20 is characterised by a good melt strength lead-

ing to a good bubble stability during extrusion. Films manufactured by Riblene® FF20

are easily heat shrinkable and characterised by good mechanical properties.

APPLICATIONS

Riblene® FF20 is recommended for the production of shrink film for medium loads, in-

dustrial packaging, mulch film and blends.

PROPERTIES

Test Typical

TYPICAL Properties

Method value

Resin Properties

Melt Flow Index190 °C / 2.16 kg (g/10’) ASTM D1238 0.8

Density (g/cm3) ASTM D1505 0,921

Melting point (°C) PE 112

Brittleness point (°C) ASTM D746 <-75

Vicat softening point 1kg (°C) ASTM D1525 91

Film Properties1 - Thickness 70 µm

MD 10

Tensile strength at yield (MPa) ASTM D882

TD 11

MD 25

Tensile strength at break (MPa) ASTM D882

TD 22

MD 450

Elongation at break (%) ASTM D882

TD 650

MD 165

1% Secant Modulus (MPa) ASTM D882

TD 185

Tear resistance (Elmendorf) MD 40

ASTM D1922

(N/mm) TD 50

Impact resistance, F50 (g)

ASTM D1709 280

(Dart Drop Test)

Coefficient of Friction (dynamic) ASTM D1894 >0.5

Haze (%) ASTM D1003 8

Gloss, 45° (%) ASTM D2457 62

1

Typical value for a film extruded with BUR 1:3, thickness 70 µm.

Actual properties are typical and may vary depending upon operating conditions and additive

package.

This document is constituted of 2 pages

®

Riblene is a registered trademark of POLIMERI EUROPA Page 1/2

May 2006

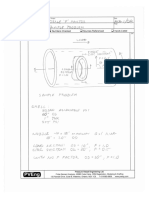

EXTRUSION

CONDITIONS

Riblene® FF20 is easily processable using blown film technology. Melt temperature

should be between 170°C and 200°C.

Recommended thickness: 40 - 150 µm

STORAGE

AND HANDLING

Riblene® FF20 is supplied in pellet form. This material may readily be conveyed and

bulk-fed through equipment designed for conventional pelletised polyethylene resin,

provided the equipment is designed to prevent accumulation of the fines and dust parti-

cles that are contained in all polyethylene resins. These fines and dust particles can, un-

der certain conditions, pose an explosion hazard. We recommend that the conveying

system used be equipped with filters of adequate size, operated and maintained in such a

manner to ensure that no leaks develop and earthed adequately. We further recommend

that good housekeeping be practised throughout your facility.

Before using this product, read and understand the current POLIMERI EUROPA Safety

Data Sheet for this product.

.

AVAILABILITY

Contact the POLIMERI EUROPA sales office nearest to you regarding availability and

your specific application requirements.

FOOD CONTACT

STATUS

Riblene® FF20 complies with the rules and regulations of the European Union, as well

as other countries, regarding the use of plastic materials in food contact applications.

Certificates of compliance are available upon request.

TECHNICAL POLIMERI EUROPA SpA POLIMERI EUROPA SAS

Piazza Boldrini 1 Route des Dunes BP59

SERVICE

20097 S.Donato Milanese (Milan)-Italy F-59279 MARDYCK

Tel. +39 02 520.1 France

Fax +39 02 520.42436 Tel. +33 3 2823.5514

Fax +33 3 2823.5520

HEADQUARTERS POLIMERI EUROPA SpA

Piazza Boldrini 1

20097 San Donato Milanese (Milan)-Italy

Tel. +39 02 520.1

Fax +39 02 520.42901

info.polyethylene@polimerieuropa.com

www.polimerieuropa.com

IMPORTANT: The descriptions and figures contained herein are provided to customer by way of a general information for the purposes

the product is intended for. These reflect POLIMERI EUROPA's knowledge at the time of publication. Since the acknowledged various

product applications by customers cannot be controlled by POLIMERI EUROPA, in no circumstances may POLIMERI EUROPA be held

responsible for the results obtained from the customers manufacturing processes or for the product used in combination with other sub-

stances. By the information contained herein POLIMERI EUROPA won't release any warranty and/or any legal responsibility and/or

give any suggestion on the use of the product, or grant any franchise on existing patents. The end-user, transformer shall always

check the specific suitability of the product for the purposes it is intended for and its compatibility with process specifications. Moreover,

the buyer shall check that retention, use or marketing of our products be in compliance with health, environmental as well as work-and-

consumer-related safety requirements. It is the buyer's responsibility to inform end-user. In no circumstances will POLIMERI EUROPA

be held responsible should not the buyer meet the obligations and recommendations indicated herein

