Академический Документы

Профессиональный Документы

Культура Документы

Parts and Functions of The Ignition System

Загружено:

JestoniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Parts and Functions of The Ignition System

Загружено:

JestoniАвторское право:

Доступные форматы

Republic of the Philippines

Department of Education

Region IX, Zamboanga Peninsula

Division of Zamboanga Sibugay

Kabasalan National High School

F.L. Peña Sr., Kabasalan, Zamboanga Sibugay

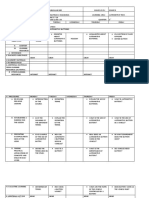

PARTS AND FUNCTIONS OF THE IGNITION SYSTEM

1. Battery supplies current to starter in order to crank the engine for operation. It also supplies

the required electric current to the ignition system.

2. Ignition Switch the key-operated main power switch that opens and closes the circuit that

supplies current to the ignition and other electrical system.

3. Ignition Resistor a resistor connected into the ignition primary circuit to reduce battery voltage

to the coil during engine operation.

4. Ignition Coil the ignition system component that set as a transformer to step up (increase) the

battery voltage into many thousands of volts.

5. Distributor any device that distribute. In the ignition system, the rotary switch that direct high

voltage surges to engine cylinders in the proper sequence.

6. Rotor the rotating parts of the distributor assembly that distributes high voltage from coil center

cable to different spark plug.

7. Contact Point the point in the distributor that opens & closes the primary circuit to build-up &

collapse the magnet line of force.

8. Condenser connected across the contact point to prevent arcing and burning. It also provides

the storage of electricity when breaker point is open.

9. Distributor Cap top cover of distributor assembly that prevents dirt or any particles from

entering the delicate parts.

10. High Tension Wires bridges of high voltage to the spark plugs.

11. Spark Plugs a device in the system that serves as lighter to produce spark on the gap.

12. Vacuum Advancer provide advancing and retarding the ignition timing by means of intake

manifold vacuum. It advances the timing just to maintain the spark at top dead center.

THE IGNITION SYSTEM ARE OF TWO INTERCONNECTED ELECTRICAL CIRCUITS.

Primary (low voltage)

1. Battery

2. Ignition Switch

3. Ballast Resistor or resistance wire

4. Ignition coil primary winding

5. Condenser

6. Contact Point

7. Ground

Secondary (high voltage circuits)

1. Ignition coil

2. Secondary winding

3. Distributor cap

4. Rotor

5. Ignition cable or high tension wire

6. Spark plug

PROCEDURE IN ADJUSTING CONTACT POINT WHEN DISTRIBUTOR ASSEMBLY REMOVE

FROM ENGINE

1. Prepare the supplies, materials, tools and equipment needed.

2. Position correctly and firmly the distributor assembly in the Bench vise.

3. Position the contact point to be set on the highest part camlobe in distributor shaft.

4. Used proper type, and size of screw driver prior to the screw head kind.

5. Loosen slightly lock and adjusting screw then, insert the feller gauge with correct size of clearance,

follow what state in the manual.

6. Tighten first the adjusting screw with two working screw drivers for it, to locks then, lastly tighten

the lock screw. If possible check it thoroughly again by retightening the adjuster and locker screws.

7. Set engine correctly then install the distributor assembly, time it properly, see the steps of initial

ignition timing.

8. Test run, then check if dwell angles is within the specified value, by the used of the dwell meter,

follow the dwell of 4 cylinders is 51⁰ (50⁰ - 52⁰)

POINT GAP ADJUSTMENT (W/O IGNITER)

1. If the points are excessively burnt or fitted, replace the breaker points.

2. Adjust point gap. Point gap 0.45 mm (0.18 in)

GASOLINE ENGINE IGNITION TIMING

First turn the crankshaft in order to bring the piston to TOP DEAD center compression stroke both

valves are close see to it that the cam lobe or nose of the camshaft is in horizontal position and

observed the timing mark of the crankshaft and camshaft. For ignition timing insert the distributor

assembly and observed the contact point is beginning to open and close.

FOUR STROKE CYCLE OPERATING PRINCIPLES OF ENGINE OPERATION

FOUR STROKE CYCLE – is a series of event following the chronological order of the engine.

1. Intake Stroke- piston going down-ward intake valve is open exhaust valve is close to allow or

enter the air and fuel mixture inside the combustion chamber.

2. Compression Stroke- piston going up-ward both valves are close to compress the air and fuel

mixture inside the combustion chamber.

3. Power Stroke- Piston going down-ward both valves are close to ignite or burned the compress

air and fuel mixture inside the combustion chamber.

4. Exhaust Stroke- Piston going up-ward intake valve close exhaust valve open to throw the

burning gasses passes the exhaust manifold.

