Академический Документы

Профессиональный Документы

Культура Документы

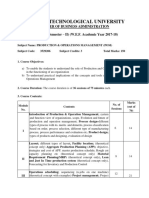

Production and Planning Control Chapter 1

Загружено:

SufreeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Production and Planning Control Chapter 1

Загружено:

SufreeАвторское право:

Доступные форматы

EXERCISE 1

MOHAMAD SUFRI BIN MOHD SHUKOR

A18DW2382

3/DDWG SEC 32

A. Describe the three major factors determining the production planning controls?

1) Sales Order

It’s a customer order rewrite defining what was purchased (product, quantity and approving the

products to be delivered to the consumer). Variations or changes in distribution order can have

a dramatic impact on the preparation and management of production.

2) Standard Process Sheet

Organized by process engineering sector or process owner, it is the source of basic data which

may include the type of machine to be used, the processing time needed, etc. For example, if

any system is under breakdown, the normal process sheet will be disrupted which will in effect

affect the planning and control of the output.

3) Project Planning Method

The component to be manufactured is produced in quantity, and its overall processing time can

be calculated. Methods best known are the Critical Path Method ( CPM) and the Technique for

Program Evaluation and Review (PERT).

B. What is the 10 critical decision area in operation management?

1) Goods and services:

This includes looking for ways to implement consistency in costs, quality, and resources

across all business divisions.

2) Quality Management:

Be clear on the customer’s demands and then meet those expectations. Use market research

to determine customer needs and batch quality assurance testing on products and services in

production.

3) Process and Capacity Design:

Design strategies which support all production goals including technology and resources. A

value stream map can help determine what processes are necessary and how to keep them

running efficiently.

4) Location:

In developing a location strategy consider supply chain and how the location will receive

supplies, the movement of goods and services internally and to customers, and the role of

marketing and public relations in the location choice.

5) Layout Design and Strategy:

Consider the placement of desks, workstations, and how materials are delivered and used.

6) Human Resources and Job Design:

Implement continuous improvement programs with regular reviews, provide continuous

training for employees, and institute employee satisfaction programs to achieve success in this

area.

7) Supply Chain Management:

Determine the best strategies to streamline, be cost effective, and to develop trusted partners.

8) Inventory:

Different markets mean different challenges when it comes to inventory but all need to

strategize and plan their inventory control. Weather, supply shortages, and labor all influence

how an organization maintains its inventory.

9) Scheduling:

Consider both production and people. Ask questions such as how much product is required to

be produced for the customer in the required time? How many people and how many machines

are required to do the job effectively and efficiently? This differs among industries and business

departments. For example, emergency rooms need to maintain different schedules than a

hospital’s corporate office.

10) Maintenance:

This includes maintaining people and machines, as well as, process. What do you need to do

to maintain quality and keep resources reliable and stable?

C. What is the inability causes to meet delivery date promised?

1) Lack of availability of material in time

2) Lack of availability of supervisor in time

3) Lack of staff in shift

4) Load balancing not done properly

5) Lack of staff in shift

D. There are three main characteristics of mass and flow production, describe it.

1) There is scope for considerable division of labor.

2) Machinery is laid as per the sequence of production.

3) Material handling is reduced to minimum.

4) Very little time is pent on the resulting of machines.

5) The flow of work is balanced.

6) Work cycles are smart and of repetitive nature.

7) Time study can be applied, to advantage, to different operations.

8) Work-in-progress in small as compared t intermittent production.

9) Procedures, tools and materials handling need proper attention.

10) Plat layout and facilities are designed to suit production requirements.

11) Flow production is preferred where their is a continuous and regular product demand.

12) It offers lowest production cost per unit.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Opertions Management Case StudyДокумент11 страницOpertions Management Case StudyAmogh ChaturvediОценок пока нет

- Lecture - 2 - 1642855339845 Operation ManagentДокумент24 страницыLecture - 2 - 1642855339845 Operation Managentvirender vermaОценок пока нет

- Operations Strategy in A Global EnvironmentДокумент44 страницыOperations Strategy in A Global EnvironmentNinik SiindoroputriiОценок пока нет

- OPEQUAL 1 - Practice QuizДокумент3 страницыOPEQUAL 1 - Practice QuizJessica MalabananОценок пока нет

- Chapter 1 - Introduction To Operations Management - CopykДокумент28 страницChapter 1 - Introduction To Operations Management - CopykShakib Ahmed Emon 0389Оценок пока нет

- Intro Project ManagementДокумент155 страницIntro Project ManagementTriet TruongОценок пока нет

- Facilities Operations ManagementДокумент13 страницFacilities Operations Managementhabib poragОценок пока нет

- Mba III Operations Management (10mba33) Question PaperДокумент13 страницMba III Operations Management (10mba33) Question Paperharishway2Оценок пока нет

- 1 - Operations and ManagementДокумент5 страниц1 - Operations and ManagementReno BrownОценок пока нет

- Principle Little's LawДокумент3 страницыPrinciple Little's LawSaravana VigneshОценок пока нет

- Inventory AnnotatedДокумент90 страницInventory AnnotatedlaithОценок пока нет

- What Is PomДокумент52 страницыWhat Is PomVikas BoyatОценок пока нет

- Cima E1 TextДокумент457 страницCima E1 TextFatima GullОценок пока нет

- Operations Management With Six Sigma : Executive Development inДокумент12 страницOperations Management With Six Sigma : Executive Development inParth MundhwaОценок пока нет

- Project ReportДокумент7 страницProject ReportShahrooz JuttОценок пока нет

- 1 OM&StrategyДокумент35 страниц1 OM&StrategyPrateek HosamaniОценок пока нет

- The Scope of Engineering ManagementДокумент6 страницThe Scope of Engineering Managementmaryrose.oseoОценок пока нет

- Siemens Plant Simulation PDFДокумент87 страницSiemens Plant Simulation PDFMarko Matić100% (1)

- Chapter 8 Process TechnologyДокумент22 страницыChapter 8 Process TechnologyfozОценок пока нет

- Unit Iv CMSДокумент43 страницыUnit Iv CMSsuganthОценок пока нет

- Perations Anagement: O P L 1 (C 1)Документ26 страницPerations Anagement: O P L 1 (C 1)Moez AlouiОценок пока нет

- BottricksДокумент27 страницBottricksshiv aroraОценок пока нет

- Case Study Inventory ManagementДокумент8 страницCase Study Inventory ManagementMohammad UmairОценок пока нет

- Week 2 - Module 1Документ3 страницыWeek 2 - Module 1Kanton FernandezОценок пока нет

- 3529206Документ4 страницы3529206HarishОценок пока нет

- Thesis Topics in Operations ManagementДокумент8 страницThesis Topics in Operations Managementgbxfr1p1100% (2)

- Chapter 2 - Competitiveness, Strategy & Productivity - 2Документ46 страницChapter 2 - Competitiveness, Strategy & Productivity - 2JeSsica Joy P. SantiagoОценок пока нет

- WK 7 Case Study/ Level OperatiomДокумент4 страницыWK 7 Case Study/ Level Operatiomkishor khadkaОценок пока нет

- MSO Tutorial 2 - Service Operations Management - STUDENTДокумент4 страницыMSO Tutorial 2 - Service Operations Management - STUDENTTika CameronОценок пока нет

- Business Logistics-Importance and Some Research Opportunities.Документ13 страницBusiness Logistics-Importance and Some Research Opportunities.Amay Eksac Rahmi FadhilaОценок пока нет