Академический Документы

Профессиональный Документы

Культура Документы

SR No Activity Characteristics To Be Checked Quantum of Check Inspection / Sign

Загружено:

Alpine ProjectsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SR No Activity Characteristics To Be Checked Quantum of Check Inspection / Sign

Загружено:

Alpine ProjectsАвторское право:

Доступные форматы

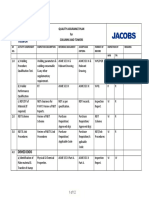

Sr No Activity Characteristics To be Checked Quantum of check Inspection / Sign

A DESIGN DOCUMENTS

1) Design Calculation Verifictaion 100% R

2) Drawings Verifictaion 100% R

B QC,NDE PROCEDURES,WPS,PQR,WPQ

1) QC Procedures Review 100% R

2) NDE Procedures Review 100% R

Review existing WPS ,PQR,WPQ & test report or

3) Welding Procedures & Welders Qualification Qualify new WPS/PQR/WPQ 100% * W/R

C FABRICATION STAGES

MATERIAL IDENTIFICATION ( VESSEL & HEAT EXCHANGER )

Reactor Vessel Parts:- Shell

Review of Marking ,Manufacturing test Report

1) 100% W

,Disheneds,Baffles,Nozzle RF Pads ,Flanges & Pipes etc…

,Dimension & Visual Check

Reactor Agitator Parts:-

Shaft ,Impeller Hub & Blades,Shaft Couplings etc…

2) UT test of Plates,Shaft ,Impeller Hub,Agitator Pads. etc... 100% R

D MANUFACTURING INSPECTION (VESSEL)

1) Plate to Plate L/s Set up & B/c DP for Dish Blank & Shell Course Formation Dimension ,Visual 100% R

2) Dishends Inspection after formation Dimension ,Visual & LPT at KR ,SF & WEP 100% W

3) Shell Rolling & L/s Set up & B/c DP Dimension & Visual Check 100% R

4) Shell to Shell & Shell to Dishends C/s.Set up & B/c DP Dimension & Visual Check 100% R

5) Nozzle set up & B/c DP on Vessel Pipe Coil & Limpets Dimension & Visual Check 100% R

External Half Limpet Coil set up on Dished end & Shell & Root weld with D/P

6)

test . As Per Approved Drawing & WPS 100% R

7) Internal Pipe Coil setup and Root weld with D/P test . 100% R

8) Pneumatic test of RF Pad & Liner Weld joints check 100% R

9) Set up & welding of Lugs Support ,Legs Dimension ,Visual 100% R

10) RT of Equipments L/s & C/s Joint & C/s joint of Internal Pipe Coil RT Film review 100% R

11) Final Inspection of Equipment Dimension & Orientation Dimension ,Visual 100% w

12) Hydro test of Internal & External Coils Visual Check 100% w

13) Reactor Vessel Hydro test Visual Check 100% w

14) Run out check of Agitator in Air 100% R

As Per Approved Drawing

15) Agitator running trial 100% w

16) Visual inspection after Pickling & Passivation of Vessel Visual Inspection 100% R

17) Painting on CS Parts & Surface Polishing Check Visual Inspection 100% R

Name Plate Verifiucation & Stamping Documentation Check, Issue of Document Review , Name Plate verification &

18) Shipping Release Note. Stamping 100% R

Вам также может понравиться

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsОт EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsРейтинг: 5 из 5 звезд5/5 (1)

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachОт EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachОценок пока нет

- ITP For Sprinkler and Spary SystemДокумент6 страницITP For Sprinkler and Spary System梁奇龙100% (2)

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Документ2 страницыVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Standard Quality Assurance Plan For Ac MotorДокумент6 страницStandard Quality Assurance Plan For Ac MotorSonti Mani kumar100% (1)

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Документ4 страницыVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharОценок пока нет

- Quality Assurance PlanДокумент4 страницыQuality Assurance PlanSasanka SekharОценок пока нет

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Документ1 страницаInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaОценок пока нет

- Amc QapДокумент8 страницAmc QapSasanka SekharОценок пока нет

- Client: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Документ2 страницыClient: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Sasanka SekharОценок пока нет

- Quality Assurance Plan - CivilДокумент11 страницQuality Assurance Plan - CivilDeviPrasadNathОценок пока нет

- Itp WeldingДокумент2 страницыItp WeldingChinni KrishnaОценок пока нет

- Jash Engineering LTD.: Quality Assurance PlanДокумент3 страницыJash Engineering LTD.: Quality Assurance PlanShree ConstructionОценок пока нет

- Quality Assurance Protocol: Raw MaterialДокумент2 страницыQuality Assurance Protocol: Raw MaterialShah Newaz KabirОценок пока нет