Page 2/2

May 2006

Вам также может понравиться

- The NicotinaДокумент8 страницThe Nicotinab0beiiiОценок пока нет

- MAS Assessment Exam Answer Key SolutionДокумент7 страницMAS Assessment Exam Answer Key SolutionJonalyn JavierОценок пока нет

- Trend Graphs - Sample AnswerДокумент4 страницыTrend Graphs - Sample AnswerannieannsОценок пока нет

- Express VPN Activation CodeДокумент5 страницExpress VPN Activation CodeButler49JuulОценок пока нет

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingДокумент21 страница30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioОценок пока нет

- TH255C Engine CAT PartsДокумент134 страницыTH255C Engine CAT PartsKevine KhaledОценок пока нет

- SOF IEO Sample Paper Class 4Документ2 страницыSOF IEO Sample Paper Class 4Rajesh RОценок пока нет

- SABIC® LDPE - HP2023JN - Global - Technical - Data - SheetДокумент2 страницыSABIC® LDPE - HP2023JN - Global - Technical - Data - SheetSarvesh SinghОценок пока нет

- LL7420D Linear Low Density Polyethylene ResinДокумент1 страницаLL7420D Linear Low Density Polyethylene ResinFahad MohamedОценок пока нет

- LDPE-HP0723JNДокумент2 страницыLDPE-HP0723JNChu ChuОценок пока нет

- SABIC® LDPE - HP0322N - Global - Technical - Data - SheetДокумент2 страницыSABIC® LDPE - HP0322N - Global - Technical - Data - SheetThamimОценок пока нет

- LF410 (영문)Документ1 страницаLF410 (영문)coordinador.comercialОценок пока нет

- Linear Low Density Polyethylene Resin for General Purpose FilmДокумент1 страницаLinear Low Density Polyethylene Resin for General Purpose FilmNitin MaheshwariОценок пока нет

- Sabicr Ldpe Hp4023wnДокумент2 страницыSabicr Ldpe Hp4023wnFarah bennourОценок пока нет

- SABIC® LDPE - HP0323NN - Global - Technical - Data - SheetДокумент2 страницыSABIC® LDPE - HP0323NN - Global - Technical - Data - SheetRubenMurguiaОценок пока нет

- SABIC® LDPE - HP4024WN - Global - Technical - Data - SheetДокумент2 страницыSABIC® LDPE - HP4024WN - Global - Technical - Data - SheetTOMALO FREEОценок пока нет

- Lldpe - Sabic® Lldpe - 118NJ PDFДокумент2 страницыLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverОценок пока нет

- Sabic Lldpe 118Wsj: Linear Low Density PolyethyleneДокумент2 страницыSabic Lldpe 118Wsj: Linear Low Density PolyethyleneFahad MohamedОценок пока нет

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetДокумент2 страницыSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDiana SarmientoОценок пока нет

- Product Data: Titanlene Ldf200GgДокумент1 страницаProduct Data: Titanlene Ldf200GgchinchotarngОценок пока нет

- Lldpe - LL7410D PDSДокумент1 страницаLldpe - LL7410D PDSchinchotarngОценок пока нет

- Aramco F2111 PDFДокумент1 страницаAramco F2111 PDFhillaireОценок пока нет

- Product Data: Titanlene Ldf250YzДокумент1 страницаProduct Data: Titanlene Ldf250YzchinchotarngОценок пока нет

- Innoplus (GC Marketing) LL7835AДокумент1 страницаInnoplus (GC Marketing) LL7835AOscar Tan IIIОценок пока нет