GAP ADJUSTMENT

Check the plug gap with plug gap gauge. If not

to specified value, adjust by bending

the ground (outer) electrode.

Plug gap 0.8 mm (0.031 in)

1.0 mm (0.039 in for USA

Вам также может понравиться

- Chapter 6 NotesДокумент13 страницChapter 6 NotesPankaj Gaurav100% (1)

- Component of Lubrication SystemДокумент12 страницComponent of Lubrication SystemJohn Jhay CanlasОценок пока нет

- Section 2 - Clutch AssemblyДокумент29 страницSection 2 - Clutch Assemblyjsmanian79Оценок пока нет

- Engine Types and ClassificationsДокумент16 страницEngine Types and ClassificationsVõ Thanh Liêm100% (1)

- Carburetor Parts and Their Function (With Diagram)Документ6 страницCarburetor Parts and Their Function (With Diagram)Celso Amoto50% (2)

- Disassembly and Reassembly (Alternator)Документ16 страницDisassembly and Reassembly (Alternator)arstjunkОценок пока нет

- Lesson PlanДокумент2 страницыLesson Planapi-351990448Оценок пока нет

- AUTOMOTIVE SERVICING NC-I (Training Plan)Документ9 страницAUTOMOTIVE SERVICING NC-I (Training Plan)Amor BayawaОценок пока нет

- 2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsДокумент14 страниц2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsJheng Delos Reyes Pantoja100% (4)

- Servicing Clutch SystemДокумент76 страницServicing Clutch SystemTesda Ptc Malilipot67% (3)

- Table of Specification in Automotive ServicingДокумент1 страницаTable of Specification in Automotive ServicingBilly Joe ArellanoОценок пока нет

- Module 1 - Industrial Arts PDFДокумент10 страницModule 1 - Industrial Arts PDFMerissa Joi DaracanОценок пока нет

- Christian - Detailed - Lesson - PlanДокумент9 страницChristian - Detailed - Lesson - PlanChristian MelgarОценок пока нет

- Engine Intake & Exhaust SystemДокумент27 страницEngine Intake & Exhaust Systemmahmudul adil60% (5)

- 6-Automotive UnderchassisДокумент3 страницы6-Automotive UnderchassisGODОценок пока нет

- Servicing Brake SystemДокумент31 страницаServicing Brake SystemFrancis Martinez100% (1)

- Competency Based Learning Material: Servicing Diesel Fuel InjectorДокумент26 страницCompetency Based Learning Material: Servicing Diesel Fuel Injectorgillian marbebeОценок пока нет

- Suspension Lesson PlanДокумент6 страницSuspension Lesson PlanShahebaz WandrickОценок пока нет

- Development of Electrical JackДокумент8 страницDevelopment of Electrical JackTom Dulin BitangaОценок пока нет

- Detailed Lesson Plan in Carbureted Fuel SystemДокумент10 страницDetailed Lesson Plan in Carbureted Fuel SystemQueenie CervantesОценок пока нет

- Starter Motor, Disassemble, Inspect and Assemble - RepairДокумент22 страницыStarter Motor, Disassemble, Inspect and Assemble - RepairWayank Van Hellsing50% (2)

- 1 Perform Diesel Engine Tune Up 1Документ29 страниц1 Perform Diesel Engine Tune Up 1Jheng Delos Reyes Pantoja100% (2)

- Automotive Interview and ReviewerДокумент20 страницAutomotive Interview and ReviewerMichael Radan90% (10)

- 1 Perform Pre Delivery InspectionДокумент48 страниц1 Perform Pre Delivery InspectionCharity AnneОценок пока нет

- K To 12 Automotive Learning Module PDFДокумент230 страницK To 12 Automotive Learning Module PDFReniel EspaldonОценок пока нет

- Adjustable - Jack - Stand FinalДокумент21 страницаAdjustable - Jack - Stand FinalRomelSorianoLadislao100% (5)

- Activity 2 - Refrigeration and Air Conditioning cycle-MORADO, NANETTEДокумент3 страницыActivity 2 - Refrigeration and Air Conditioning cycle-MORADO, NANETTENanette Morado100% (1)

- Air Induction SystemДокумент12 страницAir Induction SystemBegu CataОценок пока нет

- Hydraulic Cylinder Liner PullerДокумент4 страницыHydraulic Cylinder Liner PullerLogeshMech100% (5)

- CHAPTER 10 Position and Warning Systems PDFДокумент14 страницCHAPTER 10 Position and Warning Systems PDFxrashexОценок пока нет

- UC 1 Apply Appropriate Sealant or Adhesive Session PlanДокумент3 страницыUC 1 Apply Appropriate Sealant or Adhesive Session PlanAlran Eric Cifra100% (2)

- Final Defense ThesisДокумент16 страницFinal Defense ThesisCharmy50% (2)