- Attach-2 ITP For Building WaterДокумент29 страницAttach-2 ITP For Building WaterSukalyan BasuОценок пока нет

- Vibrating Screen QAP-17Документ8 страницVibrating Screen QAP-17Mohammad AdilОценок пока нет

- Qap - Sail-WbДокумент2 страницыQap - Sail-WbRiyu RathodОценок пока нет

- Jeritp P 170300Документ1 страницаJeritp P 170300NicolaMasteОценок пока нет

- Contoh Itp Mechanical PltuДокумент2 страницыContoh Itp Mechanical PltuyusufОценок пока нет

- Contoh Itp Mechanical PltuДокумент2 страницыContoh Itp Mechanical PltuwawanОценок пока нет

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Документ3 страницыVedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Sasanka SekharОценок пока нет

- QapДокумент4 страницыQapJagadish RajapuОценок пока нет

- F L Smidth Private Limited: Delivery ScheduleДокумент2 страницыF L Smidth Private Limited: Delivery ScheduleBaskaran BossОценок пока нет

- 2.8.2. Indicative QAP - ColumnsДокумент12 страниц2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- QAP - Filter Press FinalДокумент1 страницаQAP - Filter Press FinalStepworthОценок пока нет

- QAP FormatsДокумент13 страницQAP Formatsavvari sureshОценок пока нет

- Qa-R-01 List of Measuring Equipment and Calib. DueДокумент2 страницыQa-R-01 List of Measuring Equipment and Calib. DuevinothОценок пока нет

- K.P.Mondal & Sons: Quality Assurance PlanДокумент1 страницаK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaОценок пока нет

- Qcpi 5Документ2 страницыQcpi 5Hausland Const. Corp.Оценок пока нет

- Ladders & Platforms Inspection FormДокумент3 страницыLadders & Platforms Inspection FormRony RodriguezОценок пока нет

- ITP Mini Pile PDFДокумент2 страницыITP Mini Pile PDFscriptd_ozd3nОценок пока нет

- Inspection and Test Plan Steel Sheet Pile DriДокумент6 страницInspection and Test Plan Steel Sheet Pile DriSofda Imela100% (1)

- Inspection & Test PlanДокумент6 страницInspection & Test PlanakisdassasОценок пока нет

- Inspection and Test Paln For LSAWДокумент4 страницыInspection and Test Paln For LSAWkbpatel123Оценок пока нет

- QAP-General Fabrication & Machining ItemsДокумент1 страницаQAP-General Fabrication & Machining ItemsMohammad AdilОценок пока нет

- KBR Inspection Test Plan For Shop Fabricated PipingДокумент4 страницыKBR Inspection Test Plan For Shop Fabricated PipingSyafril AkbarОценок пока нет

- Quality Assurance Plan (QAP)Документ1 страницаQuality Assurance Plan (QAP)demas100% (1)

- Tank Maintenance ITPДокумент24 страницыTank Maintenance ITPthomas varugheseОценок пока нет

- Ex-Protecta'S Quality Plan: SURFACE FINISH (Powder Coated)Документ1 страницаEx-Protecta'S Quality Plan: SURFACE FINISH (Powder Coated)SantoshОценок пока нет

- I&tp 6648-0000-5-Qa-Itp-0002Документ9 страницI&tp 6648-0000-5-Qa-Itp-0002KHALEDОценок пока нет

- QAP For Bitumen JobДокумент2 страницыQAP For Bitumen JobSasanka SekharОценок пока нет

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Документ2 страницыSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanОценок пока нет

- Inspection Test Plan PV Nozzle Modification/AlterationДокумент4 страницыInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimОценок пока нет

- WHRS QapДокумент31 страницаWHRS Qapmd shahabuddeenОценок пока нет

- ITP For Storage Tank According To API650Документ5 страницITP For Storage Tank According To API650Maneesh KumarОценок пока нет

- Technical Specification - 2023 01 16 18 50 06Документ10 страницTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990Оценок пока нет

- PMO Office Building JobДокумент3 страницыPMO Office Building JobSasanka SekharОценок пока нет

- QAPДокумент6 страницQAPRahul ChandanОценок пока нет

- Audit ReportДокумент9 страницAudit ReportVIVEK100% (1)

- Itp-Fbe Pipe CoatingДокумент4 страницыItp-Fbe Pipe CoatingpertmasterОценок пока нет

- ITP ManifoldДокумент7 страницITP ManifoldvinothОценок пока нет

- Simple LOS QAP FormatДокумент1 страницаSimple LOS QAP Formatmechdesign2k23Оценок пока нет