- ASTM FL7100U Eng 240223Документ1 страницаASTM FL7100U Eng 240223MERVEОценок пока нет

- SABIC® LLDPE - 118NJA - Americas - Technical - Data - SheetДокумент2 страницыSABIC® LLDPE - 118NJA - Americas - Technical - Data - Sheetdiana sarmientoОценок пока нет

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneДокумент2 страницыSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozОценок пока нет

- LDF201FG R01Документ1 страницаLDF201FG R01Oscar Tan IIIОценок пока нет

- ASTM UT404 Eng 240223Документ1 страницаASTM UT404 Eng 240223MERVEОценок пока нет

- SABIC® LDPE - HP2022NN - Global - Technical - Data - SheetДокумент2 страницыSABIC® LDPE - HP2022NN - Global - Technical - Data - Sheetselman gürbüzОценок пока нет

- HD M5306 PDFДокумент2 страницыHD M5306 PDFmohamed1303Оценок пока нет

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetДокумент2 страницыSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoОценок пока нет

- Halene - H : Technical Data SheetДокумент1 страницаHalene - H : Technical Data SheetIshah KaziОценок пока нет

- LLDPE Blown Film GradeДокумент1 страницаLLDPE Blown Film GradeChetan BholeОценок пока нет

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalДокумент2 страницыLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúОценок пока нет

- TDS - LD 2023 CC PDFДокумент1 страницаTDS - LD 2023 CC PDFYasir SiddiquiОценок пока нет

- Qatofin Lotrene Q2018Документ2 страницыQatofin Lotrene Q2018HichamSalamaОценок пока нет

- Blown film resin for high-impact packagingДокумент2 страницыBlown film resin for high-impact packagingAli RazuОценок пока нет

- LLDPE Sabic 118WJAДокумент2 страницыLLDPE Sabic 118WJAGustavo DiazОценок пока нет

- DTM Bonding Primer: Protective & Marine CoatingsДокумент4 страницыDTM Bonding Primer: Protective & Marine CoatingsAna CabreraОценок пока нет

- Lldpe 22501aa22501kjДокумент2 страницыLldpe 22501aa22501kj李万福Оценок пока нет

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Документ2 страницыQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesОценок пока нет

- Specs FPEV120Документ1 страницаSpecs FPEV120Ttx Endless LoveОценок пока нет

- Opal - Hdpe - 4Документ2 страницыOpal - Hdpe - 4Piyush A JoshiОценок пока нет

- Tds Dfda 7047 AstmДокумент2 страницыTds Dfda 7047 Astmhafidz 35Оценок пока нет

- Infino Pc-Abs Hp1000xa (Natural)Документ1 страницаInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsОценок пока нет

- LL 22402 Linear Low Density Polyethylene Properties and ApplicationsДокумент1 страницаLL 22402 Linear Low Density Polyethylene Properties and ApplicationsJaime222Оценок пока нет

- Sabic BM 1052Документ2 страницыSabic BM 1052ifahОценок пока нет

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Документ1 страницаLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilОценок пока нет

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Документ2 страницыQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesОценок пока нет

- Aramco PP HP30EGДокумент2 страницыAramco PP HP30EGSayed FathyОценок пока нет

- LLDPE Blown Film Grade for PackagingДокумент1 страницаLLDPE Blown Film Grade for PackagingMallikharjuna Reddy GogireddyОценок пока нет

- TDS - TR144 - Astm (Eng)Документ2 страницыTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoОценок пока нет

- Ube Nylon 5034bДокумент1 страницаUbe Nylon 5034bDiegoTierradentroОценок пока нет

- TDS B0155DДокумент1 страницаTDS B0155DtechnopackishvarlalОценок пока нет

- Tricolene LLB1918AДокумент1 страницаTricolene LLB1918ARoberto De Mesa PОценок пока нет

- Low Density Polyethylene LD7000A: DescriptionДокумент1 страницаLow Density Polyethylene LD7000A: DescriptionJaime222Оценок пока нет

- TDS Pe 010 Uf1820t 04Документ2 страницыTDS Pe 010 Uf1820t 04Lenggana SukriaОценок пока нет