- Toyota 4k-c TuneupДокумент7 страницToyota 4k-c TuneupJessie BechaydaОценок пока нет

- Bearing PullerДокумент12 страницBearing PullerAnandraju Rajanderan100% (1)

- Performing Under Chassis Preventive MaintenanceДокумент103 страницыPerforming Under Chassis Preventive MaintenanceJean Ann Ramos100% (6)

- Questions and Answers of CLUTCHДокумент3 страницыQuestions and Answers of CLUTCHpriyankar75% (4)

- DieselДокумент2 страницыDieselRajiv Paglicawan100% (1)

- BatteriesДокумент15 страницBatteriesfrankОценок пока нет

- Engine Tune Up Procedure PDFДокумент23 страницыEngine Tune Up Procedure PDFmirna sari100% (2)

- Automotive CBCДокумент82 страницыAutomotive CBCAllan Tomas100% (1)

- Fuel Supply SystemДокумент3 страницыFuel Supply SystemSurjit Kumar Gandhi100% (2)

- What Is Fuel Injector Spray PatternДокумент8 страницWhat Is Fuel Injector Spray PatternRyan CalicaОценок пока нет

- Difference Between Petrol and Diesel EngineДокумент6 страницDifference Between Petrol and Diesel EngineWaiming Tan100% (2)

- These Are Sheet Metal Troughs With Hinged or Removable Covers For Housing and Protecting Electrical Wires and Cables and in Which Conductors Are Laid in PlaceДокумент2 страницыThese Are Sheet Metal Troughs With Hinged or Removable Covers For Housing and Protecting Electrical Wires and Cables and in Which Conductors Are Laid in PlaceNathaniel Aloba100% (5)

- Competency Assessor's Script On The Conduct of Competency AssessmentДокумент4 страницыCompetency Assessor's Script On The Conduct of Competency AssessmentMELANIE IBARDALOZAОценок пока нет

- Competency Based Learning Material-AutomotiveДокумент7 страницCompetency Based Learning Material-AutomotiveMarx Engel Monreal Juntado100% (1)

- Chapter 1 - Introduction To Automotive Electrical and Electronic SystemДокумент26 страницChapter 1 - Introduction To Automotive Electrical and Electronic SystemThao HuynhОценок пока нет

- Engine DisassemblyДокумент30 страницEngine Disassemblybertoy100% (1)

- Automotive Servicing G11 Wk1Документ10 страницAutomotive Servicing G11 Wk1jaslorОценок пока нет

- Automotive Measuring ToolsДокумент24 страницыAutomotive Measuring ToolsBrendan BrodieОценок пока нет

- 7 Thesis FinalДокумент34 страницы7 Thesis FinalShubham SaxenaОценок пока нет

- Session Plan of Service Charging System 12346548Документ6 страницSession Plan of Service Charging System 12346548Nereo Reoliquio100% (1)

- SAG - Automotive Servicing NC IДокумент3 страницыSAG - Automotive Servicing NC IROJANE F. BERNAS, PhD.Оценок пока нет

- IgnitionДокумент79 страницIgnitionJM Llaban RamosОценок пока нет

- Air Conditioning HistoryДокумент9 страницAir Conditioning HistoryJosue Carubio Ricalde Jr.Оценок пока нет

- Grade 9 AutoДокумент10 страницGrade 9 AutoKariza PugalОценок пока нет

- Detailed Lesson Plan in Charging SystemДокумент11 страницDetailed Lesson Plan in Charging SystemQueenie Cervantes100% (1)

- Jimmy Detailed Lesson PlanДокумент10 страницJimmy Detailed Lesson Planjecil perocho100% (4)

- Objective: After Reading This Information Sheet, You Must Be Able To Performed Engine Purpose of Ignition SystemДокумент11 страницObjective: After Reading This Information Sheet, You Must Be Able To Performed Engine Purpose of Ignition SystemEdz CabrigaОценок пока нет

- AEN Practical No 14Документ11 страницAEN Practical No 14Prasad KulkarniОценок пока нет

- Motion of Falling ObjectsДокумент14 страницMotion of Falling ObjectsJestoniОценок пока нет

- Perform Ignition Wiring Installation DLPДокумент6 страницPerform Ignition Wiring Installation DLPJestoniОценок пока нет

- Safety Measures in Performing Ignition TimingДокумент2 страницыSafety Measures in Performing Ignition TimingJestoniОценок пока нет

- Summative Exam For Ignition SystemДокумент1 страницаSummative Exam For Ignition SystemJestoniОценок пока нет

- Procedure On Setting Base Ignition Timing IMSДокумент1 страницаProcedure On Setting Base Ignition Timing IMSJestoniОценок пока нет

- Identifying - Explaining Brake System FunctionsДокумент39 страницIdentifying - Explaining Brake System FunctionsJestoni100% (1)