- Ecc Mech Sharq 22 016 Rev 01Документ6 страницEcc Mech Sharq 22 016 Rev 01Muthu SaravananОценок пока нет

- ITP Steel Structure Rev.01Документ2 страницыITP Steel Structure Rev.01Imam SyarifudinОценок пока нет

- Modelquality Assuranceplanforpot 1Документ8 страницModelquality Assuranceplanforpot 1mouni9301997Оценок пока нет

- UNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationДокумент3 страницыUNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationrakibnjtechОценок пока нет

- Itp PRDSДокумент3 страницыItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- Itp-Shop Fabricated PipingДокумент4 страницыItp-Shop Fabricated PipingkamlОценок пока нет

- ITP For Boiler ErectionДокумент6 страницITP For Boiler ErectionUmair Awan100% (2)

- Qap - NRLДокумент1 страницаQap - NRLStructures ProductionОценок пока нет

- Installation Instructions: - Split System Air ConditionerДокумент45 страницInstallation Instructions: - Split System Air ConditionerpejdewitОценок пока нет

- Polyaniline Coating On Stainless Steel PlatesДокумент6 страницPolyaniline Coating On Stainless Steel PlatesMatthew MarpleОценок пока нет

- C3Документ18 страницC3Nick LeeОценок пока нет

- Nissim Amzallag - From Metallurgy To Bronze Age Civilizations - The Synthetic TheoryДокумент23 страницыNissim Amzallag - From Metallurgy To Bronze Age Civilizations - The Synthetic TheoryLulo GpeОценок пока нет

- PowerPoint Sample: BioDiesel Production Power Point PresentationДокумент16 страницPowerPoint Sample: BioDiesel Production Power Point PresentationJohn MelendezОценок пока нет

- F1582 1479757-1Документ3 страницыF1582 1479757-1Thaweekarn ChangthongОценок пока нет

- State-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateДокумент18 страницState-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateShaker QaidiОценок пока нет

- 46TMSS01R0 Station Battery Bank Lead AcidДокумент14 страниц46TMSS01R0 Station Battery Bank Lead AcidAsim KaleemОценок пока нет

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESДокумент3 страницыPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongОценок пока нет

- Advanced Cleaning Product Formulations Volume5Документ255 страницAdvanced Cleaning Product Formulations Volume5joe89% (35)

- 07 01 METALLURGY Principles and Methods of ExtractionДокумент17 страниц07 01 METALLURGY Principles and Methods of ExtractionrcraktimcОценок пока нет

- The Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteДокумент8 страницThe Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteJarek PlaszczycaОценок пока нет

- Just in TimeДокумент4 страницыJust in TimeRohit KumarОценок пока нет

- Qualitest Canada BrochureДокумент7 страницQualitest Canada BrochureBala SingamОценок пока нет

- ScribdДокумент1 страницаScribdsarthak tripathiОценок пока нет

- Building Services - ThermodynamicsДокумент108 страницBuilding Services - ThermodynamicsDevansh MehtaОценок пока нет

- SN200Документ111 страницSN200tajinder231280% (5)

- Home Assignment - 3: Chapter-3Документ3 страницыHome Assignment - 3: Chapter-3AkhilОценок пока нет

- Assignment FMSДокумент2 страницыAssignment FMSAnuragShrivastavОценок пока нет

- Enlightened Polymer Clay BLAD WebДокумент8 страницEnlightened Polymer Clay BLAD WebMonika Timári85% (13)

- Unit-4 Polymer ChemistryДокумент35 страницUnit-4 Polymer ChemistryHermione GrangerОценок пока нет

- M90 01Документ2 страницыM90 01DiegoTierradentroОценок пока нет

- Trinic GFRC Mix Design CalculatorДокумент6 страницTrinic GFRC Mix Design CalculatorJonathan SanchezОценок пока нет

- PMRC Mar Va 122 PDFДокумент26 страницPMRC Mar Va 122 PDFMohamadIbnuHassan100% (1)

- Pedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Документ35 страницPedestrian Cable-Stayed Bridge Project: Ce 491C - Senior Design SPRING 2000Ing Manolo HernandezОценок пока нет

- Transmision FunkДокумент98 страницTransmision FunkManuel Jesús Zhicay Quillay100% (1)

- Chapter 1 7Документ76 страницChapter 1 7Ian ReyesОценок пока нет

- BT2353 NolДокумент69 страницBT2353 NolHari Priya0% (1)

- D 692 - 00 Rdy5mi0wmaДокумент2 страницыD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- LEVA Parts Catalog V1.4 COLORДокумент84 страницыLEVA Parts Catalog V1.4 COLORMionnix KM-Service-premiumОценок пока нет