- Low Density Polyethylene: Lamination Film ApplicationsДокумент1 страницаLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatОценок пока нет

- LL0220AA Linear Low Density Polyethylene Film PropertiesДокумент1 страницаLL0220AA Linear Low Density Polyethylene Film PropertiesXuân Giang NguyễnОценок пока нет

- Virgin Ptfe DatasheetДокумент1 страницаVirgin Ptfe DatasheetFelipe Zúñiga ParedesОценок пока нет

- Exact 8201Документ2 страницыExact 8201Kashif MuhammadОценок пока нет

- EHMW HDPE EH120 (Mtegrity)Документ1 страницаEHMW HDPE EH120 (Mtegrity)Derly Lorena Gomez RodriguezОценок пока нет

- LL0209 AA-shazand PDFДокумент1 страницаLL0209 AA-shazand PDFmohamad mostafaviОценок пока нет

- Certene™ Llbf-218aДокумент1 страницаCertene™ Llbf-218aJose FernandezОценок пока нет

- Name: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh MishraДокумент5 страницName: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh Mishrachakshu purohitОценок пока нет

- Rapid ECG Interpretation Skills ChallengeДокумент91 страницаRapid ECG Interpretation Skills ChallengeMiguel LizarragaОценок пока нет

- Neuroimaging - Methods PDFДокумент372 страницыNeuroimaging - Methods PDFliliana lilianaОценок пока нет

- Amino AcidsДокумент17 страницAmino AcidsANAND sОценок пока нет

- Tips For Effective Presentation Design and DeliveryДокумент2 страницыTips For Effective Presentation Design and DeliveryJames Manrique100% (1)

- 2018 JC2 H2 Maths SA2 River Valley High SchoolДокумент50 страниц2018 JC2 H2 Maths SA2 River Valley High SchoolZtolenstarОценок пока нет

- NT140WHM N46Документ34 страницыNT140WHM N46arif.fahmiОценок пока нет

- MT8820C LTE Measurement GuideДокумент136 страницMT8820C LTE Measurement GuideMuthannaОценок пока нет

- Building MassingДокумент6 страницBuilding MassingJohn AmirОценок пока нет

- Doohap supplier and customer segmentationДокумент2 страницыDoohap supplier and customer segmentationPriyah RathakrishnahОценок пока нет

- Investigation Report on Engine Room Fire on Ferry BerlinДокумент63 страницыInvestigation Report on Engine Room Fire on Ferry Berlin卓文翔Оценок пока нет

- Food Sub Inspector Question PaperДокумент12 страницFood Sub Inspector Question PaperGoutam shitОценок пока нет

- Dice Resume CV Narendhar ReddyДокумент5 страницDice Resume CV Narendhar ReddyjaniОценок пока нет

- Applied SciencesДокумент25 страницApplied SciencesMario BarbarossaОценок пока нет

- Fundamental of Computer MCQ: 1. A. 2. A. 3. A. 4. A. 5. A. 6. AДокумент17 страницFundamental of Computer MCQ: 1. A. 2. A. 3. A. 4. A. 5. A. 6. AacercОценок пока нет

- DesignWS P1 PDFДокумент673 страницыDesignWS P1 PDFcaubehamchoi6328Оценок пока нет

- India's 1991 Economic ReformsДокумент5 страницIndia's 1991 Economic ReformsLive AspireОценок пока нет

- JVW 110Документ2 страницыJVW 110Miguel Leon BustosОценок пока нет

- Adjective: the girl is beautifulДокумент15 страницAdjective: the girl is beautifulIn'am TraboulsiОценок пока нет

- Nozzle F Factor CalculationsДокумент5 страницNozzle F Factor CalculationsSivateja NallamothuОценок пока нет

- Canary TreatmentДокумент117 страницCanary TreatmentRam KLОценок пока нет

- Counter Circuit Types, Components and ApplicationsДокумент22 страницыCounter Circuit Types, Components and Applicationsnavin_barnwalОценок пока нет

- 935 Ubi PBK Statement PDFДокумент20 страниц935 Ubi PBK Statement PDFTECHNO ACCOUNTОценок пока нет