- Value Focus: Helpfulness: Lesson Plan in Mathematics V DATEДокумент11 страницValue Focus: Helpfulness: Lesson Plan in Mathematics V DATEJestoniОценок пока нет

- A) Timing Marks Illuminated by A Timing Light and Showing 10 Degrees BTDCДокумент1 страницаA) Timing Marks Illuminated by A Timing Light and Showing 10 Degrees BTDCJestoniОценок пока нет

- The Best Apps For Teachers and Educators: KahootДокумент33 страницыThe Best Apps For Teachers and Educators: KahootJestoniОценок пока нет

- Automotive PartsДокумент9 страницAutomotive PartsJestoniОценок пока нет

- DLL FOR Grade-9Документ45 страницDLL FOR Grade-9Jestoni100% (1)

- Td1210g Volvo PentaДокумент2 страницыTd1210g Volvo PentaMaría Rosa Tomapasca0% (1)

- ATPL - AGK WEB 07 Janu 19Документ96 страницATPL - AGK WEB 07 Janu 19Tanvir HasanОценок пока нет

- AHD186FAДокумент47 страницAHD186FAthe707100% (4)

- Servis Manual Yamaha VX 700 2011 PDFДокумент181 страницаServis Manual Yamaha VX 700 2011 PDFArthur100% (1)

- List of Recommended Spare Parts - FE45.B1Документ1 страницаList of Recommended Spare Parts - FE45.B1Alex MohanОценок пока нет

- Internal Combustion EnginesДокумент19 страницInternal Combustion EnginesS V Garata ReddyОценок пока нет

- DA70 ManualДокумент9 страницDA70 ManualJunior BatistaОценок пока нет

- Engine Part b2Документ12 страницEngine Part b2Yash TakalkarОценок пока нет

- Hicom - CRDi Injectors CodingДокумент3 страницыHicom - CRDi Injectors CodingHermawan 0103Оценок пока нет

- Engine HistoryДокумент9 страницEngine HistorycowpunchrОценок пока нет

- Lista de Repuestos Motor 3408 SERPELДокумент5 страницLista de Repuestos Motor 3408 SERPELConfiequipos AdministraciónОценок пока нет

- Rattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsДокумент2 страницыRattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsWILFRED TSI-KAHОценок пока нет

- Design and Analysis of Turbochargers: March 2016Документ12 страницDesign and Analysis of Turbochargers: March 2016Irah ZinirahОценок пока нет

- Engine Management SystemsДокумент30 страницEngine Management SystemsAmal Roy100% (5)

- 99609-50000 - Service Manual 4DQ50Документ118 страниц99609-50000 - Service Manual 4DQ50Anonymous Pk3VzhXUGB100% (1)

- Part Number Per 1 Maret 13Документ266 страницPart Number Per 1 Maret 13Muhammad FaridОценок пока нет

- MH 4025-4WDДокумент116 страницMH 4025-4WDHendra Syalala100% (1)

- Zenoah Owner Service ManualДокумент20 страницZenoah Owner Service ManualMochtar SusantoОценок пока нет

- X 19 1974 PDFДокумент347 страницX 19 1974 PDFJulio OrtizОценок пока нет

- 40.26 TRACTOR Parts CatalogueДокумент269 страниц40.26 TRACTOR Parts CatalogueBhawani CopyОценок пока нет

- Soal UAS Engine Piston 2020 UtamaДокумент5 страницSoal UAS Engine Piston 2020 UtamaKrasakKrusuk Si MaulОценок пока нет

- DT5 (80 82) DT5W (81 82) PDFДокумент47 страницDT5 (80 82) DT5W (81 82) PDFСергей ОсипенкоОценок пока нет

- 2012-06-29 052659 Om403 Adjustment of The V... La, 403, 421, 422, 422 A PDFДокумент5 страниц2012-06-29 052659 Om403 Adjustment of The V... La, 403, 421, 422, 422 A PDFcommoril50% (2)

- EM 8903iДокумент9 страницEM 8903iPeterson RamosОценок пока нет

- Engince Control CircuitsДокумент12 страницEngince Control Circuitsferas alkassmОценок пока нет

- INDEX : Version - 1450 RPMДокумент2 страницыINDEX : Version - 1450 RPMChanko DenevОценок пока нет

- 1300 Series Perkins PDFДокумент1 страница1300 Series Perkins PDFThong ChanОценок пока нет

- Matid MatkeyДокумент68 страницMatid MatkeyHari SreyasОценок пока нет

- Ignition - Wiring Basic Wiring Diagram BRIGGS & STRATTONДокумент1 страницаIgnition - Wiring Basic Wiring Diagram BRIGGS & STRATTONvulpinor58% (12)

- 00000635Документ3 страницы00000635alcoholahmedОценок пока нет